Low-cycle fatigue (LCF) is a type of fatigue failure that occurs in materials subjected to relatively high stress levels and a low number of cycles, typically less than 10⁴–10⁵ cycles. This phenomenon is common in components exposed to cyclic plastic deformation, such as those in aerospace, nuclear, and power generation industries.

To model and predict LCF damage, traditional stress-life (S-N) or strain-life (ε-N) methods have limitations, particularly when plasticity plays a significant role. An alternative and more physically meaningful approach is the hysteresis energy-based model, which considers the energy dissipated per cycle as a direct measure of fatigue damage.

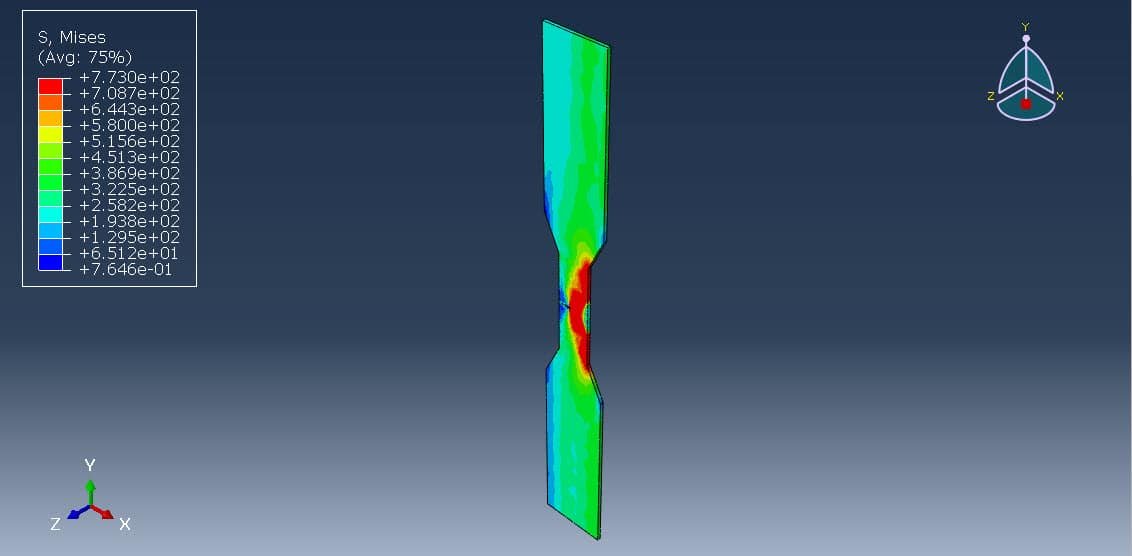

The hysteresis energy approach is based on the idea that fatigue damage correlates with the energy dissipated in the material during each loading cycle. When a material is cyclically loaded beyond its elastic limit, it undergoes plastic deformation, creating a stress-strain hysteresis loop. The area within this loop represents the energy dissipated per cycle due to plastic deformation.

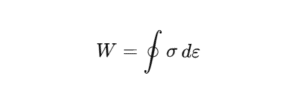

The hysteresis energy per cycle (W) is calculated as the area enclosed by the stress-strain loop:

Where:

This energy correlates with microstructural damage mechanisms such as crack initiation and propagation.

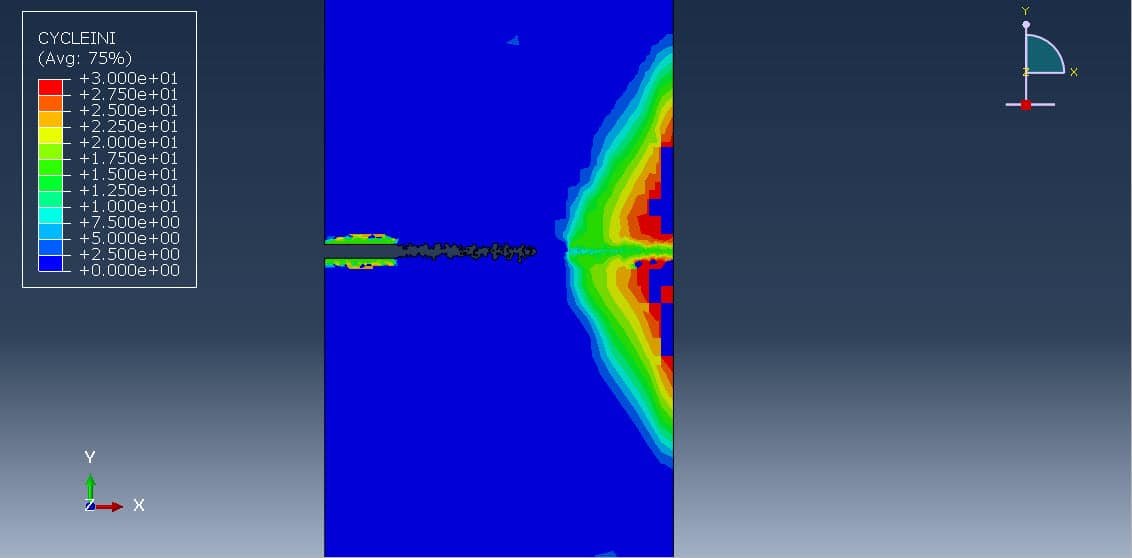

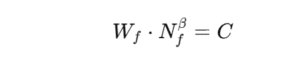

Fatigue life prediction using hysteresis energy typically follows a power-law form:

Where:

This equation implies that the higher the energy per cycle, the fewer the cycles to failure, making it suitable for LCF regimes where large plastic strains dominate.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?