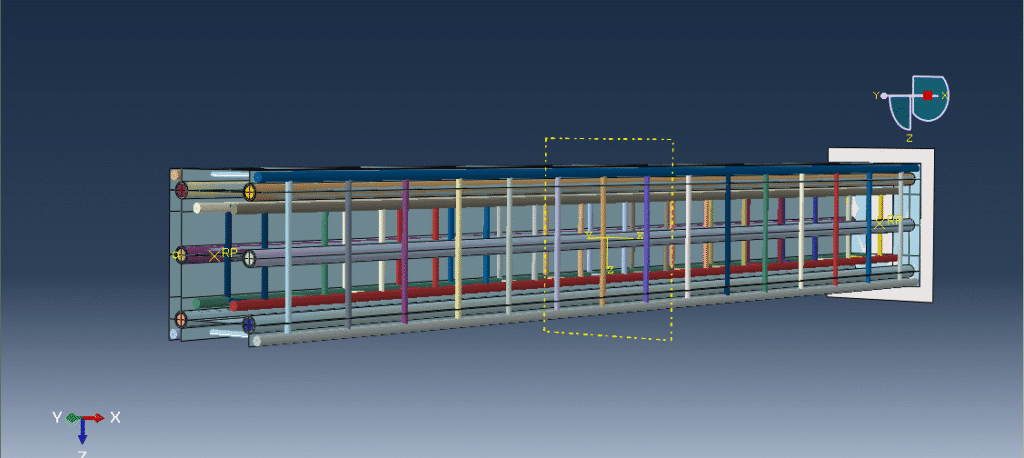

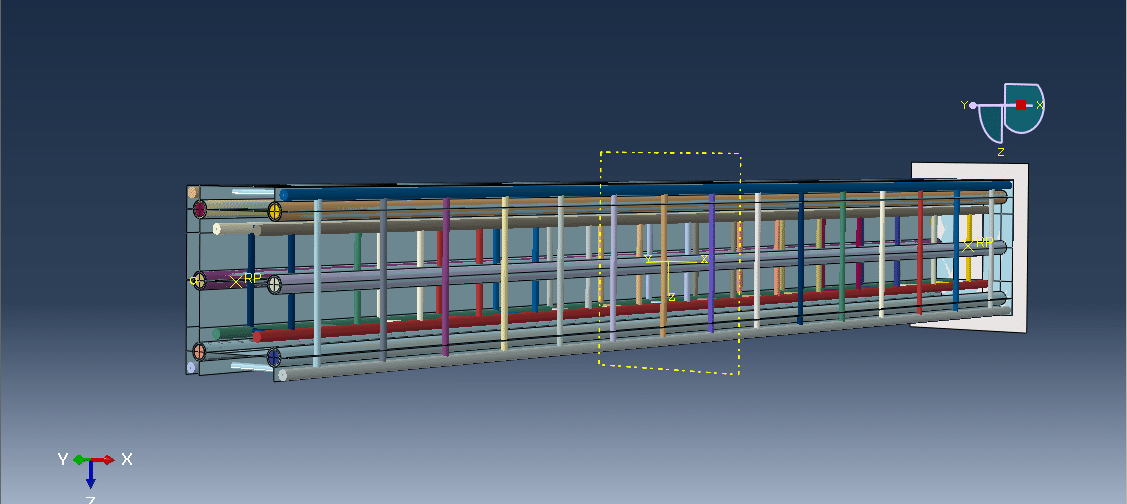

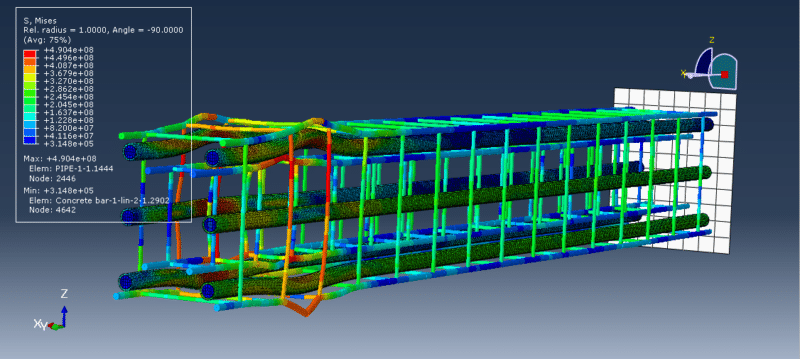

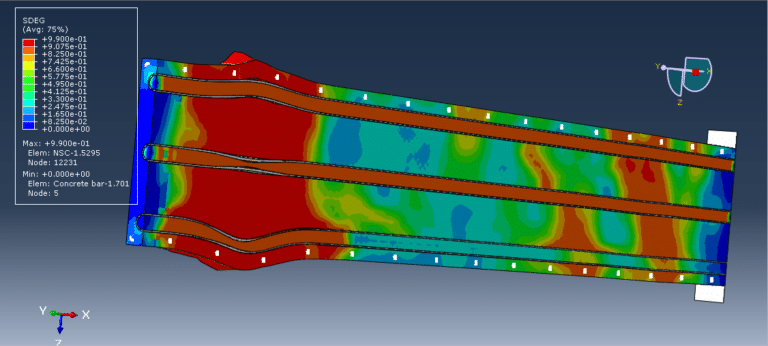

This tutorial presents the simulation of concrete-encased concrete-filled steel tubular (CFST) box stub columns under axial compression in Abaqus. The concrete column is modeled as a three-dimensional solid, while the steel pipes are also represented as solids. Steel bars and strips are modeled as wires, and the concrete inside the steel tubes is defined as a three-dimensional solid. The composite CFST box column consists of a reinforced concrete (RC) box column with several CFST components embedded in the web walls and corners. Typically, there are six CFST components—four in the corners and two in the web walls. The corner components are given larger diameters to improve flexural capacity. Compared with conventional RC or standard CFST columns, this composite system provides higher bearing capacity and greater construction efficiency.

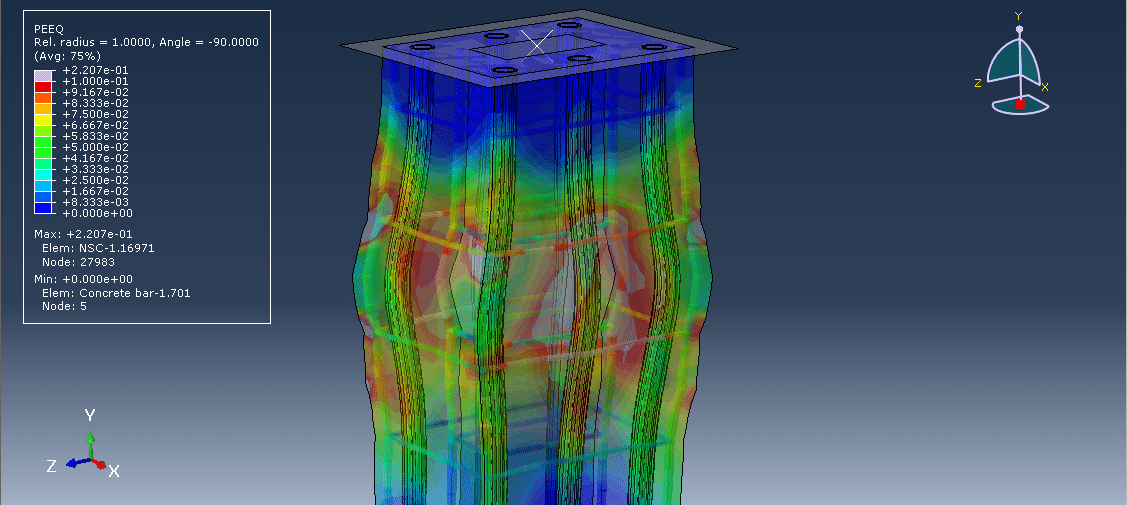

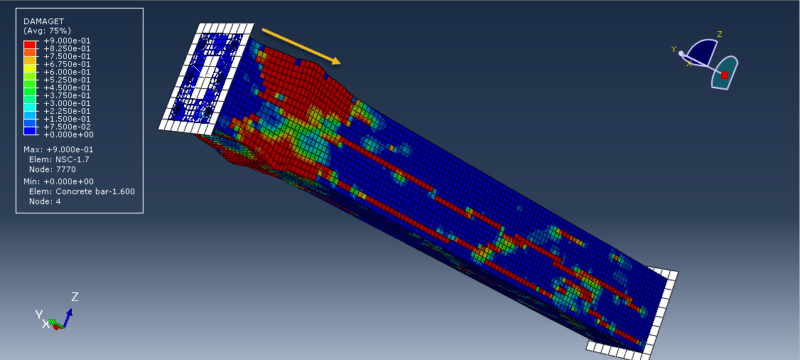

The Concrete Damage Plasticity (CDP) model is used to represent the nonlinear behavior of concrete, combining plasticity theory with damage mechanics for a realistic material response. All steel components are modeled with an elastic–plastic material definition. The dynamic explicit step with mass scaling is employed to reduce computational time, while the general contact algorithm governs interactions among all parts. Appropriate constraints, boundary conditions, and loads are applied, and a fine mesh ensures accuracy.

The analysis produces results including stress, strain, tension and compression damage, force response, and overall failure characteristics, offering a detailed understanding of the structural performance of CFST box stub columns.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?