Papers abstract:

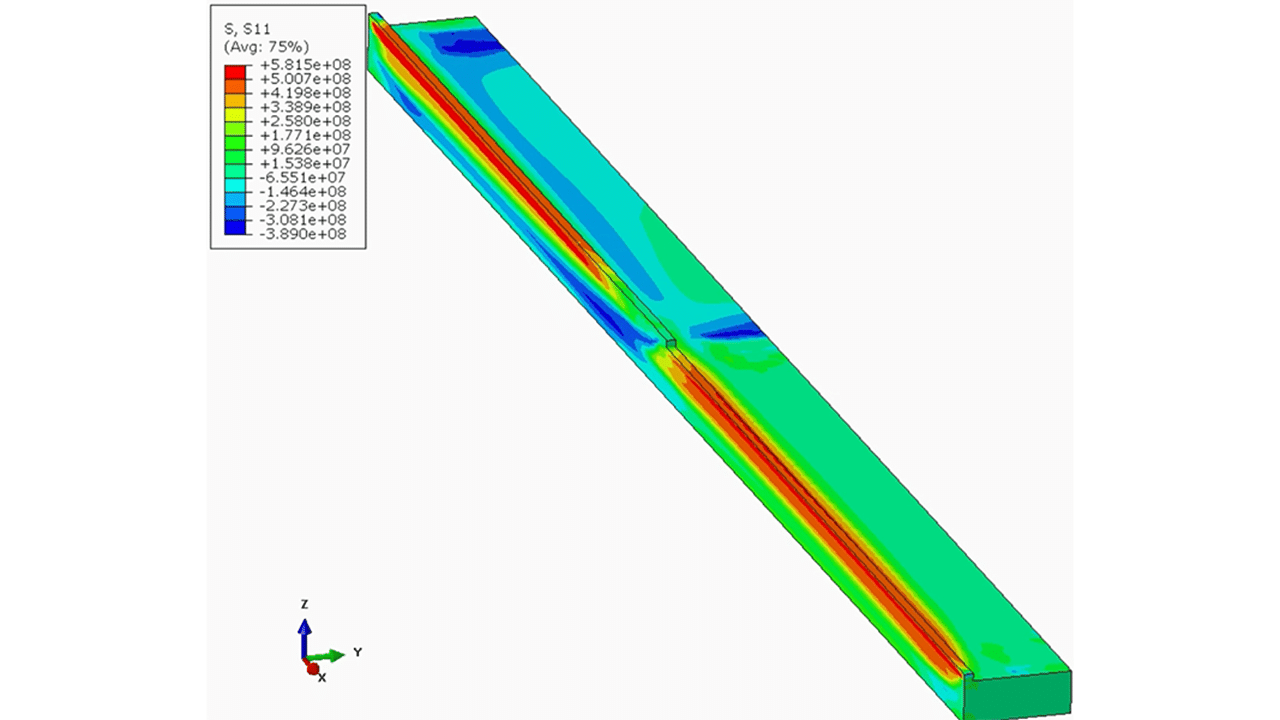

Wire and arc additive manufacturing (WAAM) is an emerging technology that has the potential to significantly reduce material usage and manufacturing time through the production of near net-shape components with high deposition rates. One of the main problems of this process is the residual stresses and distortions of the deposited workpiece. To help understand and optimise the process, finite element (FE) models are commonly used; however, the conventional

Transient models are not efficient for simulating a large-scale WAAM process. In this paper, the stress evolution during the thermal cycles of the WAAM process was investigated with the help of a transient thermomechanical FE model. It was

found that the peak temperatures experienced during the thermal cycles of the WAAM process determine the residual stress of that point. Based on this finding, an efficient “engineering” FE model was developed. Compared to the conventional transient thermomechanical approach, this model can save the computational time by 99 %. This new model produced distortion and residual stress predictions that were nearly identical to the original transient model and the experimental results.

Predicting residual stresses and deformations in Wire Arc Additive Manufacturing (WAAM) is critical for part quality. This course teaches you to replicate Ding’s paper proven methodology using two powerful approaches.

What You’ll Achieve:

✔ Accurately simulate WAAM thermal cycles, stresses, and distortions

✔ Replicate results from Ding’s seminal paper

✔ Compare 2 Methods:

Coding Method (Python + DFLUX Subroutine)

AM Modeler Plugin (No-code GUI)

✔ Validate outputs against experimental data

Why WAAM? High deposition rates, minimal waste, ideal for large-scale metal parts.

Key Challenge: Thermal cycling → Residual stresses → Part distortion & failure.

Solution: Finite Element (FE) simulations for predictive accuracy.

| Advantages | Limitations |

|---|---|

| Full control over heat sources | Requires Python/FORTRAN expertise |

| Supports coupled/decoupled analysis | 30+ hours replication time |

| Automated layer activation | Complex geometry sync needed |

Key Steps:

Layer-by-layer activation via Python scripting

Goldak heat source implementation in DFLUX

Thermal-stress sequential modeling

| Advantages | Limitations |

|---|---|

| No coding needed (GUI-based) | Limited heat source models |

| 5-hour replication time | Occasional software bugs |

| Handles complex infill patterns | Requires latest Abaqus version |

Key Features:

Single-step multi-layer deposition

Integrated cooling management

Automated path synchronization

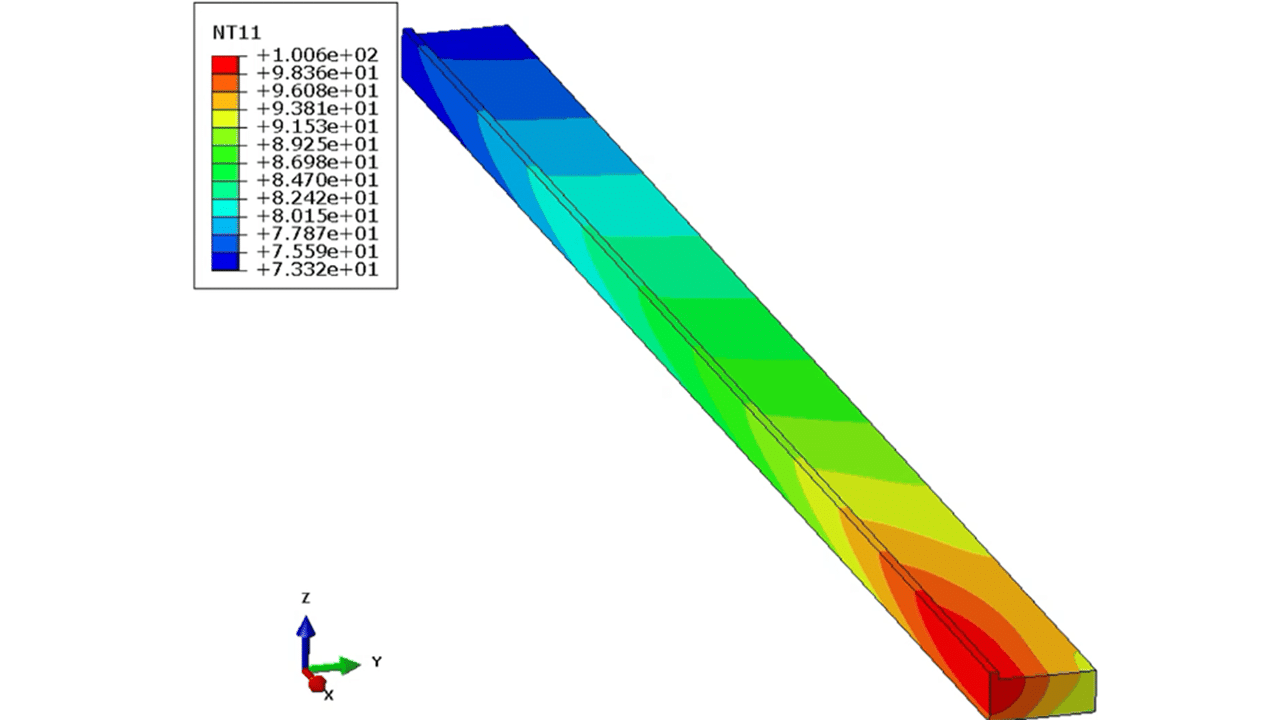

Geometry: 500mm length, 2mm/layer (4 layers → 8mm height)

Material: Temp-dependent conductivity, density, Young’s modulus

Thermal Inputs:

Laser power: 2,246 W

Feed rate: 8.33 mm/s

Heat Source: Goldak model (a=3mm, b=2.5mm)

Boundary Conditions:

Convection: Film coefficient 5.7 (sides), 300 (base plate)

Radiation: Emissivity 0.2

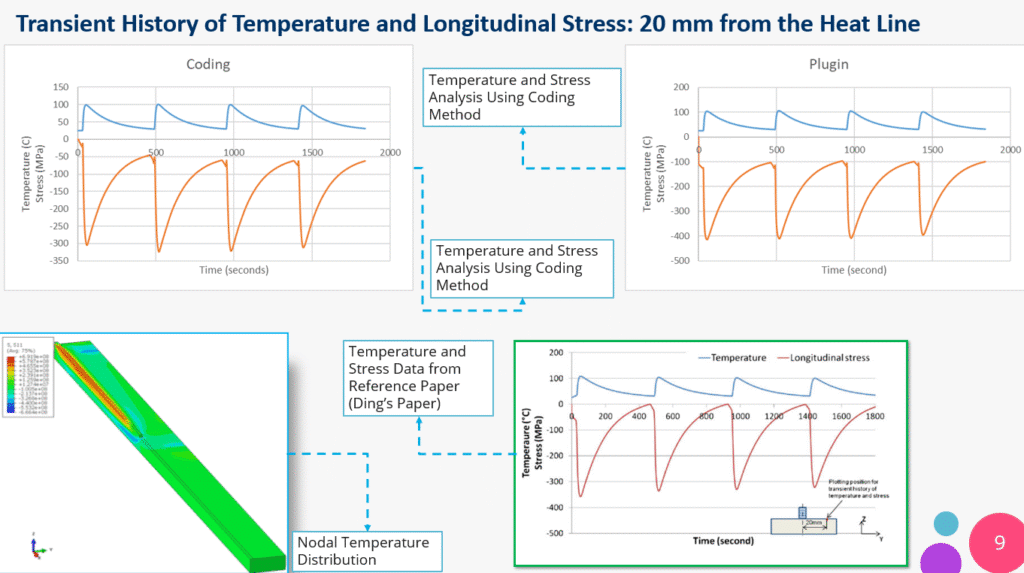

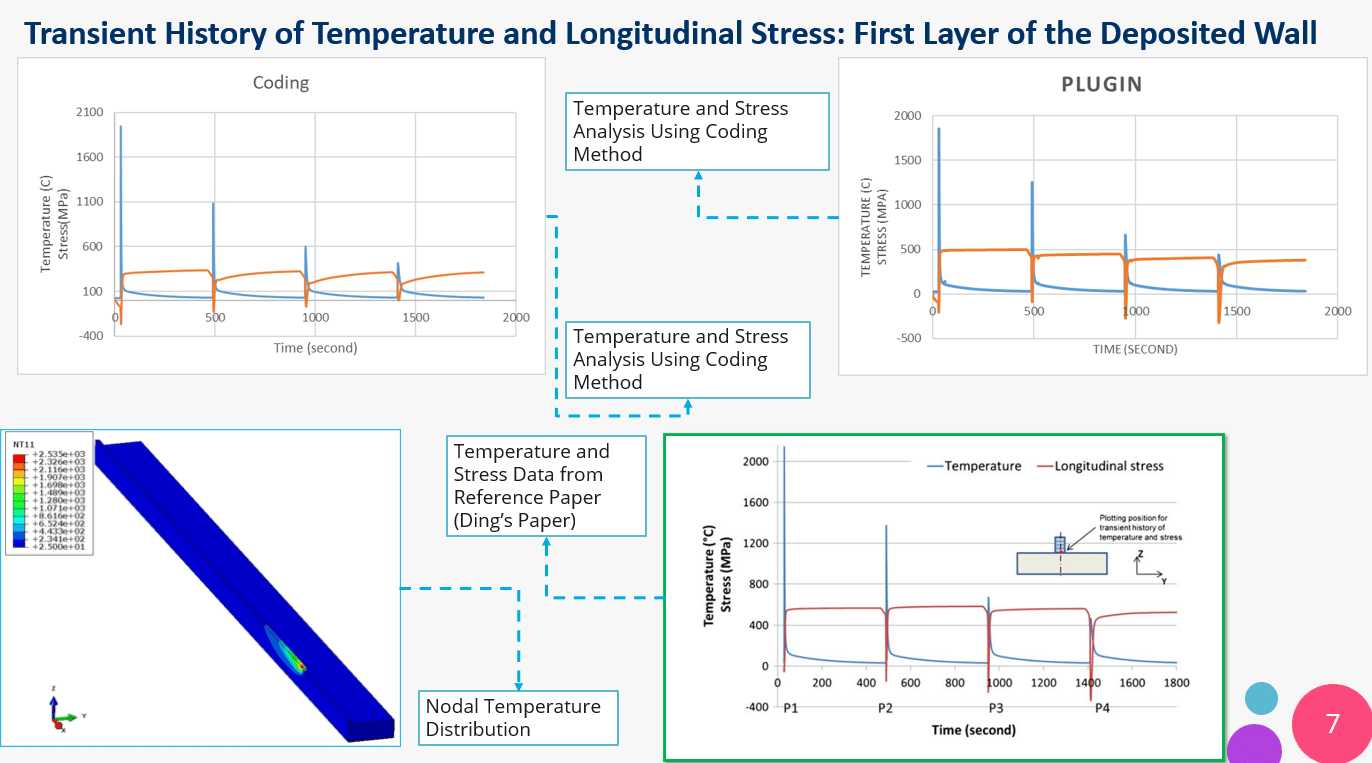

| Position | Coding Method | Plugin Method | Ding’s Paper |

|---|---|---|---|

| Weld Center | Matched stress trends | Slightly higher stress | Baseline reference |

| 5mm from Center | Temp: ≈400°C | Temp: ≈400°C | Temp: 300-400°C |

| 20mm from Wall | Stress: -350 MPa | Stress: Exceeded paper | Stress: ≈-350 MPa |

💡 Key Insight: Distant points (>20mm) show best alignment – calibration is critical near heat sources.

📩 Contact Saman Hosseini at info@engineeringdownloads.com or visit Saman’s Page for more details.

Q: Which method is better for beginners?

A: The AM Plugin (no coding). For advanced control, choose the Coding method.

Q: What Abaqus version is needed?

A: AM Modeler requires the 2023 and above.

Q: Can I simulate multi-layer geometries?

A: Yes! Both methods support 4+ layers (demoed in the course).

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?