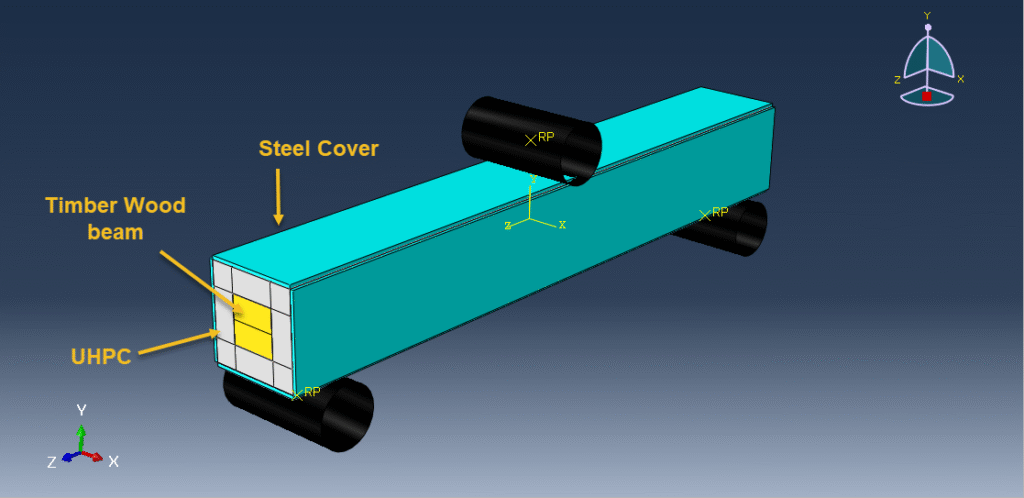

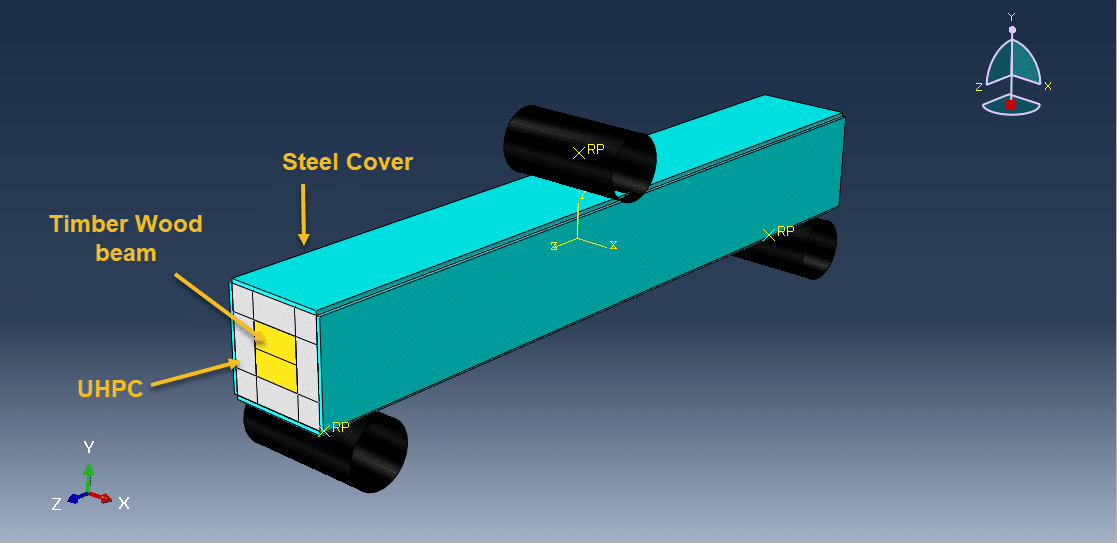

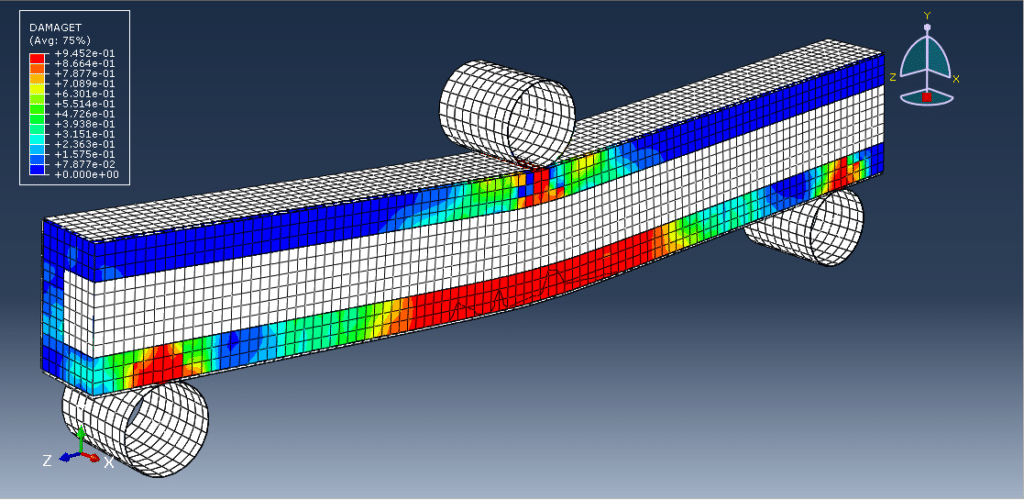

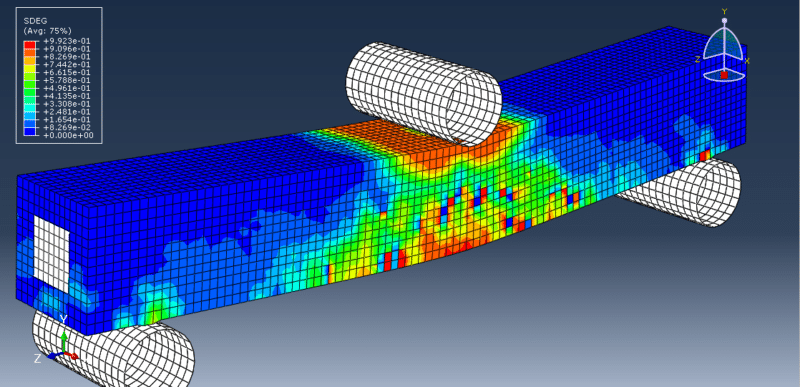

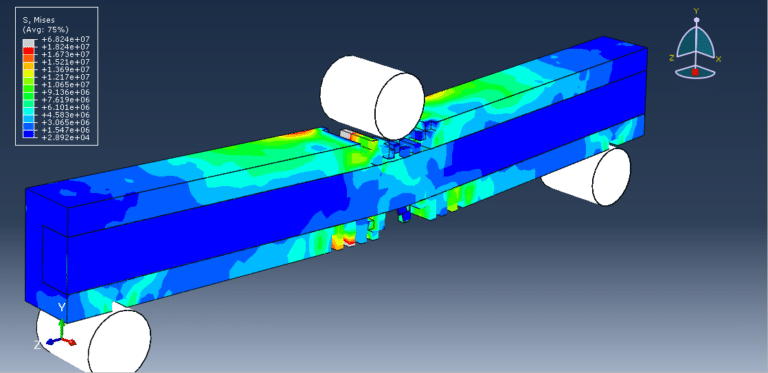

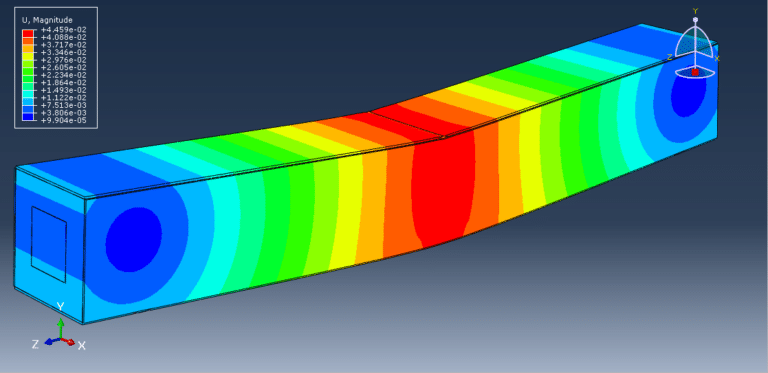

In this tutorial, the bending test of a composite beam consisting of wood, ultra-high-performance concrete (UHPC), and steel has been simulated in Abaqus. The wood is modeled as a three-dimensional solid part with two layers, where the top layer experiences compression and the bottom layer is subjected to tension. The UHPC is modeled as a three-dimensional solid part using the Concrete Damaged Plasticity (CDP) model, which accounts for tensile cracking and compressive crushing as the primary failure mechanisms. The steel cover is defined as a shell part. To capture wood behavior, elastic-plastic properties with Hill’s function coefficients are applied to distinguish tension and compression performance. The steel material is modeled with elastic-plastic data and a ductile damage criterion. A dynamic explicit step with general contact capability is used for the analysis. Perfect contact is assumed among internal surfaces, while surface-to-surface contact with friction is applied between the rigid body and steel cover. Proper boundary conditions and meshing are assigned to all components. Additionally, in a second model setup, a strain-based failure criterion is introduced to capture the complete failure behavior of the UHPC material. After running the simulation, results such as stress, strain, tension and compression damage, force–displacement curves, wood bending response, plastic strain, and failure modes are obtained for detailed evaluation.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?