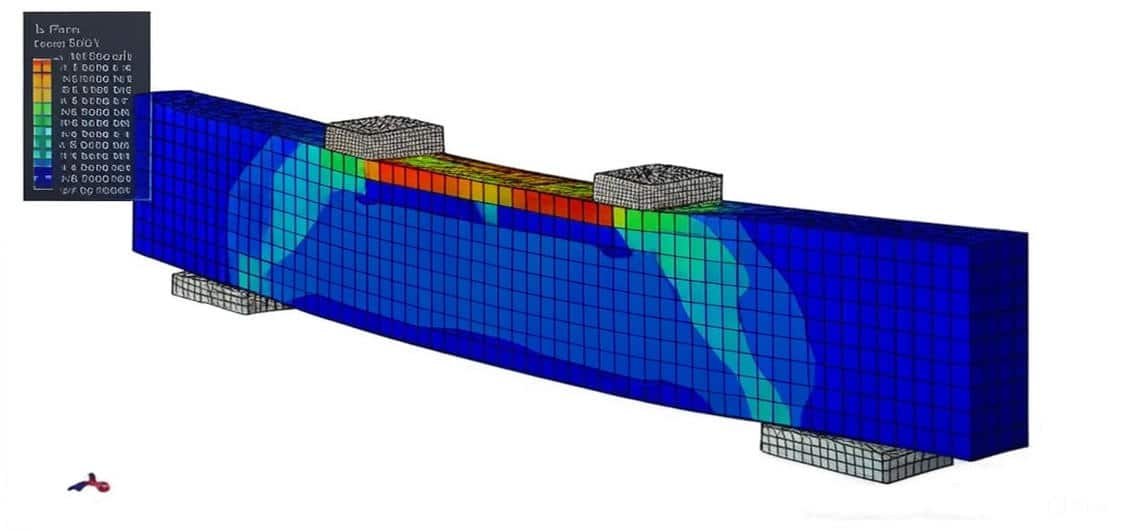

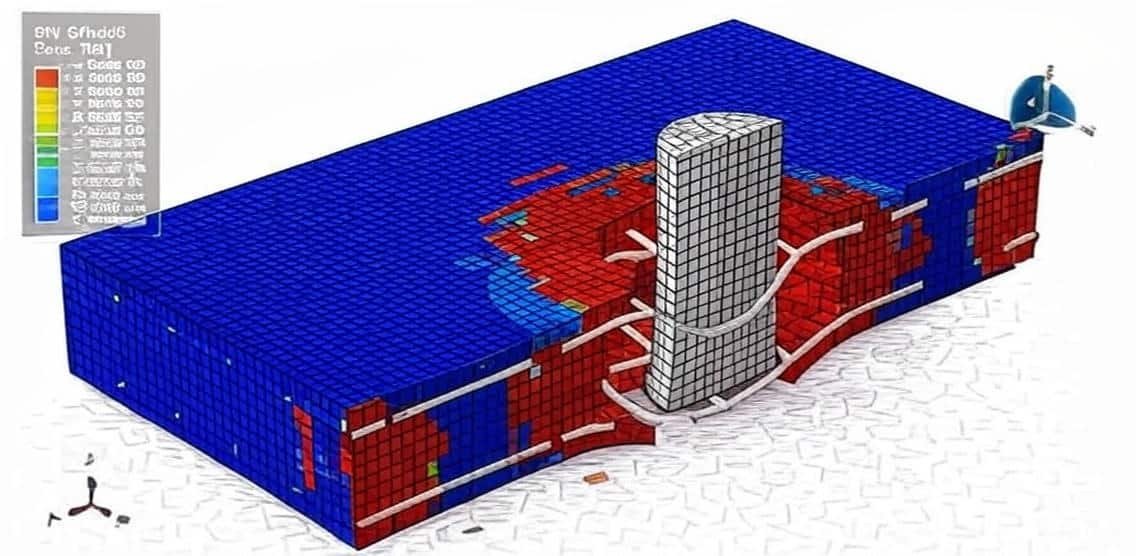

Ultra High Performance Concrete (UHPC) is an advanced cementitious composite that significantly outperforms conventional concrete in terms of compressive strength, tensile capacity, toughness, and durability. With compressive strengths often exceeding 150 MPa, very low permeability, and high resistance to environmental degradation, UHPC has emerged as a material of choice for critical infrastructure, long-span bridges, high-rise buildings, and resilient structures.

This package includes 20 tutorials that cover all about UHPC analysis in Abaqus software, such as beam column, beam-column joint, slab, composite beam, composite column, low and high-velocity impact, bending, flexure, cyclic loading, explosion, damage, failure, and …

The superior performance of UHPC arises from its optimized granular packing, low water-to-binder ratio, and the incorporation of supplementary cementitious materials (SCMs), fine powders, and steel or synthetic fibers. This unique composition enables UHPC to exhibit quasi-ductile behavior, allowing it to resist cracking and sustain loads even after initial damage.

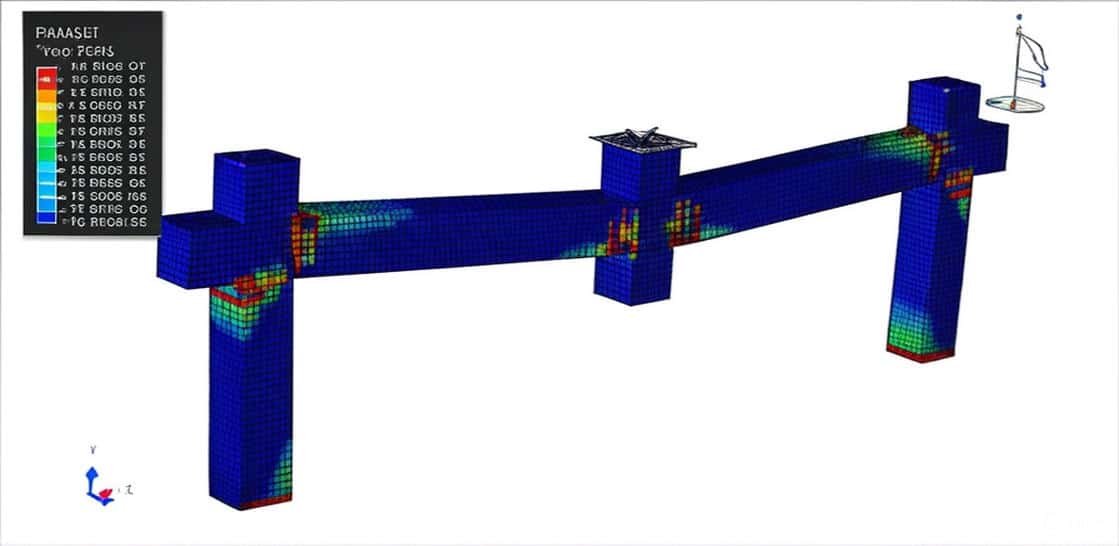

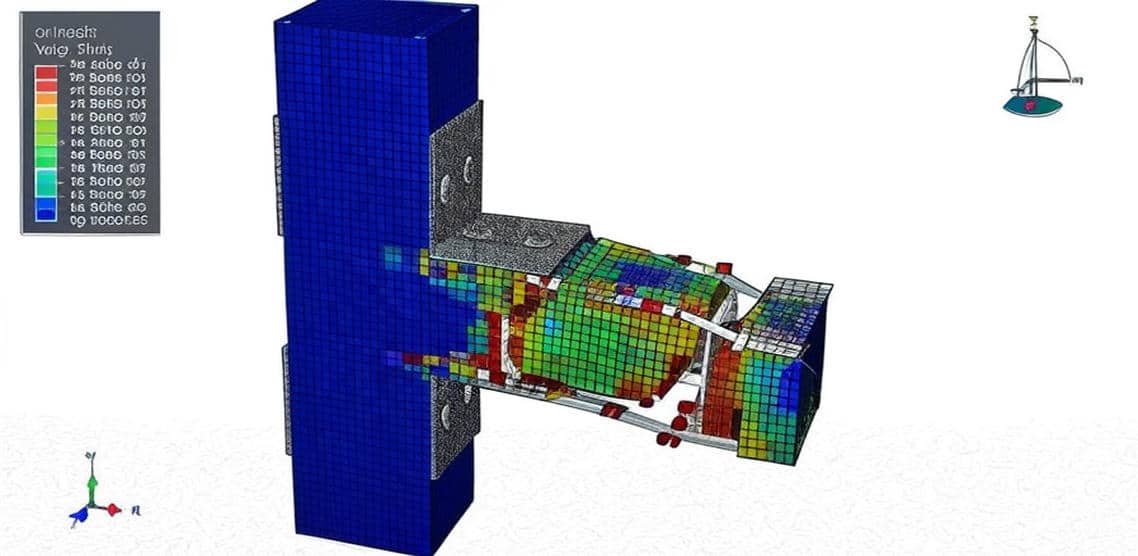

Given its complex material behavior, analysis and simulation play a crucial role in understanding, predicting, and optimizing UHPC performance. Numerical and computational modeling tools are used to study its behavior across multiple scales:

Through advanced simulation frameworks—ranging from finite element methods (FEM) and discrete element methods (DEM) to machine learning-assisted models—engineers and researchers can optimize mix designs, predict structural responses, and extend the service life of UHPC-based systems.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?