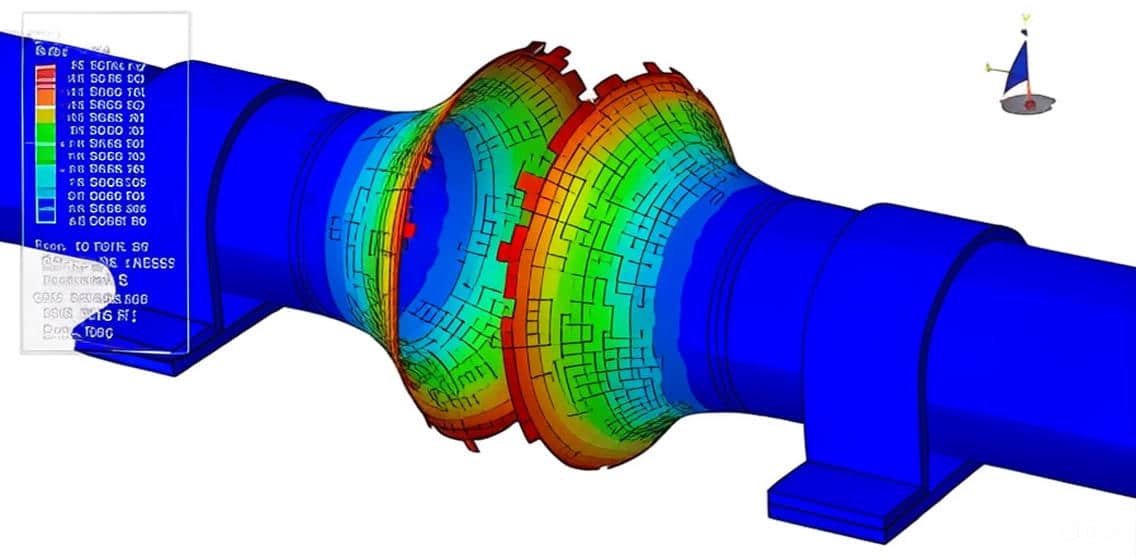

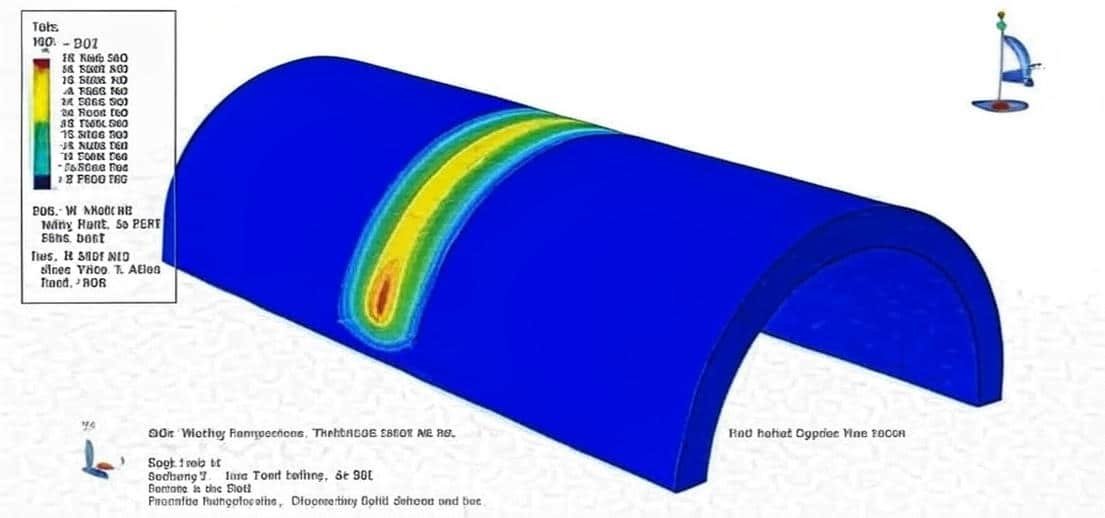

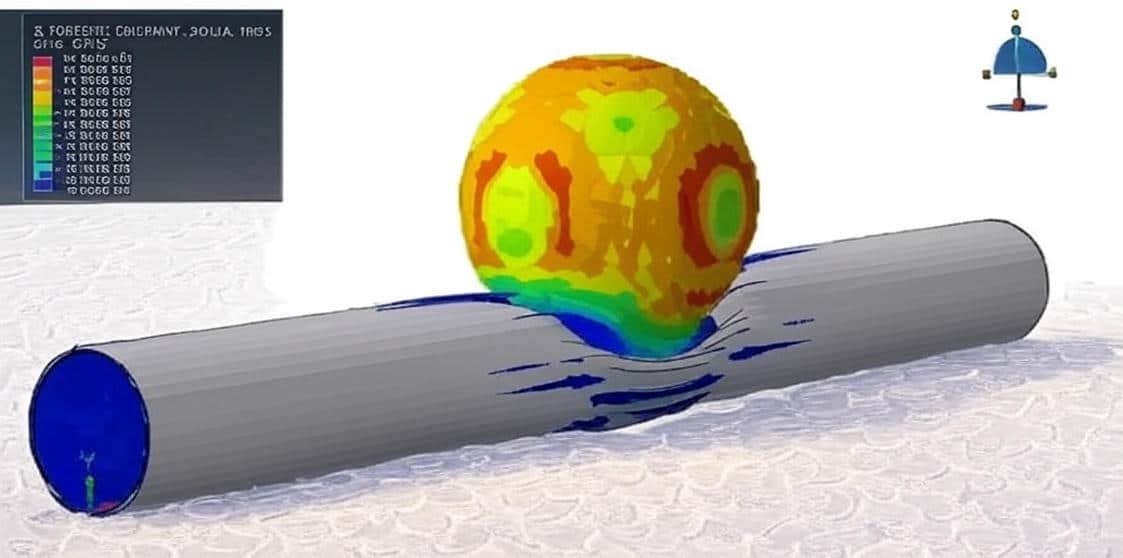

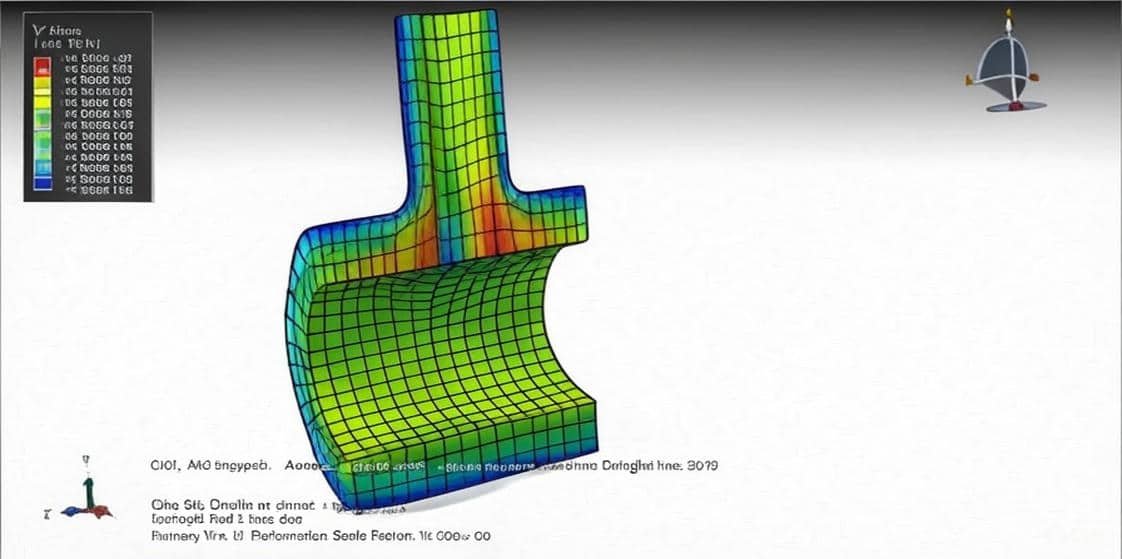

The simulation and analysis of pipes made from various materials—such as steel, aluminum, concrete, and composite materials—play a vital role in modern engineering design, infrastructure development, and industrial applications. By using advanced Finite Element Analysis (FEA) tools like Abaqus, engineers can accurately model, simulate, and predict the behavior of pipes under diverse loading and environmental conditions.

This package includes 21 tutorials that cover all about steel, concrete, aluminum, and concrete pipes. Analysis, including topics such as internal explosion using CONWEP, and the CEL method, corrosion, welding, bending, FRP reinforcement, creep, temperature modeling, explosive welding, impact, cyclic loading, and pipeline.

Pipes are fundamental components in transportation systems for fluids, gases, and slurries, as well as in structural applications such as bridges, tunnels, and offshore platforms. Each material type exhibits unique mechanical properties and performance characteristics:

Steel pipes offer high strength, ductility, and durability, making them ideal for high-pressure and structural applications.

Aluminum pipes are lightweight and corrosion-resistant, suitable for aerospace, marine, and lightweight industrial systems.

Concrete pipes provide rigidity and longevity in civil and infrastructure projects, such as water conveyance and sewage systems.

Composite pipes combine materials (e.g., fiber-reinforced polymers) to achieve a balance of strength, corrosion resistance, and reduced weight.

Using Abaqus’ Pipe simulation Package, engineers can simulate:

Static and dynamic loading conditions

Internal and external pressure effects

Thermal expansion and contraction

Fluid-structure interaction

Buckling, fatigue, and failure modes

Through such simulations, design optimization and performance verification can be achieved before physical prototyping, leading to cost savings, improved safety, and enhanced efficiency. The results enable informed decisions in selecting suitable materials, pipe dimensions, and joining methods for specific engineering applications.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?