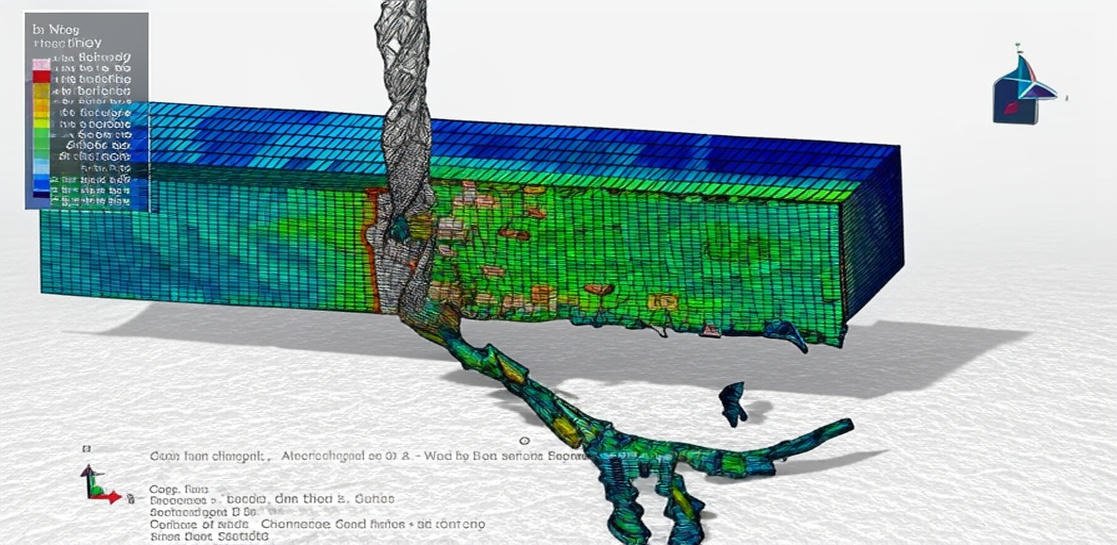

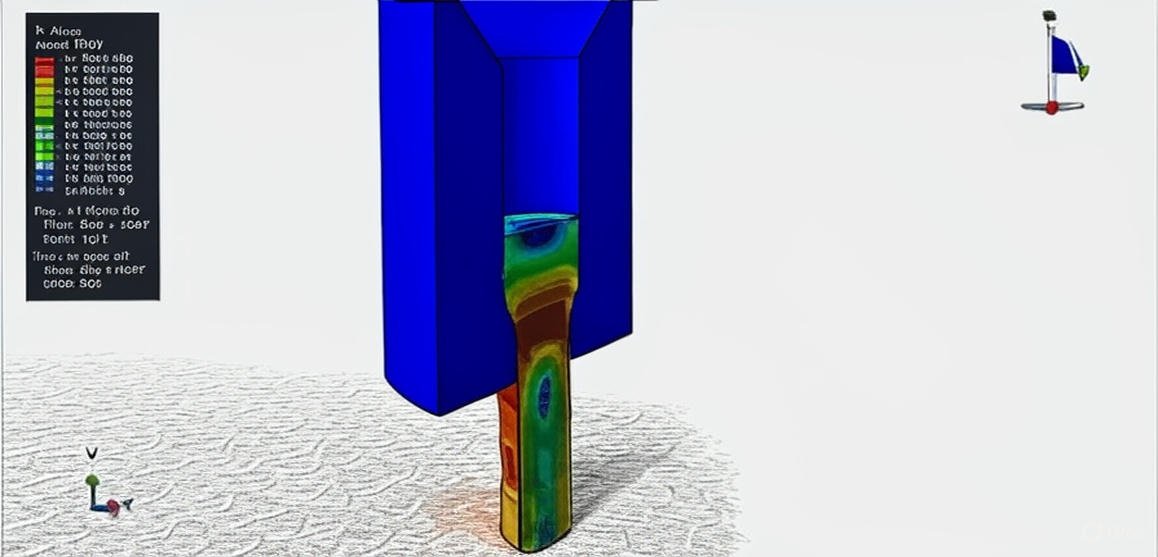

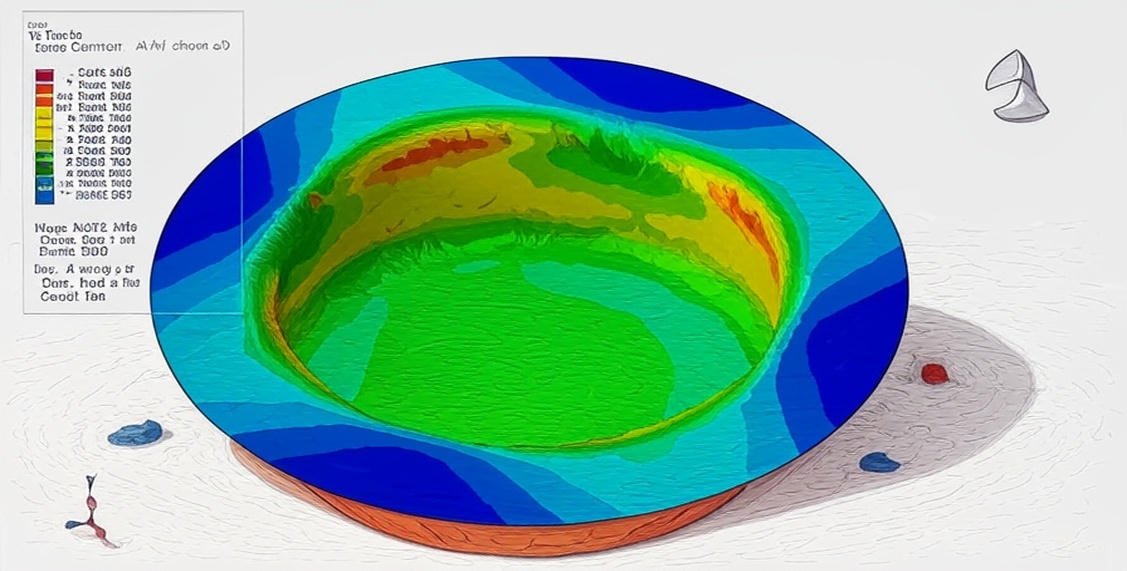

Metal forming is a key manufacturing process where metal is plastically deformed into a desired shape without material removal. Instead of cutting, material is reshaped by applying external forces through tools such as dies, punches, and rollers. Common metal forming processes include forging, extrusion, rolling, drawing, bending, drilling, composite forming, waterjet cutting, and stamping.

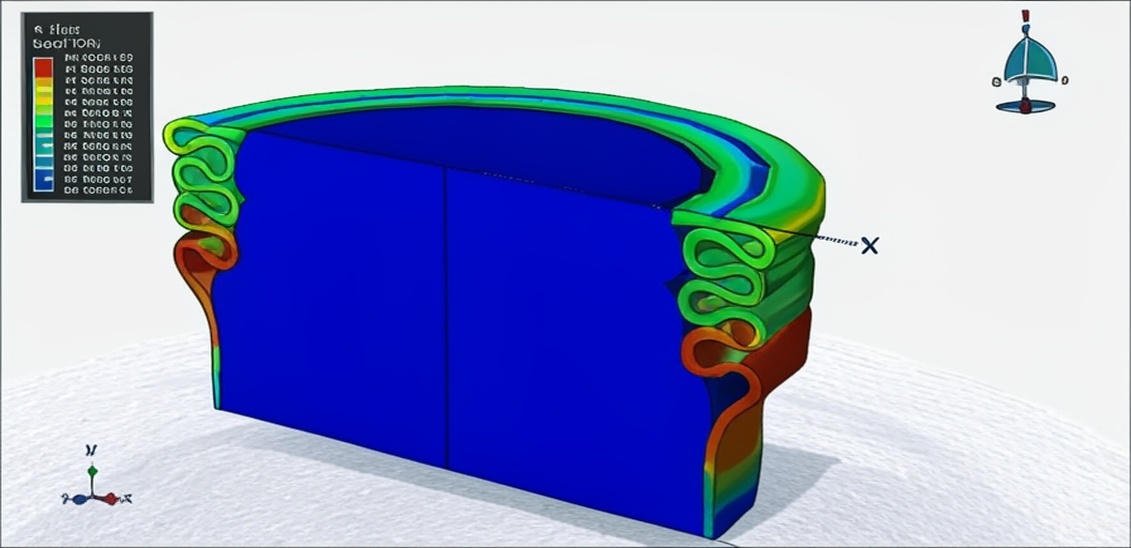

To design these processes efficiently and predict outcomes, engineers use metal forming analysis. This analysis applies engineering principles and computational simulations to understand how metals behave during deformation.

This package includes 15 tutorials that cover all that you need to know about the forming process in Abaqus.

With modern Finite Element Analysis (FEA) tools like Abaqus, engineers can create detailed simulations of forming processes. These simulations help to:

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?