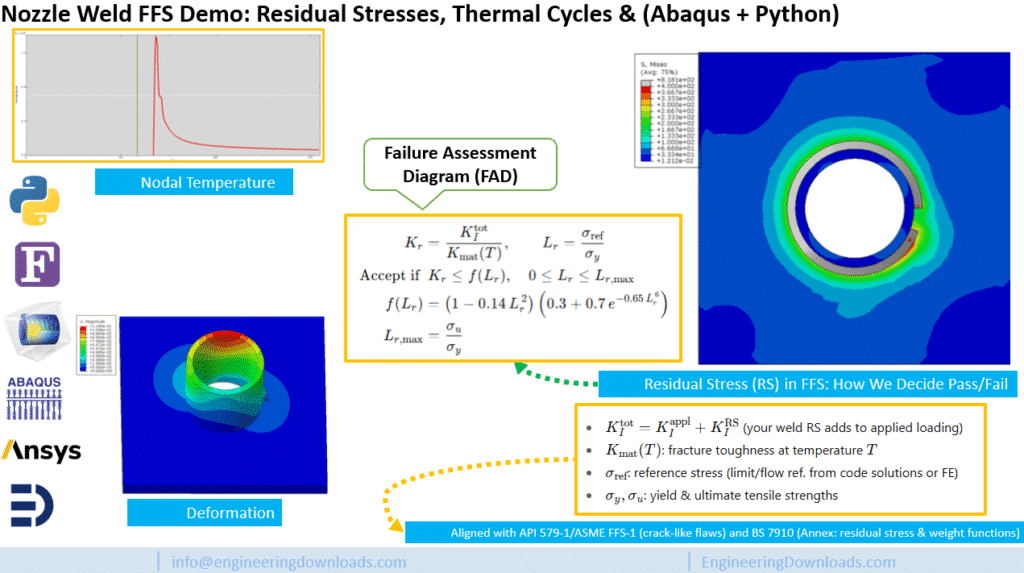

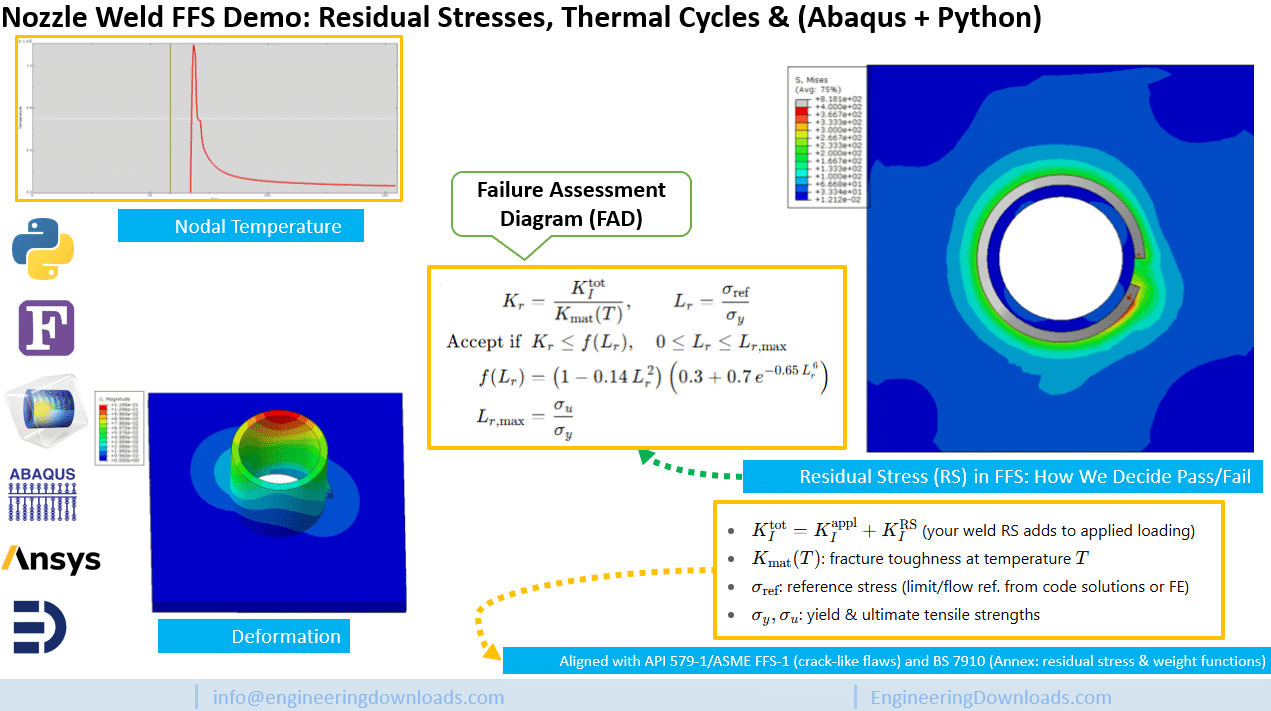

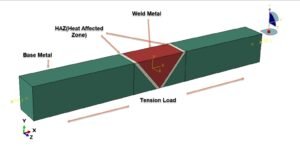

This demo package provides a Python-automated Abaqus model for evaluating welding integrity in nozzle-to-vessel attachments. It includes a full thermal & residual stress simulation with burn-through risk screening and Fitness-for-Service (FFS) analysis using API 579-1/ASME FFS-1 and BS 7910 (FAD Option-1). Perfect for engineers in oil & gas or pressure equipment design, this demo highlights how thermal cycles, residual stresses, and fracture mechanics come together to assess weld integrity.

Key Features

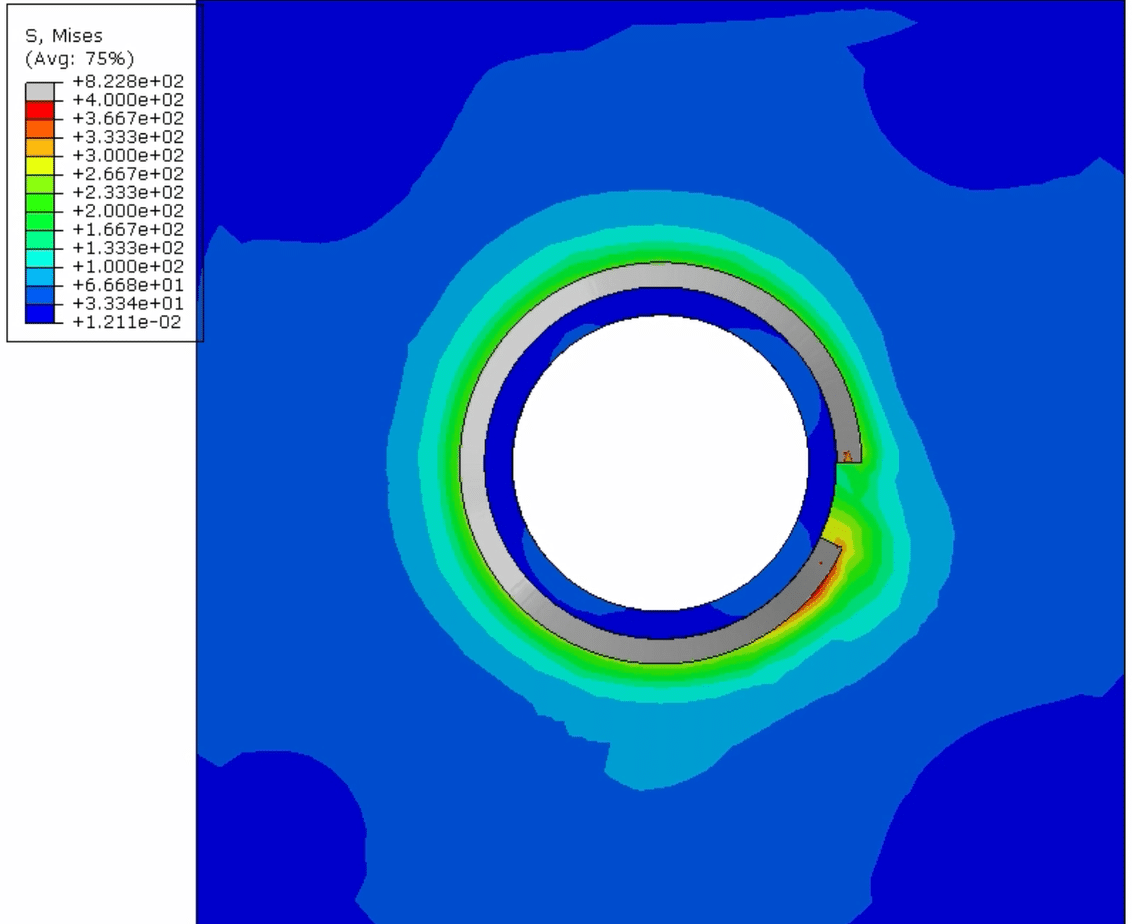

- Residual Stress Simulation:

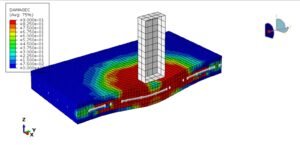

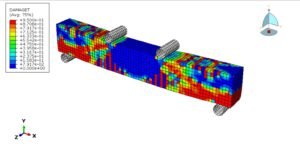

- Hoop & longitudinal stress distributions around the nozzle, based on your welding sequence.

- Thermal Cycle & Burn-Through Screening:

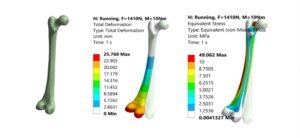

- Nodal temperature history from heat source simulation (nozzle-to-plate weld, transient thermal analysis).

- Temperature-based burn-through risk assessments at critical regions.

- Fitness-for-Service (FFS) Analysis:

- Uses the FAD (Failure Assessment Diagram) to assess weld integrity.

- Includes residual stress contribution in the (K_I^{\mathrm{tot}}) (combined applied + RS stress) for failure prediction.

- Validated against API 579-1/ASME FFS-1 and BS 7910.

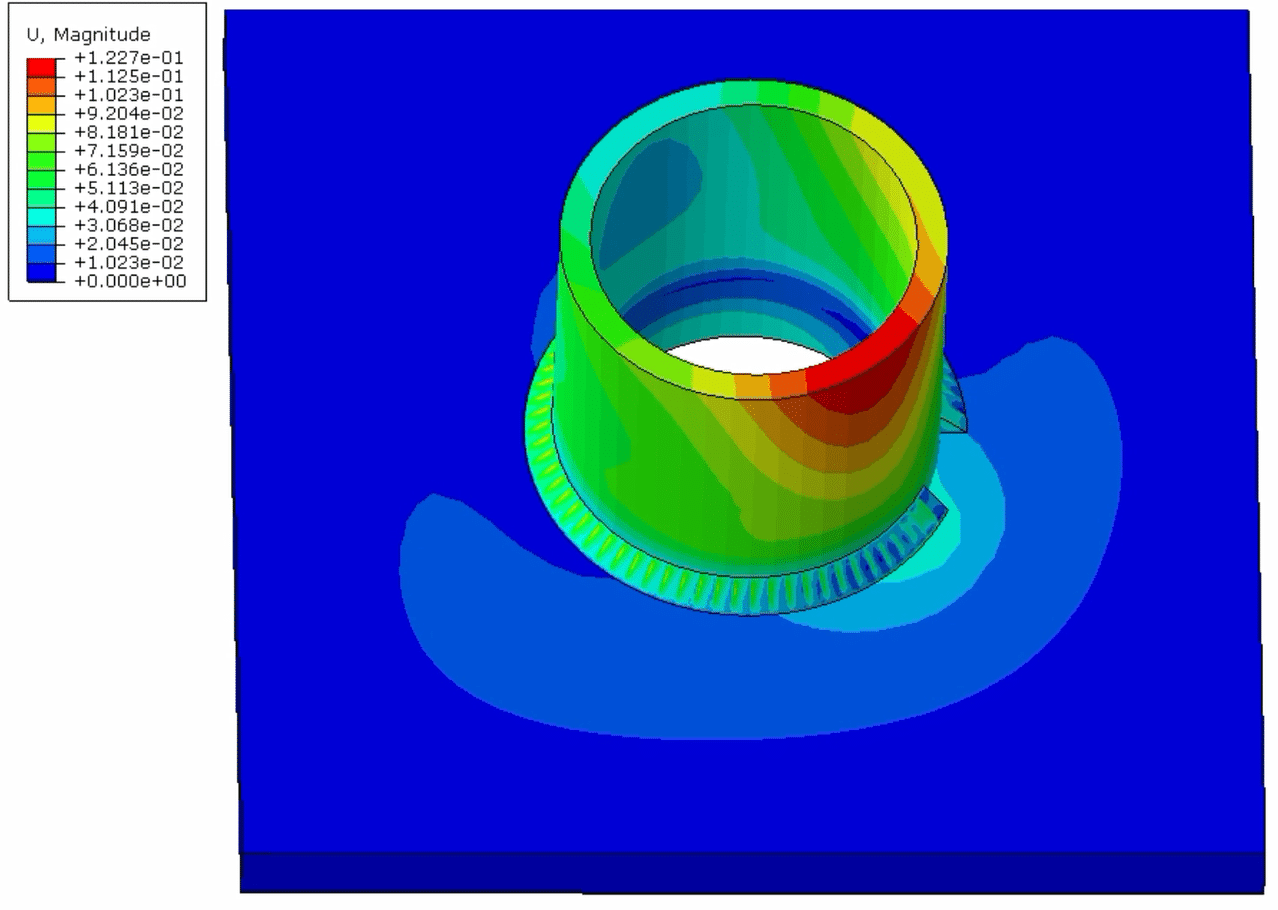

- Fully Automatable in Abaqus + Python:

- Stepwise model change (activation/deactivation) for weld pass sequencing.

- Heat flux activation based on user-defined welding parameters (current, voltage, speed).

- Complete control over simulation parameters via Python scripting.

- Ready for Customization:

- Easily swap geometry, material properties, welding sequences, and welding heat input.

- Code available for tailoring to your specific weld design (nozzle-to-shell, pipe-to-pipe, etc.).

What’s Included

- Abaqus Model:

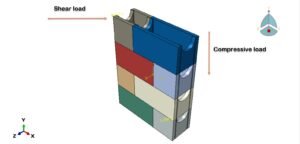

- Full CAE file for nozzle-to-vessel weld simulation.

- INP export ready for job submission.

- Python Scripts:

- Heat flux activation and deactivation.

- ModelChange automation for multi-pass welding sequences.

- Residual stress post-processing and FAD assessment.

- Post-Processing Results:

- Residual stress maps (hoop/longitudinal) for stress analysis.

- Temperature history for burn-through screening.

- Deformation contours for weld distortion.

Applications

- Weld Integrity Evaluation:

- Assess burn-through risk in thin-walled welds.

- Study residual stress impact on weld fatigue and brittle fracture.

- Pressure Equipment Design:

- Use this simulation to check nozzle-to-vessel welds, pipe connections, and more.

- Evaluate code acceptance based on real simulation data.

- Training & Education:

- This demo is great for students and engineers to explore welding simulations and FFS methods used in industry.

- Detailed documentation on code standards (API 579, ASME FFS-1, BS 7910) for further study.

Why This Model Matters

This Abaqus/Python-based model allows you to go beyond generic residual stress estimates and simulate real-world welding scenarios.

- Unlike standard code profiles, this demo uses your real welding conditions (geometry, sequence, heat input).

- It directly connects thermal + residual stress data to FFS acceptance with the FAD method.

- Use it to de-risk welding decisions, optimize PWHT, and avoid costly over-designs in pressure vessel welding.

Requirements

- Abaqus/CAE (2014 or later recommended)

- Python (Abaqus scripting)

- Optional: Fortran compiler if you plan to switch to DFLUX heat source later

License & Use

- Personal & internal use: Ready for educational and industrial purposes.

- Customization & consulting: Reach out for help to adapt this demo to your specific welding geometry and conditions.

Call to Action

Download the demo and start exploring residual stress, thermal cycles, and FFS checks today

Visit EngineeringDownloads.com or Contact us for customized support.