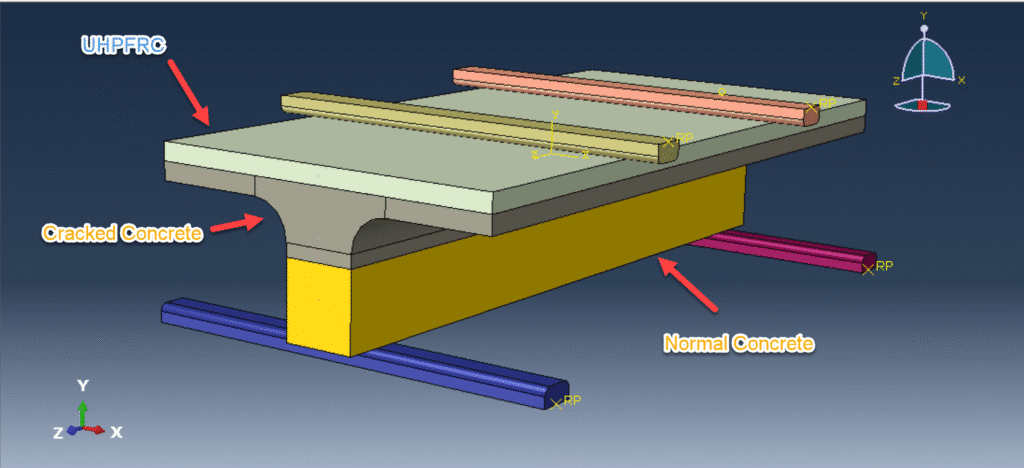

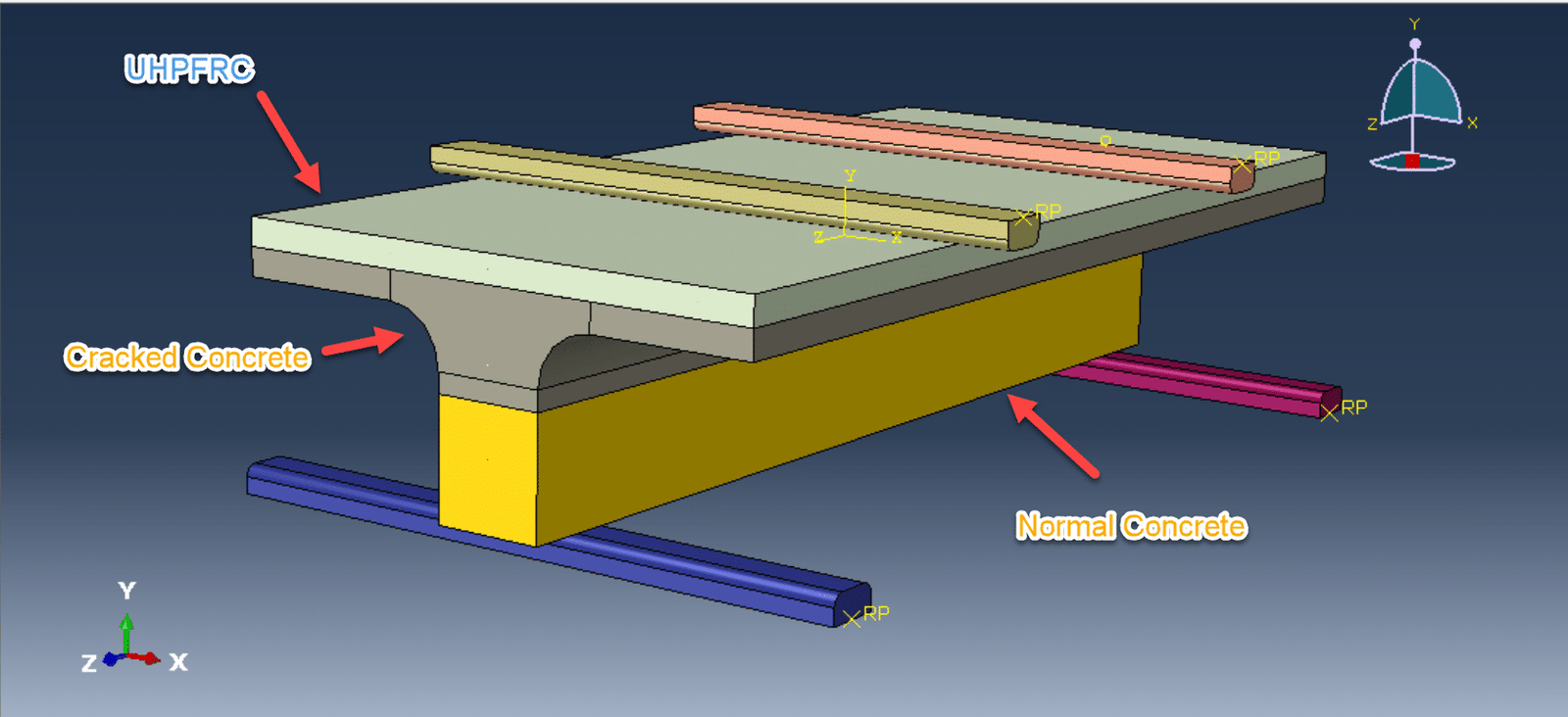

Concrete slabs, particularly in bridges and floor systems, are often subjected to combined shear and bending stresses. When conventional reinforced concrete (RC) slabs crack due to loading or environmental effects, their ability to resist shear and bending is significantly compromised. To address these issues, Ultra-High Performance Fiber-Reinforced Concrete (UHPFRC) has emerged as an advanced material with exceptional mechanical properties, making it highly effective for enhancing structural performance, especially in retrofitting and hybrid construction applications.

UHPFRC is a class of cementitious composite characterized by:

Compressive strength exceeding 150 MPa,

Tensile strength typically ranges from 8 to 15 MPa,

Significant strain-hardening behavior, and

A dense matrix reinforced with high volumes of steel microfibers, offering enhanced crack bridging and post-cracking resistance.

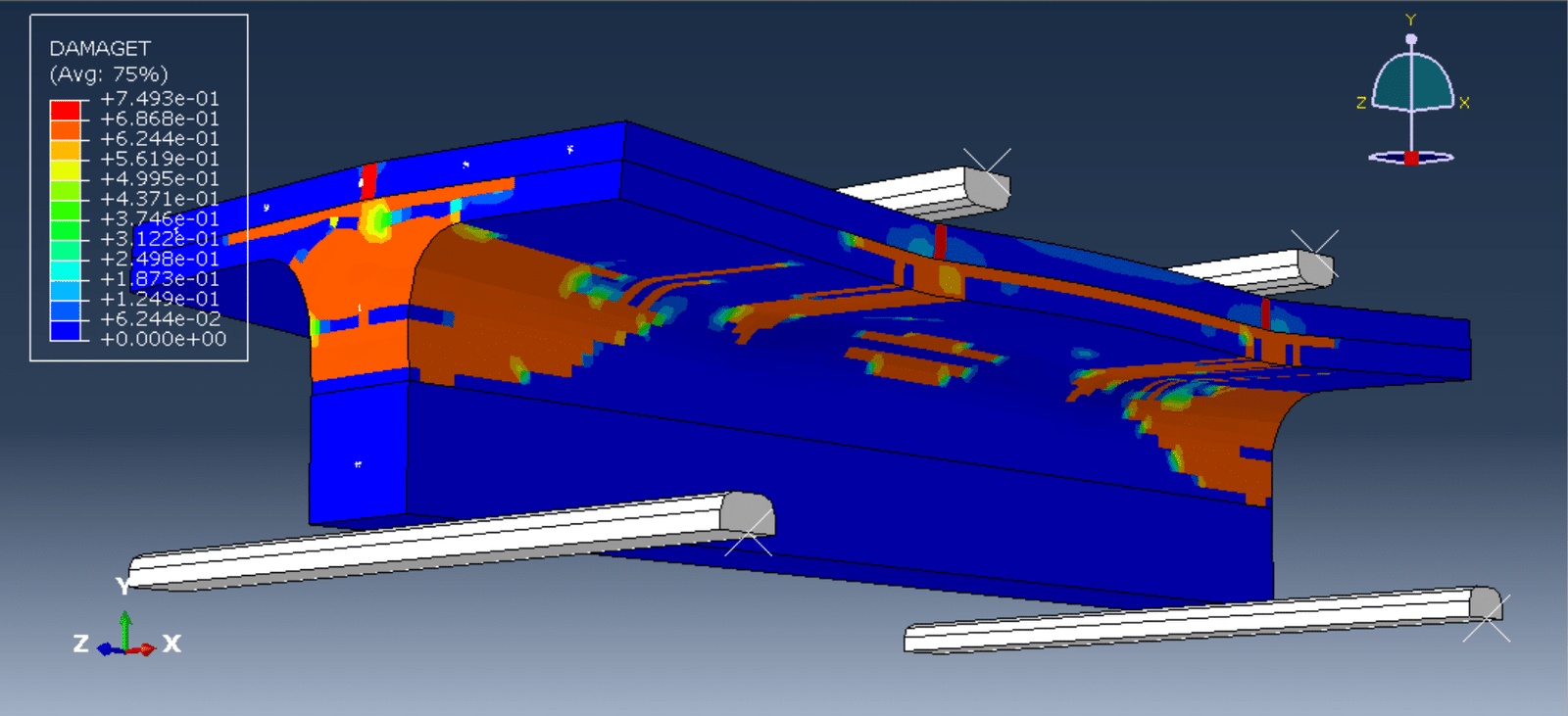

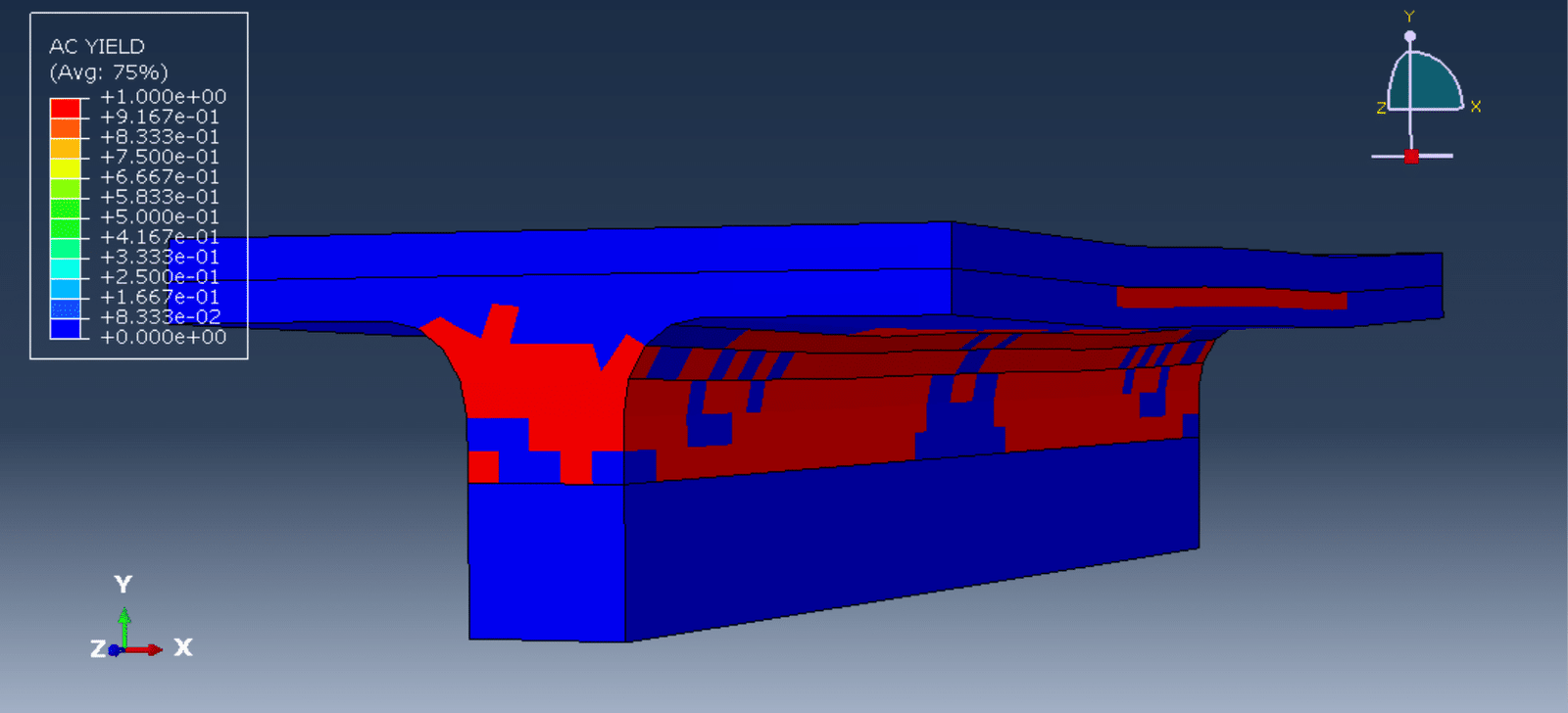

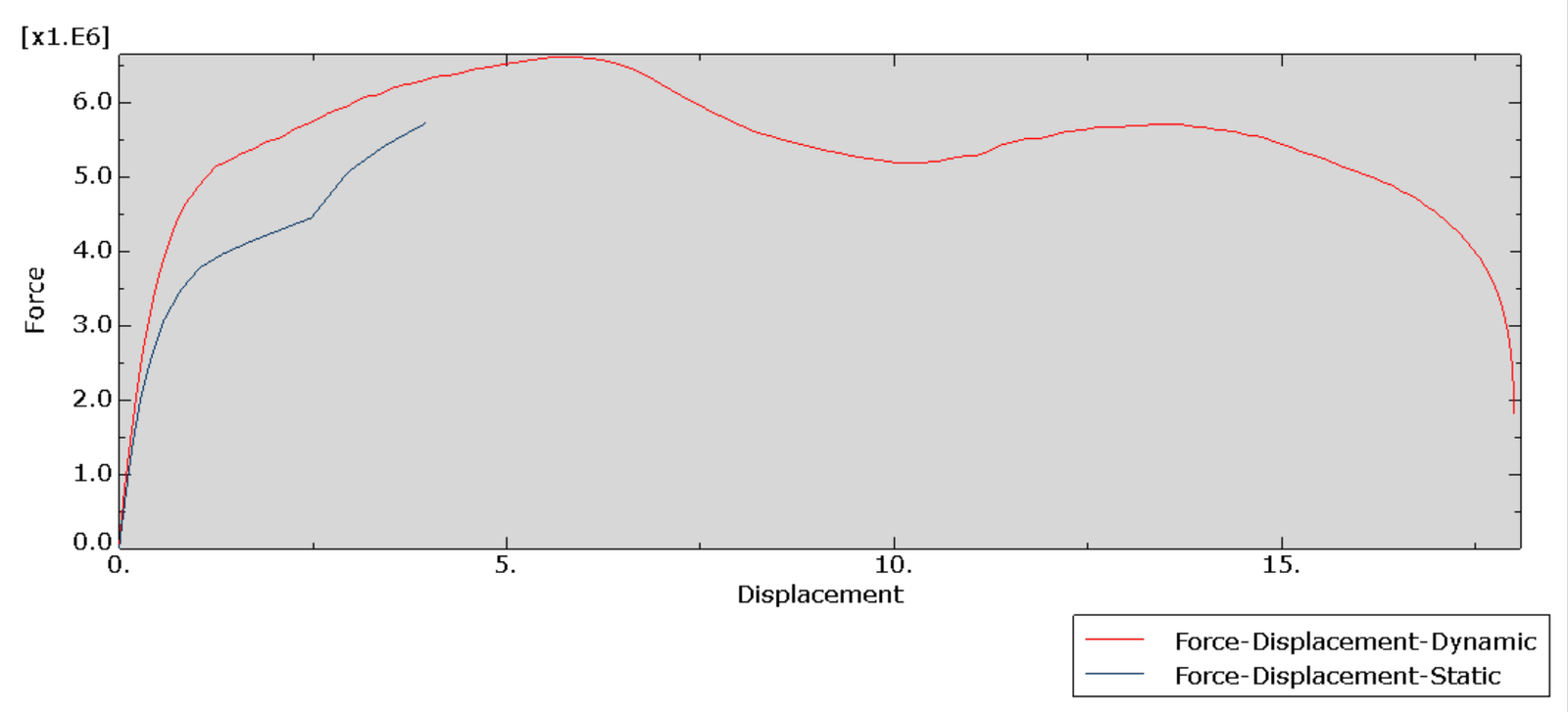

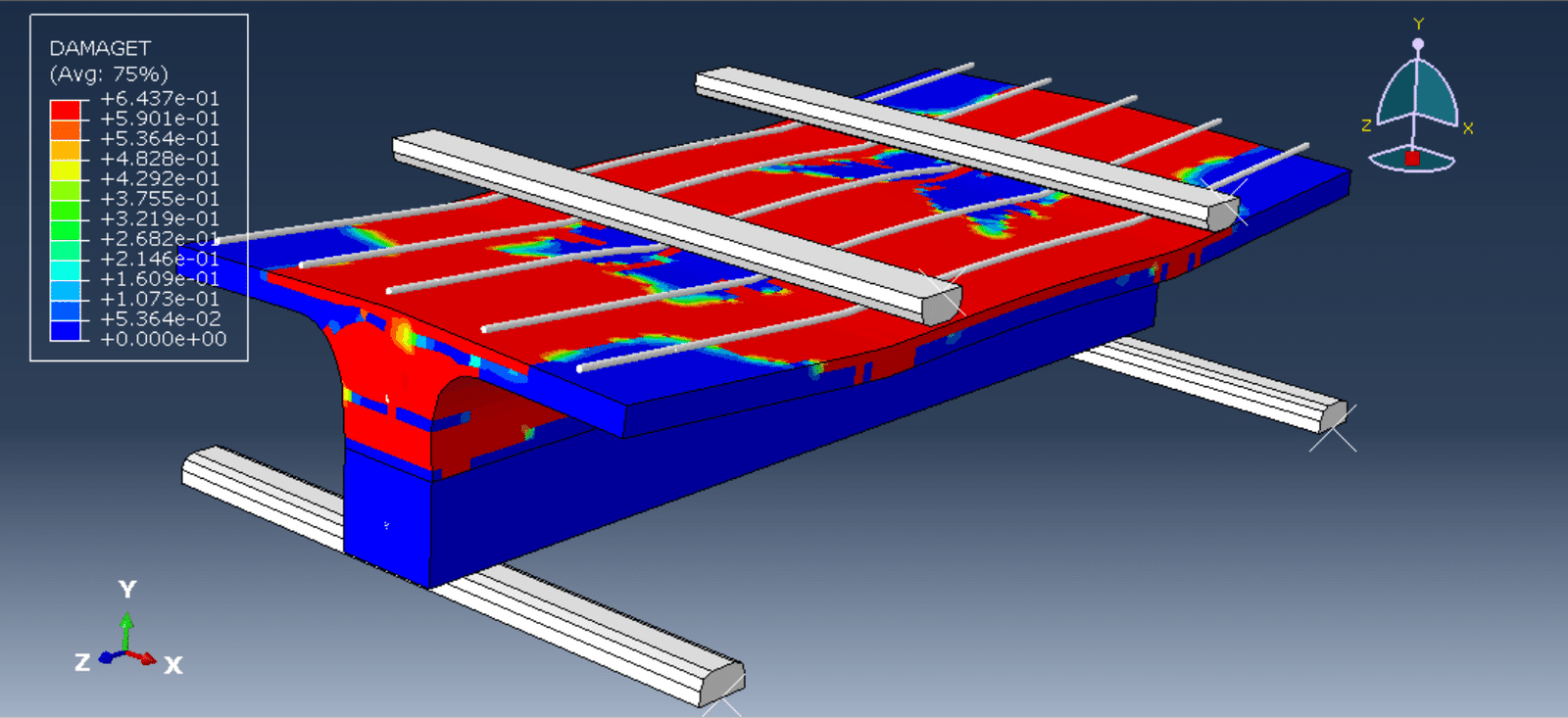

When UHPFRC is used to strengthen or overlay cracked RC slabs, it contributes substantially to shear resistance, flexural stiffness, and ductility, particularly after the initiation of cracking in the existing concrete. The composite action between the UHPFRC layer and the existing concrete is critical in redistributing internal forces and delaying failure mechanisms. The UHPFRC overlay enhances the crack control, leading to a multi-cracking pattern rather than localized failure, which improves the overall load-carrying capacity and extends the service life of the structure.

In the shear-bending interaction, UHPFRC plays a dual role:

Flexural Enhancement: The high tensile strength and fiber bridging capacity of UHPFRC provide additional moment capacity after the original concrete cracks.

Shear Resistance: The dense matrix and fiber reinforcement improve the dowel action and shear friction along cracks, reducing shear slip and increasing the slab’s ability to carry combined loading.

Overall, the integration of UHPFRC into cracked concrete slabs offers a resilient and durable solution, with experimental and numerical studies confirming notable improvements in shear-bending behavior, crack width limitation, and post-cracking ductility. This makes UHPFRC a promising material for the rehabilitation and strengthening of deteriorated infrastructure.

This example is close to the paper here: Shear-bending failure modeling of concrete ribbed slabs strengthened with UHPFRC

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?