Introduction to Underwater and Underground Explosions: Simulation and Analysis

1. Overview

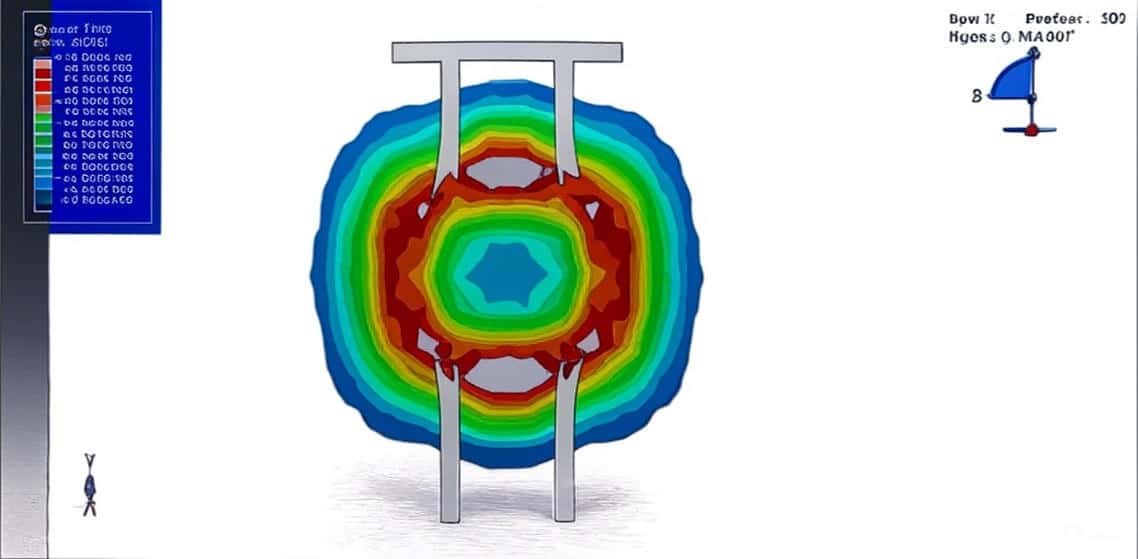

Explosions occurring in confined or dense media such as water and soil differ significantly from those in the air. The interaction between the explosive energy and the surrounding medium creates complex physical phenomena involving shock wave propagation, fluid-structure interaction, and material deformation. Understanding and simulating these events are critical for applications in defense engineering, mining, civil infrastructure protection, and marine systems.

This package includes 20 detailed tutorials that comprehensively explain underwater and underground explosions using various methods such as CEL, acoustic, and CONWEP. The course covers a wide range of simulations, including ice damage, CFDST structures, floating structures, water explosion shocks, concrete dams, concrete slabs, soil craters, concrete gravity dams, hulls, marine structures, sandwich structures, steel piles, concrete piled-raft structures, pipelines, and tunnels.

2. Nature of the Explosions

- Underwater Explosions (UNDEX):

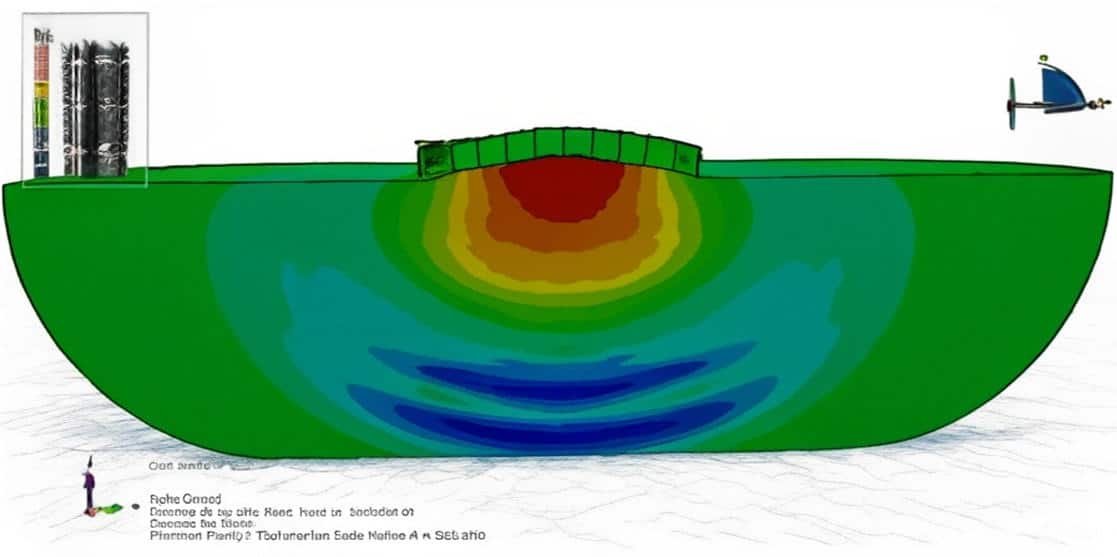

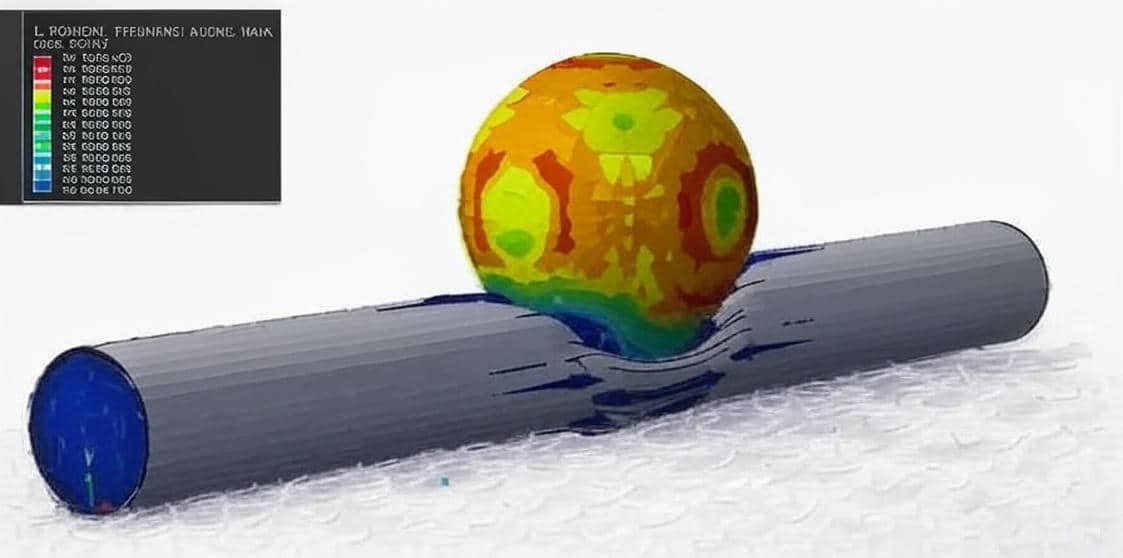

When an explosive detonates underwater, the rapid release of chemical energy generates a shock wave followed by bubble oscillations due to the expansion and contraction of detonation gases. These phenomena exert transient and oscillatory loads on nearby structures such as ships, submarines, or underwater pipelines.

- Underground Explosions (UGEX):

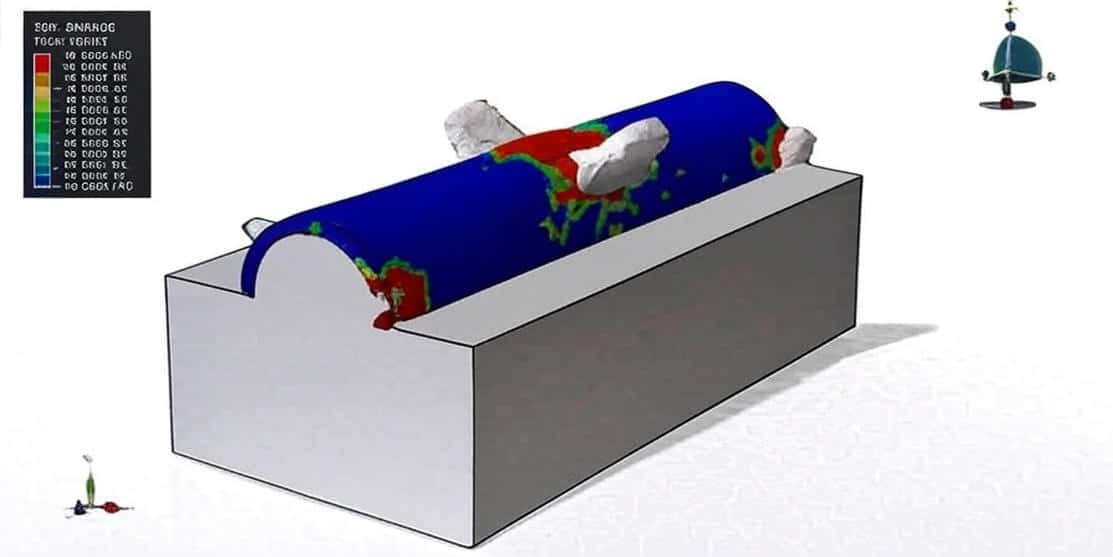

In soil or rock, the explosion produces a shock front that rapidly transitions into a stress wave as it travels through heterogeneous geological materials. The resulting wave propagation, reflection, and attenuation influence crater formation, ground motion, and structural damage in nearby facilities or tunnels.

3. Simulation Objectives

Numerical simulations of these explosions aim to:

- Predict pressure-time histories, impulse loads, and structural responses.

- Analyze shock wave propagation, bubble dynamics, and ground/soil deformation.

- Reduce the need for costly full-scale experiments and improve design safety and blast mitigation strategies.

4. Modeling and Computational Approaches

Simulation and analysis typically employ advanced computational methods, including:

- Finite Element Method (FEM): For solid structures and soil deformation under blast loading.

- Finite Volume Method (FVM) and Smoothed Particle Hydrodynamics (SPH): For fluid or coupled fluid–structure interaction modeling.

- Coupled Eulerian–Lagrangian (CEL) or Arbitrary Lagrangian–Eulerian (ALE) formulations: To model interactions between fluids (water/air) and solids (structures or ground).

- Equation of State (EOS) models: Such as Jones–Wilkins–Lee (JWL) or Mie–Grüneisen, used to represent the thermodynamic behavior of explosives and surrounding media.

5. Key Analysis Aspects

- Shock Wave Propagation: Understanding attenuation, reflection, and refraction in dense media.

- Bubble Dynamics (for UNDEX): Studying oscillation cycles and their secondary loading effects.

- Soil and Rock Response (for UGEX): Evaluating plastic deformation, compaction, and crack propagation.

- Structural Interaction: Assessing fluid–structure coupling effects and evaluating potential damage or failure mechanisms.

6. Applications

- Naval Engineering: Hull design against underwater blasts.

- Mining and Tunneling: Controlled underground detonations.

- Civil Defense and Infrastructure: Blast-resistant design of tunnels, bunkers, and critical facilities.

- Environmental Impact Studies: Assessing seismic or acoustic effects of underwater detonations.

7. Conclusion

Accurate simulation and analysis of underwater and underground explosions require multidisciplinary approaches combining computational mechanics, fluid dynamics, material science, and blast physics. With advancements in numerical solvers, high-performance computing, and experimental validation, engineers can now achieve reliable predictions of explosion effects and optimize protective or operational designs accordingly.