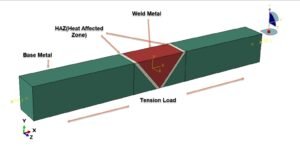

The pull-out behavior of a single steel fiber embedded in concrete is one of the fundamental mechanisms governing the mechanical performance of steel fiber–reinforced concrete (SFRC). The load transfer between the fiber and the surrounding concrete matrix controls crack bridging, post-cracking strength, toughness, and energy absorption capacity of the composite material. Therefore, accurate characterization and numerical simulation of the fiber–matrix bond behavior are essential for understanding and predicting the structural performance of SFRC.

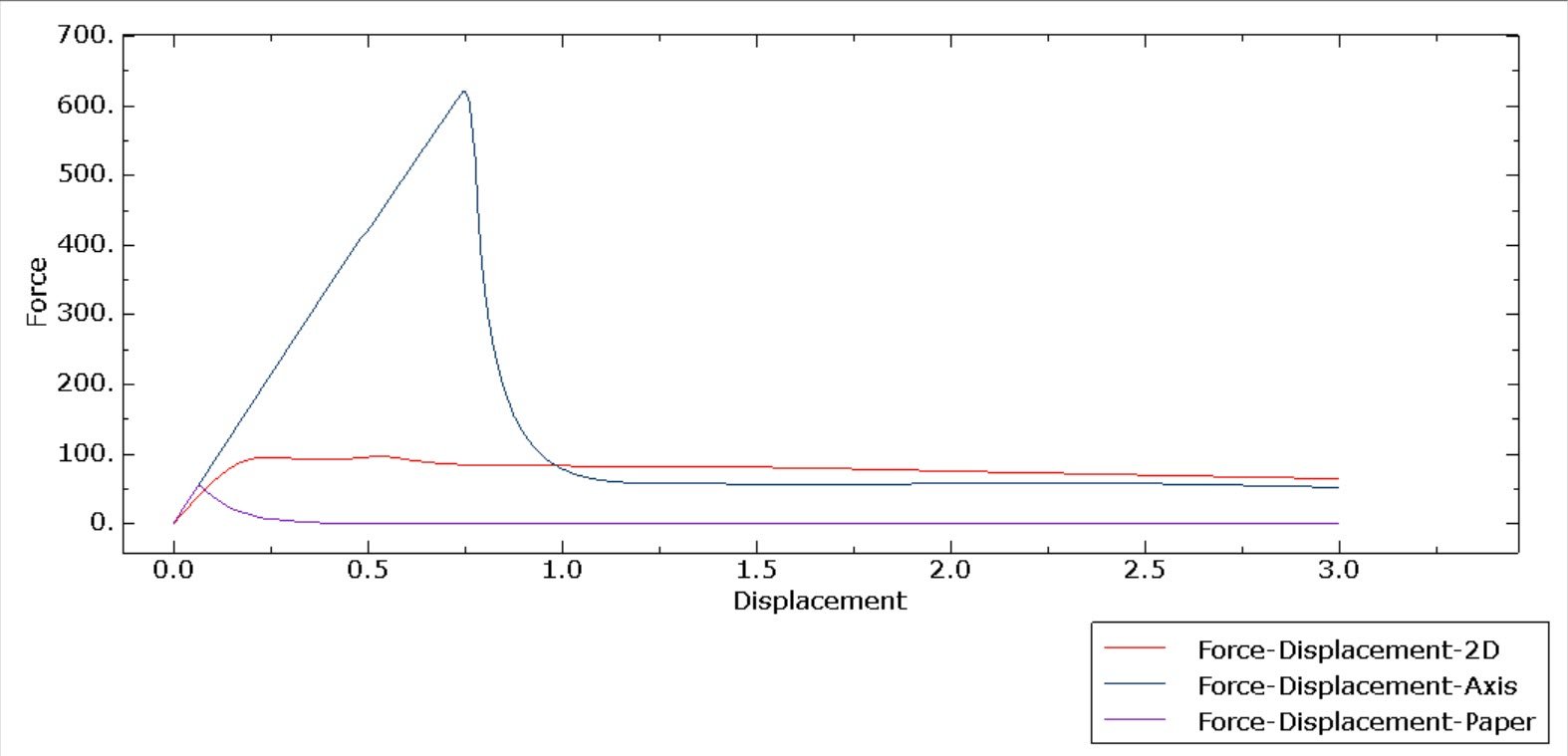

The single-fiber pull-out test is widely adopted to evaluate interfacial bond properties. In this test, a steel fiber partially embedded in a concrete matrix is subjected to tensile displacement until complete debonding and extraction occur. The resulting load–slip response reflects several key mechanisms, including elastic bonding, damage initiation at the interface, progressive debonding, frictional sliding, and local cracking of the surrounding concrete.

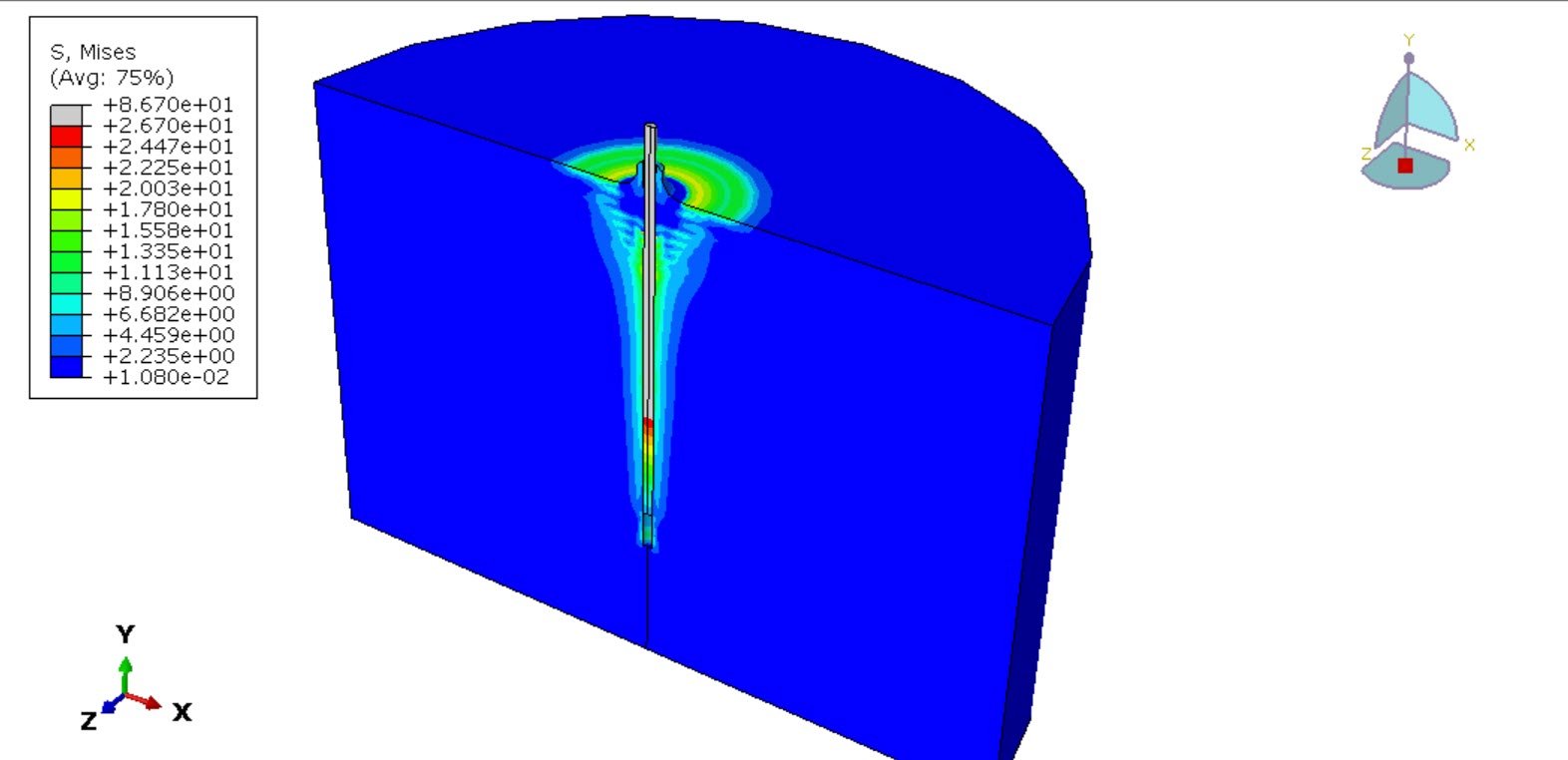

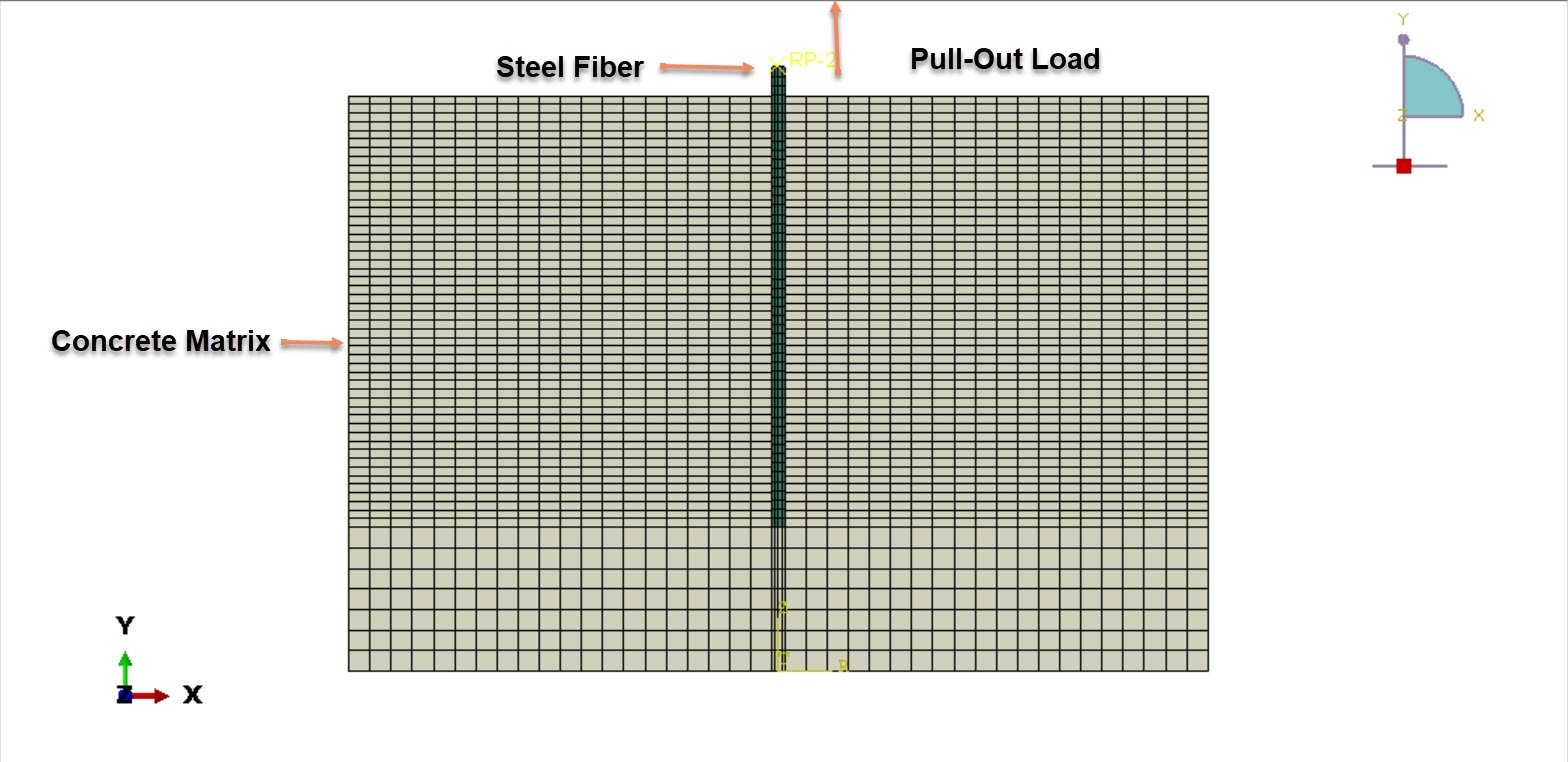

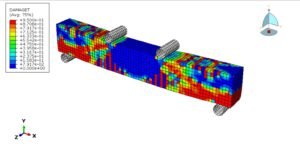

Due to the highly nonlinear behavior involved—such as concrete cracking, stiffness degradation, and interface damage—finite element modeling provides an efficient and powerful tool for simulating the pull-out response. In this study, numerical simulations were performed using Abaqus to analyze the pull-out behavior of a straight steel fiber using both two-dimensional (2D) and axisymmetric modeling approaches.

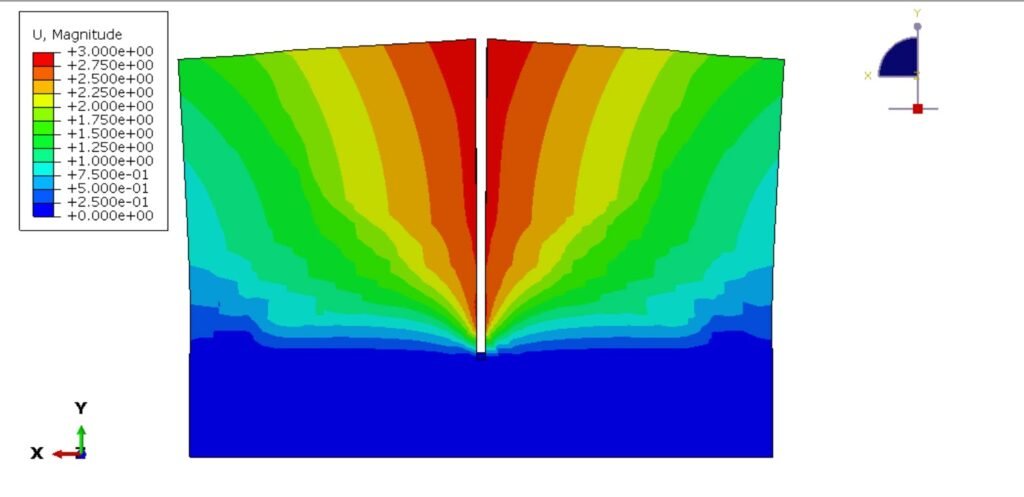

The 2D model provides a simplified representation of the pull-out test geometry. This approach reduces computational cost while capturing the essential mechanical response of the fiber–matrix interaction. It is particularly useful for parametric studies and preliminary investigations of bond strength and stiffness.

Although the 2D formulation does not fully represent the cylindrical geometry of the fiber, it enables efficient simulation of interface debonding, crack initiation in concrete, and post-peak softening behavior. The computational efficiency of this approach makes it suitable for sensitivity analyses involving material parameters and interface properties.

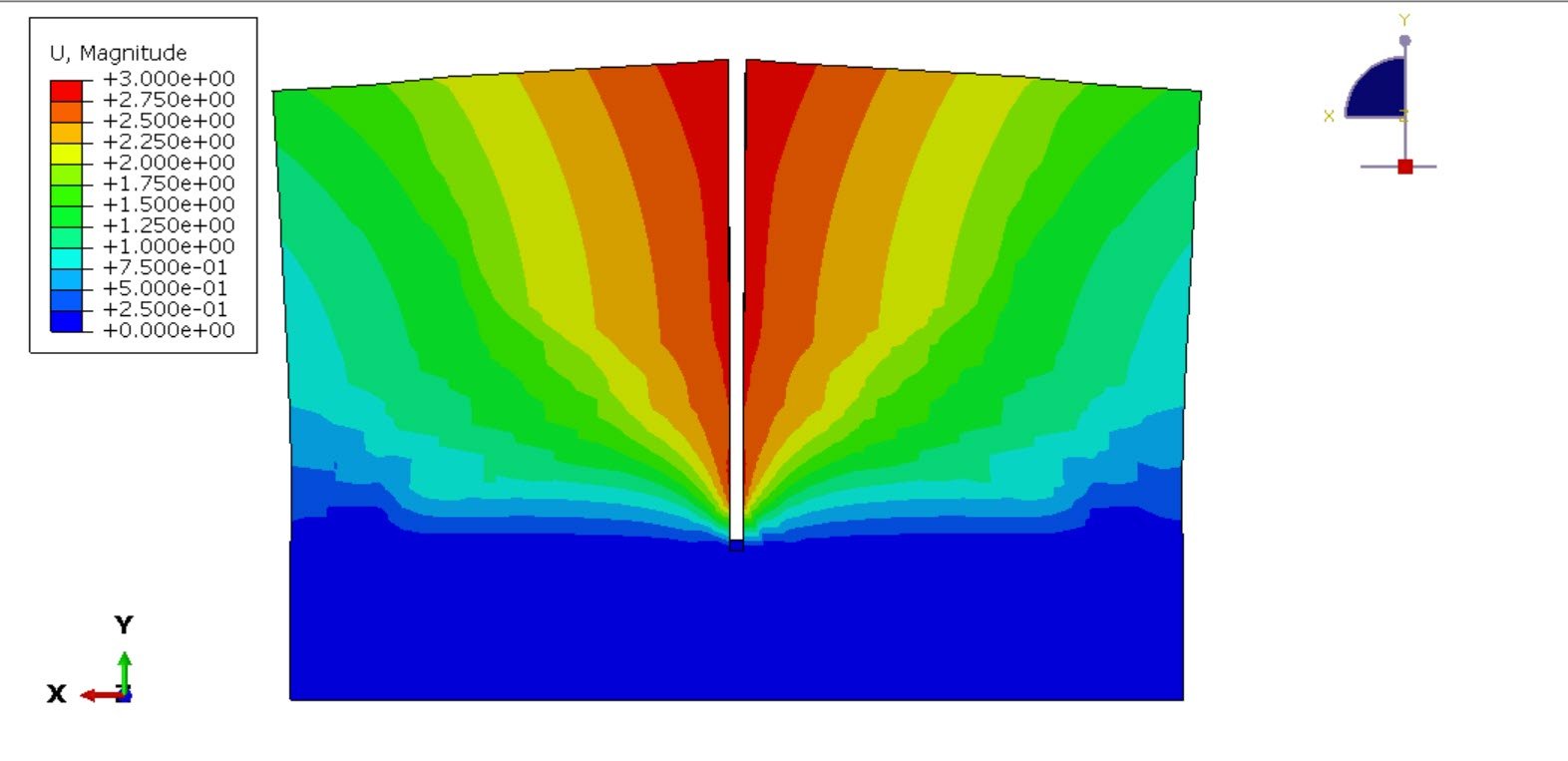

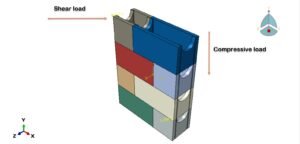

The axisymmetric model offers a more realistic representation of the physical pull-out test configuration for straight fibers with uniform embedment. By assuming rotational symmetry around the fiber axis, the model captures the cylindrical geometry of both the fiber and the surrounding concrete while maintaining lower computational demand compared to a full 3D model.

This approach allows more accurate prediction of stress distribution, radial confinement effects, and interfacial shear stress transfer along the embedded length. Consequently, axisymmetric modeling provides improved insight into bond mechanisms and damage evolution near the fiber–matrix interface.

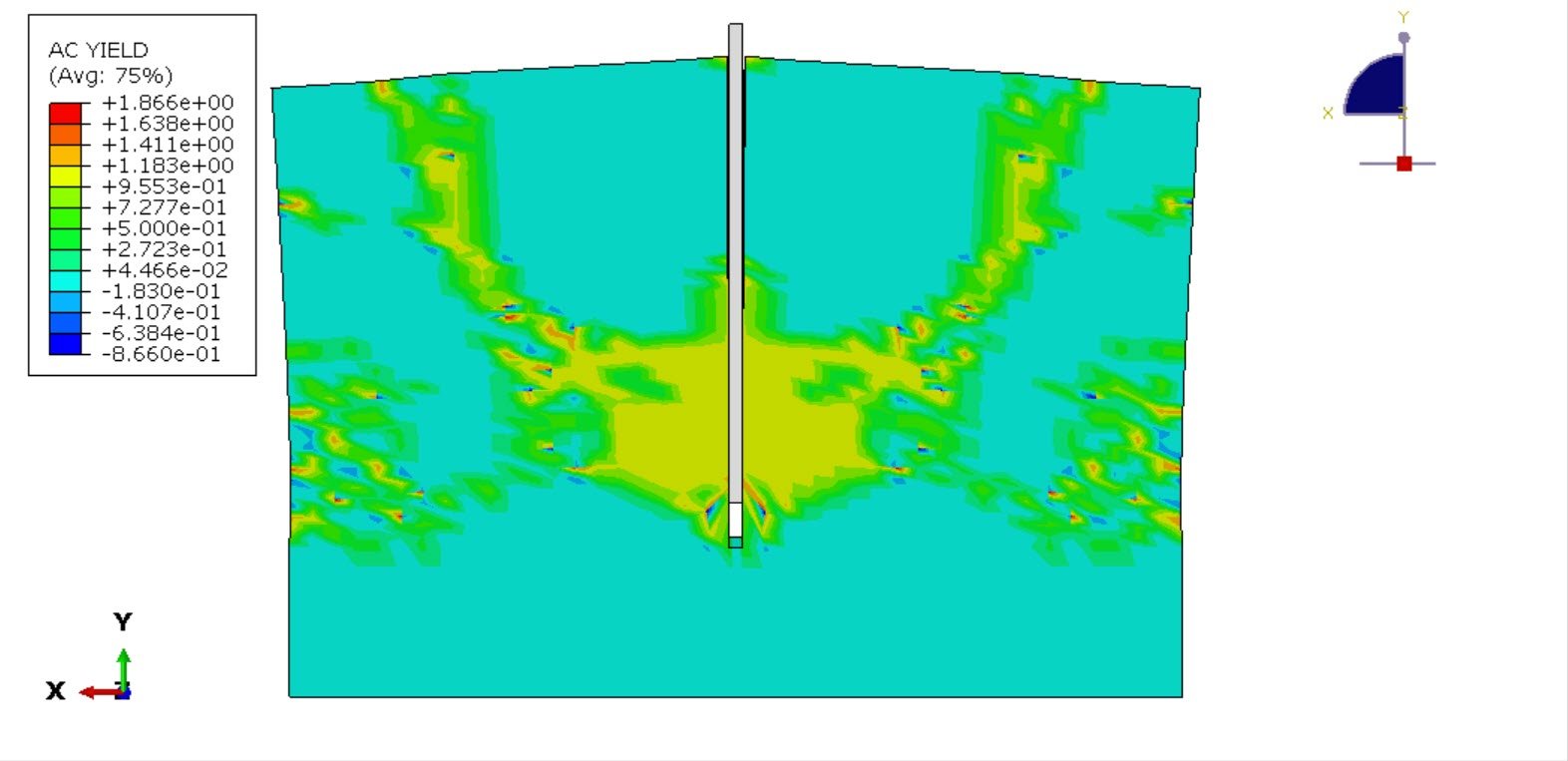

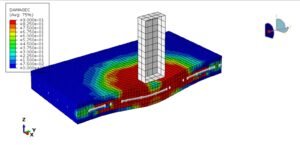

The concrete matrix was modeled using the Concrete Damaged Plasticity (CDP) model available in Abaqus. The CDP formulation accounts for:

Nonlinear compressive behavior

Tensile cracking

Stiffness degradation due to damage

Plastic flow under multiaxial stress states

This constitutive model enables a realistic simulation of cracking and localized damage around the embedded fiber during pull-out.

The steel fiber was modeled as a linear elastic material, considering its significantly higher stiffness and strength relative to concrete and the limited plastic deformation expected during pull-out.

Abaqus

€97,00 €54,00

Engineering files

€60,00 €50,00

Abaqus

€146,00 €89,00

Abaqus

€85,00 €47,00

Abaqus

€78,00 €39,00

See more

Want to receive push notifications for all major on-site activities?