What is the Best FEA Software in 2025

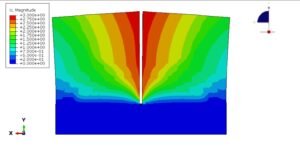

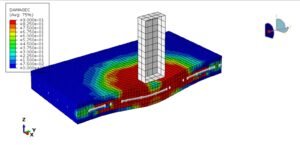

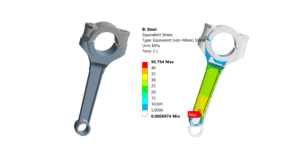

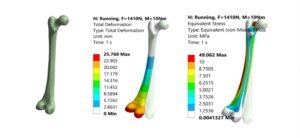

Finite Element Analysis (FEA) software has become a cornerstone of modern engineering, allowing designers to virtually test how products and structures behave under various forces and conditions. By breaking complex structures into smaller “finite” elements and simulating physical phenomena (like stress, heat, or fluid flow) on each element, FEA tools can predict real-world performance with impressive accuracy. This capability is crucial in 2025’s fast-paced development cycles – it helps engineers identify weak points and optimize designs early, saving time and cost by reducing the need for physical prototypes. With numerous FEA software options available, each with unique strengths, a common question arises: what is the best FEA software in 2025? The answer isn’t straightforward, as the “best” choice depends on your specific needs. Let’s explore how to determine the top FEA tool for you by examining key selection factors and reviewing the leading software contenders of 2025.

Factors to Consider When Choosing FEA Software

Selecting an FEA package involves weighing several important criteria to ensure it fits your requirements:

Capabilities and Physics Covered: FEA software varies in the range of simulations it can handle. High-end tools (like ANSYS or Abaqus) offer Multiphysics capabilities – from structural and thermal analysis to fluid dynamics and electromagnetics – whereas simpler or specialized programs might focus only on specific domains. Consider whether you need a broad, all-in-one solver or a specialized tool for your particular field (e.g. crash simulation, linear static analysis, etc.).

Ease of Use and User Interface: An intuitive interface and good pre-/post-processing features can greatly affect productivity. Some FEA programs integrate with CAD software (for example, SolidWorks Simulation is built into the CAD environment), making them easier to learn for design engineers. Others may offer advanced functionality at the cost of a steep learning curve. If you’re newer to FEA, a user-friendly tool with tutorials and a supportive community can be invaluable.

Advanced Analysis Features: Think about the complexity of the problems you’ll solve. Do you require nonlinear material models, dynamic crash simulations, or multi-physics coupling? Not all FEA software handles highly nonlinear or transient problems equally well. For instance, Abaqus is renowned for its ability to tackle nonlinear solid mechanics and complex material behavior (like plastics, rubbers, or composites under large deformation). On the other hand, LS-DYNA (an explicit solver now part of ANSYS) is the industry leader for simulating short-duration events such as impacts and crashes. Ensure the software you pick has the specific solvers or modules needed for your analysis types.

Integration and Automation: In a modern workflow, FEA tools often need to work alongside CAD, PLM, or other simulation software. Good compatibility (importing geometry directly, exporting results, etc.) can save you time. Additionally, consider if you need scripting or API access for customization. Many top tools support scripting (e.g. Python in ANSYS/Abaqus or MATLAB in some cases) to automate repetitive tasks – a crucial feature if you plan to run parametric studies or optimize designs.

Support and Training: The learning curve for advanced simulation software can be steep. Having access to technical support, documentation, and training resources is a big plus. Well-established FEA packages usually have extensive user communities (forums like Eng-Tips, Stack Exchange, etc.) where you can seek advice. Evaluate whether the software vendor or third parties offer tutorials, certification courses, or consulting services; this can greatly shorten your ramp-up time.

Cost and Licensing: Licensing models range from free open-source programs to very expensive enterprise solutions. High-end FEA software often comes with substantial license fees or annual subscriptions, which might be justified by their capabilities. If you’re a student or running a small business, budget-friendly options (including limited student editions or cloud-based pay-per-use services) might be more appropriate. On the other hand, if FEA is central to your work and you need advanced features, be prepared to invest. It’s often said on engineering forums that you get what you pay for – professional engineers tend to trust proven commercial tools for mission-critical projects. Free or low-cost tools exist (like CalculiX, Code_Aster, or vendor-provided lite versions), but these are typically geared towards academia or basic use and may lack the advanced capabilities and validation of commercial solvers.

Finally, remember that “best” depends on context. Experienced engineers often use multiple FEA packages, each excelling in different applications – a classic “horses for courses” scenario. There is no single FEA software that is unequivocally superior for every possible problem. Instead, the goal is to find which tool is best for your needs in 2025.

Leading FEA Software Options in 2025

In 2025, several FEA software platforms stand out as industry leaders or popular choices. Here we review the top contenders, highlighting their strengths and typical use cases. This list covers both well-established giants and some rising alternatives:

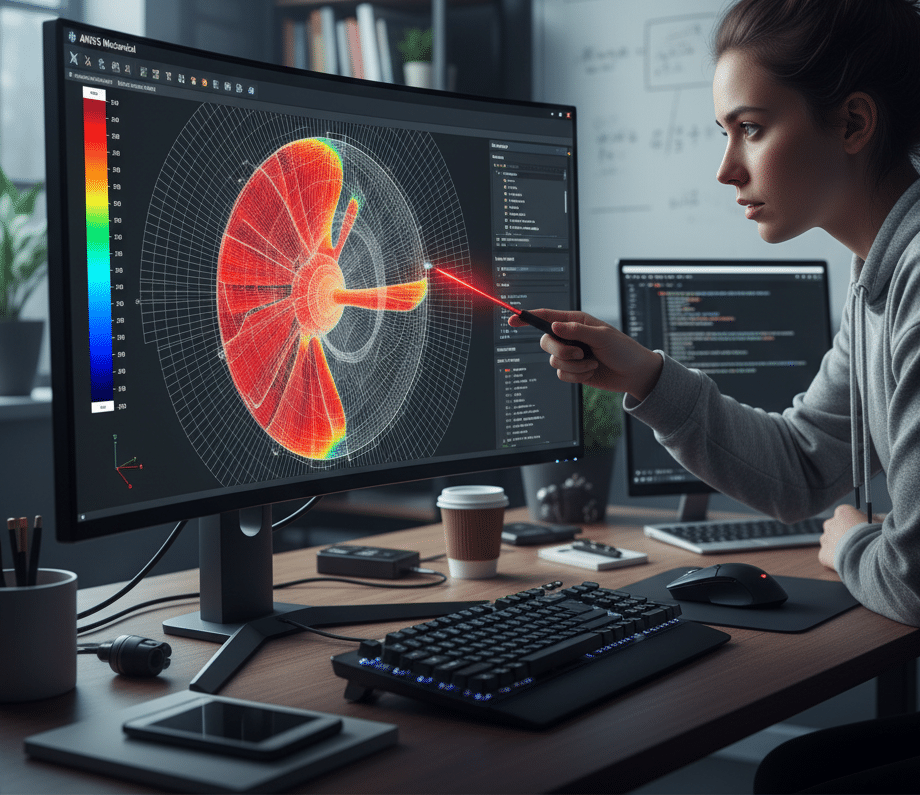

ANSYS Mechanical

ANSYS is often considered the gold standard in engineering simulation. It provides a comprehensive suite covering FEA for structural analysis, computational fluid dynamics (CFD), electromagnetics, and more under one umbrella. ANSYS Mechanical in particular is renowned for its robust structural analysis capabilities and can tackle everything from simple linear static problems to complex nonlinear and dynamic simulations. It offers high-fidelity results and an extensive material library, making it ideal for aerospace, automotive, electronics and other industries that demand accuracy.

Key advantages of ANSYS include its Multiphysics integration (coupling different physics in one model) and support for high-performance computing, which allows very large or detailed simulations. It also has strong automation and customization support – users can write Python scripts or use ANSYS APDL for parametrization and advanced control. The downside is that ANSYS comes with a steep learning curve and a high price tag, which can be a barrier for smaller organizations Nevertheless, in terms of all-around capability in 2025, ANSYS Mechanical remains a top choice and is widely adopted across industries (it’s often the go-to solver in corporate engineering teams for its proven reliability). Check Out ANSYS Mechanical Tutorial for Beginners to Intermediate Users.

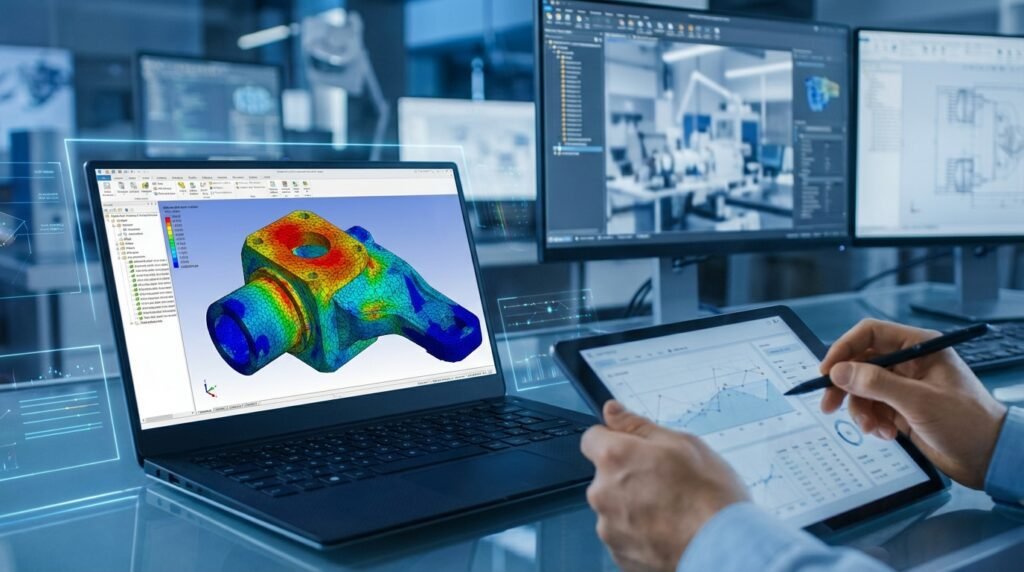

Abaqus (Dassault Systèmes SIMULIA)

Abaqus, part of Dassault Systèmes’ SIMULIA suite, is another heavyweight FEA tool highly respected in the engineering community. Abaqus is especially known for its advanced non-linear analysis prowess. When it comes to simulating complex material behavior (like rubber elasticity, plastic deformation, or composite damage) and challenging contacts (e.g. simulating how an assembly with many touching parts behaves under load), Abaqus excels. It’s a favorite in industries such as automotive (for things like tyre modeling, crashworthiness, etc.), aerospace, and defense, where such sophisticated simulations are common.

Abaqus offers two main modules: Abaqus/Standard (implicit solver for static and low-speed dynamic problems) and Abaqus/Explicit (explicit solver suited for high-speed dynamic events like impacts). This gives users flexibility to tackle a range of scenarios. Abaqus also integrates well with other Dassault tools (like CATIA for CAD and fe safe for fatigue analysis) as part of a larger ecosystem. Similar to ANSYS, Abaqus supports Python scripting for automating analyses and customizing workflows. Its user interface is considered less intuitive by some, and, like ANSYS, the cost is significant – so it’s often used by larger companies or research institutions. If your work involves highly non-linear FEA or you require a very robust solver for complex physics, Abaqus in 2025 is arguably one of the best choices available. Check out our Fatigue and Cyclic Loading Package in Abaqus.

MSC Nastran (with Patran or Femap)

MSC Nastran is a classic FEA solver with a long heritage (initially developed for NASA in the 1960s) and remains a workhorse for structural analysis, particularly in aerospace and automotive fields. Many consider Nastran the industry standard for stress and vibration analysis of structures like aircraft frames, vehicle chassis, etc. In 2025, Nastran is available from multiple sources – MSC Software (now part of Hexagon) offers MSC Nastran, while Siemens provides a version known as Simcenter Nastran (formerly NX Nastran). Both derive from the original Nastran code and have similar capabilities.

Nastran is typically used alongside a pre/post-processor: Patran (from MSC) or Femap (from Siemens) are two popular GUI tools to build models and visualize results for the Nastran solver. Users praise Nastran for its reliability, extensive verification history, and efficiency in solving large models. It’s particularly strong in linear statics, dynamics (modal analysis, frequency response), and buckling analysis – tasks important in structural and mechanical engineering. Nonlinear and thermal capabilities exist but these are areas where tools like Abaqus might be chosen instead if extreme fidelity is required.

One notable strength of Nastran is its performance on large models with millions of degrees of freedom, a reason it’s trusted for big projects like aircraft or spacecraft components. Companies in aerospace often mandate Nastran because of legacy and confidence in its results (it’s widely used throughout the aerospace and automotive industries to this day). If you work in those fields, there’s a good chance you’ll encounter Nastran in 2025. The learning curve can be moderate – especially using older interfaces but Femap and Patran provide user-friendly environments. For many structural engineers, MSC/Patran-Nastran remains a go-to combo for everyday FEA needs due to its robustness and the trust it has earned over decades.

Altair HyperWorks (Including OptiStruct and HyperMesh)

Altair HyperWorks is a suite of simulation tools known particularly for design optimization and lightweighting. Within this suite, OptiStruct is Altair’s flagship FEA solver for structural analysis, and it doubles as a powerful optimization solver (e.g. for topology optimization, finding the best material layout for a given design space). HyperMesh is Altair’s advanced pre-processor, famous for its meshing capabilities – many analysts use HyperMesh even if they eventually solve using another solver, because of its ability to handle complex geometry meshing and model setup.

Altair’s tools have a strong presence in the automotive industry (for NVH – noise, vibration, harshness – analyses, crash, durability etc.) and are also used in aerospace and industrial design. OptiStruct can handle linear and nonlinear problems and has grown into an all-purpose solver, but Altair also offers Radioss (for explicit dynamics like crash simulations) and Motion Solve (for multi-body dynamics). The integration under HyperWorks means you can set up a model once and solve it with multiple solvers as needed.

A distinguishing feature of Altair is its focus on optimization and simulation-driven design – if your goal is to automatically improve a design (minimize weight, for example, while meeting strength targets), OptiStruct’s optimization algorithms are among the best. Altair also pioneered a unique licensing system (units-based licensing) that can be cost-effective if you use several tools interchangeably. In terms of 2025’s “best” FEA software, Altair HyperWorks deserves mention not only because its solvers (like OptiStruct) are very capable for general FEA, but also because it excels in areas of optimization that traditional tools like ANSYS/Nastran don’t inherently focus on. Companies looking to innovate with new materials or aggressive weight targets often rely on Altair’s software. The trade-off is that mastering HyperMesh and the Altair way of working can take time – it’s a very powerful toolkit, but not the simplest for casual users.

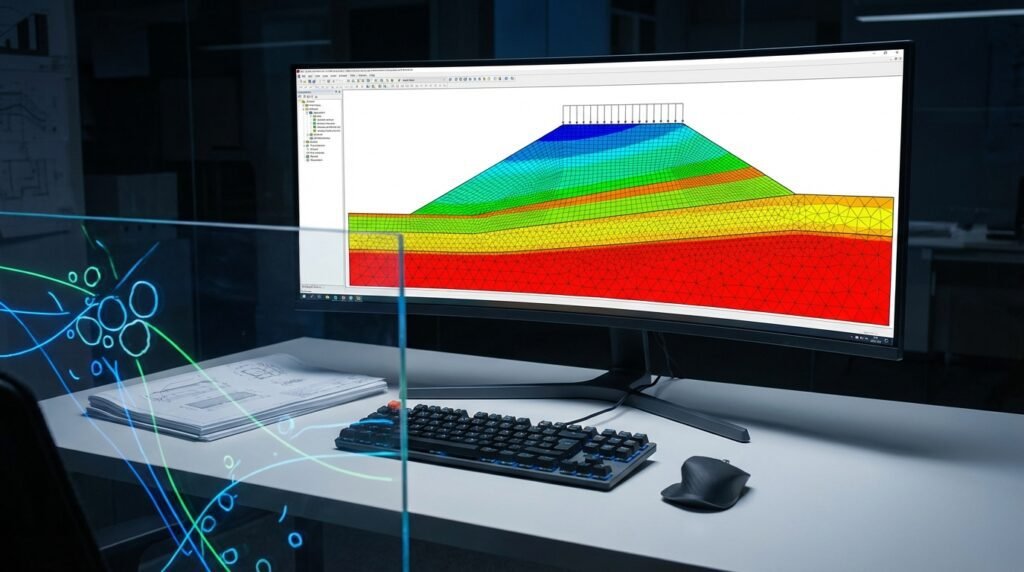

COMSOL Multiphysics

COMSOL Multiphysics is a bit different from the other names on this list. It’s designed as a multiphysics simulation platform from the ground up, meaning it allows coupling between a wide variety of physics in one unified environment. COMSOL’s strength lies in its flexibility and breadth: you can simulate structural mechanics (FEA), fluid flow, heat transfer, electromagnetics, chemical diffusion, acoustics, and even user-defined physics, all in one model if needed. This makes COMSOL extremely popular in research and R&D settings, such as universities and R&D departments, especially for problems where interactions between physics are critical (for example, simulating how an electromagnetic heating device induces thermal stresses in a material).

In 2025, COMSOL continues to be a top choice for Multiphysics problems and for engineers who prefer a graphical, user-friendly interface with lots of tutorial examples. It has a library of add-on modules for different applications (RF, microfluidics, batteries, etc.) and even allows creating custom apps for end-users. However, COMSOL might not always be the first choice for pure structural mechanics if that’s the only need – dedicated FEA tools like ANSYS or Abaqus can handle large structural models more efficiently. COMSOL’s meshing and solver technology are very capable but sometimes struggle with very large 3D models compared to the specialized codes. Also, like others, it is commercial software with licensing costs to consider.

That said, COMSOL’s impact is significant enough that it’s considered one of the leading FEA-related tools of 2025, especially valued for its versatility. If your work involves coupling multiple physics or you want an accessible interface to set up complex simulations without deep programming, COMSOL is likely one of the best options to explore. Check out COMSOL Multiphysics Tutorial Course .

SimScale (Cloud-Based FEA)

SimScale represents a newer generation of FEA tools that leverage cloud computing. Founded in the 2010s, SimScale is a fully cloud-based simulation platform where you run analyses through a web browser instead of on local hardware. In 2025, as cloud services are even more mature, SimScale and similar offerings have gained traction, especially among freelancers, small firms, and those who prefer not to invest in expensive high-performance computers. SimScale provides FEA capabilities (as well as CFD) accessible on-demand; their platform can handle structural simulations using proven solver codes on the backend, and you only pay for what you use in terms of compute time (they also have a free community tier for public projects).

The advantages of a cloud FEA solution like SimScale are collaboration and accessibility – team members can share simulation projects easily, and you can run heavy simulations from a modest laptop since the number-crunching happens on cloud servers. It also lowers the entry barrier for advanced simulation: you don’t need to install complex software or worry about license servers. For occasional users or those needing flexibility, this is potentially the “best” approach.

However, cloud FEA may not (yet) replace desktop applications for very large or highly sensitive projects. Some analysts prefer local control due to data security or because they require extremely customized setups not available in a simplified web interface. Performance can also depend on internet connectivity. Nonetheless, SimScale in 2025 is a leading option for cloud-based FEA and has been making sophisticated simulation more accessible. It’s a sign of where the industry is headed – even established companies like ANSYS and MSC offer cloud options now – but SimScale is purpose-built for it. If ease of access and lower upfront cost are your priorities, SimScale could be the best FEA solution for your needs, offering a decent range of analysis types through a convenient platform.

Other Notable Mentions

Beyond the main players above, there are several other FEA software tools worth mentioning that might be “best” for certain niches or user groups in 2025:

LS-DYNA: Now under the ANSYS umbrella (as Ansys LS-DYNA), this software is the leader in explicit dynamic simulations like crash tests, drop impacts, and explosions. If your focus is automotive crash safety or impact analysis, LS-DYNA is virtually the default choice in industry. It’s highly specialized but unrivaled in that domain.

Autodesk Inventor Nastran / Fusion 360: Autodesk offers FEA capabilities integrated with their CAD tools (Inventor and Fusion 360 use a Nastran solver under the hood). These are aimed at design engineers for routine analysis. While not as powerful as ANSYS or Abaqus, they can be the best fit for CAD-centric workflows or for companies already using Autodesk products, providing a convenient “quick check” FEA within the design environment.

SOLIDWORKS Simulation: Similar to Autodesk’s tools, SOLIDWORKS Simulation brings FEA into the SOLIDWORKS CAD interface. It’s quite user-friendly and sufficient for many linear static, thermal, and modal analyses. For small-to-medium manufacturers where engineers wear multiple hats, this integrated approach can be more efficient than using a separate high-end FEA package – even if the capabilities are somewhat limited. It’s a trade-off between depth of features and ease of use/cost.

Open-Source FEA: There are open-source FEA codes like CalculiX, Code Aster, Elmer and others. These can actually perform advanced analyses and in some cases approach the capabilities of commercial tools, but they usually require more manual work (often lacking a polished GUI) and user expertise. In academia or hobby projects, they might be the best (or only) choice if budget is zero. For example, Code Aster (originating from EDF in France) is quite powerful in nonlinear structural analysis, and CalculiX has an interface somewhat similar to Abaqus. The downside is the significant effort to learn and validate these tools for critical use – they come without formal support and with sparse documentation, which is why in professional settings they are less common.

Industry-Specific Software: Depending on your sector, the “best” FEA software might actually be a niche product. Civil engineering has specialized structural analysis programs (like SAP2000, ETABS for buildings, or Abaqus with civil material libraries for geotechnical analysis). For electromagnetics-heavy work, you might look at ANSYS HFSS or COMSOL. If biomechanical FEA is your field, something like FEBio (open-source focused on biomedical) could be ideal. These tools might not rank as top general FEA software, but for their intended purpose they can outperform generalists.

As we can see, the landscape of FEA software in 2025 is rich and varied. A survey of engineers on an expert forum succinctly concluded that there is no single “best” FEA software for all purposes – most comprehensive packages (like Ansys or Abaqus) cover a wide range of needs, but each tool has its own niches of excellence.

Conclusion: Finding Your Best FEA Software

So, what is the best FEA software in 2025? The best choice ultimately depends on your specific requirements – your industry, the types of simulations you run, your budget, and even your personal workflow preferences. For a mechanical product company needing broad analysis capabilities, ANSYS Mechanical might be the top pick due to its all-round strength and industry validation. If you’re doing cutting-edge materials or non-linear simulations in aerospace or automotive, Abaqus could be your best bet for its superior handling of complex physics. Those focusing on optimization-driven design might lean towards Altair HyperWorks for its unique optimization features. And if accessibility and collaboration are key, a cloud platform like SimScale could be “the best” for your team’s workflow.

It’s important to match the tool to the task. As one seasoned engineer put it, trying to declare an absolute best FEA software is like debating the best vehicle – a Formula 1 car, a lorry, and a family sedan are all “best” at different things. Similarly, each leading FEA software in 2025 shines in particular aspects: some in user-friendliness, some in sheer power, some in specialized applications. The good news is that the top-tier options (ANSYS, Abaqus, Nastran, etc.) have all been proven to deliver accurate results when used properly – any of them can be the best in the right hands and the right situation.

Before committing to one, it’s wise to take advantage of trial versions or academic licenses (if applicable) to test a few tools. Evaluate how well they integrate into your workflow and handle your benchmark problems. Check the support resources and community activity, as these often indicate how easy it will be to troubleshoot issues or learn advanced tips. The FEA software market is mature, but it continues to evolve with trends like cloud computing and AI-driven features starting to appear. By staying informed about these options (as we’ve done in this overview) and aligning them with your project needs, you’ll be able to select the FEA software in 2025 that is best for you – which is, in the end, the definition of “the best” software.

In summary, there is no one-size-fits-all answer to the best FEA software question. However, armed with the knowledge of what each leading tool offers, you can confidently choose a simulation software that empowers you to innovate and engineer effectively. Whether you opt for the heavyweights like ANSYS/Abaqus, a specialized solver, or a cutting-edge cloud platform, the key is that it meets your needs and helps turn your ideas into reality with accuracy and efficiency. Happy simulating in 2025!