Intro

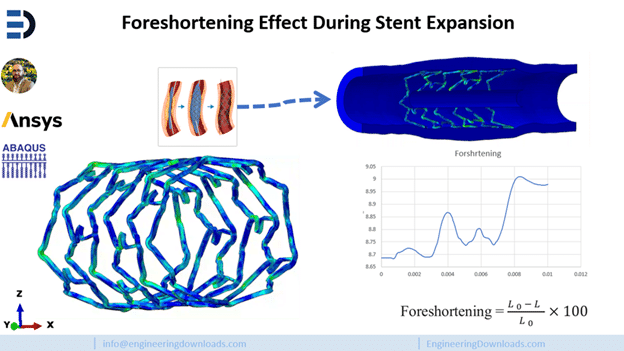

When placing a stent in a coronary artery, we expect it to hold its shape and position—but did you know that stent length can shorten by up to 10% during expansion? This change, known as foreshortening, is one of the key challenges in ensuring accurate and safe stent deployment.

At EngineeringDownloads.com, we’ve been running advanced simulations to better understand and predict this behavior, using finite element analysis (FEA) in Abaqus and Ansys software.

What Is Foreshortening?

Foreshortening occurs when the stent shortens in the longitudinal direction during balloon expansion. It means that even if your stent is perfectly positioned before inflation, it could shift or misalign after deployment, leaving parts of the vessel untreated or even causing damage.

In the animation and simulation above, you can clearly see how the stent interacts with the artery wall, shortening as the balloon expands. This matters because even small changes in length can lead to critical vessel segments being missed.

What Causes Foreshortening?

Foreshortening is a mechanical response that depends on:

- Stent geometry

- Balloon inflation strategy

- Artery curvature and plaque location

- Material properties of the stent and vessel

In addition to foreshortening, our simulations also capture other key deployment effects:

- Radial Coil (Recoil): The stent’s tendency to contract slightly after balloon deflation.

- Longitudinal Retraction: Backward movement of the stent after inflation.

- Dog Boning: Over-expansion at the ends of the stent compared to its center.

These phenomena are all critical to achieving safe, accurate, and durable outcomes in real-world stent placement.

Our Simulation Workflow

To study this, we built a realistic coronary artery–stent–plaque model in CAE software:

- Balloon pressures were incrementally applied.

- Stent geometry and behavior were monitored during inflation and recoil.

- The change in length was calculated over time and compared across different stent designs.

The result? A repeatable FEA workflow that can predict and minimize foreshortening before a patient ever enters the cath lab.

Key Results from Our Study

- Foreshortening can be reduced by over 50% with design improvements.

- Stent 1 (auxetic design) showed significantly lower foreshortening and longitudinal retraction compared to the non-auxetic model (Stent 3).

- Stent 2 (another auxetic design) had excellent expansion behavior but caused higher stress on the artery wall, making it less safe in some cases.

- Dog boning and recoil were also quantified, offering a full picture of deployment dynamics.

We asked: “Which is the most difficult deployment effect to design for—dog boning, recoil, or foreshortening?” Let us know your thoughts in the comments!

Real-Life Reference Study: Auxetic vs. Non-Auxetic Stents

We also referenced the paper by Pramanik et al. (2023):

“Additive Manufacturing and Mechanical Properties of Auxetic and Non-Auxetic Ti24Nb4Zr8Sn Biomedical Stents: A Combined Experimental and Computational Modelling Approach” (DOI: 10.3390/cryst13111592).

This study compared auxetic and non-auxetic stents in both unrestricted and restricted (in-artery) environments. Auxetic designs showed:

- Less foreshortening

- Better adaptability to vessel geometry

- Superior mechanical performance in some cases

Our simulations align closely with their findings.

Applications: FEM Products for Stent–Plaque Interaction

We offer two detailed simulation products related to stent deployment in plaque-affected vessels:

- Stent Expansion in a Vessel with Symmetric Plaque

- Focus: Balanced pressure and smooth expansion

- Best for: Teaching, research, and design testing

- Stent Expansion in a Vessel with Asymmetric Plaque

- Focus: Realistic complex scenarios with localized stress concentrations

- Best for: Advanced simulations and design optimization

Both products are available in our FEM simulation library.

About the Author

Saman Hosseini is a mechanical engineer and simulation specialist at EngineeringDownloads.com. With deep expertise in Abaqus and cardiovascular simulations, Saman focuses on combining bioengineering insights with powerful FEA tools to improve medical device performance before they reach the patient.

Let’s Talk: Have you experienced issues with stent foreshortening or dog boning in your simulations? What tools or strategies do you use to minimize deployment errors?

Leave a comment below or share this post with colleagues working in medical device design!

Explore More: Download our stent simulation whitepaper

Contact: info@engineeringdownloads.com