What is Ultra High Performance Fiber Reinforced Concrete?

Ultra High Performance Fiber Reinforced Concrete (UHPFRC) is an advanced cementitious composite material characterized by:

- Very high compressive strength (>150 MPa).

- Significant tensile strength and ductility are achieved with steel or synthetic fibers.

- Dense microstructure with low permeability, leading to exceptional durability.

- Superior energy absorption and toughness compared to conventional reinforced concrete.

Its unique properties make it suitable for bridges, high-rise buildings, nuclear facilities, and defense applications, where both strength and durability are critical.

This applicable package includes 14 tutorials that cover all about UHPFRC beam, column, beam-column joint, slab, composite beam, composite column, and … in many models like bending, flexure, blast, pull-out, compression, impact, and…This package will enable you to become a master in UHPFRC analysis and simulation.

Why Analysis and Simulation?

Unlike conventional concrete, UHPFRC shows complex nonlinear behavior due to fiber reinforcement and dense microstructure. Accurate analysis and simulation are essential to:

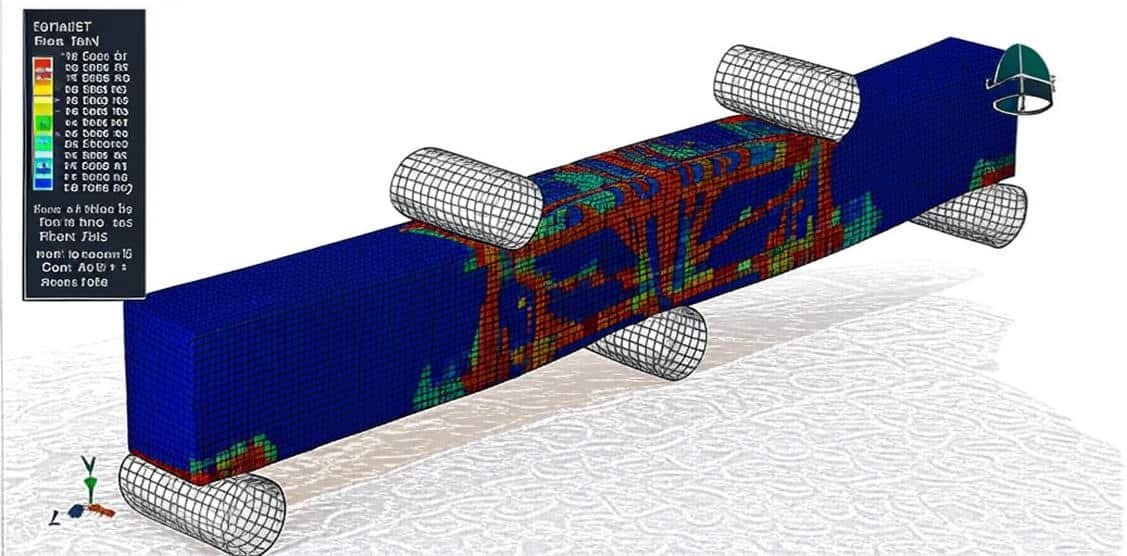

- Predict structural performance (stiffness, strength, ductility, failure modes).

- Optimize fiber type, orientation, and volume fraction.

- Assess cracking, strain-hardening, and post-cracking response.

- Support design codes and guidelines, which are still evolving for UHPFRC.

Main Aspects of UHPFRC Analysis

- Material Modeling

- Constitutive laws:

- Stress-strain relationships in tension and compression.

- Strain-hardening/softening behavior.

- Fiber effects: Bridging stress, crack control, and orientation distribution.

- Rate-dependent effects: Dynamic loading and impact resistance.

- Structural Modeling

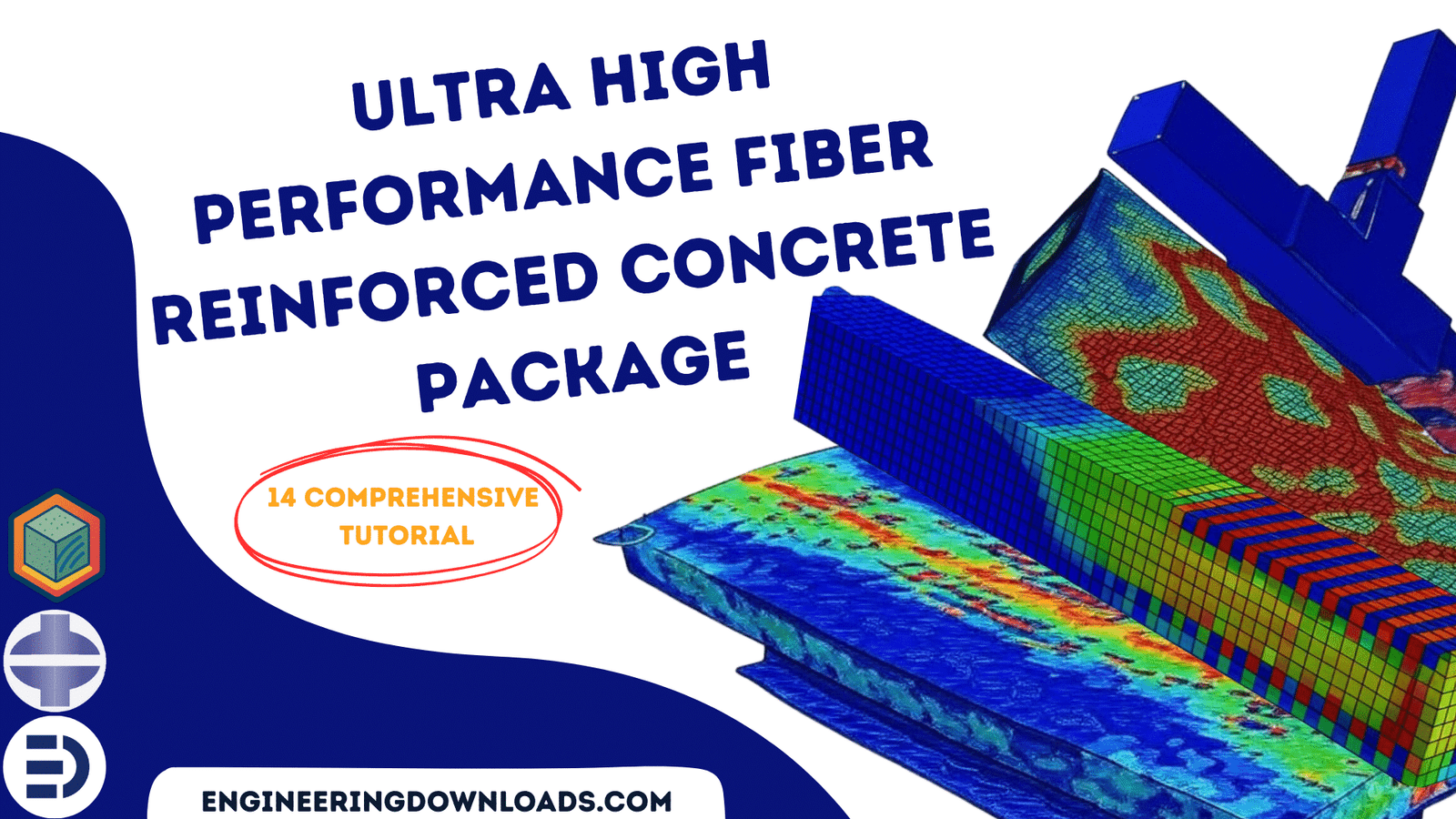

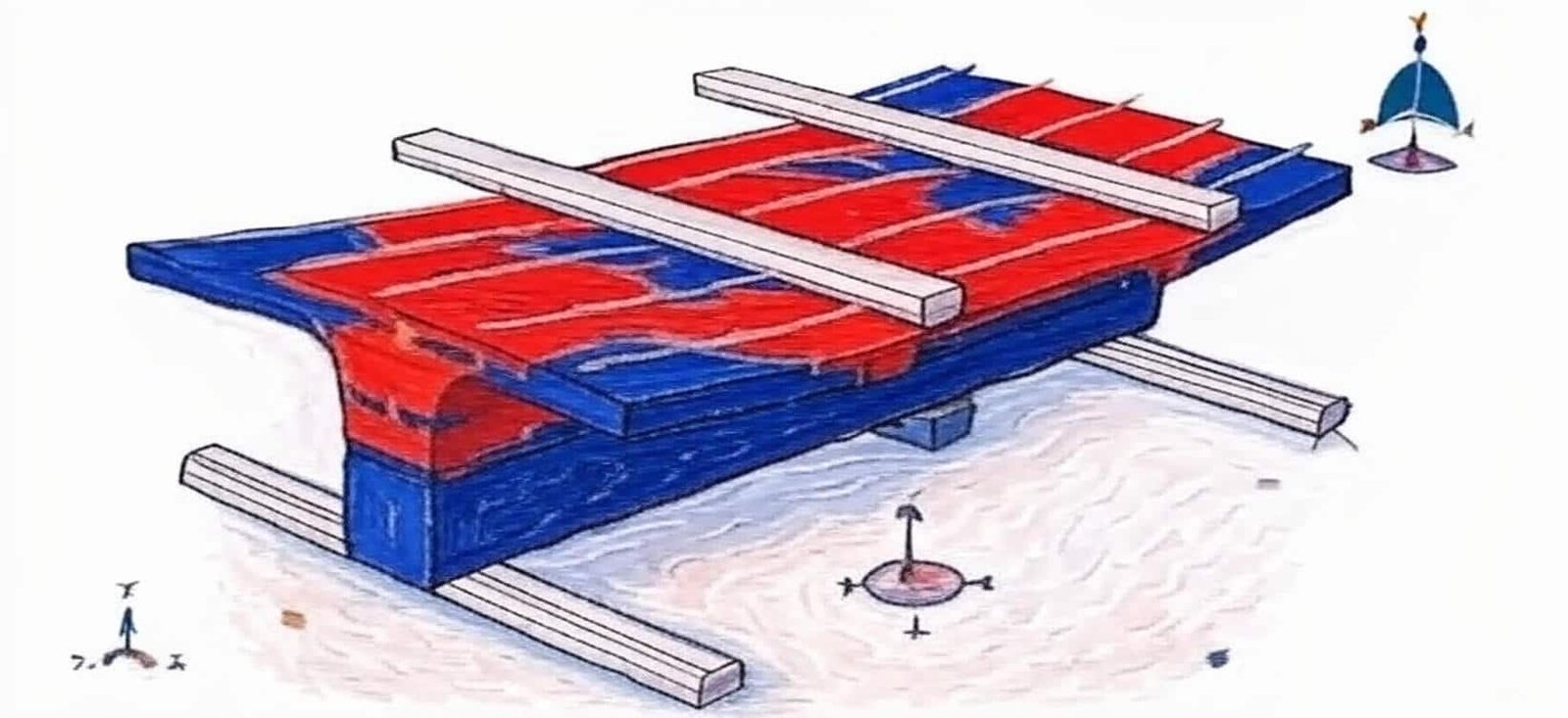

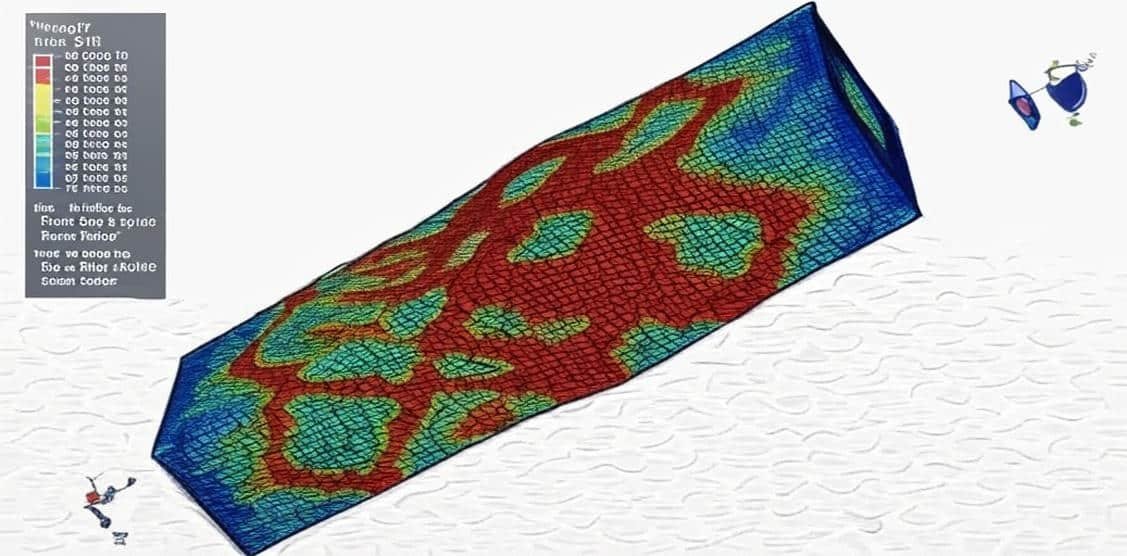

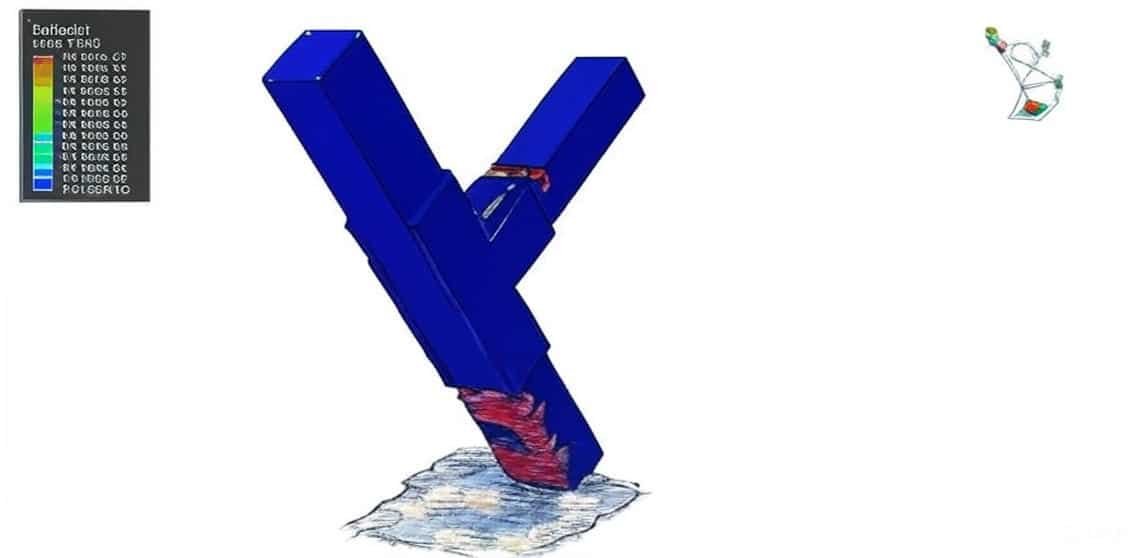

- Finite Element Analysis (FEA) for beams, slabs, and shells.

- Multi-scale modeling: Linking fiber-level behavior to macro-scale response.

- Fracture mechanics: Modeling crack initiation and propagation.

- Durability and Service Life

- Chloride penetration, freeze-thaw cycles, and carbonation.

- Long-term creep and shrinkage simulations.

Simulation Approaches

- Analytical Models

- Simplified stress-strain laws (e.g., bilinear, trilinear).

- Crack-bridging models (fiber pullout).

- Numerical Models

- Finite Element Models (FEM): Nonlinear solid elements, cohesive zone models.

- Discrete Element Models (DEM): Capturing crack patterns explicitly.

- Lattice/Peridynamic Models: Suitable for fracture simulation.

- Multi-Scale Simulation

- Microscale: Fiber pullout tests, ITZ (interfacial transition zone) behavior.

- Mesoscale: Crack network and fiber orientation effects.

- Macroscale: Structural element analysis (beams, columns, slabs).

- Software Tools

- Commercial FEA: ABAQUS, ANSYS, LS-DYNA.

- Specialized research codes: ATENA (for concrete), OpenSees.

- Custom implementations in MATLAB/Python for constitutive modeling.

Challenges in UHPFRC Simulation

- Capturing fiber distribution and orientation realistically.

- Representing strain-hardening and tension-softening accurately.

- Computational cost of multi-scale fracture models.

- Lack of unified design standards requiring calibration with experiments.

In summary:

UHPFRC analysis and simulation aim to capture its superior strength, ductility, and durability through advanced material modeling, structural simulations, and multi-scale approaches. Finite element and fracture mechanics-based simulations are most common, but an accurate representation of fiber behavior remains a key research focus.