Product Overview:

Arc welding is a widely utilized fusion process for metal joining. Through the application of intense heat, the metal at the joint between two components melts, allowing it to fuse—either directly or with the use of a molten filler metal. As the metal cools and solidifies, a metallurgical bond is formed, which typically results in a weld with strength comparable to that of the original metal parts. This differentiates fusion welding from other non-fusion joining methods like soldering or brazing, where the strength and mechanical properties of the joint often differ from those of the base materials.

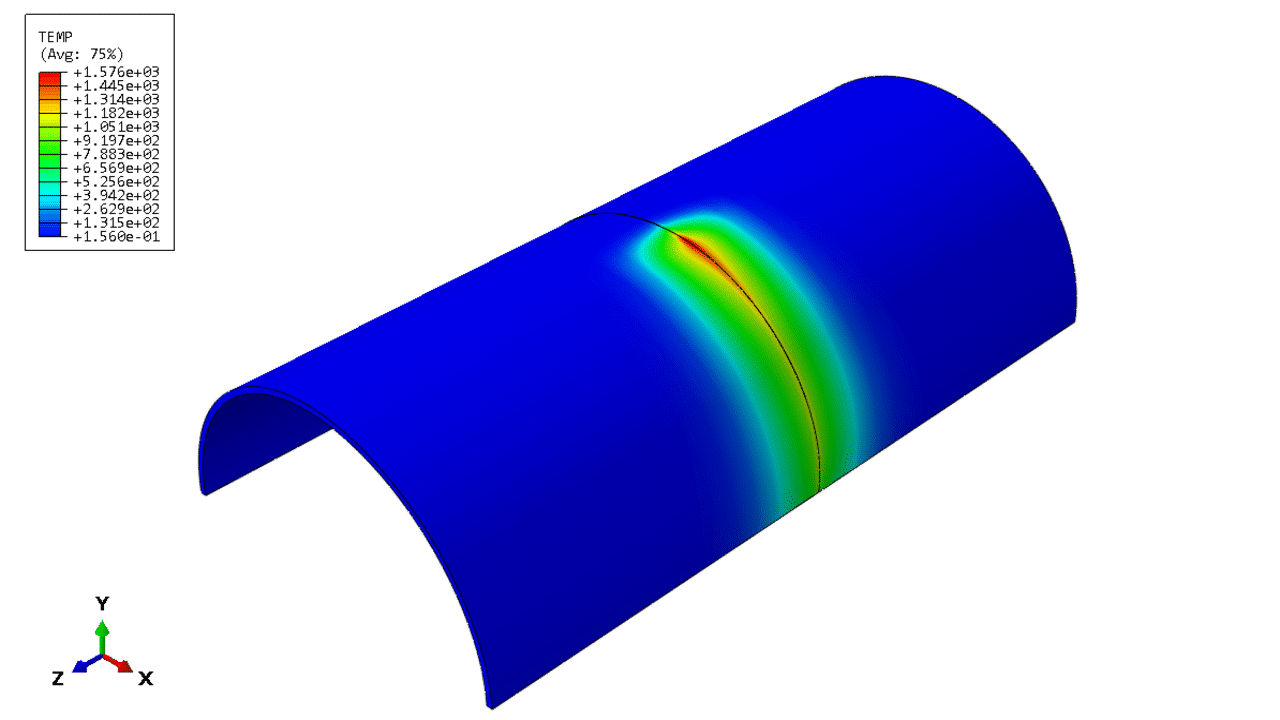

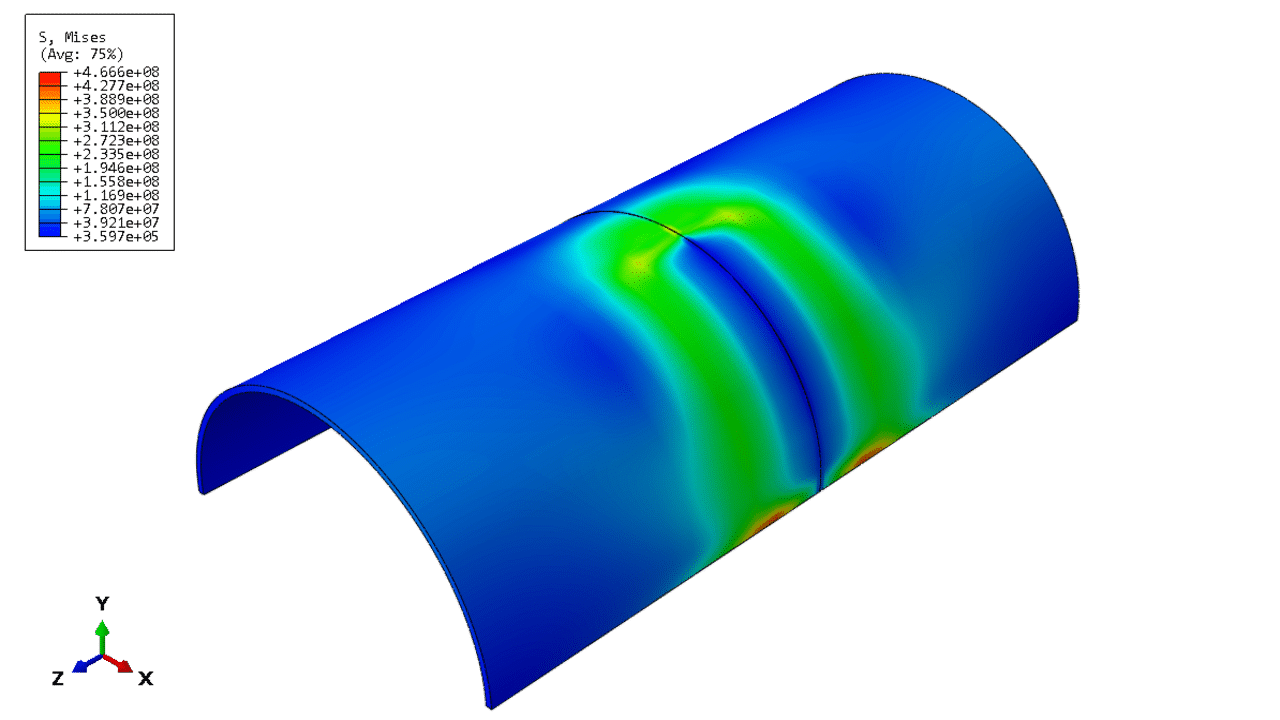

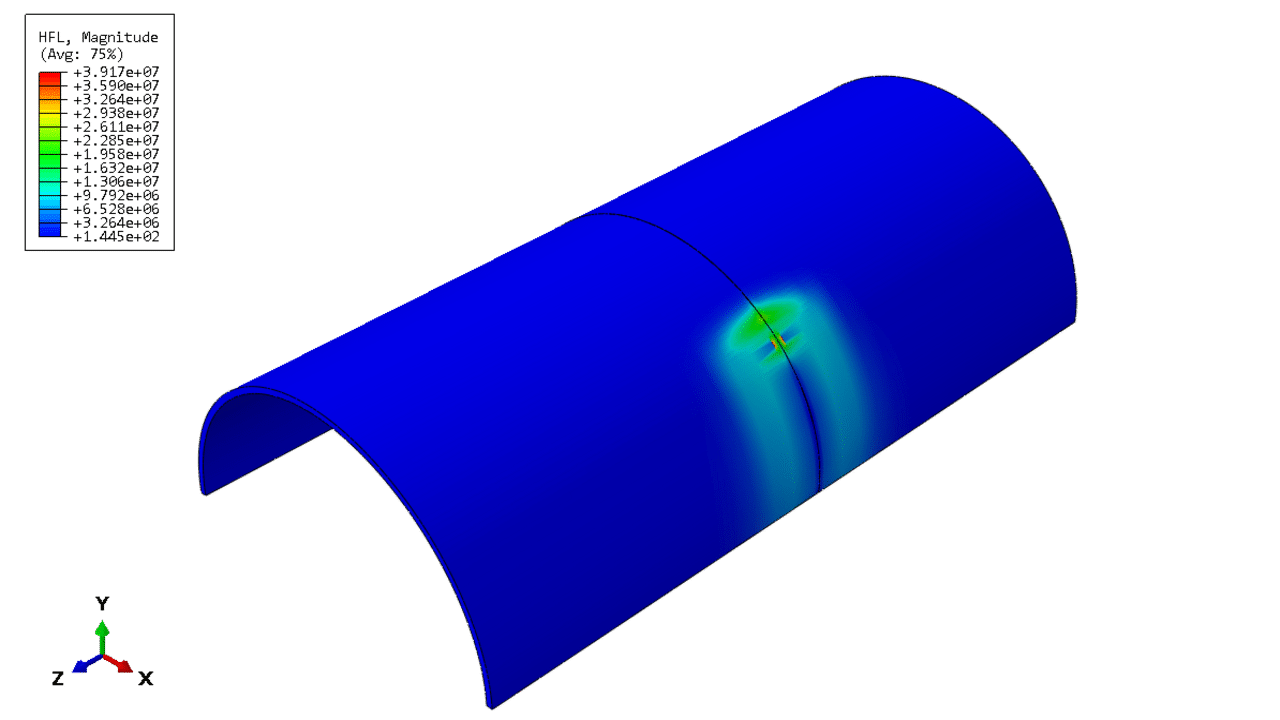

In this tutorial, we simulate an arc welding process involving steel pipes, utilizing the DFLUX subroutine to account for non-uniform heat distribution. The material properties for steel are temperature-dependent, and the welding analysis is performed using a displacement-temperature coupled step. This approach helps simulate the thermal and mechanical behavior of the material during the welding process.

Key Topics:

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?