Introduction to Polymer and Metal Foam Analysis

1. Metal and Polymer foam

- Polymers

Polymers are long-chain molecules with diverse mechanical, thermal, and chemical properties. They are widely used in structural, biomedical, and automotive applications due to their light weight, flexibility, and tunable behavior (elastic, viscoelastic, or plastic).

- Metal Foams

Metal foams are lightweight, porous structures created by introducing gas bubbles into molten metal. They combine high strength with low density, excellent energy absorption, and thermal/electrical conductivity. Common applications include crash protection, aerospace components, and thermal management systems.

This package includes 20 practical tutorials that cover all about polymer and metal foam.

2. Why Analyze Them Together?

The combination of polymers and metal foams leads to hybrid materials that exhibit a balance of toughness, light weight, and multifunctional performance. For example:

- Polymer-metal foam composites can be used in impact-resistant panels.

- Polymer infiltration of metal foams creates advanced structural materials with improved energy absorption.

- Understanding their coupled mechanical, thermal, and failure behavior is essential for engineering design.

3. Key Analysis Challenges

- Heterogeneous microstructure: Random foam cell distributions and polymer chain networks require specialized modeling.

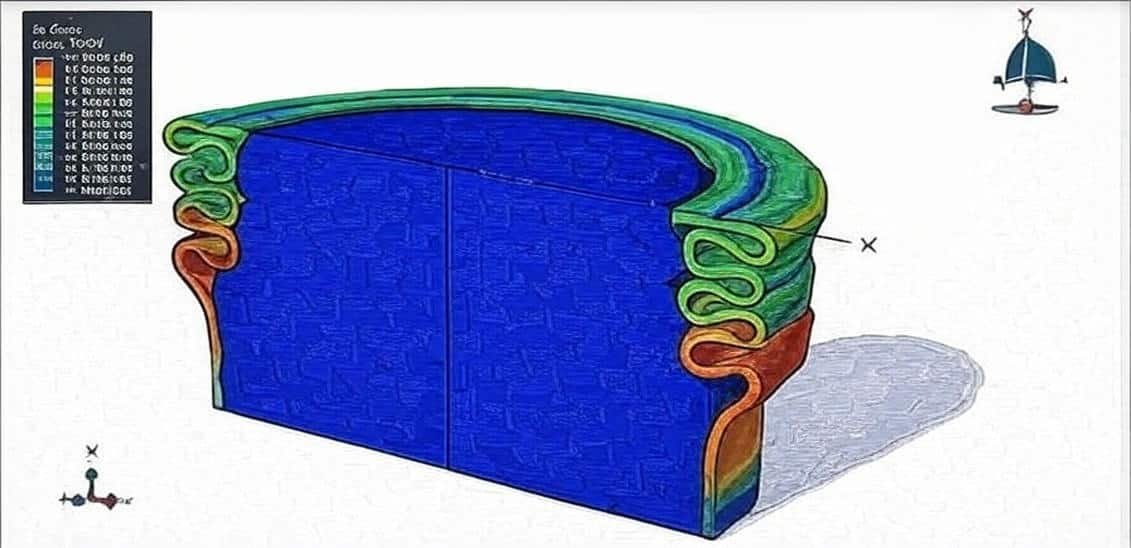

- Nonlinear material behavior: Both polymers (viscoelasticity, plasticity) and foams (crushing, densification) exhibit nonlinear stress-strain responses.

- Coupled phenomena: Mechanical, thermal, and fatigue interactions must often be considered simultaneously.

4. Simulation in Abaqus

Abaqus provides a robust platform for simulating polymer and metal foam behavior through:

- Material Models

- Hyperelastic & viscoelastic models for polymers.

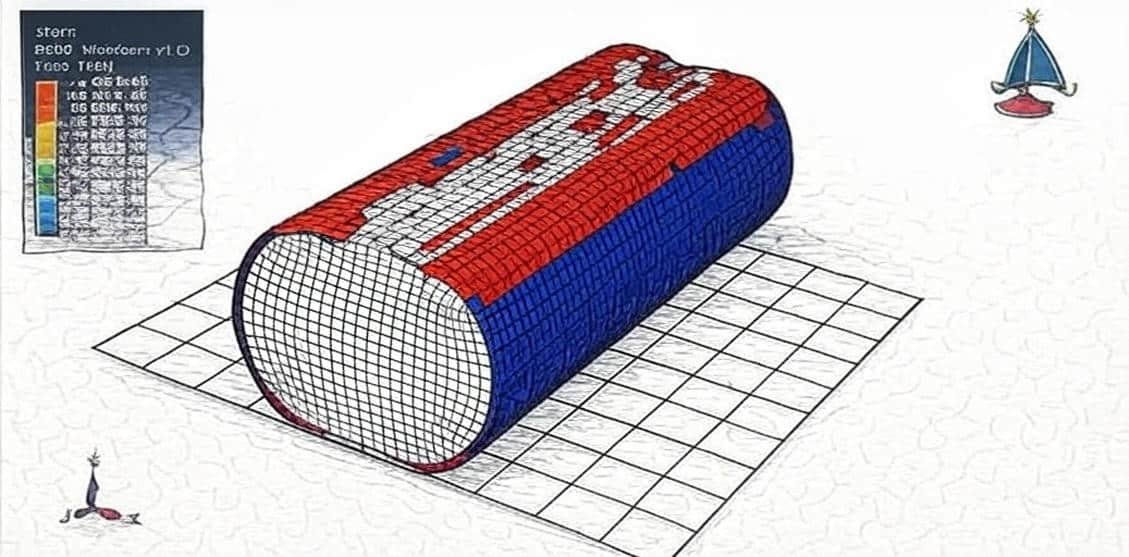

- Crushable foam and porous metal plasticity models for foams.

- Multiscale Modeling

- Micromechanical cell models (RVE – Representative Volume Element).

- Continuum models for large structures.

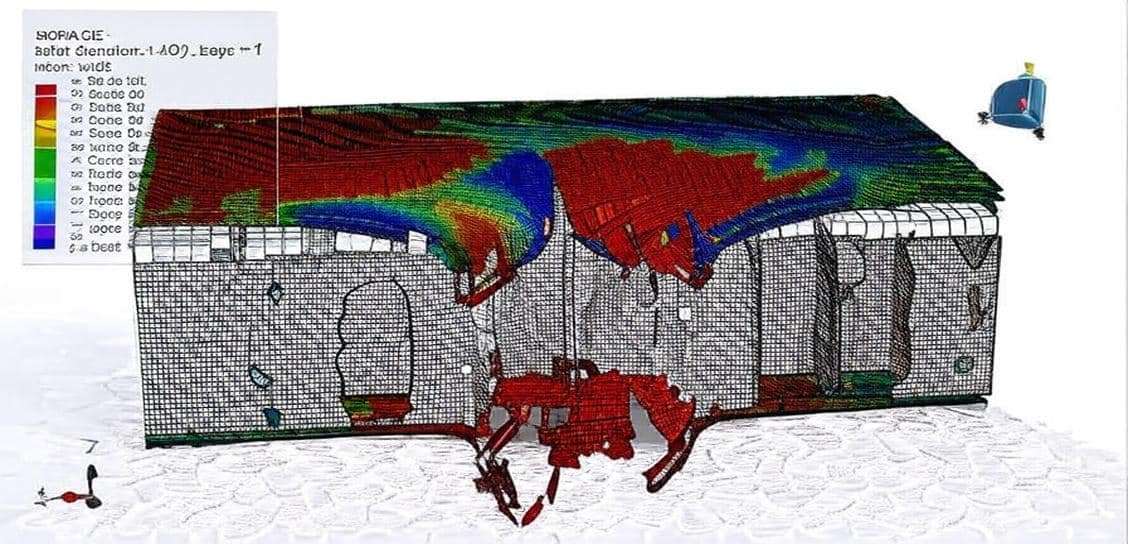

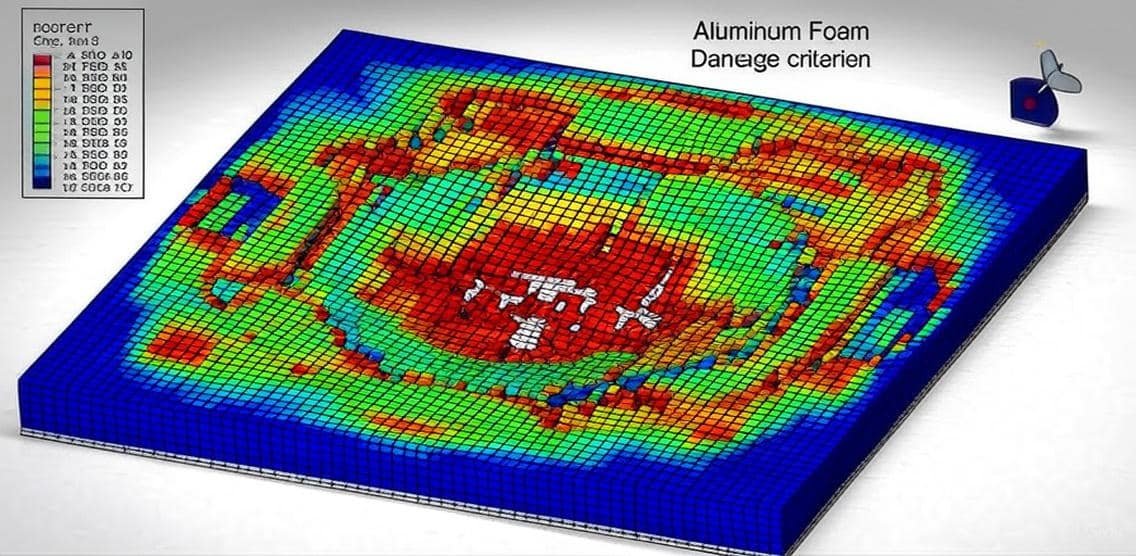

- Failure and Damage Analysis

- Progressive collapse in foams.

- Crack propagation in polymer-foam composites.

- Applications

- Impact/Crashworthiness simulations.

- Thermal insulation and heat transfer analysis.

- Lightweight structural component design.

5. Applications in Industry

- Automotive: Crash absorbers, lightweight panels.

- Aerospace: High-strength-to-weight ratio components.

- Biomedical: Porous implants mimicking bone structure.

- Energy: Heat exchangers, battery casings, and hydrogen storage.

In summary:

Polymer and metal foam analysis is a critical research and engineering field that aims to understand and predict the complex behavior of these advanced materials. Using simulation tools like Abaqus, engineers can optimize design, reduce experimental costs, and accelerate innovation in lightweight and high-performance structures.