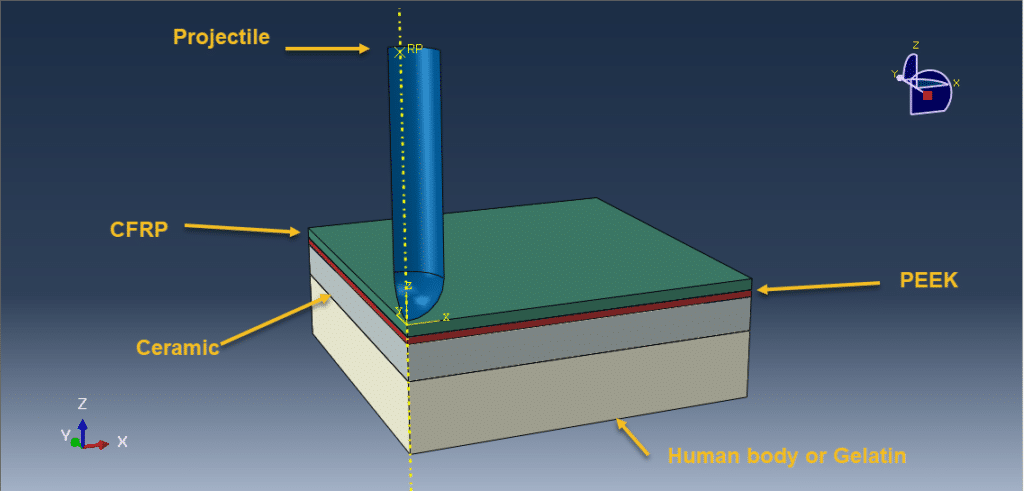

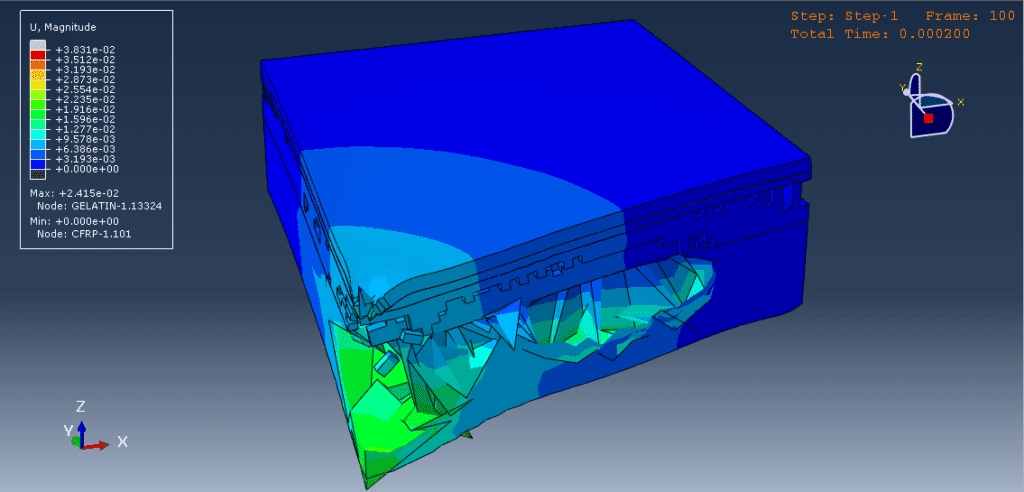

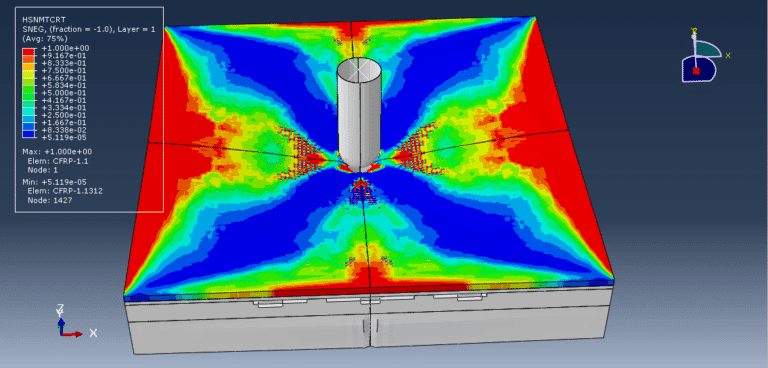

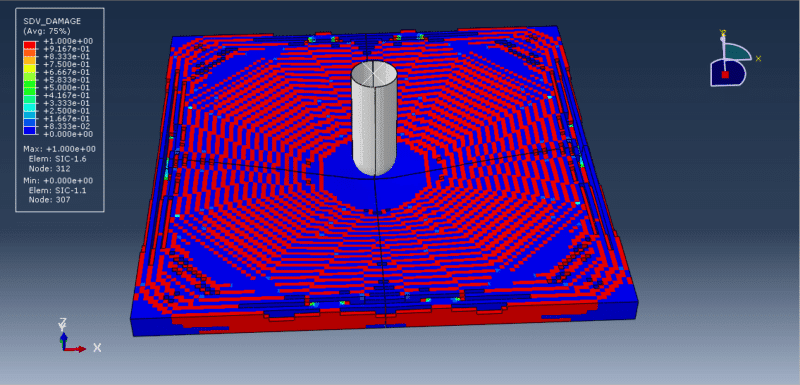

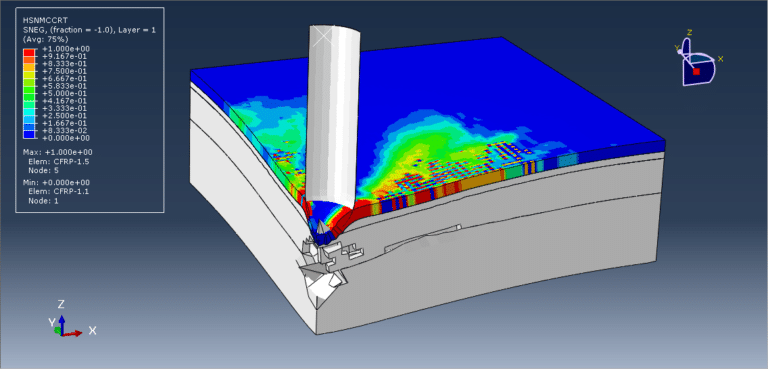

In this tutorial, the impact analysis of a CFRP/PEEK/ceramic/gelatin composite panel for evaluating behind-armor trauma (BAT) has been carried out in Abaqus. The carbon fiber reinforced polymer (CFRP) is modeled as a three-dimensional shell part with elastic layers and Hashin’s damage criterion to capture its failure behavior. A thin polyether-ether-ketone (PEEK) layer is modeled as a solid plate on the surface to protect the underlying layers, while silicon carbide (SiC) ceramic is modeled as a three-dimensional solid core, and gelatin, representing human tissue, is modeled as a three-dimensional solid back plate. The projectile is modeled as a rigid body. Ceramic-based armor systems are designed to prevent penetration and dissipate impact energy, and in this study, the total linear momentum transferred to the wearer is used as a measure of behind-armor blunt trauma (BABT). The SiC ceramic is represented using the Johnson-Holmquist (JH-2) model, which accounts for its hardness, compressive strength, brittleness in tension, and progressive damage under high-speed impact, with applications including bulletproof vests and car brakes. The PEEK layer is modeled with the Johnson-Cook hardening and damage formulation, and gelatin is defined as an elastic-plastic material with an equation of state to represent tissue behavior. All materials are assumed to be homogeneous and isotropic, and the PEEK layer is bonded to the ceramic to assess momentum transfer. The analysis is conducted using a dynamic explicit step with a defined time increment. Perfect contact is assumed between the composite layers, while surface-to-surface contact with frictional properties is applied between the projectile and the CFRP front surface. Symmetry boundary conditions are applied to the panel, and the projectile is assigned an initial velocity. A sufficiently fine mesh is used to ensure accurate results. After the simulation, detailed outputs including stress, strain, displacement, damage, failure, penetration, and related responses are obtained for evaluation.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?