Understanding API 579 and FFS Assessment Levels: From Screening to Advanced Analysis

Industrial equipment doesn’t last forever. Corrosion, fatigue and accidental damage gradually erode the strength of pipelines, pressure vessels and other critical assets. Fitness for Service (FFS) assessments give engineers a structured way to decide whether a piece of equipment can safely continue operating or whether it should be repaired or replaced. An FFS evaluation examines the design, material properties, operating conditions and defect geometry of a component to make data‑driven decisions about running, repairing or retiring it.

What Is Fitness for Service (FFS)?

FFS is a quantitative engineering method used to evaluate the condition of in‑service industrial assets such

as pipelines, pressure vessels and storage tanks. It assesses whether these components can continue performing their intended functions safely by considering design specifications, material properties, operating conditions and any existing damage. The primary objective is to determine how well pressurized or stressed components will hold up over time and to allow continued use without unnecessary repair or derating.

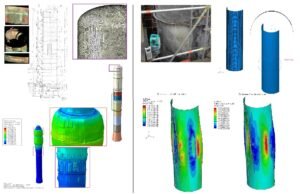

Modern FFS standards provide specific guidelines for different damage mechanisms. For example, API 579‑1/ASME FFS‑1 covers brittle fracture, general and local metal loss, pitting corrosion, hydrogen damage, weld misalignment, crack‑like flaws, creep, fire damage, dents and laminations. By following recognized procedures, engineers can estimate remaining life, evaluate risk and choose an appropriate course of action. Check out this case study !

API 579‑1/ASME FFS‑1 vs. BS 7910: Choosing the Right Standard

Two widely used standards guide FFS evaluations:

- API 579‑1/ASMEFFS‑1 – A standard developed jointly by the American Petroleum Institute (API) and ASME, tailored for pressurized equipment in refining, petrochemical and related industries. It provides procedures for different types of metal loss, physical damage and crack‑like defects. API 579 is intended for equipment built to ASME design codes and delivers results consistent with those safety margins.

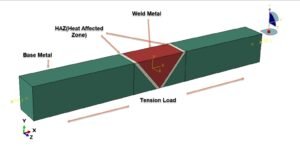

- BS 7910 – A British guide on methods for assessing the acceptability of flaws in all metallic structures and materials. It is written in a more generalized manner without reference to a particular design code or industry, giving users flexibility to set safety margins. BS 7910 deals comprehensively with fatigue and fracture of defects in and around welded joints and includes annexes covering advanced topics such as residual stresses and leak‑before‑break criteria.

While both standards offer procedures for FFS assessment, the choice depends on the asset and context. API 579 is geared toward pressure equipment and includes level 1 assessments that inspectors can perform with minimal data. BS 7910 requires greater expertise in fracture mechanics and access to fracture parameter solutions at all levels. Because BS 7910 isn’t tied to a specific design code, it can be applied to a broader range of structures (e.g., offshore platforms, bridges or nuclear components) as long as appropriate material data and safety factors are selected.

Understanding the FFS Assessment Levels

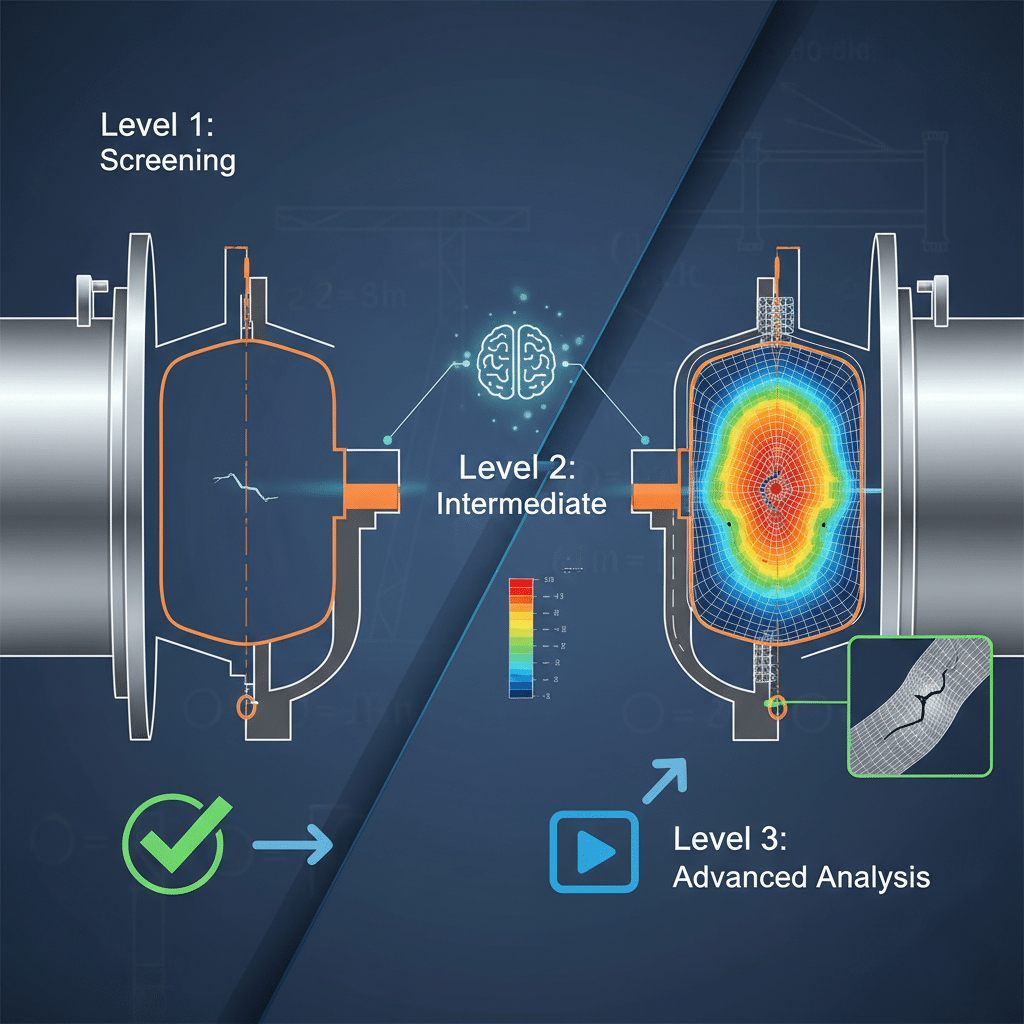

Recognizing that not every problem requires complex analysis, FFS standards use a tiered approach. Each level increases in complexity and required data, so engineers can start with simple screening and only progress to advanced methods when needed.

- Level 1 – Screening: This level uses conservative screening curves and simple formulas. It requires minimal data and experience, making it suitable for inspectors who need quick decisions on whether equipment is clearly fit or unfit. Because the calculations are conservative, level 1 assessments may reject components that could be acceptable with more detailed analysis.

- Level 2 – Intermediate: If a level 1 assessment fails or is inconclusive, level 2 applies more refined calculations and considers additional parameters. These assessments often rely on specialized software and more detailed inspection data. Level 2 balances improved accuracy with manageable effort and is frequently used for complex corrosion or crack‑like flaws.

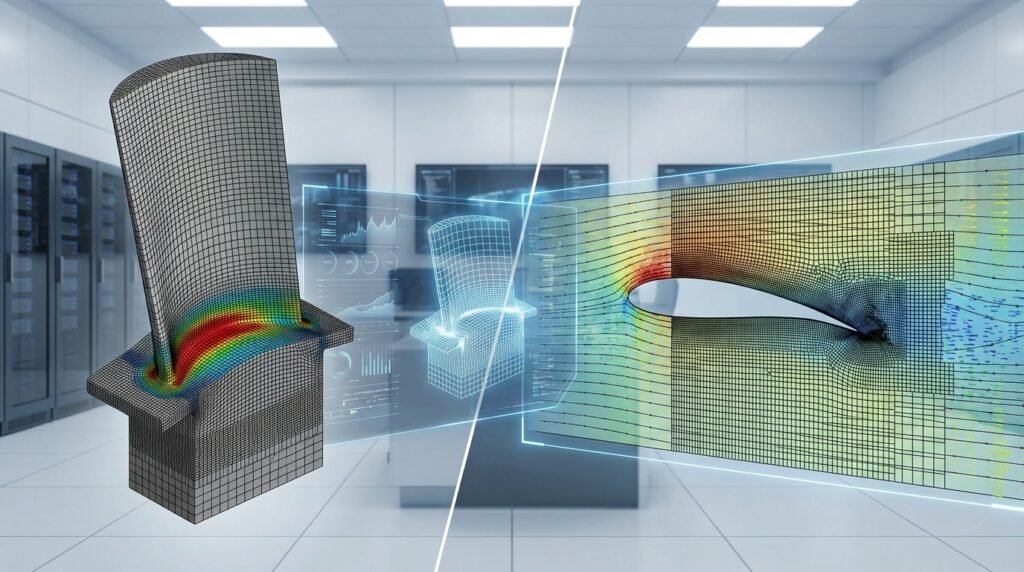

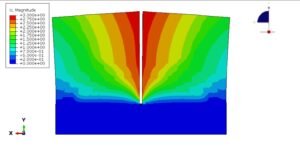

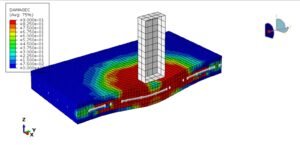

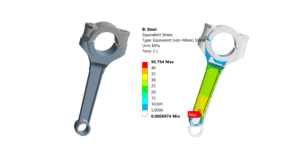

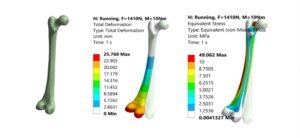

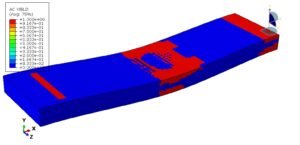

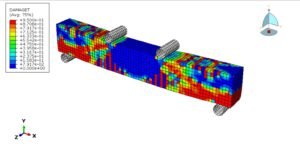

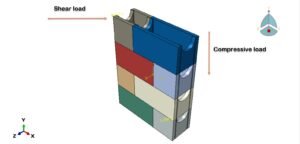

- Level 3 – Advanced (FEA): Reserved for severe or complicated cases, level 3 uses finite element analysis (FEA) and other advanced techniques to model stress distributions and defect interactions. It requires extensive material data and operational experience, but it yields the most accurate representation of the component’s structural integrity. Because of the effort and potential for error, level 3 assessments are performed only when necessary.

Selecting the appropriate level depends on the quality of available data, the seriousness of the flaw and how critical the equipment is to operations. Starting with a quick screening and escalating only when needed keeps assessments efficient while maintaining safety.

How FFS Evaluations Work: From Hoop Stress to Failure Assessment Diagrams

FFS assessments combine material science, structural mechanics and inspection data. One fundamental concept is hoop stress, the circumferential stress in a pipe wall due to internal pressure. For a thin‑walled cylinder, hoop stress (σₕ) can be approximated by Barlow’s equation:

where is the internal pressure, is the pipe’s outside diameter and is the wall thickness. This simple formula shows how increasing pressure or diameter raises the stress, while a thicker wall reduces it. Engineers use this relationship to estimate design pressure and determine safe operating limits.

Beyond simple stress calculations, FFS standards employ failure assessment diagrams (FADs). A FAD plots fracture toughness against plastic collapse resistance, allowing engineers to evaluate whether a crack is acceptable. Both API 579 and BS 7910 include FAD‑based procedures. For example, the pipeline standards ASME B31G and DNV RP‑F101 use FADs to plot defect length versus depth and determine safe working pressure. Points below the curve indicate safe conditions; points above it suggest that failure is likely and repair or replacement is needed.

Why FFS Matters: Key Benefits for Asset Operators

Conducting FFS assessments provides tangible benefits throughout an asset’s life cycle:

- Extended Asset Life: Accurate evaluations allow organizations to prolong the operating life of equipment by quantifying remaining life and addressing only critical defects.

- Cost Savings: By identifying the true condition of equipment, FFS helps prevent unnecessary repairs and replacements. Minimizing capital expenditure frees budget for other priorities.

- Enhanced Safety: Evaluating structural integrity and remaining life improves plant safety and reduces the risk of sudden failures that could harm personnel or the environment.

- Improved Reliability: Maintaining mechanical integrity helps prevent unplanned downtime and ensures consistent operation.

- Optimized Maintenance Planning: FFS insights inform inspection schedules and maintenance activities, allowing operators to plan work rather than react to surprises.

- Regulatory Compliance: Adhering to recognized FFS standards demonstrate due diligence and can reduce legal liability.

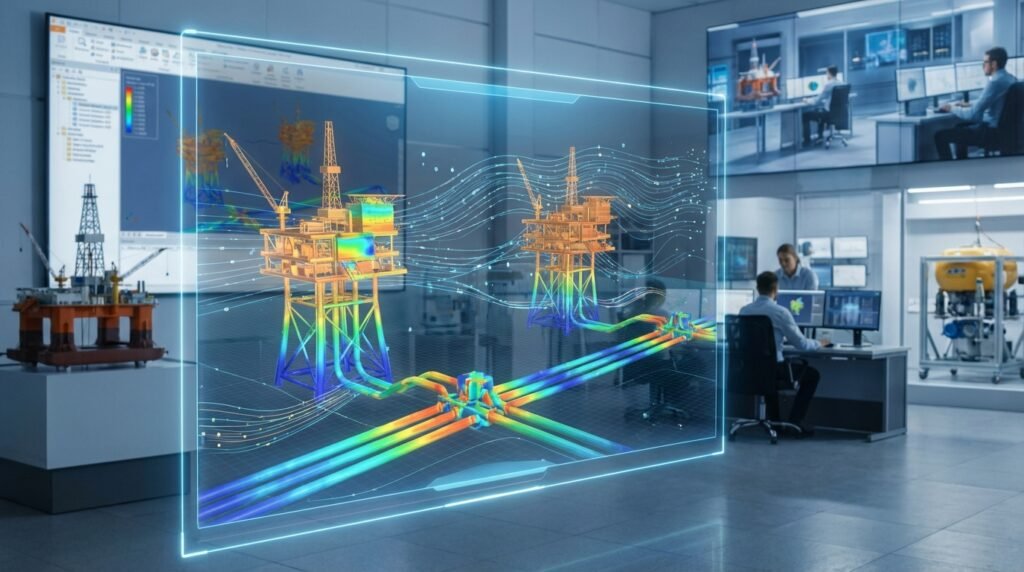

These advantages make FFS a cornerstone of asset integrity management. In industries such as oil and gas, chemical processing and power generation, equipment operates under high pressure and harsh environments. An FFS program helps balance safety, reliability and cost, enabling organizations to make informed decisions about running, repairing or replacing critical assets.

Bringing It All Together

Understanding the basics of FFS and the differences between API 579 and BS 7910 helps you navigate complex integrity challenges. Start with a level 1 screening when inspection data are limited, advance to level 2 for more nuanced problems and reserve level 3 for cases that require detailed finite element analysis. When choosing between API 579 and BS 7910, consider the equipment type, available data and regulatory context. Both standards offer robust procedures, but API 579 aligns closely with ASME design codes, while BS 7910 provides a more general framework applicable across industries.

Ready for a Tailored FFS Assessment?

If your facility operates aging pipelines, pressure vessels or other critical assets, a well‑designed FFS program can extend service life and reduce maintenance costs. At EngineeringDownloads.com, our engineers combine decades of industry experience with advanced simulation tools (Abaqus, Ansys and proprietary FEA codes) to deliver custom Fitness for Service assessments. Whether you need a quick screening or a full finite element analysis, we can help you evaluate defects, estimate remaining life and plan repairs. Check out our Simulation of XFEM Crack Growth in a Pressure Vessel.

Contact our team today to discuss your specific assets and discover how a tailored FFS assessment can enhance safety, reliability and cost efficiency.