Introduction to Sloshing Simulation and Analysis

Sloshing refers to the oscillatory motion of liquid inside a partially filled container when subjected to dynamic excitations such as acceleration, vibration, or external loads. This phenomenon is commonly encountered in engineering applications like fuel tanks, LNG (liquefied natural gas) carriers, water reservoirs, spacecraft propellant tanks, and road tankers. Understanding sloshing behavior is critical for safety, performance, and structural integrity.

This package includes 10 practical tutorials that help you become a master in sloshing analysis.

Why Sloshing Matters

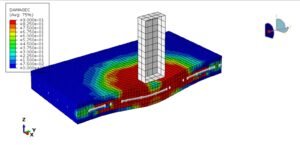

- Dynamic Loads on Structures

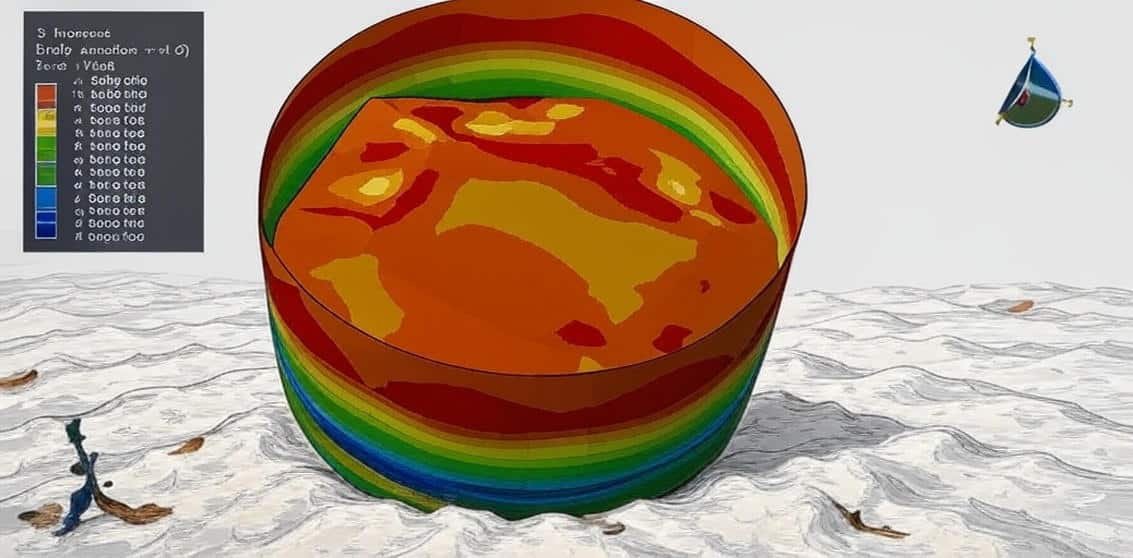

Liquid movement creates fluctuating pressures on container walls and roofs, which can cause fatigue, cracks, or even catastrophic failure if not properly considered.

- Stability Issues

In moving vehicles (ships, aircraft, trucks), liquid sloshing may shift the center of mass, affecting stability and control.

- Operational Performance

Excessive sloshing can reduce the efficiency of fluid transport systems (e.g., fuel in aerospace systems).

Key Factors Affecting Sloshing

- Fill Level: A Higher free-surface area generally increases sloshing effects.

- Excitation Frequency: Resonance occurs when the excitation frequency matches the natural frequency of the liquid.

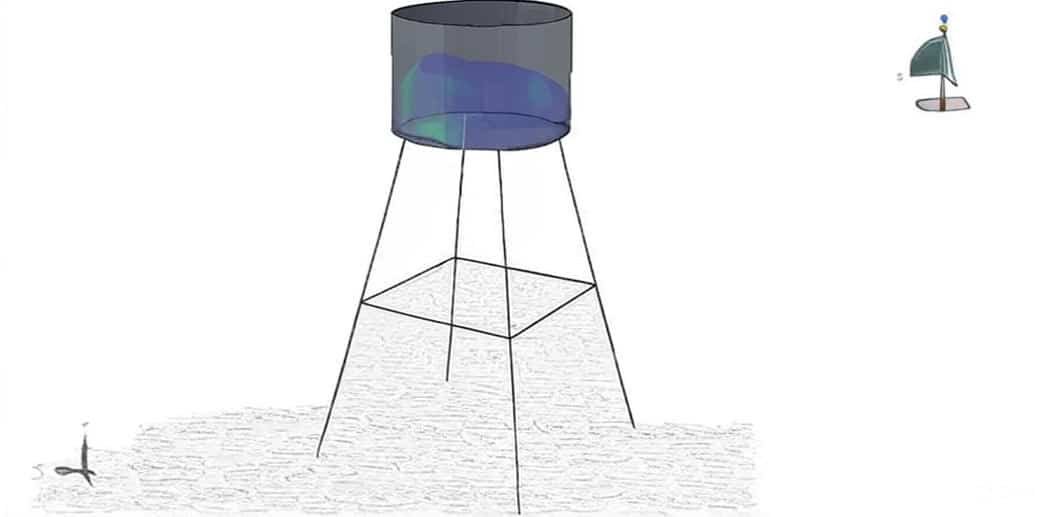

- Container Geometry: Cylindrical, rectangular, or spherical tanks exhibit different sloshing modes.

- Fluid Properties: Density, viscosity, and surface tension influence wave patterns.

Sloshing Simulation Approaches

- Analytical Methods

- Based on linear potential flow theory.

- Useful for small-amplitude oscillations and simple geometries.

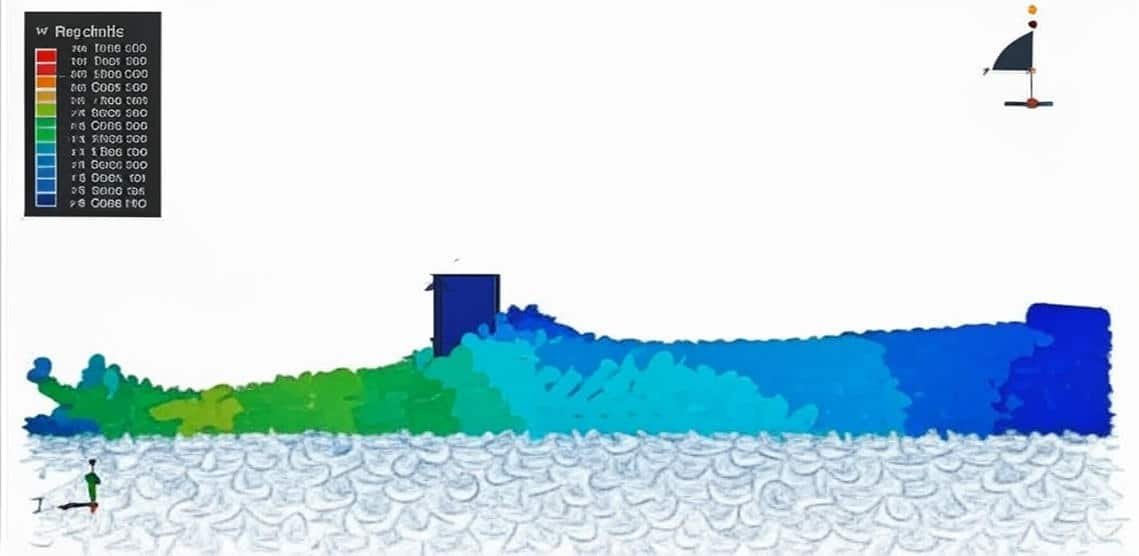

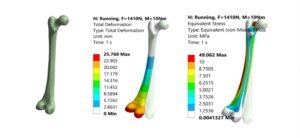

- Computational Fluid Dynamics (CFD)

- Solves the Navier–Stokes equations with free-surface tracking methods (VOF, ALE, SPH).

- Captures nonlinear sloshing, wave breaking, and impact pressures.

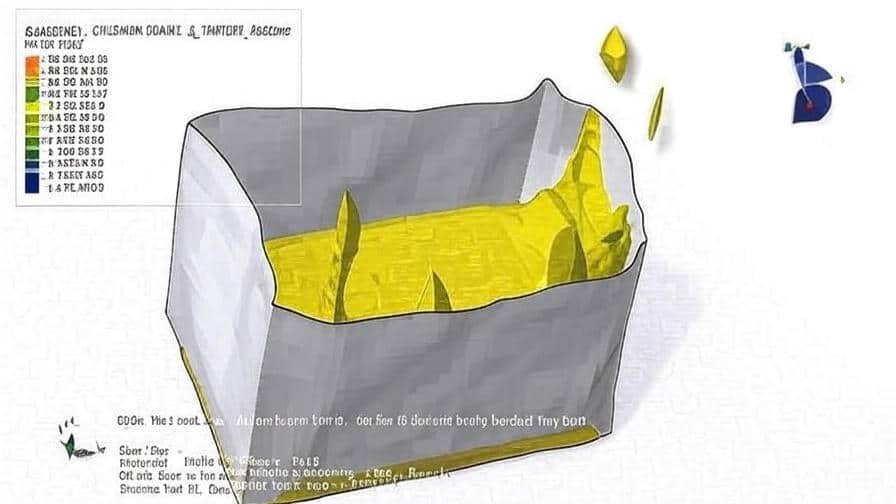

- Finite Element Analysis (FEA) with Abaqus

- Combines structural and fluid interactions.

- Uses techniques like Eulerian–Lagrangian coupling to simulate the fluid–structure interaction (FSI).

Applications

- Marine Engineering: Predicting sloshing loads in LNG carrier tanks.

- Aerospace: Understanding fuel slosh in rockets and satellites.

- Civil Engineering: Designing earthquake-resistant liquid storage tanks.

- Automotive: Minimizing slosh in vehicle fuel tanks for stability.

In essence, Sloshing Simulation and Analysis helps engineers predict and mitigate the risks associated with liquid motion, ensuring safer and more efficient designs.