This package includes 11 tutorials that cover everything about the tunnel and TBM analysis in Abaqus

🔹 Introduction to Tunnel and TBM Analysis and Simulation

1. Tunneling and TBM in Civil Engineering

Tunnels are essential for transportation (rail, metro, highways), utilities (water, sewage, cables), and energy (hydropower, oil & gas).

- Modern tunneling projects often use Tunnel Boring Machines (TBMs) — massive mechanized systems designed to excavate soil or rock while simultaneously installing tunnel linings.

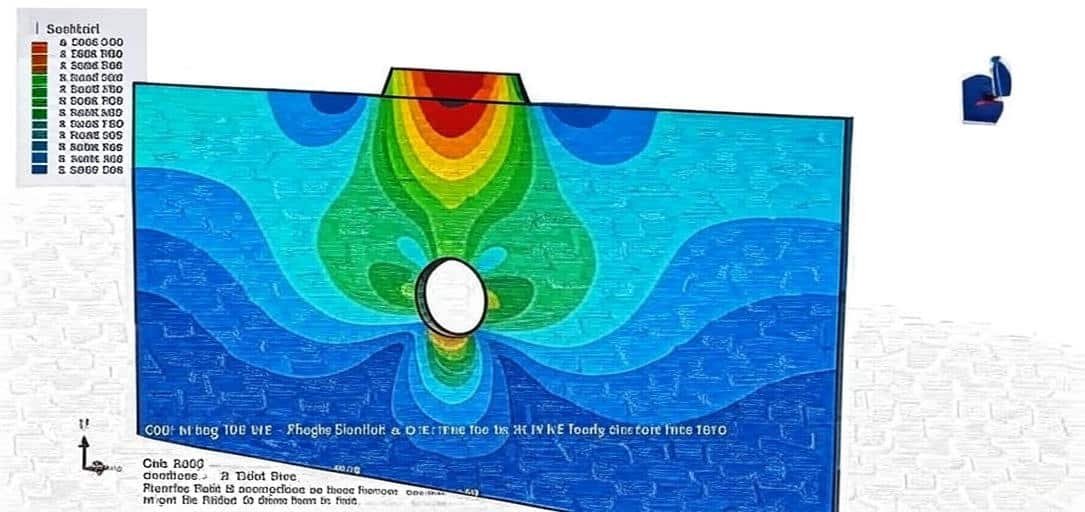

- TBM excavation is a soil–structure interaction problem, involving excavation-induced ground deformation, support installation, and lining–ground interaction.

2. Why Simulation is Needed?

Tunneling in complex geology poses major risks:

- Ground settlement (can damage nearby buildings).

- Face instability or collapse.

- Water inflow under high pressure.

- Excessive lining stresses or segment cracking.

Physical testing of tunnels at full scale is impossible, so numerical simulation (e.g., using Abaqus, FLAC, PLAXIS, LS-DYNA) provides a virtual way to:

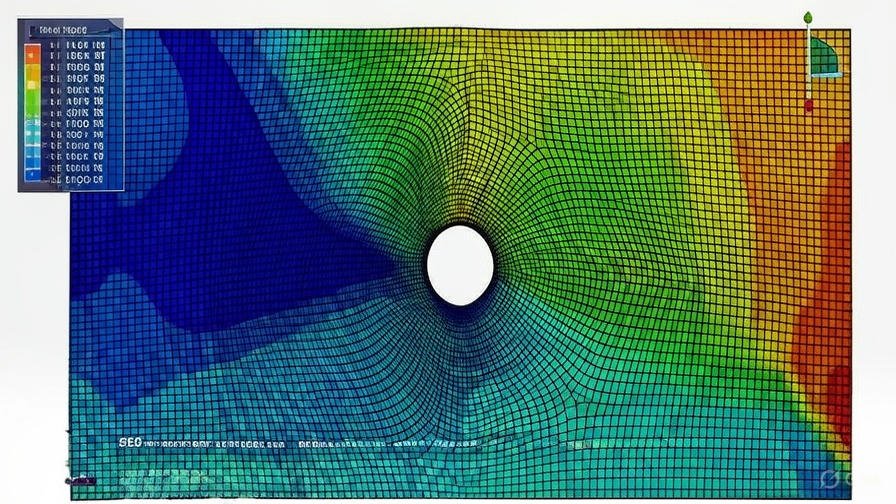

- Predict ground deformation.

- Assess TBM performance.

- Optimize lining design.

- Reduce construction risks.

3. Key Aspects of Tunnel & TBM Simulation

(a) Geotechnical Model

- Soil/rock properties (elastic–plastic, viscoplastic, Mohr-Coulomb, Drucker–Prager, Hoek–Brown).

- Groundwater effects (pore pressure, seepage).

(b) Excavation Modeling

- Step-by-step excavation to replicate tunnel advancement.

- Removal of soil/rock elements with simultaneous TBM face pressure application.

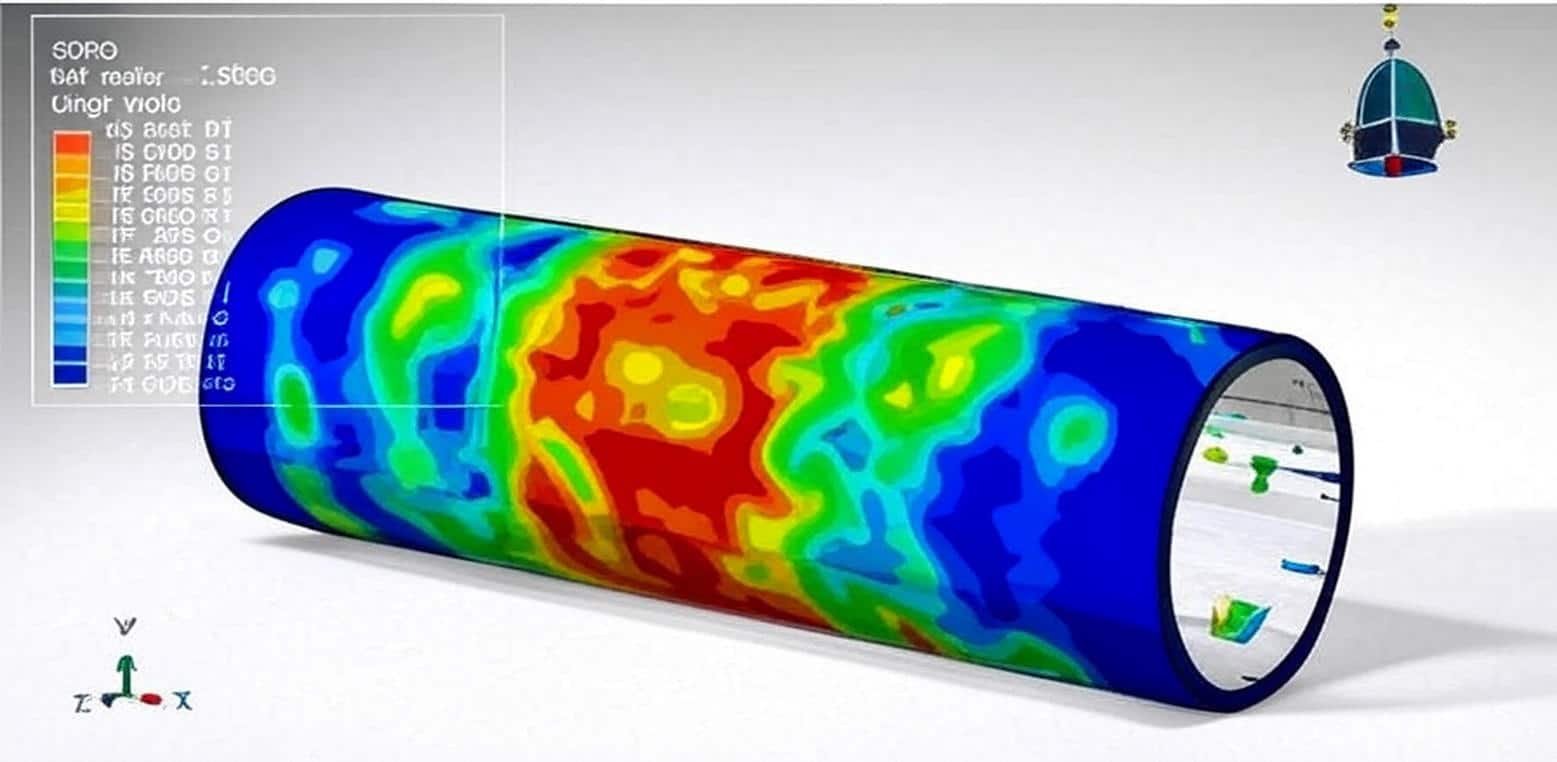

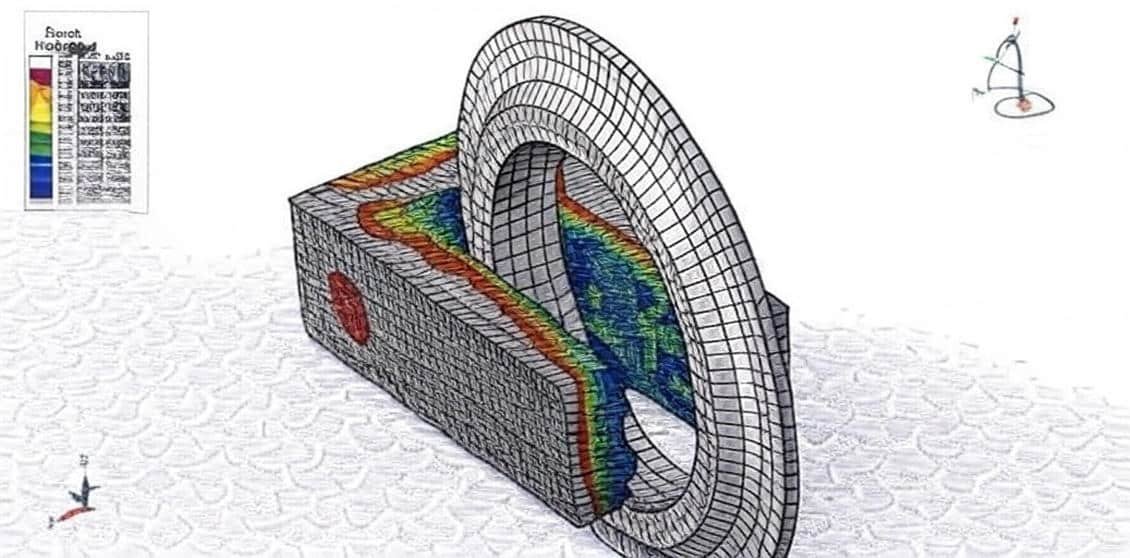

(c) Tunnel Boring Machine (TBM) Modeling

- TBM is modeled as a boundary condition or rigid body applying:

- Face support pressure (earth pressure balance, slurry pressure).

- Thrust forces from jacks.

- Frictional contact between the cutterhead/shield and the ground.

(d) Lining Installation

- Segmental lining is installed immediately after TBM passage.

- Simulation includes bolt connections, gaskets, and contact behavior.

(e) Coupled Analyses

- Geomechanical: Stress redistribution, settlements.

- Hydro-mechanical: Water pressure and seepage effects.

- Machine–Ground Interaction: TBM thrust, torque, wear.

4. Simulation Workflow (Abaqus)

- Define geometry: Soil domain + tunnel alignment.

- Assign material models: Soil/rock + concrete lining.

- Apply boundary conditions: Fix far-field, allow excavation deformation.

- Step-by-step excavation: Deactivate elements at the tunnel face.

- Apply TBM face pressure + lining installation.

- Analyze results: Ground settlement troughs, lining stresses, TBM forces.

5. Applications

- Metro projects: Predict settlements under urban areas.

- Hydropower: TBM-driven pressure tunnels.

- Oil & Gas: Deep subsea tunnels.

- Nuclear waste storage: Long-life underground tunnels.

6. Benefits of Tunnel & TBM Simulation

- Reduces construction risk and cost overruns.

- Optimizes TBM operational parameters (thrust, torque, face pressure).

- Ensures the safety of nearby infrastructure.

- Helps in designing sustainable and durable tunnel linings.

👉 In Abaqus, the Tunnel and TBM Analysis Package usually combines:

- Soil/rock constitutive models,

- Excavation simulation (element deactivation/birth & death techniques),

- Coupled temperature–pore pressure analysis (if groundwater present),

- And contact models for TBM–ground–lining interaction.