🔹 Introduction to Welding Analysis and Simulation

Welding is one of the most widely used manufacturing processes in industries such as automotive, aerospace, shipbuilding, energy, and construction. While it provides strong and durable joints, welding introduces complex thermal, mechanical, and metallurgical phenomena that can significantly influence the performance of the final product.

1. Why Welding Analysis and Simulation?

- Welding involves localized heating and cooling, leading to temperature gradients, residual stresses, and distortions.

- Mechanical properties can change due to phase transformations and microstructural evolution.

- Traditional trial-and-error approaches for optimizing welding processes are expensive, time-consuming, and limited.

- Numerical simulation tools (e.g., Abaqus, ANSYS, SYSWELD) allow engineers to predict, analyze, and optimize welding processes before physical experiments.

2. Key Aspects of Welding Simulation

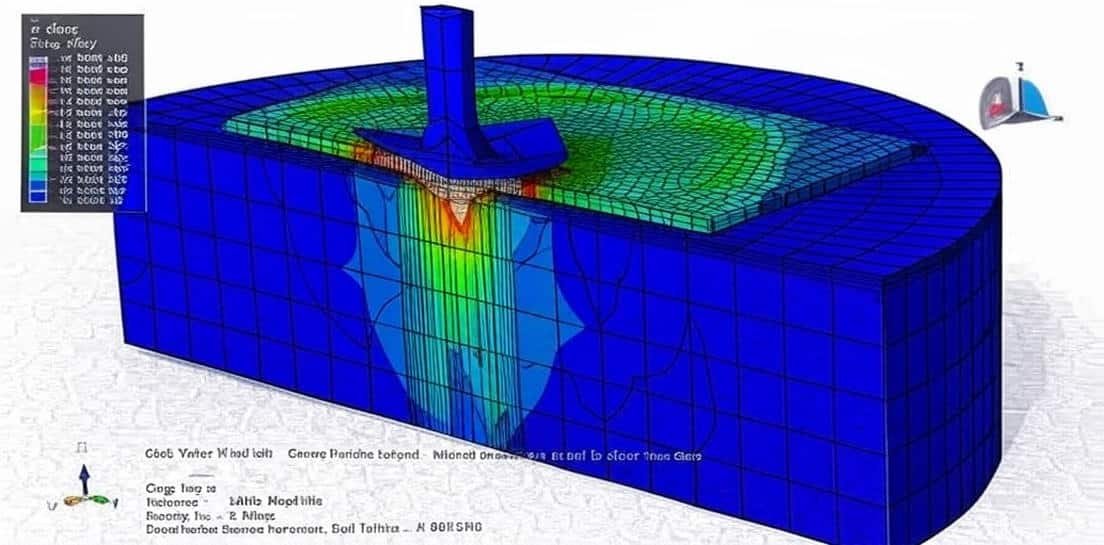

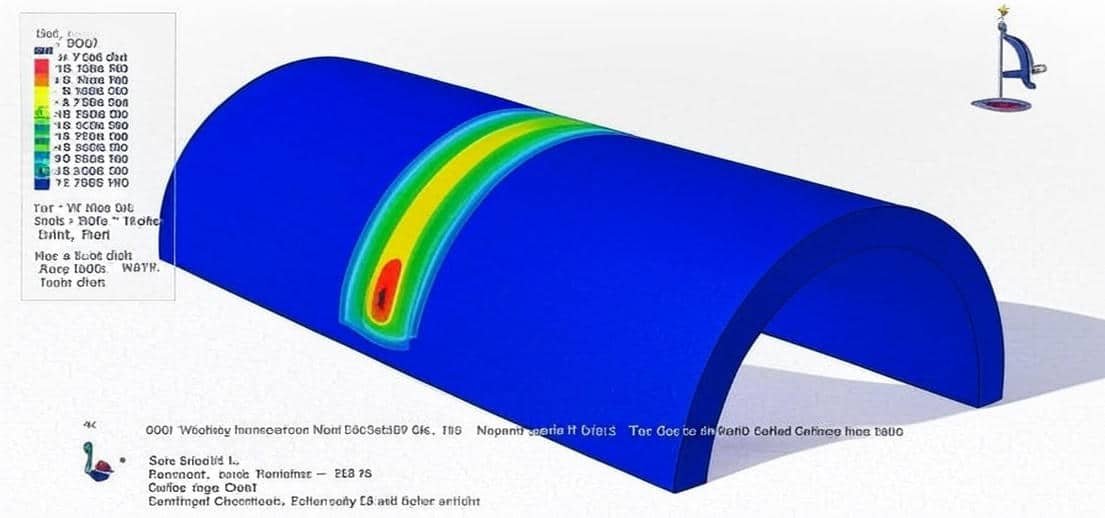

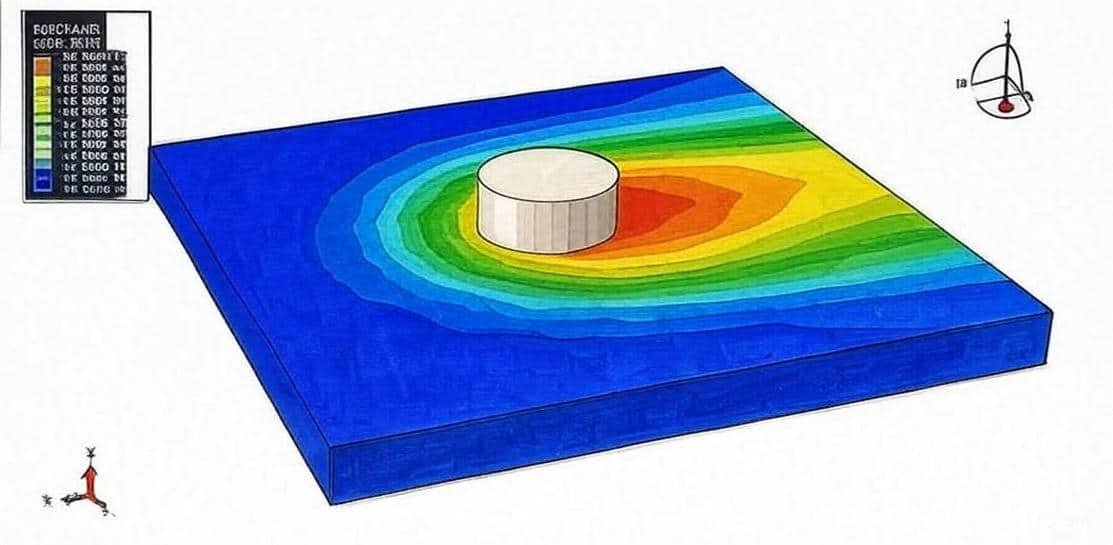

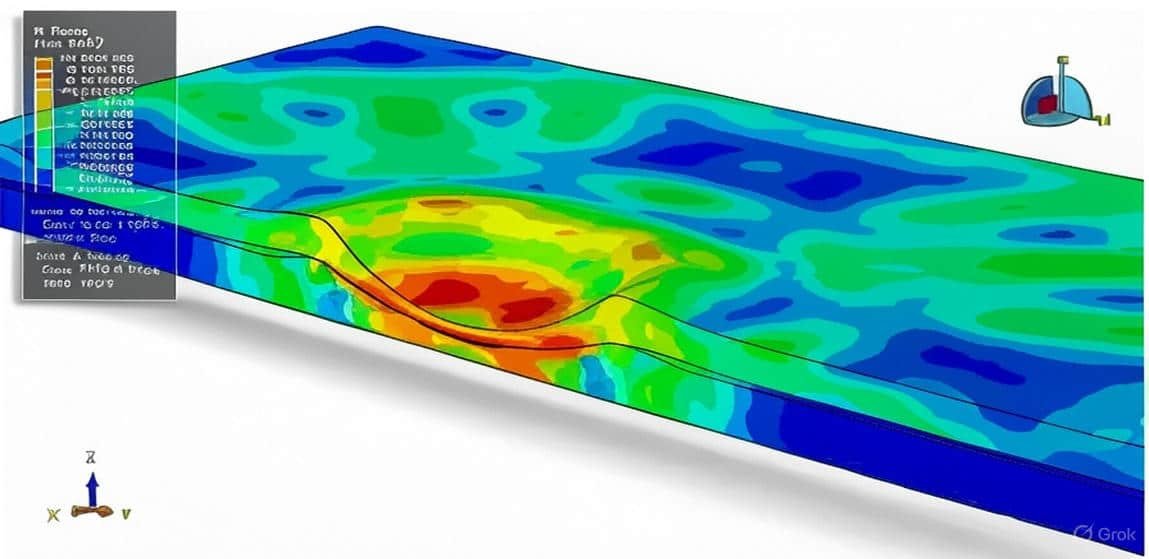

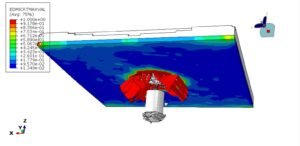

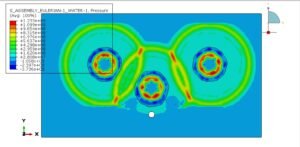

- Thermal Analysis

- Predicts heat distribution, cooling rates, and temperature history.

- Models heat sources (e.g., Goldak double ellipsoidal model).

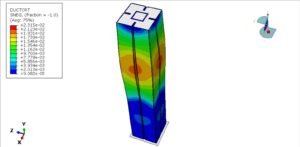

- Structural/Mechanical Analysis

- Determines residual stresses and distortions caused by thermal expansion and contraction.

- Helps prevent warping, cracking, and dimensional inaccuracies.

- Metallurgical Analysis

- Simulates phase transformations, hardness distribution, and microstructural evolution in Heat-Affected Zones (HAZ).

- Critical for ensuring mechanical integrity.

- Coupled Thermo-Mechanical Analysis

- Integrates heat transfer with mechanical response for realistic predictions.

3. Applications of Welding Simulation

- Automotive & Aerospace: lightweight structures with precise tolerance.

- Shipbuilding: large welded panels with distortion control.

- Oil & Gas / Energy: welding of pressure vessels and pipelines.

- Nuclear Industry: high-integrity welds with strict safety requirements.

4. Benefits of Welding Simulation

- Reduces costly experimental trials.

- Improves product quality and reliability.

- Optimizes welding parameters (speed, heat input, sequence).

- Enhances safety by predicting potential weld defects.

- Shortens design and production cycles.

👉 In Abaqus, welding simulations are usually performed using coupled temperature-displacement analyses, with specialized subroutines or packages to model moving heat sources, filler deposition, and metallurgical changes.

This package includes 14 practical tutorials that cover all aspects of welding simulation and analysis.