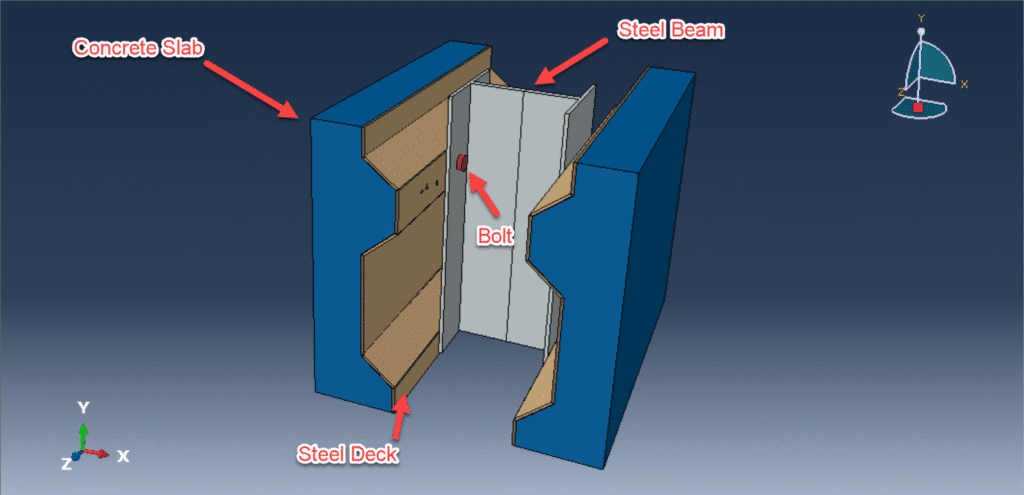

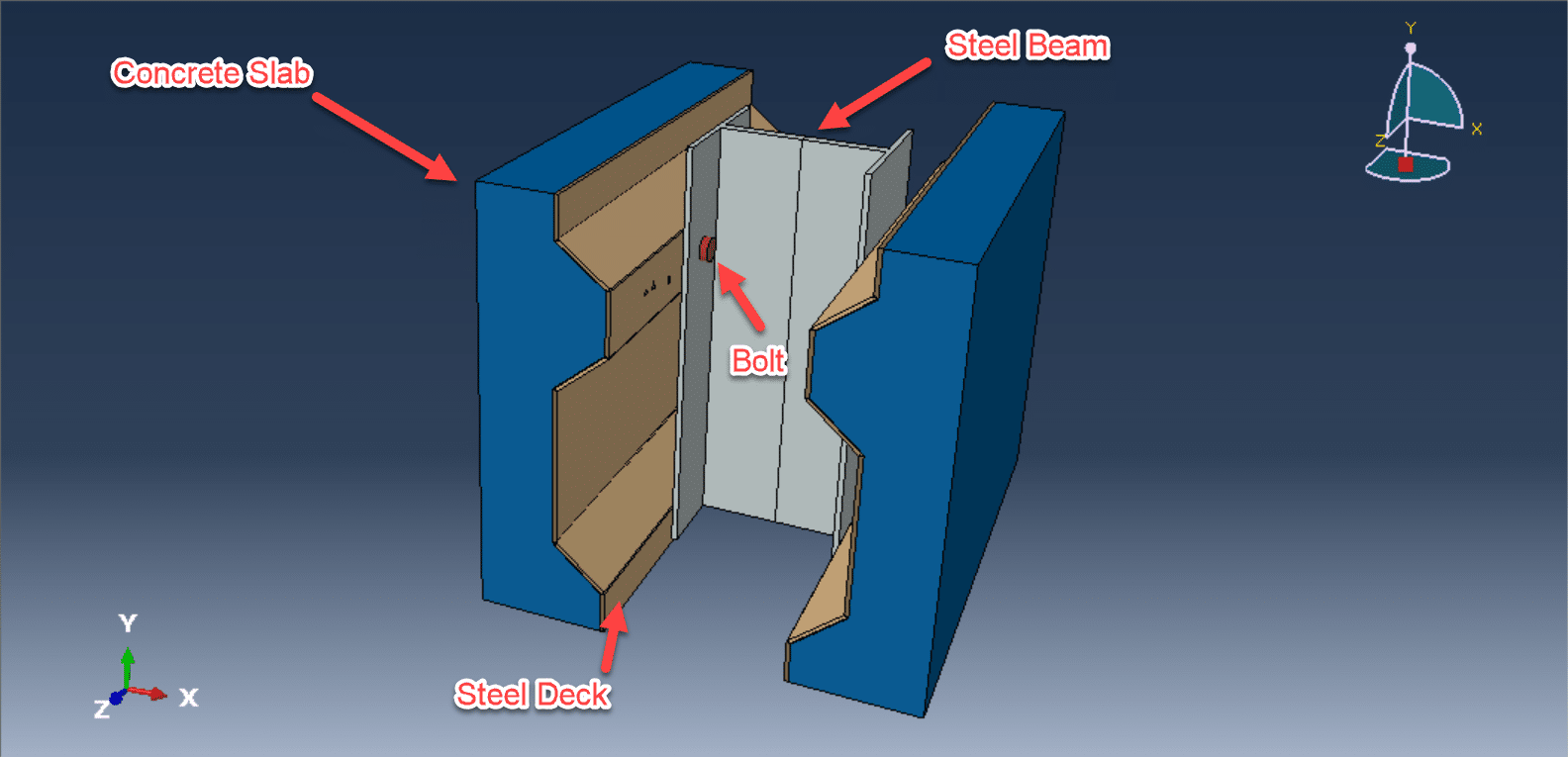

In composite construction, the integration of concrete slabs with steel beams is a widely adopted method due to its efficiency in structural performance and cost-effectiveness. A crucial element in this system is the shear connector, which ensures composite action between the concrete slab and the steel member by transferring longitudinal shear forces across the interface. Among various types of shear connectors, bolted shear connectors are gaining attention as an alternative to traditional welded studs, particularly for applications requiring demountability, ease of assembly, or in environments where welding is impractical.

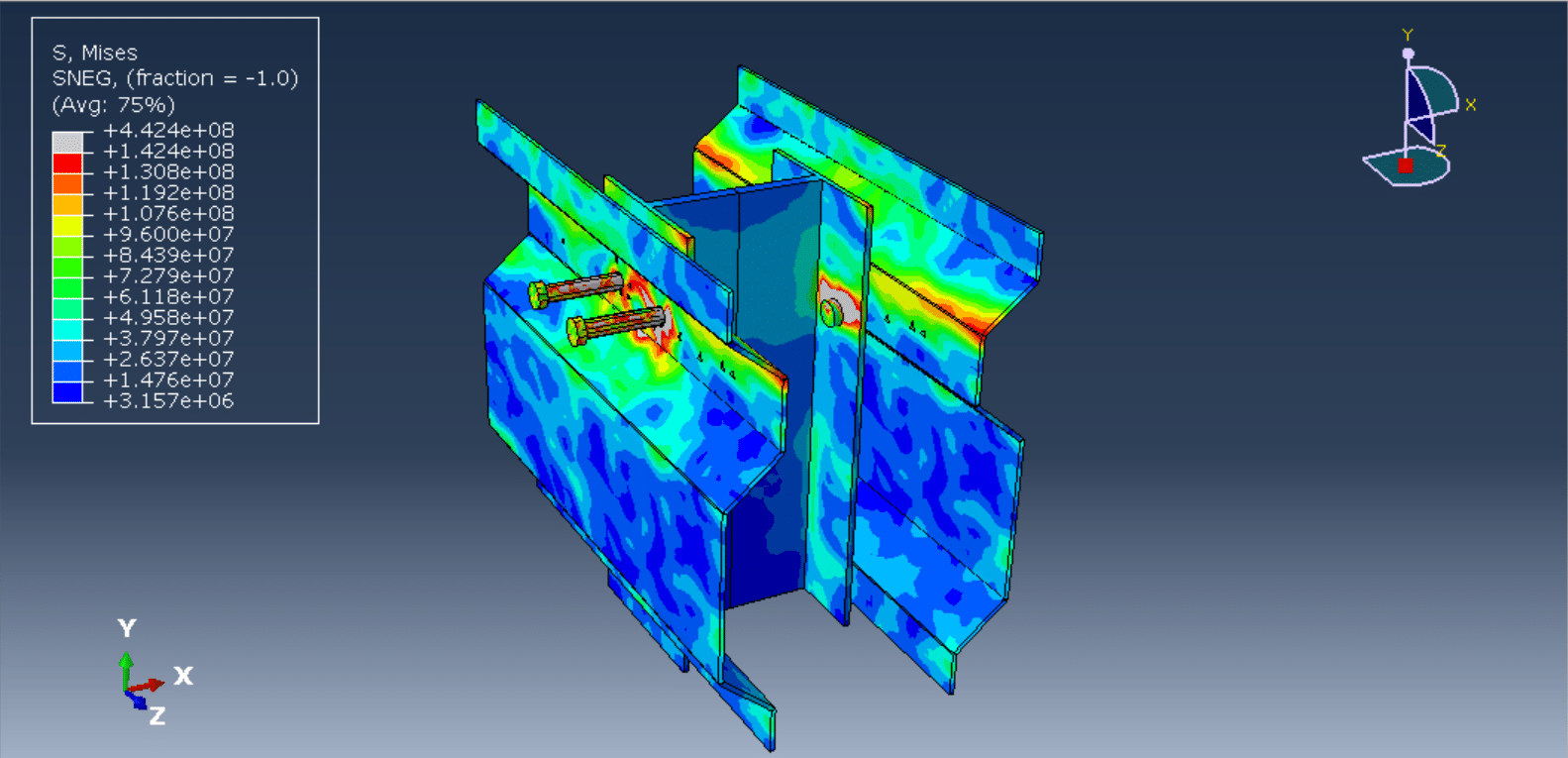

When combined with profiled steel decking, which serves as both permanent formwork and reinforcement during construction, the behavior of bolted shear connectors becomes more complex due to the composite interaction between concrete, steel deck, and bolts. The geometry and mechanical properties of the decking influence load distribution, stress concentrations, and potential failure mechanisms.

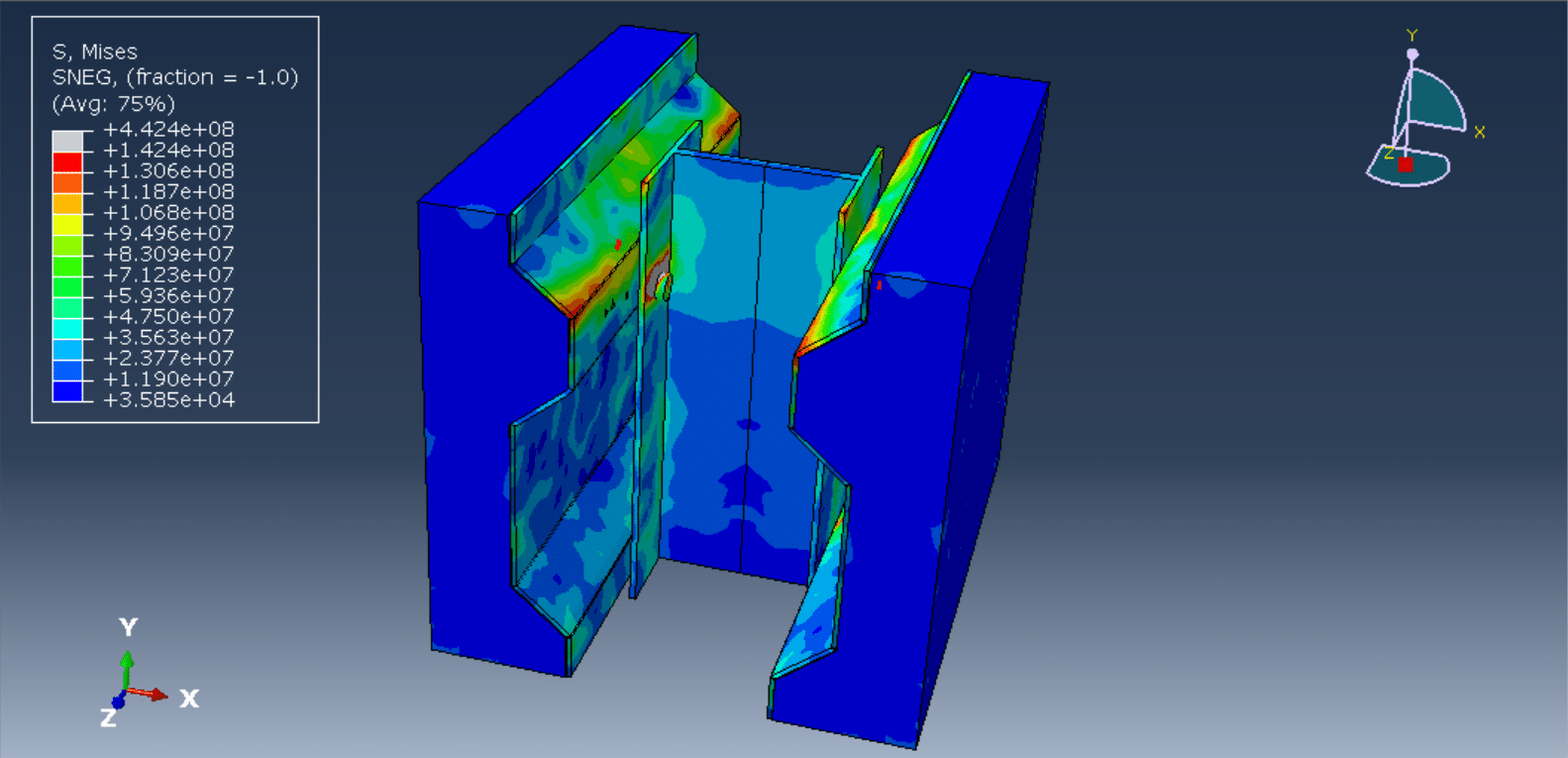

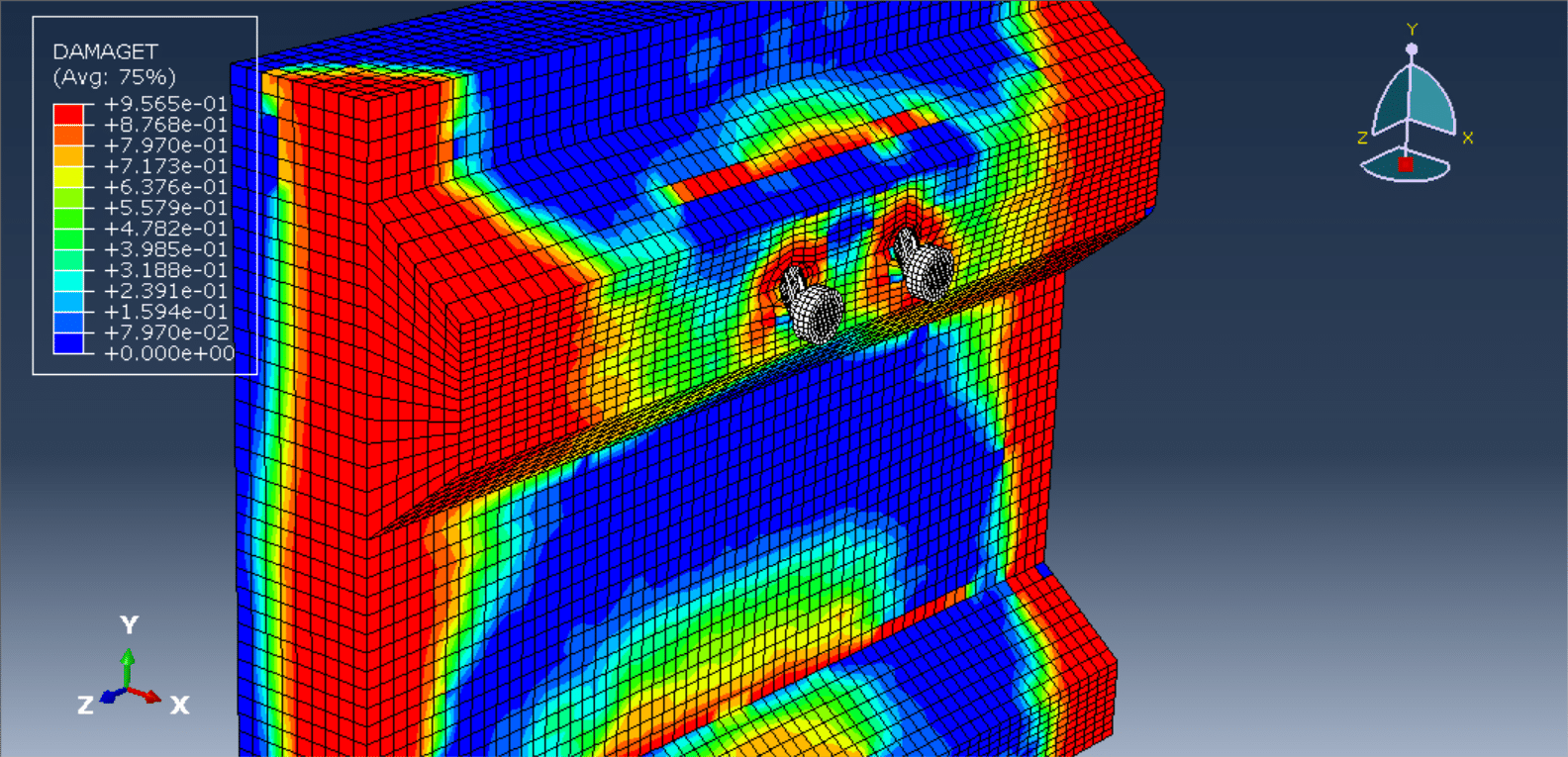

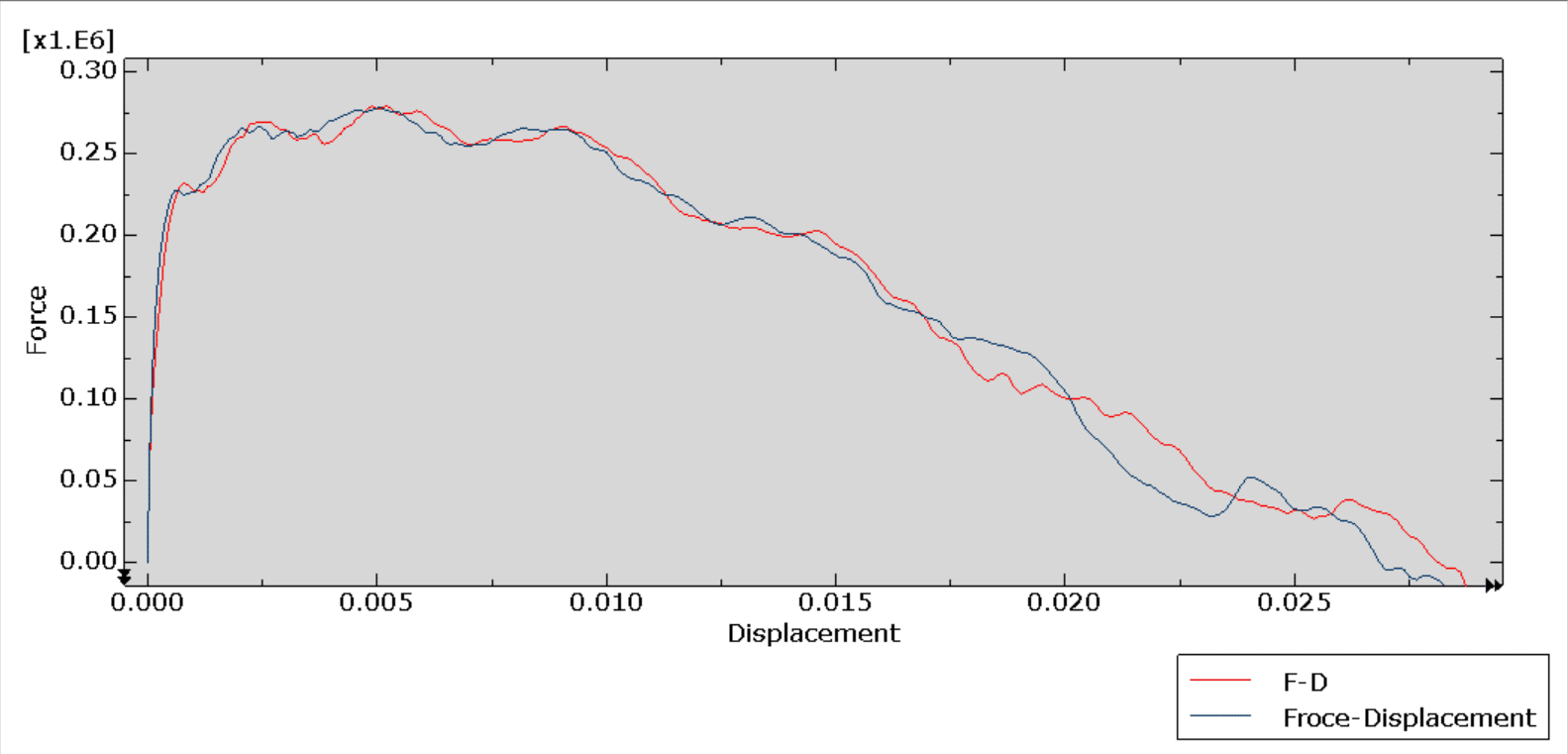

Numerical analysis, particularly through finite element modeling (FEM), has emerged as a powerful tool for studying the behavior of bolted shear connectors under various loading and boundary conditions. It allows for detailed insight into stress development, crack initiation, and propagation in concrete, as well as bolt slip and potential failure modes. By simulating different parameters—such as bolt size, preload, embedment depth, and deck orientation—researchers can optimize connector design for strength, stiffness, and durability.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?