Introduction to Steel Structure Analysis and Simulation

Steel structures are widely used in bridges, towers, industrial plants, and high-rise buildings because of steel’s high strength-to-weight ratio, ductility, and predictable behavior. To ensure safety and efficiency, engineers use structural analysis and simulation tools to model how steel members (beams, columns, frames, trusses, etc.) behave under different loading and boundary conditions.

This package includes 21 practical tutorials, and during this journey, you’ll be a master in steel structure analysis.

1. Basic Components of Steel Structures

- Beams

- Horizontal members are designed to resist bending and shear.

- Common shapes: I-beams (wide flange), channels, hollow sections.

- Carry loads mainly transverse to their longitudinal axis.

- Columns

- Vertical members are designed to resist axial compression and sometimes bending.

- Critical aspect: buckling stability.

- Frames

- Assemblies of beams and columns are connected.

- Rigid frames transfer moments between members.

- Braced frames use diagonal bracing to resist lateral loads.

- Trusses

- Lightweight triangulated frameworks where members carry mostly axial forces.

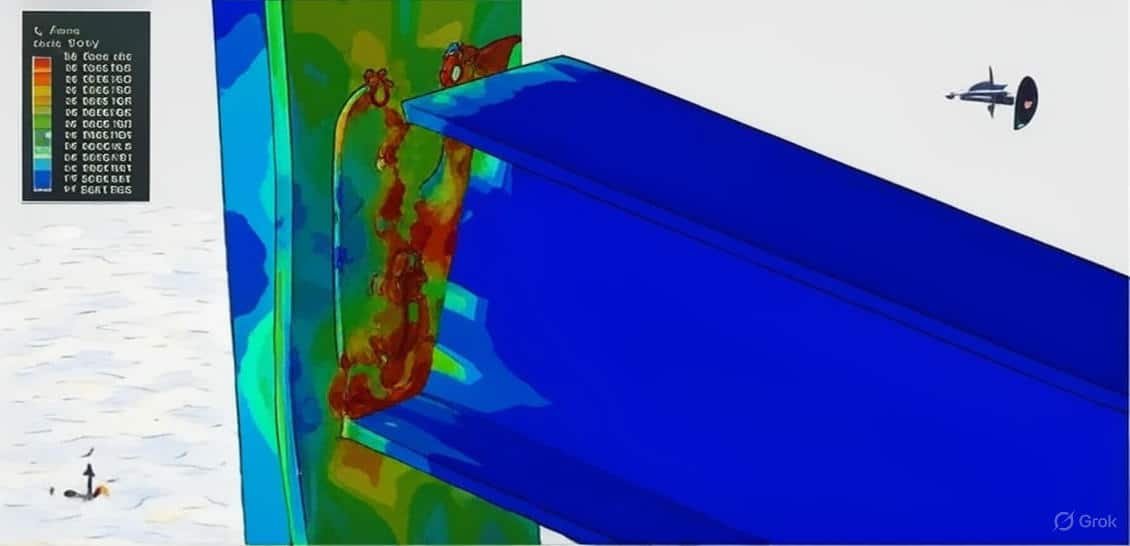

- Connections/Joints

- Can be pinned (hinged) → allows rotation, no moment transfer.

- Rigid (moment) → resist rotation, transfer moments.

- Bolted or welded, depending on design.

- Plates and Shells

- Thin steel plates are used in tanks, silos, bridges, and building floors.

2. Structural Analysis Basics

Structural analysis answers: How does a structure deform, and what internal forces develop under applied loads?

- Load Types

- Dead loads (self-weight, permanent equipment)

- Live loads (people, furniture, vehicles)

- Environmental loads (wind, snow, seismic, temperature effects)

- Analysis Methods

- Classical methods (hand calculations): bending theory, truss analysis, moment distribution, portal method.

- Matrix methods: stiffness method, flexibility method → foundation of modern software.

- Finite Element Method (FEM): most widely used today for complex geometries and loading.

- Key Response Quantities

- Displacements (deflections, rotations)

- Internal forces (axial, shear, bending moment, torsion)

- Stresses and strains

- Buckling capacity and vibration modes

3. Simulation of Steel Structures

Modern engineering relies heavily on simulation to predict structural behavior more accurately.

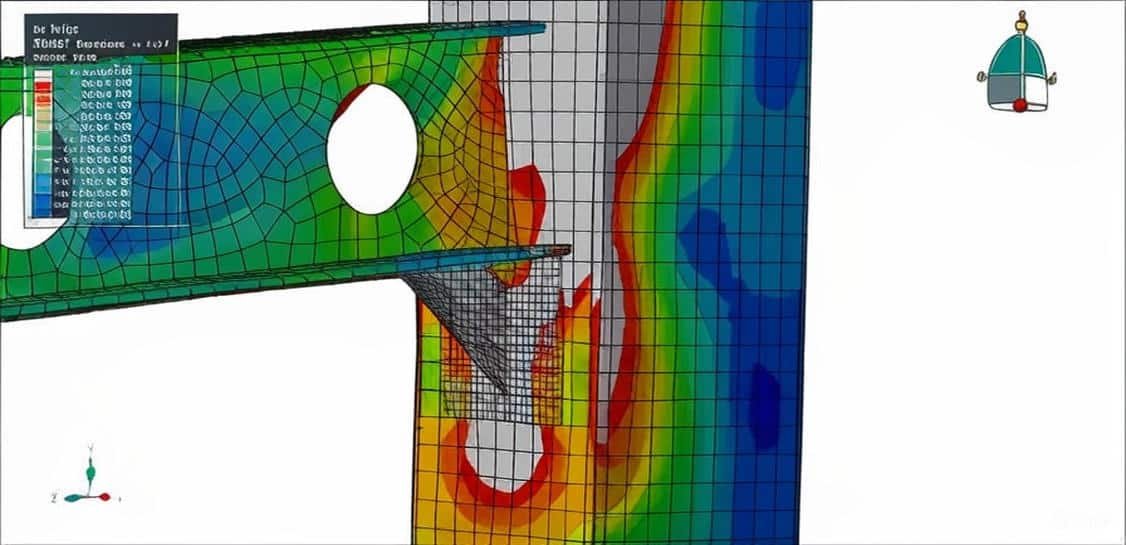

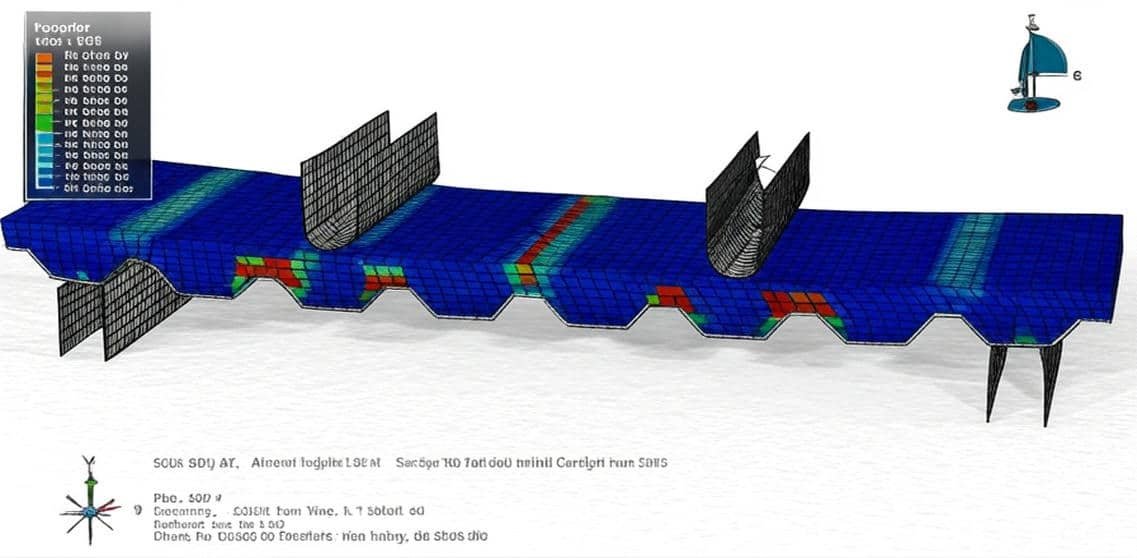

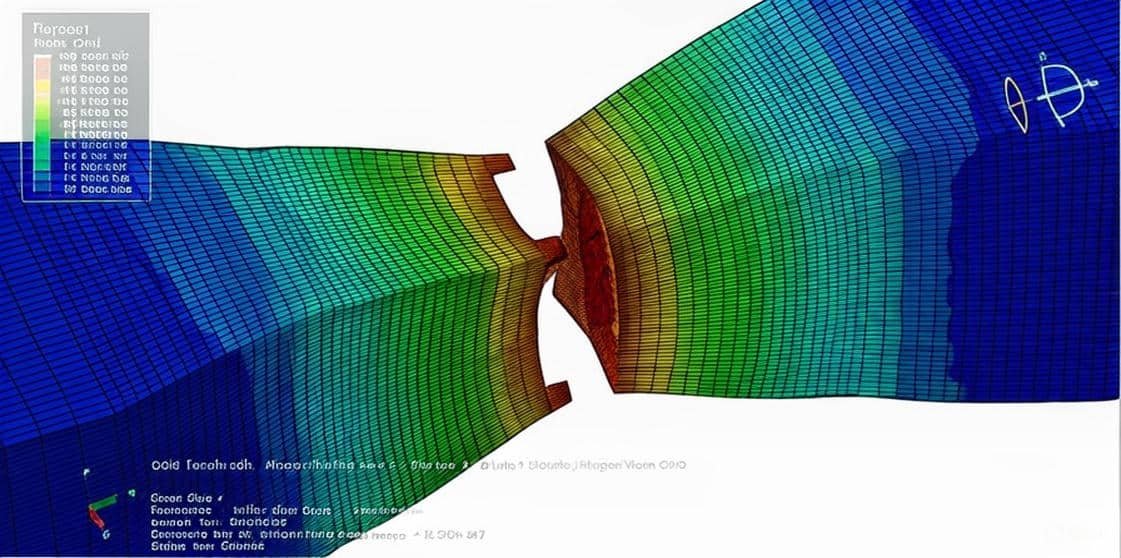

a) Finite Element Modeling (FEM)

- Structures are discretized into elements (beam elements, shell elements, solid elements).

- The governing equations are solved numerically.

- Captures local stresses, stability, and nonlinearities.

b) Types of Analysis in Simulation

- Linear static analysis – small deformations, linear material.

- Nonlinear analysis – includes large deflections, material yielding, and contact.

- Buckling analysis – eigenvalue buckling (idealized), nonlinear buckling (realistic).

- Dynamic analysis – natural frequencies, vibration, seismic response.

- Fatigue and fracture simulation – important for bridges, cranes, and offshore structures.

4. Design Considerations in Simulation

- Material properties: Yield strength, modulus of elasticity, strain-hardening, ductility.

- Imperfections: Initial crookedness of columns, residual stresses from welding.

- Load combinations: As per codes (Eurocode, AISC, IS, etc.).

- Safety factors: Account for uncertainties in load, material, and modeling.

5. Applications

- Buildings: Multi-story steel frames, composite slabs.

- Bridges: Plate girders, cable-stayed, truss bridges.

- Industrial plants: Pipe racks, cranes, offshore rigs.

- Towers & masts: Lattice towers, communication towers.

In short:

Steel structure analysis and simulation combine mechanics (theory) and computing (FEM, software) to model the response of beams, columns, frames, and connections under various loads. This allows engineers to design safe, efficient, and economical steel structures.