JH2 and JHB

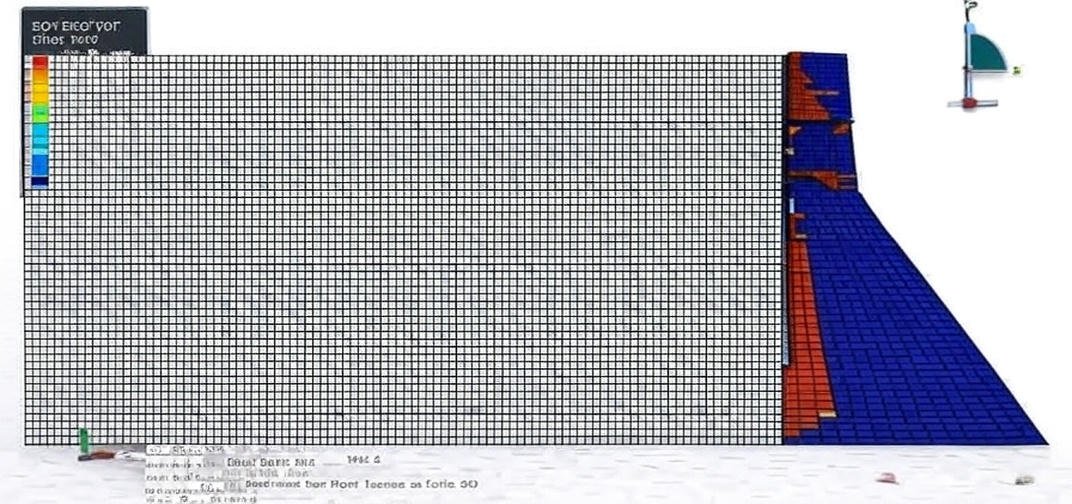

JH2 (Johnson Holmquist II) and JHB (Johnson Holmquist Beissel) material models. These are specialized constitutive models used in computational mechanics (often in hydrocode simulations like ABAQUS, LS-DYNA, AUTODYN, CTH, etc.) for representing the response of brittle materials (e.g., ceramics, glass, rocks, concrete) under large strains, high strain rates, and high pressures.

This package includes 12 tutorials that cover all about JH2 and JHB material model for rock, glass, ice, concrete, and ceramic.

1. Background

- Traditional material models often fail to capture the behavior of brittle materials under impact, penetration, or blast loading.

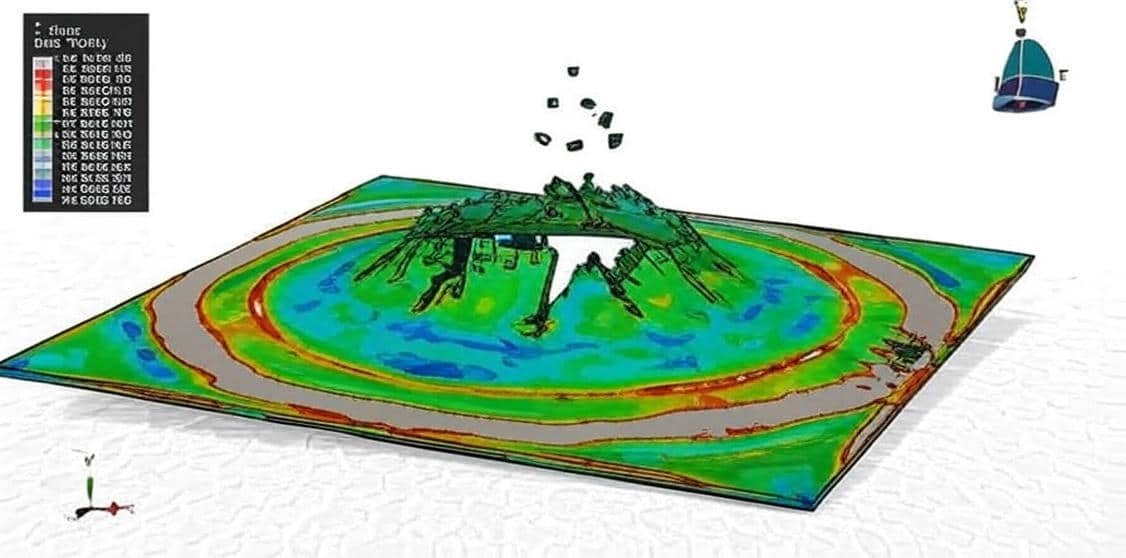

- Brittle solids show elastic behavior up to failure, followed by damage accumulation, fracture, and eventually granular flow when fully comminuted.

- The Johnson–Holmquist family of models was developed to capture this in numerical simulations.

2. JH-2 (Johnson–Holmquist II) Model

- Developed as an improvement over the earlier JH-1 model.

- Designed for ceramics and similar brittle solids.

- Key features:

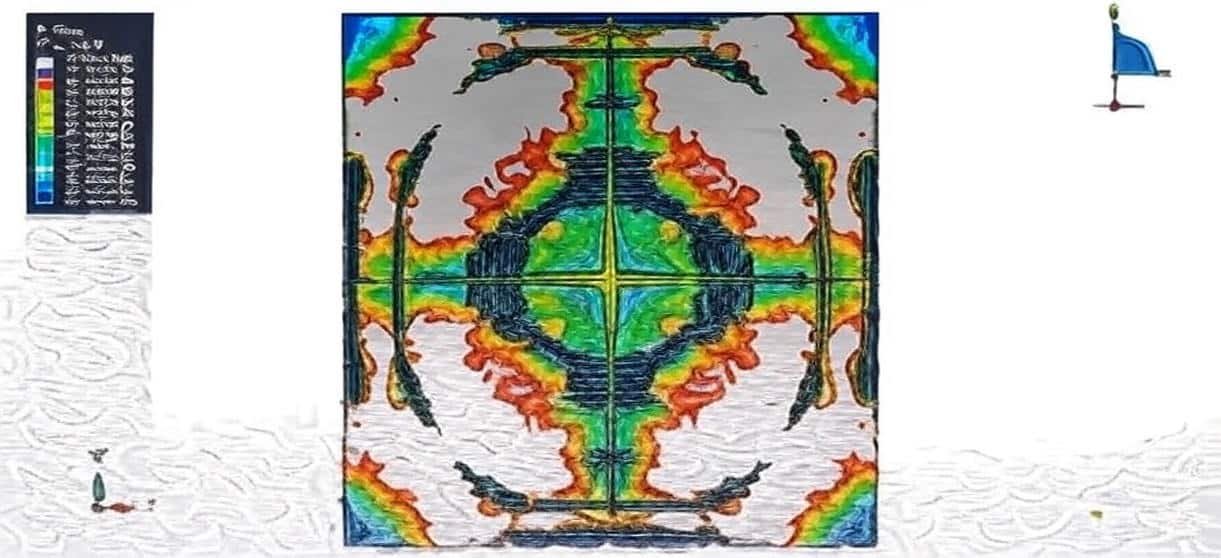

- Pressure- and strain-rate–dependent strength.

- Damage accumulation based on plastic strain.

- A smooth transition from intact material behavior to fully fractured (damaged) behavior.

- Fractured material is modeled with a reduced strength that still depends on pressure.

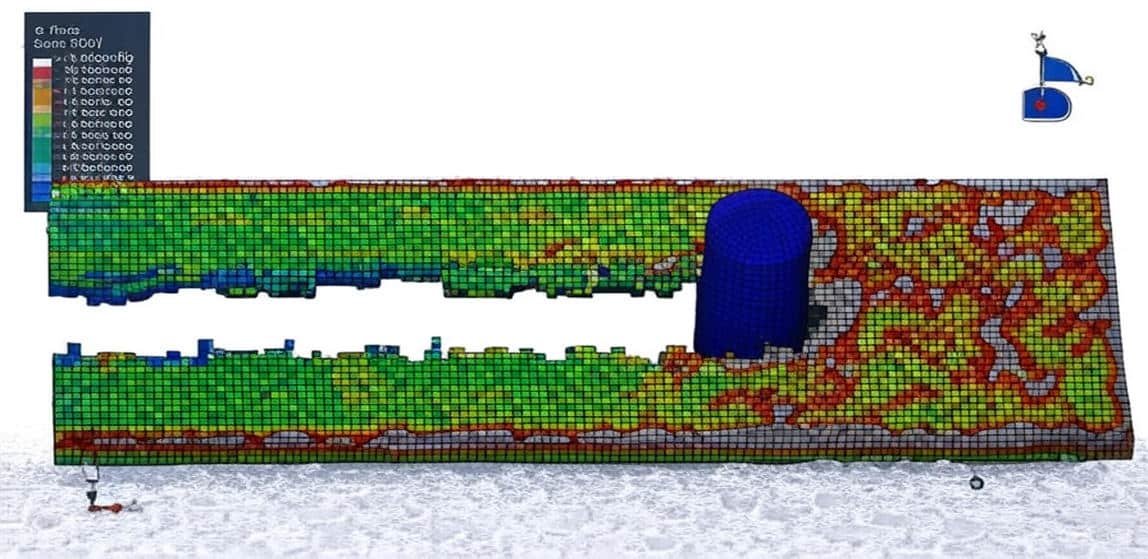

- Equation of state (EOS) governs the pressure–volume response, allowing for shock compression.

Applications:

- Ballistic impact on ceramic armor.

- Penetration mechanics.

- Blast response of brittle materials.

3. JHB (Johnson–Holmquist–Beissel) Model

- An extension and refinement of JH-2, created to address limitations and add flexibility.

- Sometimes called the JH-2 Beissel model.

- Enhancements over JH-2:

- More robust treatment of damage evolution.

- Improved high-pressure response and failure modeling.

- Often includes optional features like strain-rate softening or more sophisticated EOS formulations.

- Provides better numerical stability in certain codes (e.g., AUTODYN).

4. General Model Structure

Both JH-2 and JHB share the same conceptual foundation:

- Equation of State (EOS): Defines volumetric response under compression and tension.

- Strength Model: Provides pressure- and strain-rate–dependent deviatoric strength for intact and fractured states.

- Damage Evolution: Scalar damage parameter (0 = intact, 1 = fully damaged) that blends intact and fractured strengths.

- Failure Surface: Defines conditions where cracking and granular flow dominate.

Summary: