Product Overview:

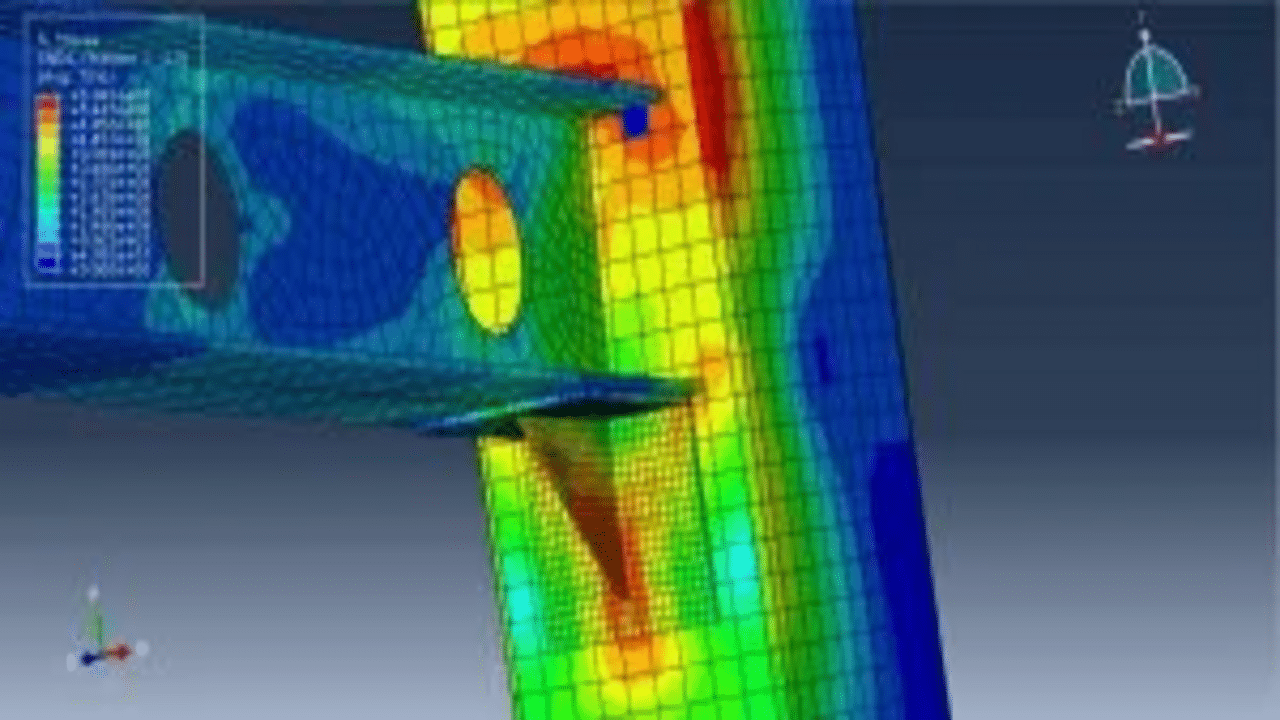

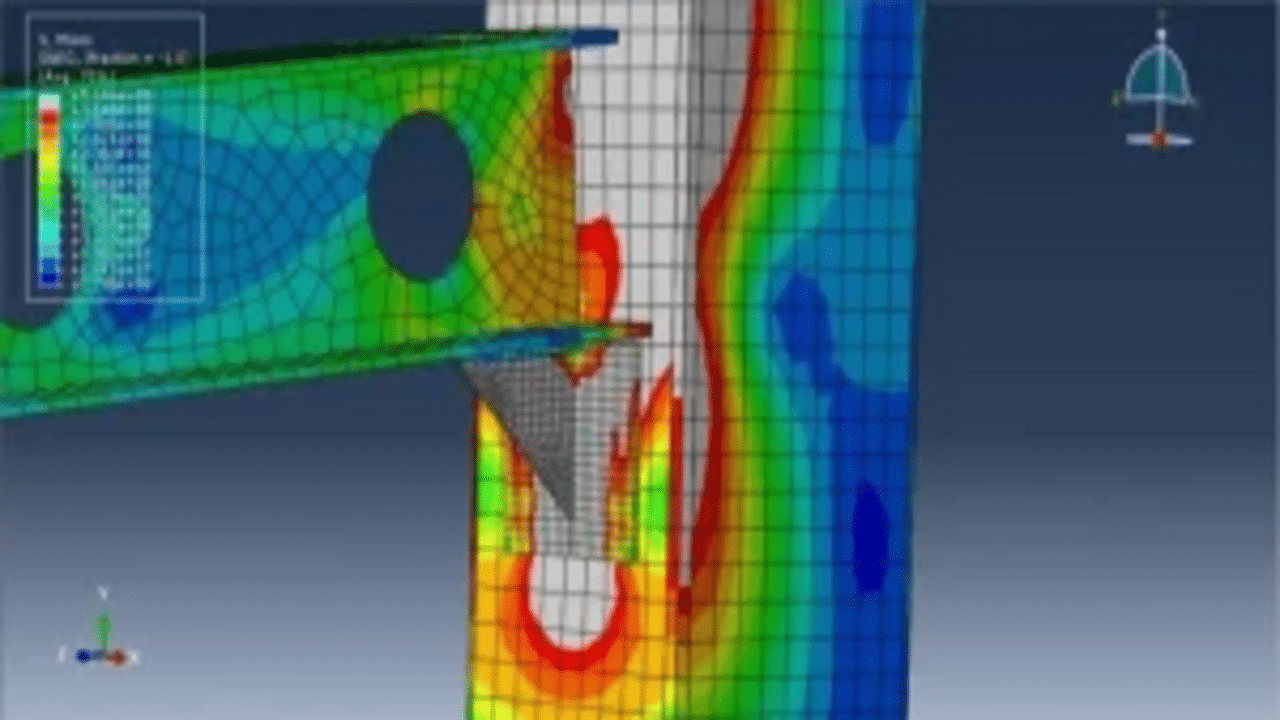

In this tutorial, we investigate the simulation of cyclic loading on a steel beam-column connection, incorporating a steel angle and gusset, using Abaqus. The steel beam and box column are modeled as three-dimensional shell parts, while the steel angle and gusset are modeled as three-dimensional solid parts.

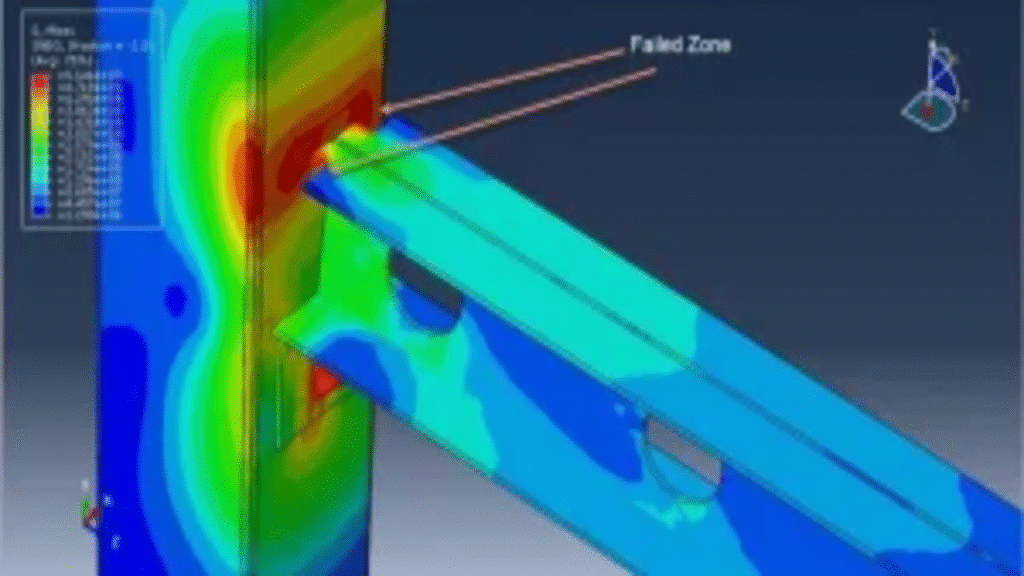

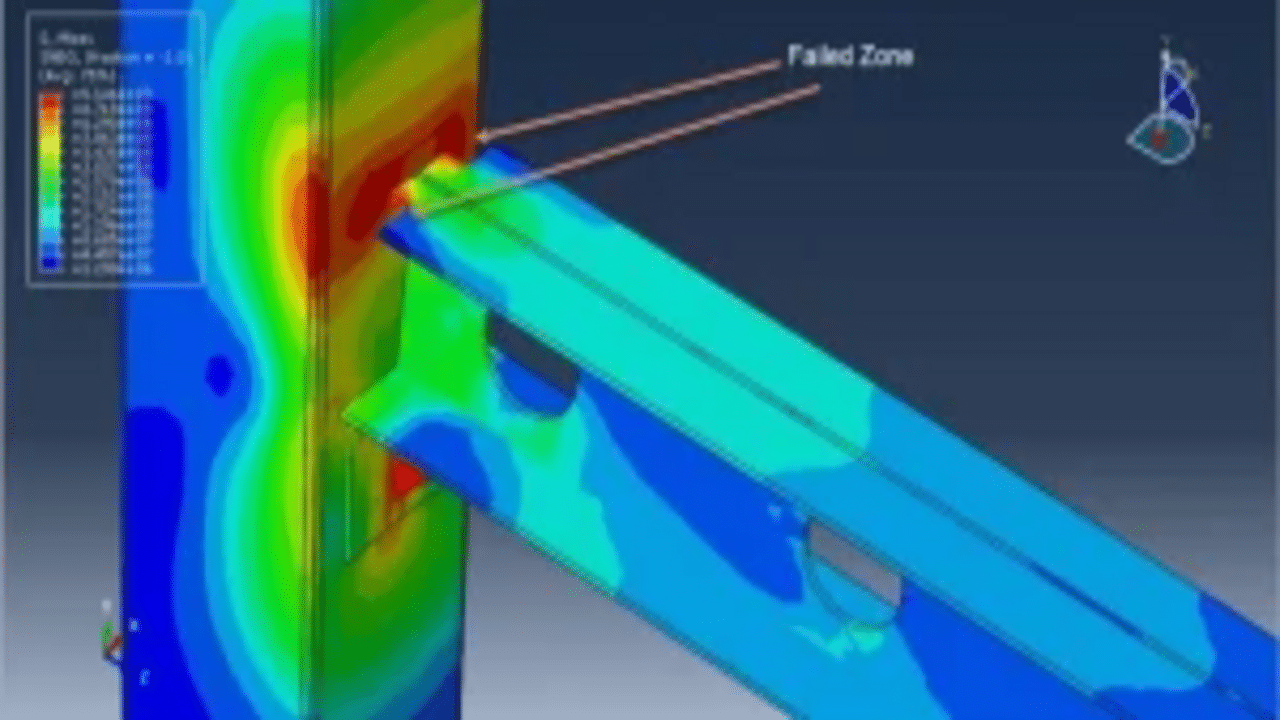

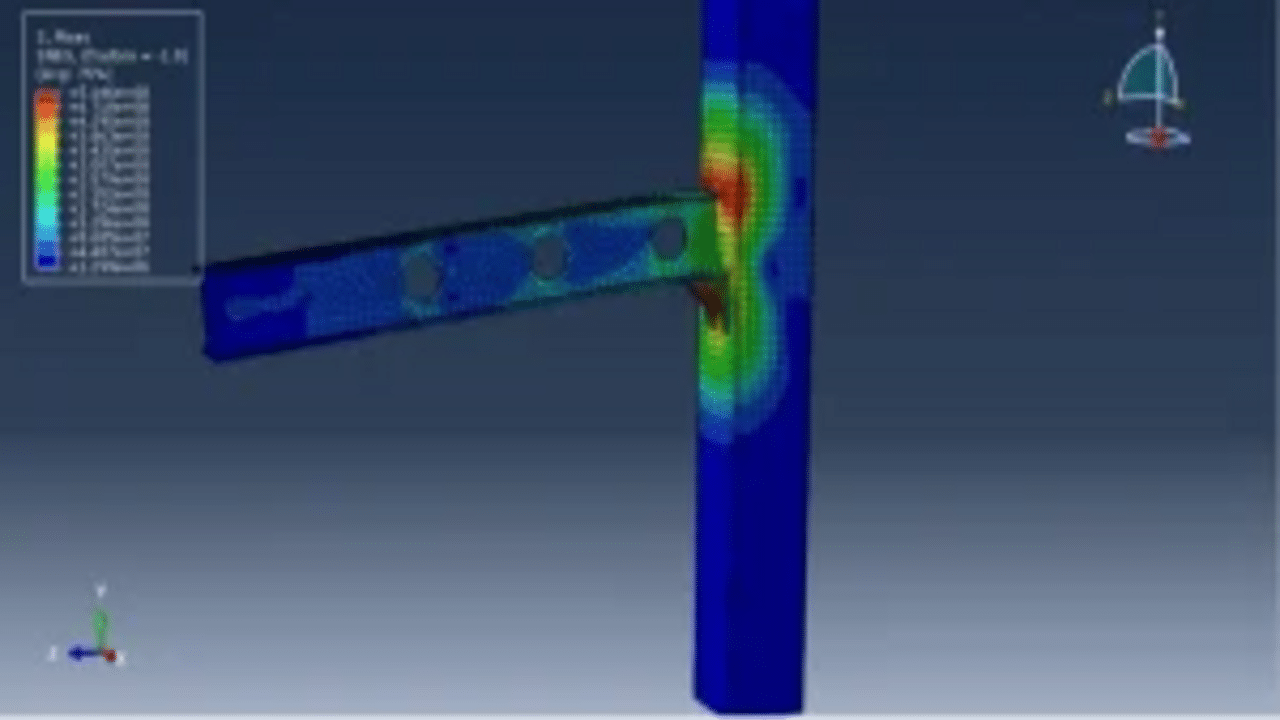

For all components, the steel material is characterized by elastic-plastic behavior and a ductile damage criterion, allowing for accurate predictions of the damaged zones. The cyclic loading induces failure and damage, particularly at the joint zones, which this damage criterion effectively captures.

A general static step with a specific time period is selected for the simulation. Perfect contact is assumed between the steel angle and the beam, as well as between the steel angle and the column, simulating a weld joint. Fixed boundary conditions are assigned to the top and bottom edges of the column, while a displacement with a specified amplitude is applied to the beam as part of the loading protocol.

To ensure accurate predictions of damage propagation, a fine mesh is necessary throughout the model.

Upon completing the simulation, the influence of the steel angle with gusset becomes evident due to their enhanced stiffness. Less damage is observed at the bottom side of the beam, while significant damage occurs at the top surface of the beam where the steel angle is absent. Comprehensive results, including stress, strain, and displacement data, can be obtained from the simulation.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?