Cyclic loading plays a critical role in the structural integrity and fatigue life of welded steel components. Structures such as bridges, offshore platforms, pressure vessels, and heavy machinery are frequently subjected to repeated loading and unloading during service. These load reversals can induce progressive plastic deformation, stiffness degradation, and crack initiation—particularly in welded regions where metallurgical and geometric discontinuities exist.

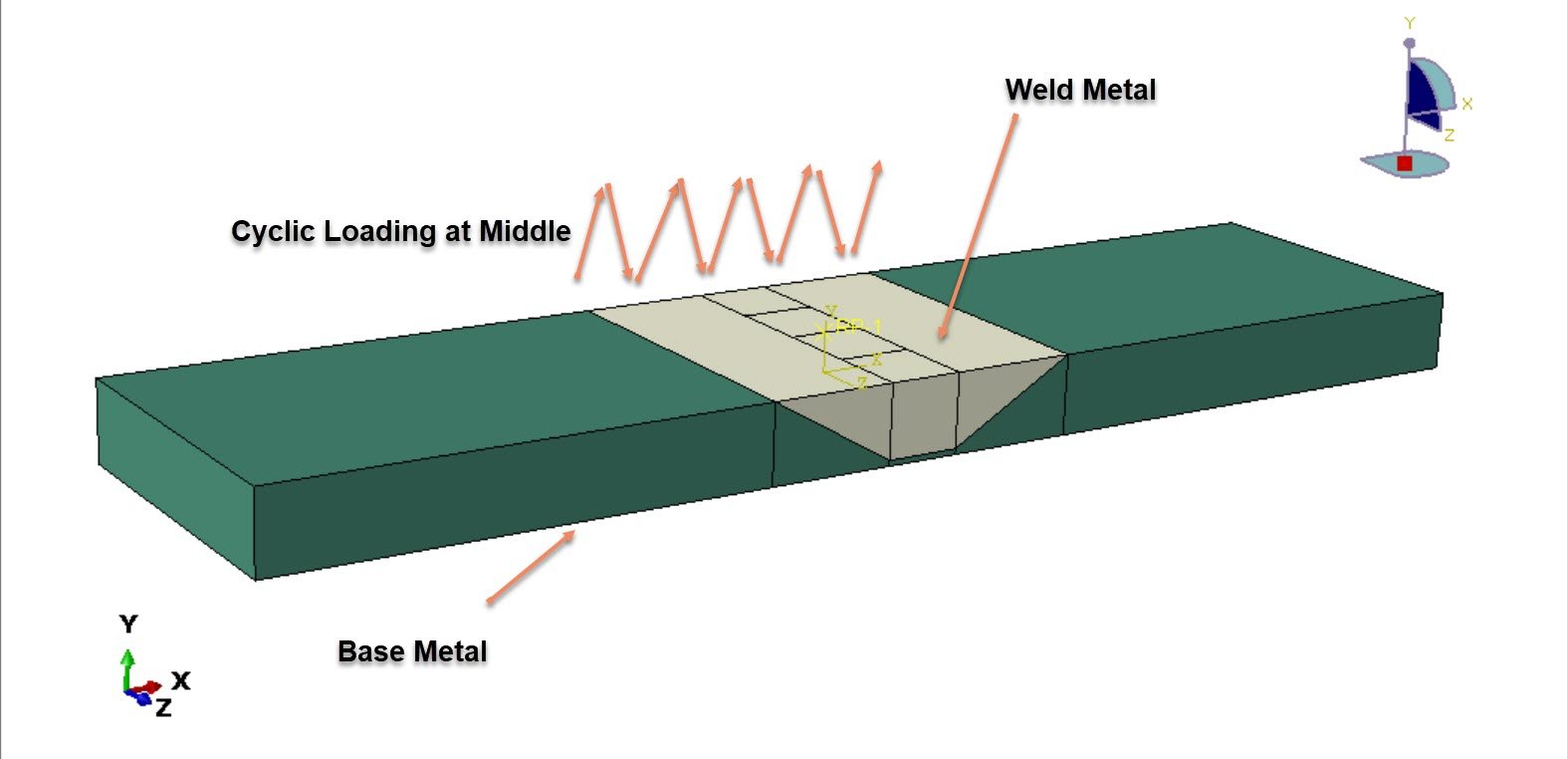

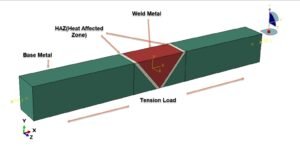

Welded joints are inherently heterogeneous due to the presence of three distinct material zones:

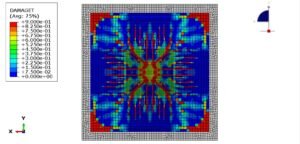

Among these, the weld metal and adjacent regions often exhibit different mechanical properties, residual stresses, and microstructural transformations compared to the base plate. This mismatch can lead to localized stress–strain concentration under cyclic loading, making the weld region a critical site for plastic strain accumulation and fatigue damage.

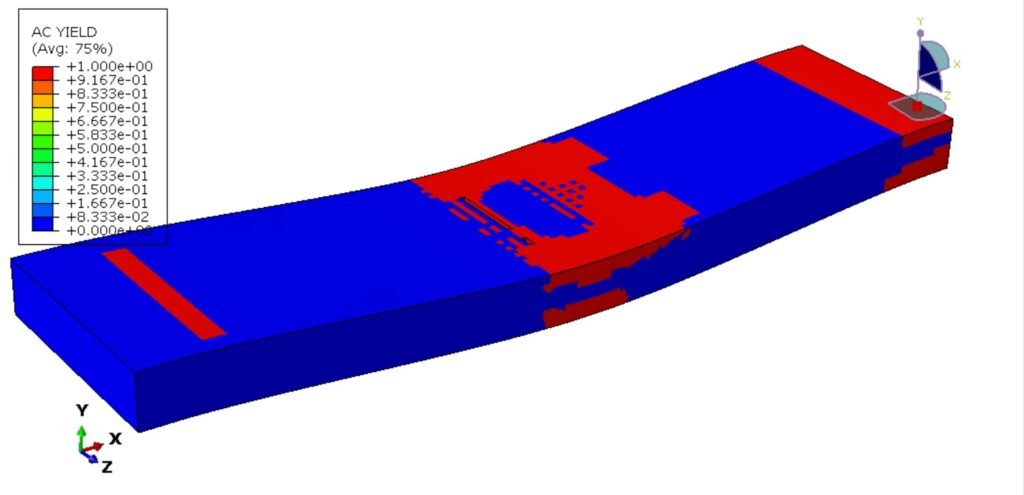

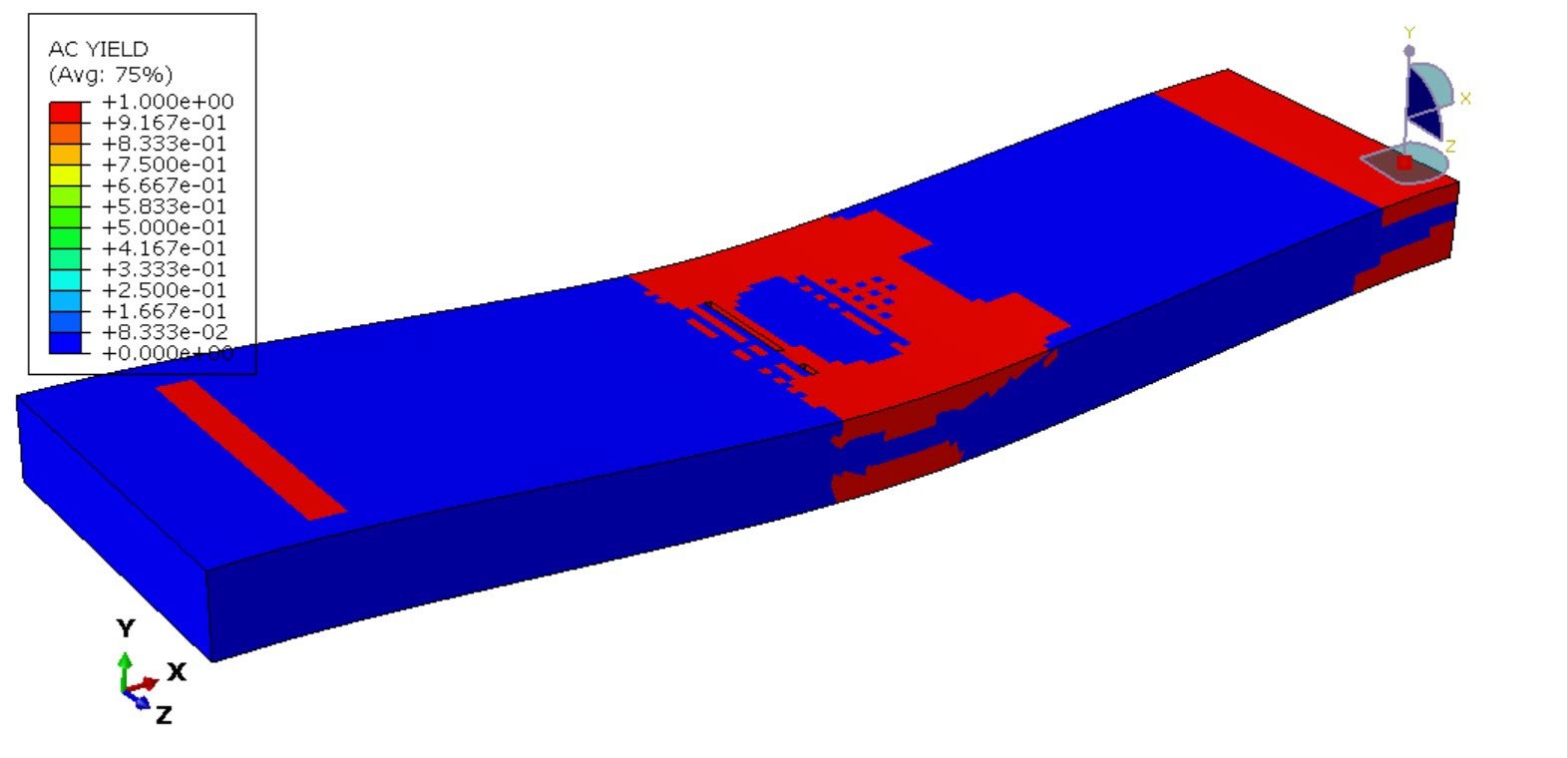

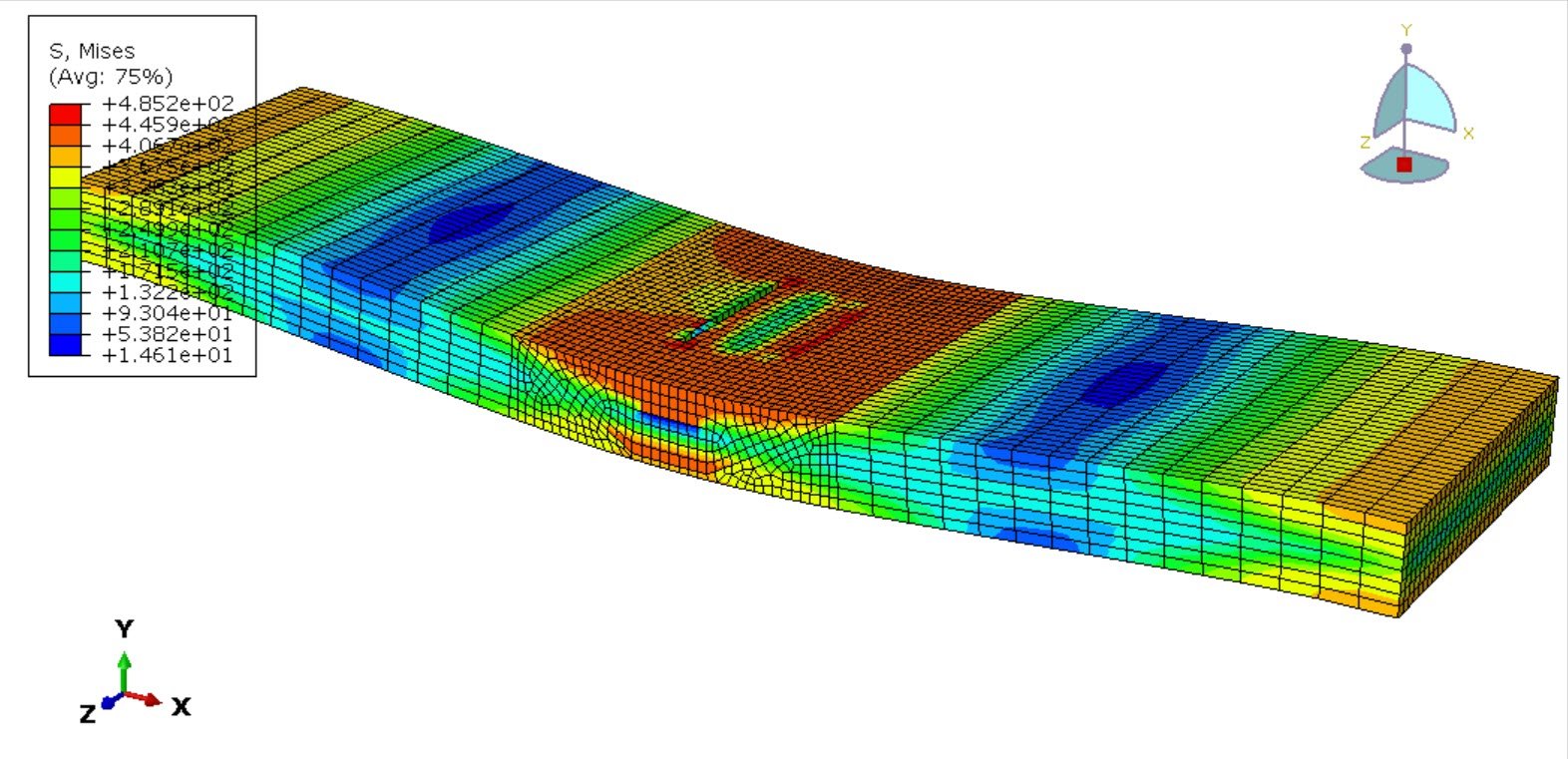

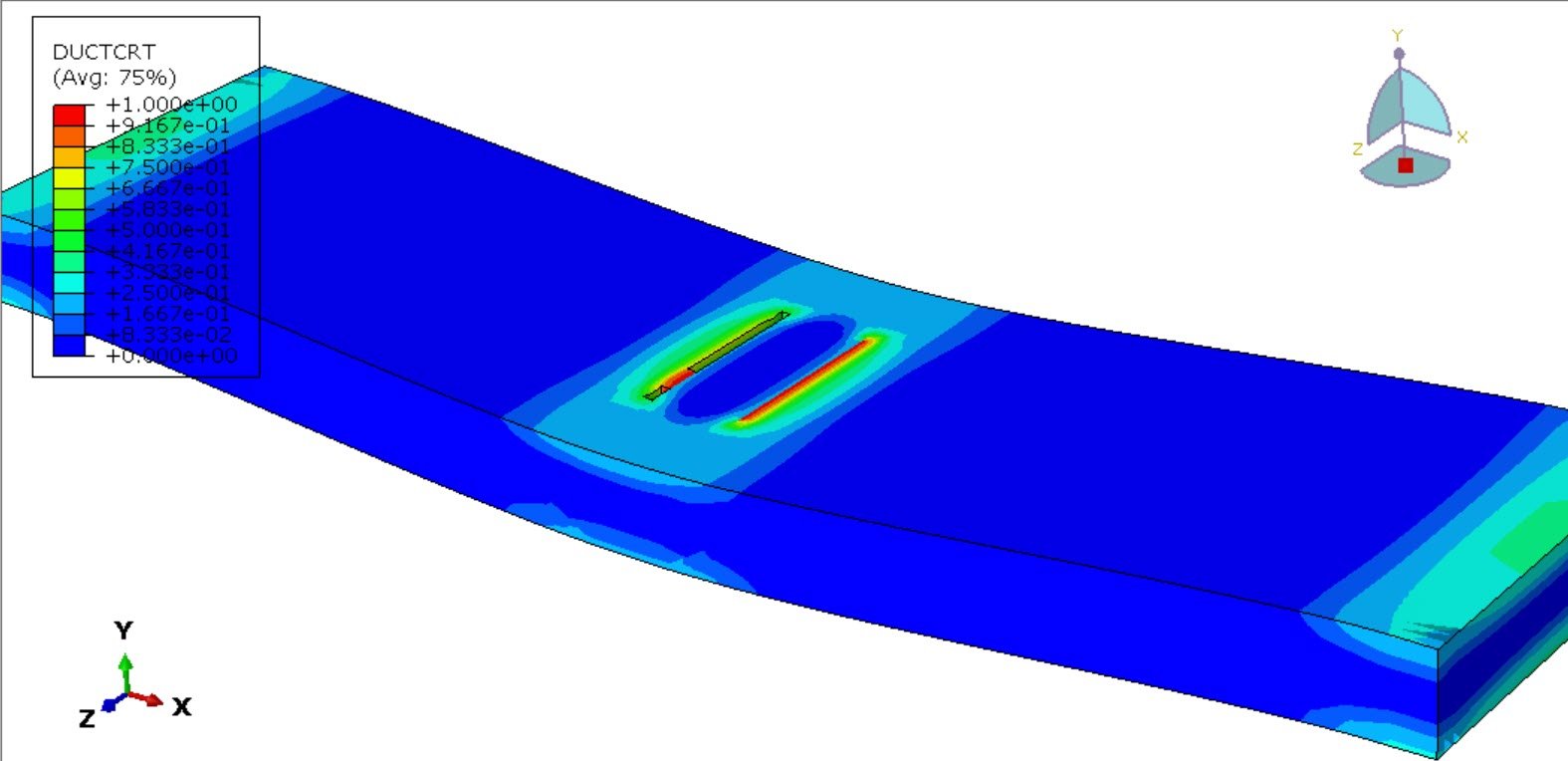

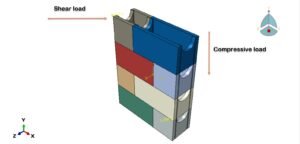

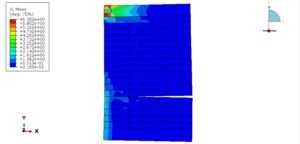

To investigate this behavior, a finite element–based cyclic loading analysis was performed on a steel plate containing a weld bead located at the mid-section. The numerical simulation was conducted using Abaqus, employing an elastic–plastic constitutive framework for both the base metal and weld metal.

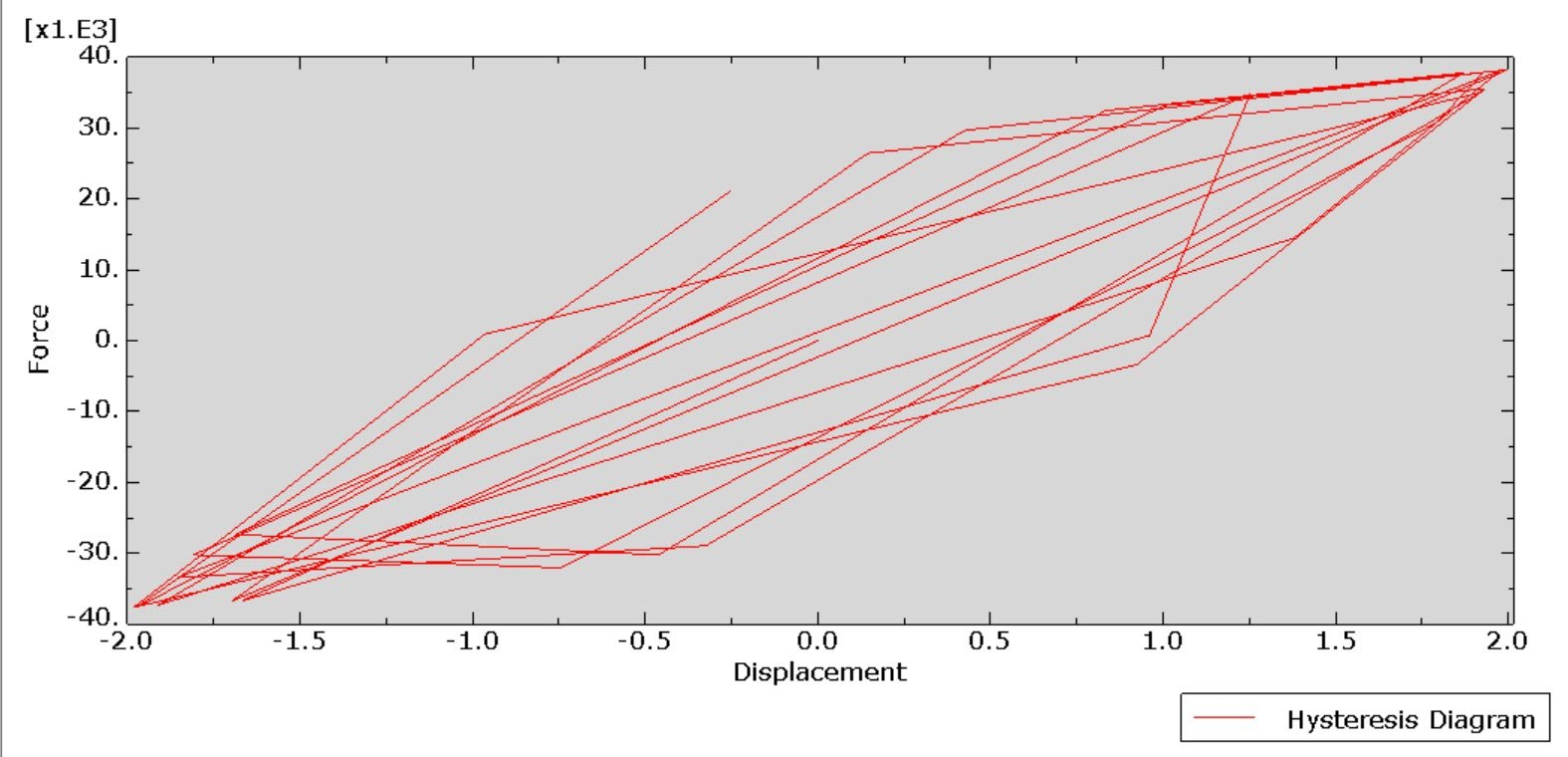

The material nonlinearity was represented using a combined plasticity model (isotropic + kinematic hardening). This formulation is particularly suitable for cyclic loading simulations because it can capture key hysteresis phenomena, including:

Kinematic hardening governs the translation of the yield surface in stress space, enabling accurate representation of load reversal behavior, while isotropic hardening controls the expansion/contraction of the yield surface with accumulated plastic strain.

The analysis step was defined as a General Static step with nonlinear geometry and material behavior activated. Although the loading is cyclic, a quasi-static approach is appropriate when inertial effects are negligible, and the focus is on stabilized cyclic stress–strain response rather than dynamic amplification.

A prescribed cyclic load (or displacement) history was applied to the plate to simulate repeated service loading. Special attention was given to:

Mesh refinement was implemented in the weld region to accurately capture steep stress gradients arising from material mismatch and weld geometry.

This cyclic loading analysis provides insight into the inelastic response of welded steel plates and supports the prediction of structural durability under repeated loading. The results can be used to evaluate weld performance, optimize joint design, and improve fatigue life assessment methodologies.

Engineering files

€60,00 €50,00

Abaqus

€146,00 €89,00

Abaqus

€85,00 €47,00

Abaqus

€78,00 €39,00

Abaqus

€84,00 €41,00

Abaqus

€86,00 €43,00

Abaqus

€88,00 €49,00

See more

Want to receive push notifications for all major on-site activities?