Packages & Tutorials

Engineering Files & Tools

Software

Ready-to-use Models (FEA/CFD)

Excel Sheets & Hand Calculations

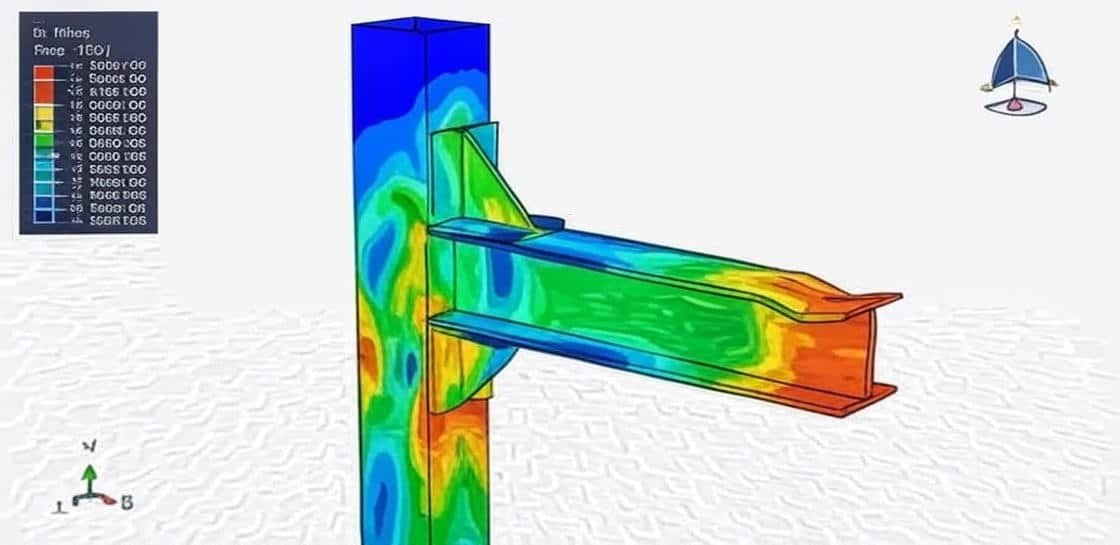

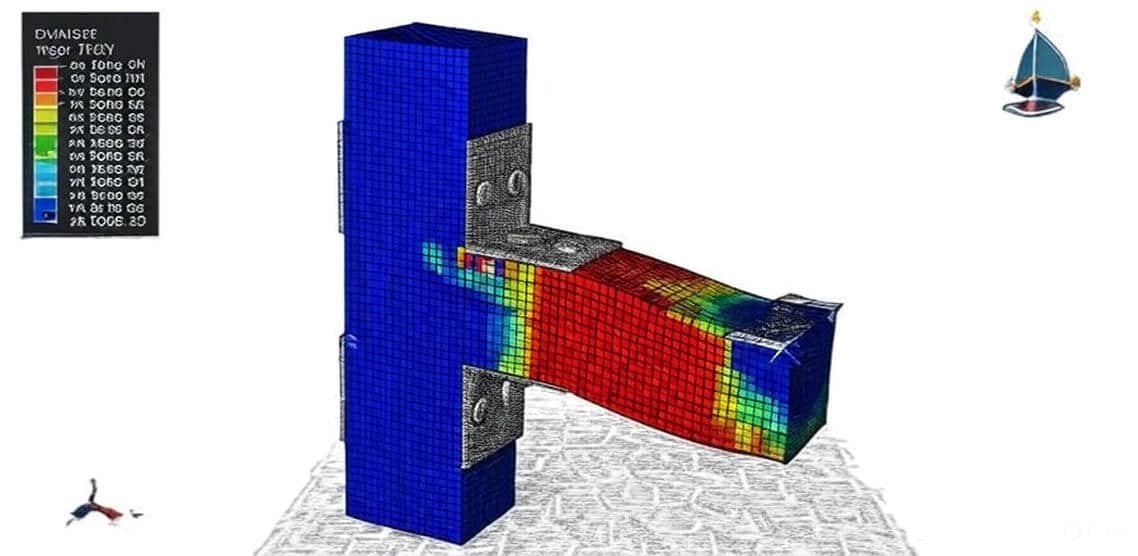

Steel and concrete beams are fundamental structural elements in civil and structural engineering, widely used in bridges, buildings, and industrial structures. Their analysis is crucial to ensure safety, serviceability, and cost efficiency in construction. Since beams primarily resist bending, shear, and axial forces, engineers must accurately predict their mechanical behavior under different loading and boundary conditions.

This course includes 22 tutorials that cover all about concrete and steel beam modeling and simulation in Abaqus software.

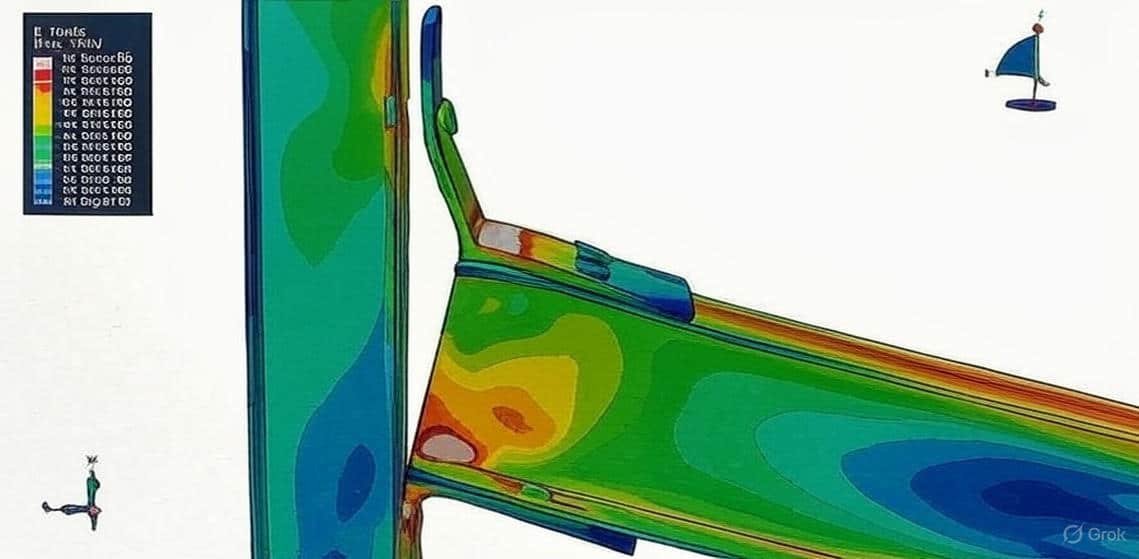

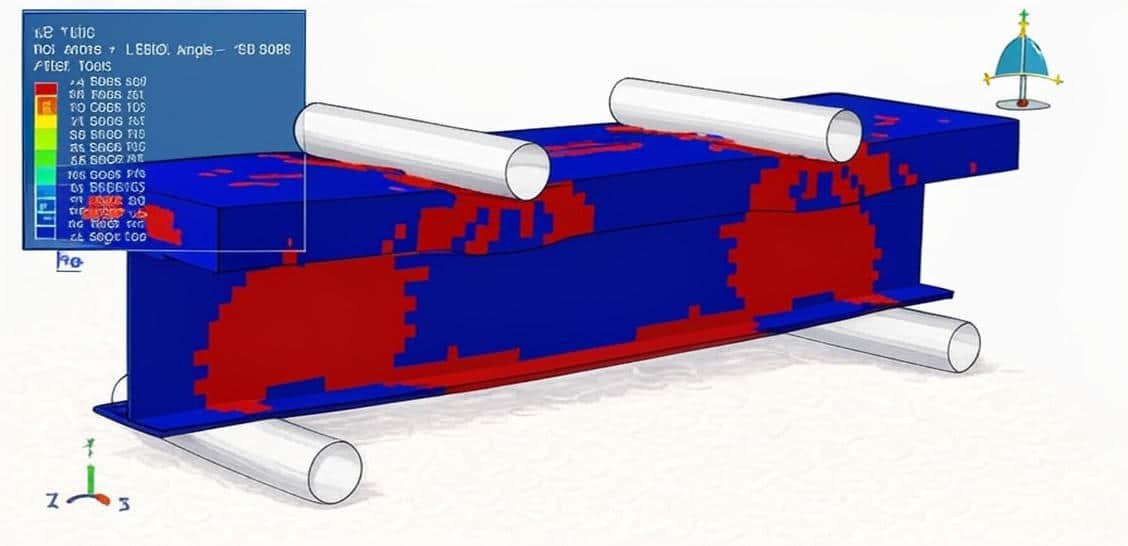

Steel beams are preferred for their high strength-to-weight ratio, ductility, and ease of fabrication. Their behavior can often be described using linear elastic models, but nonlinear effects such as plastic deformation, buckling, and fatigue must also be considered in advanced simulations.

Concrete beams, particularly reinforced concrete (RC) beams, rely on the combination of concrete’s compressive strength and steel reinforcement’s tensile capacity. Their analysis is more complex due to nonlinear stress–strain relationships, cracking, creep, and shrinkage. Simulation helps capture these effects accurately, especially for ultimate load capacity and serviceability checks.

Modern structural analysis software, such as Abaqus, ANSYS, and SAP2000, provides advanced tools for modeling and simulating steel and concrete beams:

In summary, simulation of steel and concrete beams enables engineers to go beyond traditional hand calculations, providing deeper insights into structural performance under real-world conditions. It supports safer, more efficient, and more innovative designs.

Dynamic

€1,00 €0,00

See more

Want to receive push notifications for all major on-site activities?