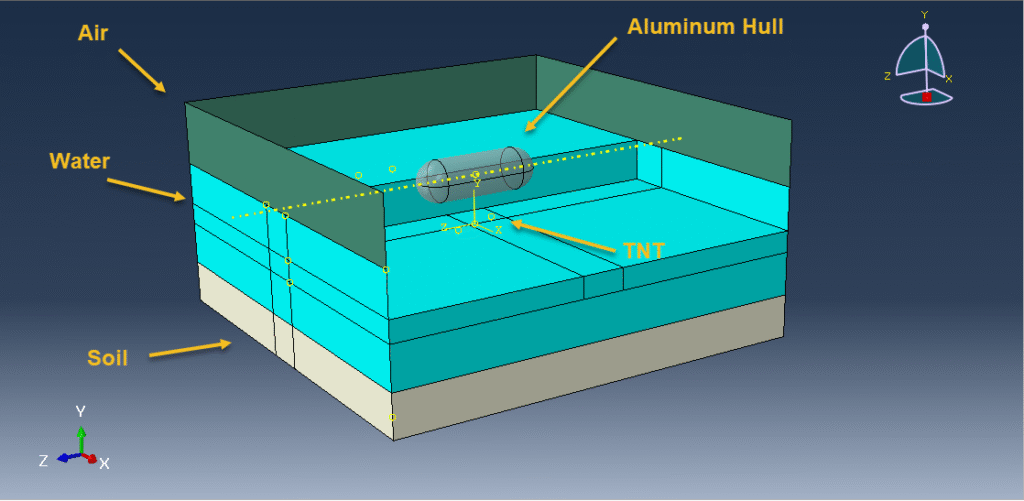

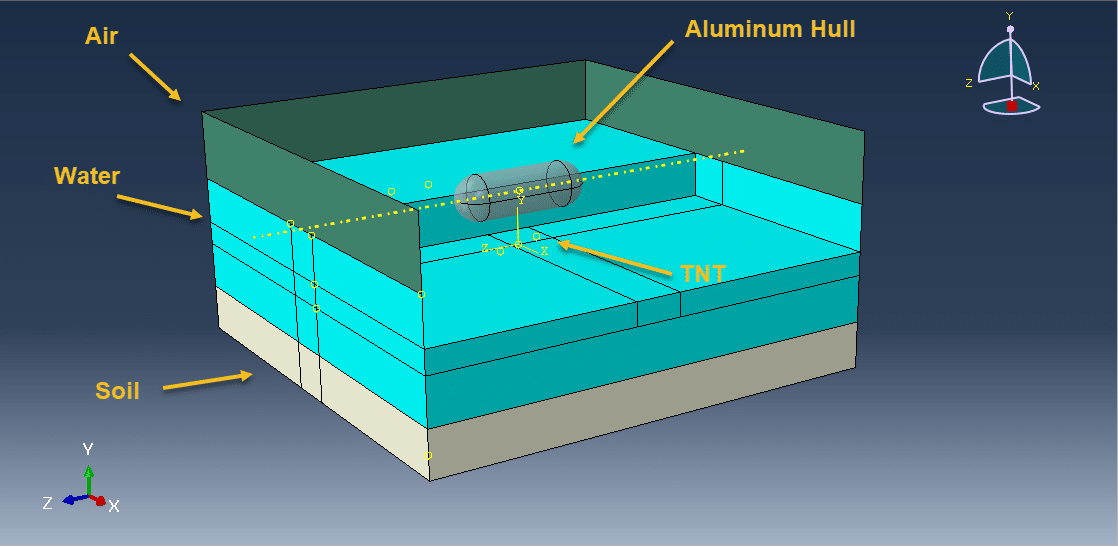

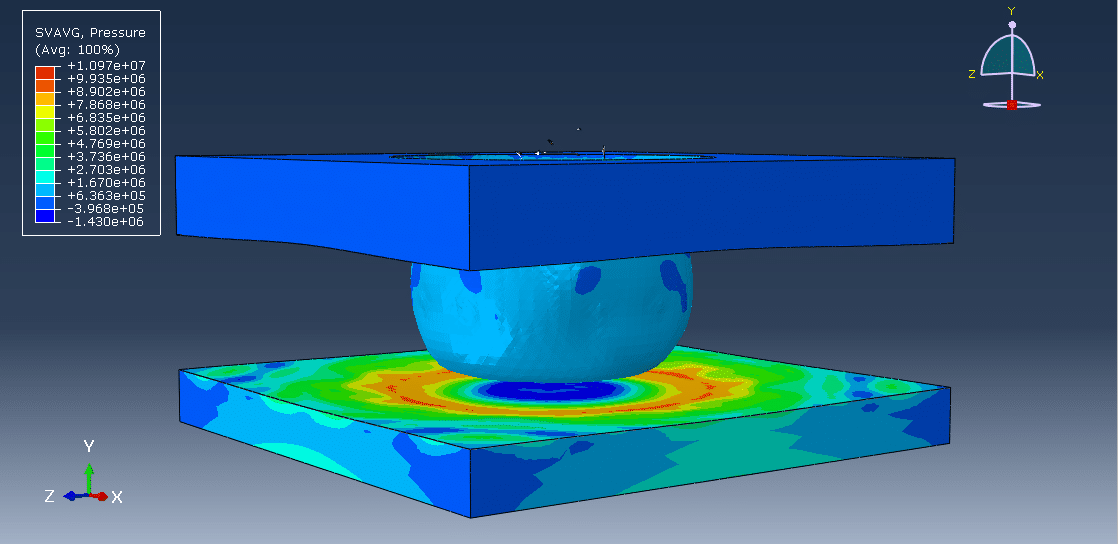

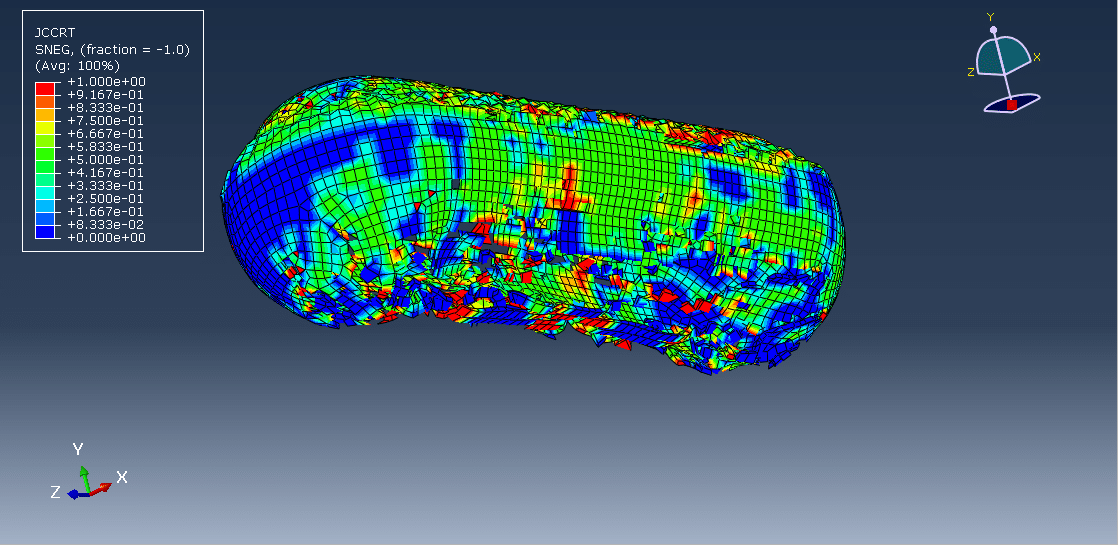

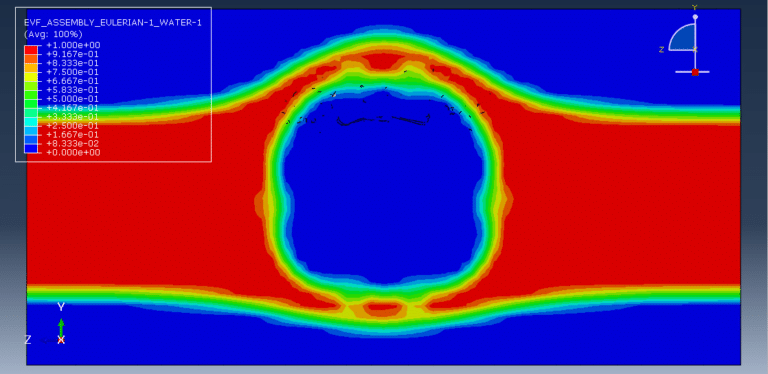

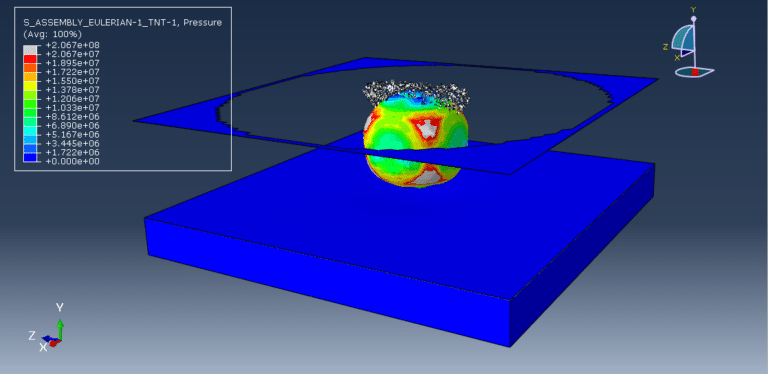

In this tutorial, the simulation of an underwater explosion near a floating structure has been carried out in Abaqus using the Coupled Eulerian Lagrangian (CEL) method. The aluminum hull is modeled as a three-dimensional thick shell part, while soil, TNT, water, and air are represented as three-dimensional Eulerian parts. Underwater explosions pose complex challenges such as fluid–solid coupling, added water mass effects, and liquid jet formation. Structural damage typically occurs in the early stages due to the impact of shock waves. Naval vessels are highly vulnerable to collisions and underwater explosions, which represent some of the most serious threats to survival in wartime. Explosions generate pulsating gas bubbles that contain nearly half of the explosive energy, making shock physics and bubble dynamics crucial in understanding structural responses. To represent explosive behavior, the TNT charge is modeled using the Jones-Wilkins-Lee (JWL) equation of state, a common model for detonation products based on the Mie-Grueneisen form. Soil behavior is captured using Mohr-Coulomb plasticity with elastic data, water is modeled with a Us–Up linear shock model, and air is represented as an ideal gas. The aluminum hull is modeled with Johnson-Cook hardening and damage to capture its performance under extreme loading. A dynamic explicit step with general contact capability is employed, as it is well-suited for complex interactions between fluids and solids. Proper mechanical and Eulerian boundary conditions are applied to the domain, and the uniform material method is used to define the mass and volume of TNT and other Eulerian parts. A fine mesh is applied to ensure accuracy. After the analysis, results such as stress, strain, explosion wave propagation, structural damage, and soil deformation are obtained for evaluation.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?