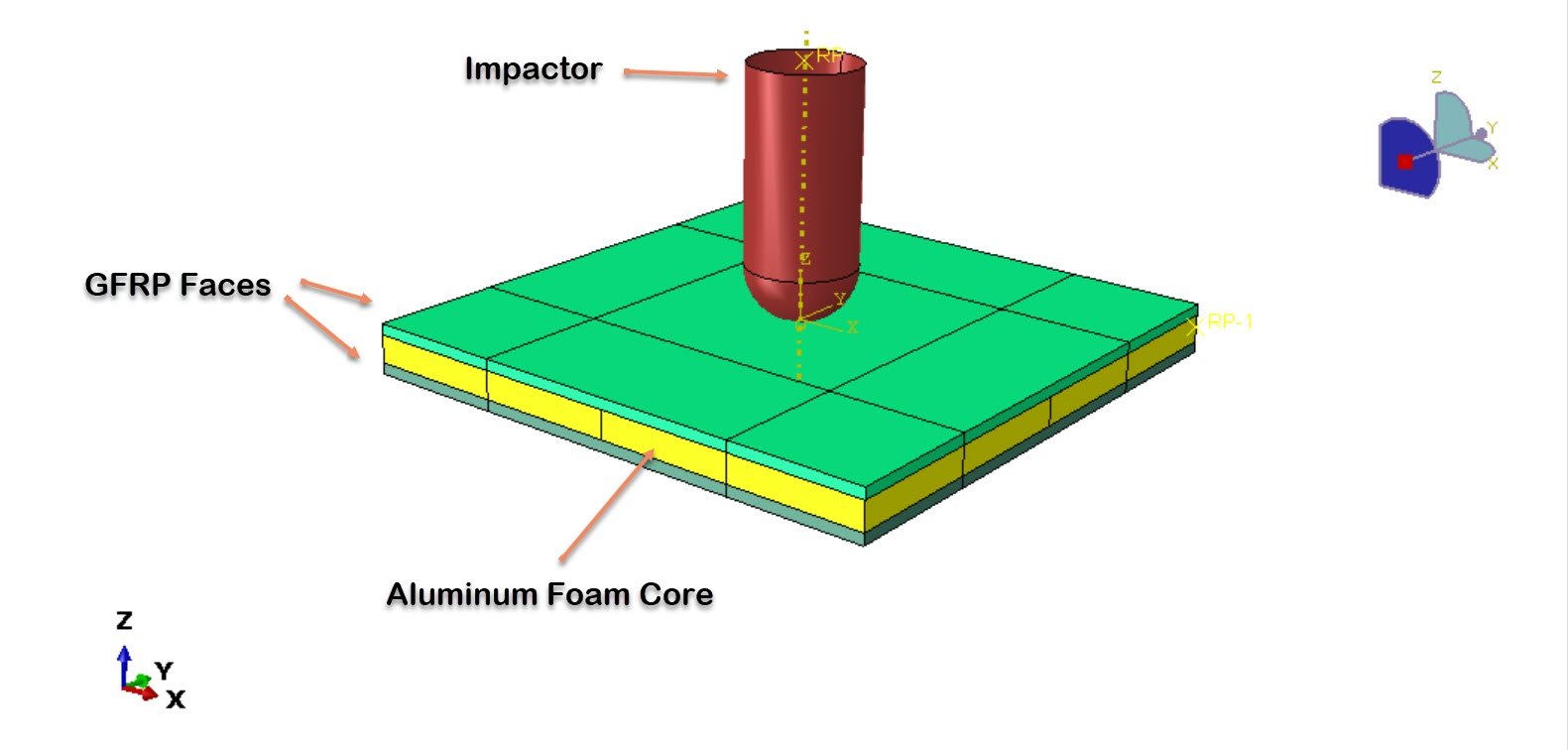

Composite sandwich panels are widely used in aerospace, automotive, marine, and protective structures due to their exceptional stiffness-to-weight ratio, energy absorption capability, and structural efficiency. A typical sandwich configuration consists of two high-strength face sheets bonded to a lightweight core, enabling the panel to carry bending loads efficiently while minimizing mass. Among various material combinations, glass fiber-reinforced polymer (GFRP) face sheets combined with an aluminum foam core have attracted considerable attention for impact-resistant applications because they provide a balanced combination of strength, ductility, and cost-effectiveness.

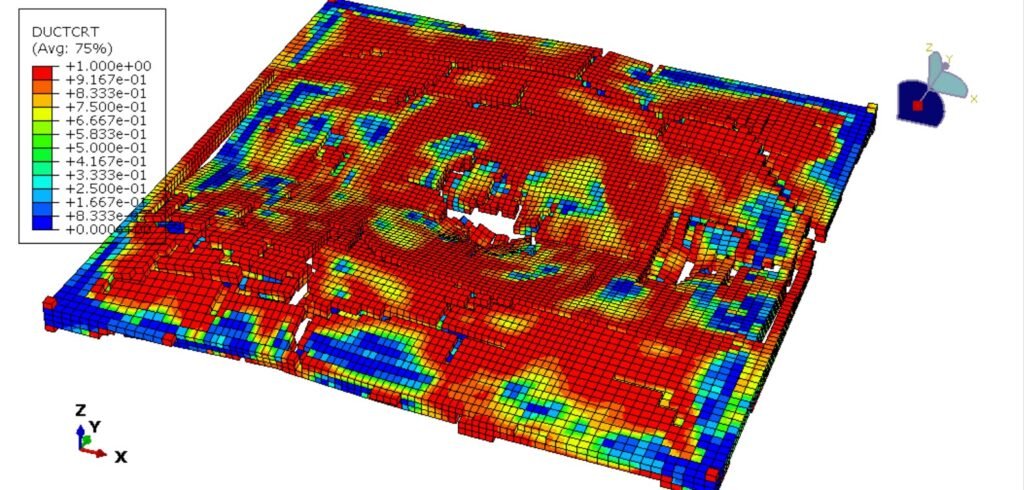

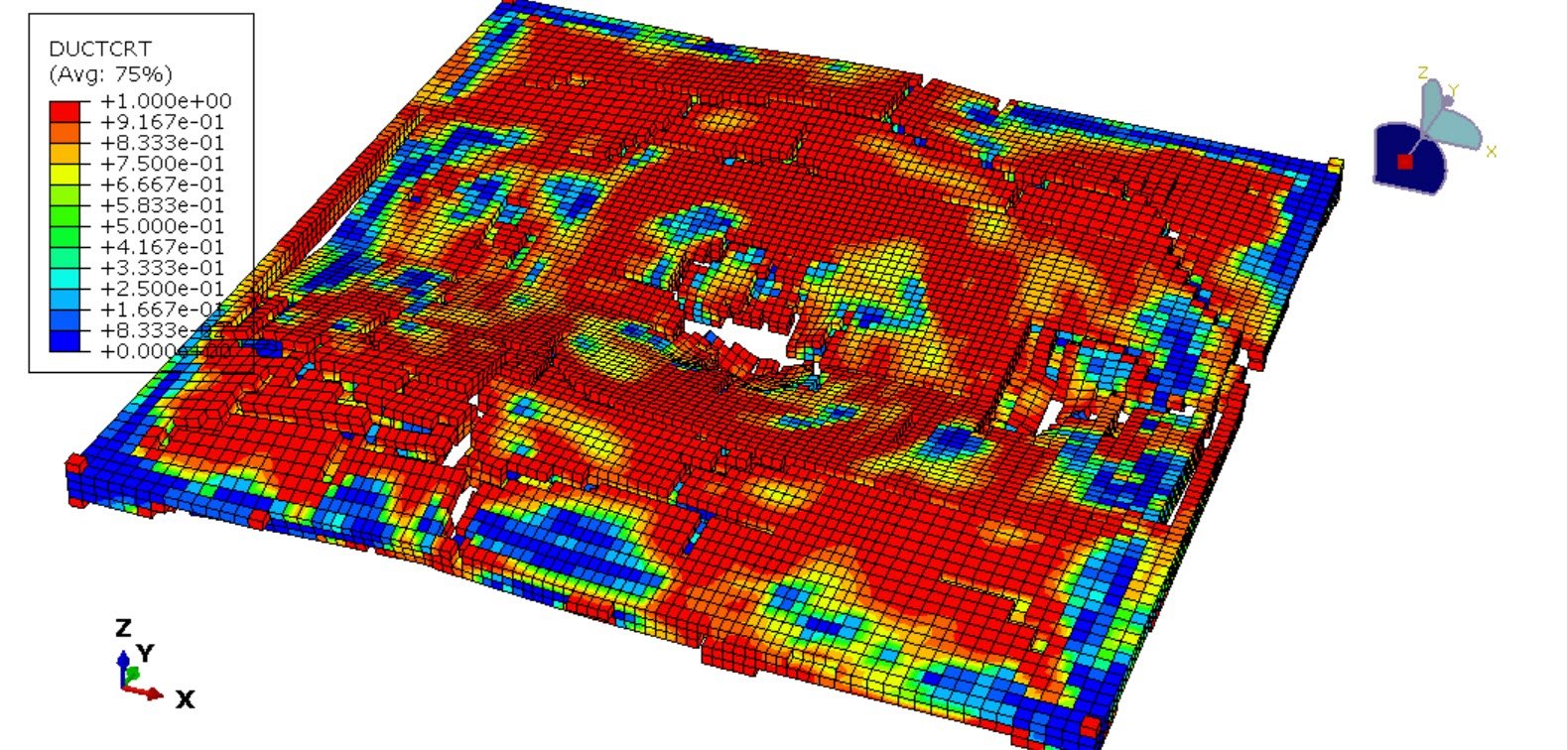

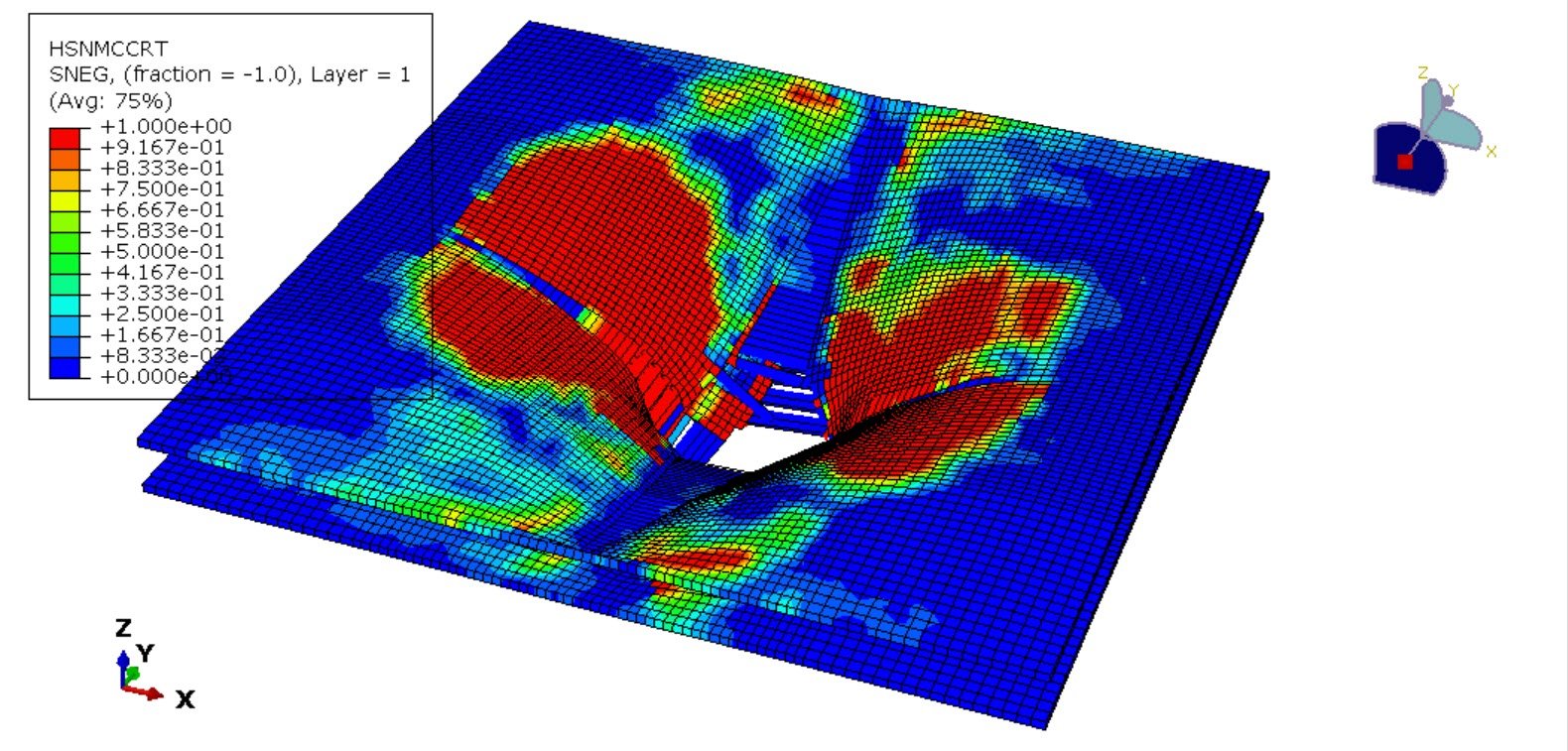

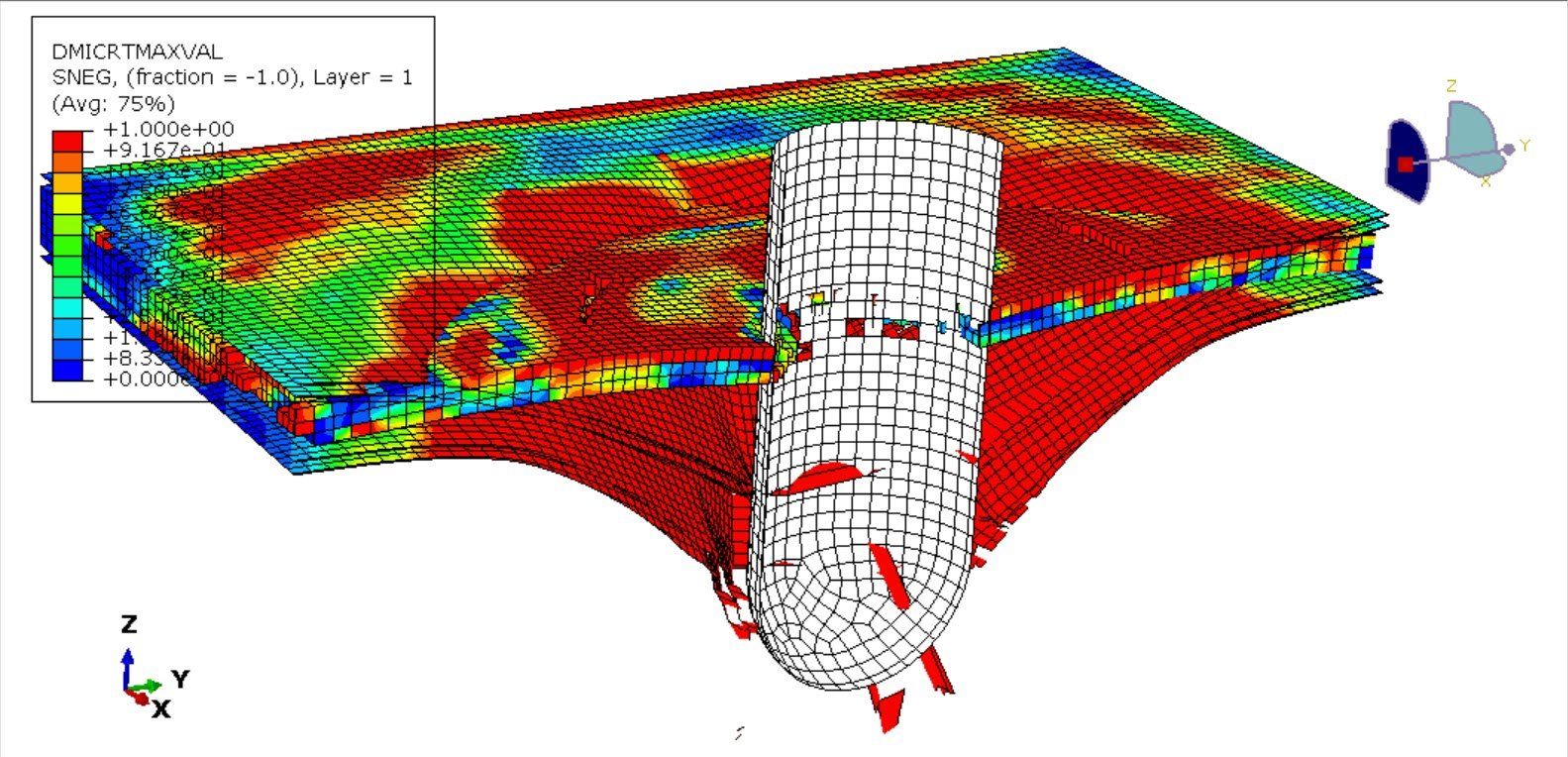

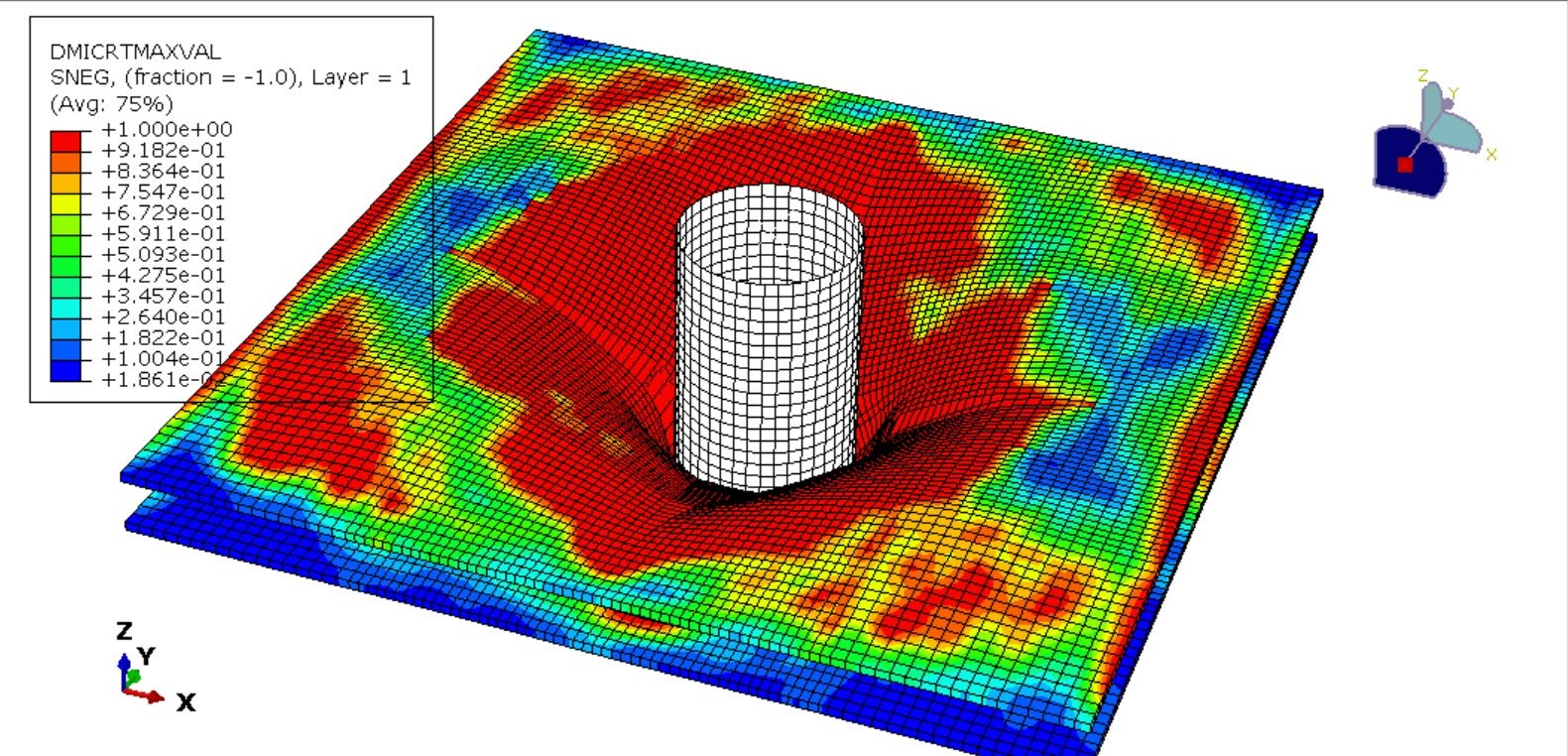

In this example, the aluminum foam core is modeled as a three-dimensional solid using an elastic–crushable foam hardening model in conjunction with a ductile damage criterion. The two GFRP face sheets are modeled as three-dimensional shell elements with multiple laminate layers. The Hashin damage failure criterion is employed to capture the progressive failure of the GFRP laminates under impact loading. A dynamic explicit analysis step, along with appropriate interactions, loading conditions, and mesh definitions, is adopted.

High-velocity impact (HVI), generally characterized by impact velocities exceeding 100 m/s, represents a critical loading scenario for sandwich structures. Such impacts may occur due to foreign object debris, ballistic threats, or high-speed tool or fragment strikes. Under these conditions, the structural response is dominated by stress wave propagation, localized material failure, and severe nonlinear deformation, making experimental investigation alone costly and challenging. Consequently, numerical analysis and simulation have become essential tools for understanding impact mechanisms and predicting damage evolution in sandwich panels.

When subjected to high-velocity impact, GFRP face sheets primarily experience fiber breakage, matrix cracking, and delamination, while the aluminum foam core undergoes progressive crushing, plastic deformation, and densification. The interaction between the face sheets and the foam core plays a critical role in energy dissipation and load transfer. Accurate modeling of this interaction requires advanced material constitutive laws capable of capturing strain-rate sensitivity, damage initiation, and failure progression in both composite and metallic foam materials.

Finite element (FE) methods, particularly explicit dynamic solvers such as LS-DYNA and ABAQUS/Explicit, are commonly employed to simulate high-velocity impact events. These simulations typically incorporate orthotropic damage models for GFRP face sheets and crushable foam models for the aluminum core, along with appropriate contact and cohesive zone formulations to represent face-core debonding. Validation of numerical results through experimental data remains essential to ensure predictive accuracy.

The objective of high-velocity impact analysis on GFRP–aluminum foam sandwich panels is to evaluate key performance metrics such as penetration resistance, residual velocity, energy absorption, and damage extent. Understanding these responses supports the optimization of panel configurations, material selection, and thickness distribution for enhanced impact resistance. As lightweight protective structures continue to gain importance, reliable simulation frameworks are indispensable for reducing development costs and improving structural safety under extreme loading conditions.

Ansys

€129,00

Abaqus

€79,00 €38,00

Abaqus

€78,00 €37,00

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

See more

Want to receive push notifications for all major on-site activities?