Flat slabs are widely used in reinforced concrete structures due to their architectural flexibility, reduced story height, and simplified formwork. However, one of the most critical limit states governing their design is punching shear failure at slab–column connections. This type of failure is typically brittle, occurs with little warning, and can lead to progressive collapse if not adequately prevented. Therefore, enhancing the punching capacity and ductility of flat slabs remains a key research and design priority.

Traditional reinforced concrete flat slabs made with normal concrete (NC) rely on flexural reinforcement and, in some cases, shear reinforcement (stud rails, stirrups, shear heads) to resist punching. Despite these measures, stress concentrations around the column region often lead to diagonal cracking, stiffness degradation, and eventual punching failure. The inherent low tensile strength and limited fracture energy of NC further contribute to the sudden nature of this failure mode.

To address these limitations, recent research has explored the use of Ultra-High-Performance Fiber-Reinforced Concrete (UHPFRC) in critical regions of flat slabs. UHPFRC is characterized by:

Very high compressive strength (>150 MPa typical)

Enhanced tensile strength due to steel fibers

Strain-hardening behavior in tension

Superior fracture energy and crack-bridging capacity

Improved durability and bond performance

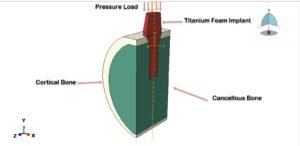

Rather than casting the entire slab with UHPFRC—which is costly and may be unnecessary—rational use involves placing UHPFRC only in the high-stress zone around the column. This hybrid system aims to:

Increase punching shear resistance

Delay crack initiation and propagation

Improve post-cracking ductility

Enhance energy absorption capacity

Optimize material cost versus structural performance

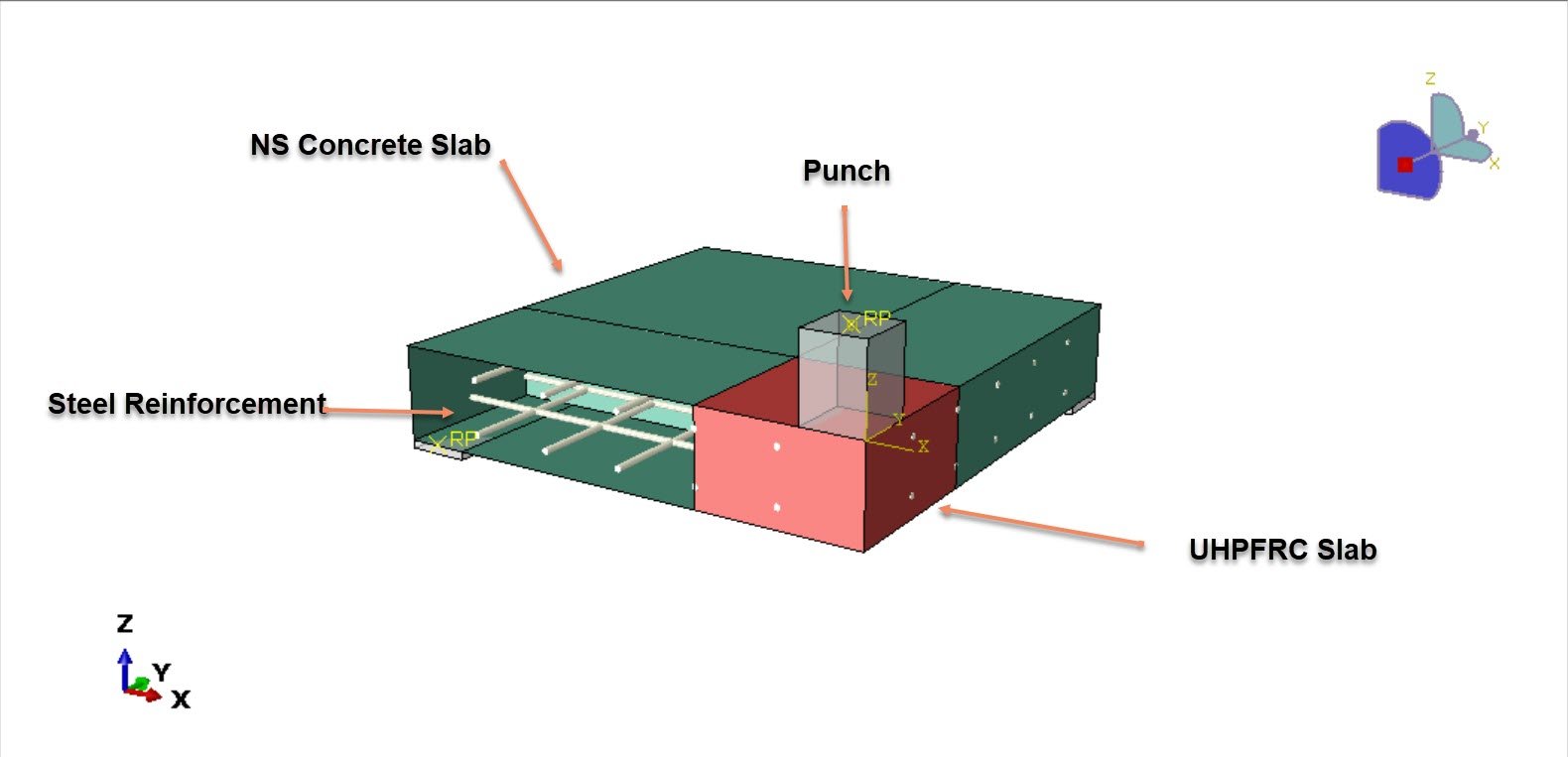

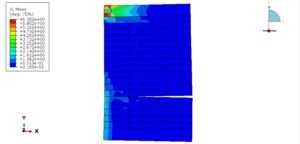

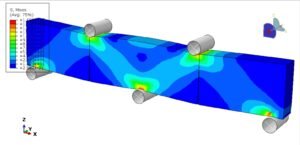

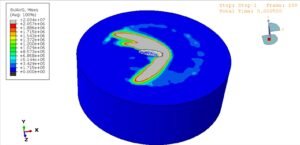

In this study, the structural behavior and punching capacity of flat slabs incorporating a localized UHPFRC zone were investigated using the finite element software Abaqus.

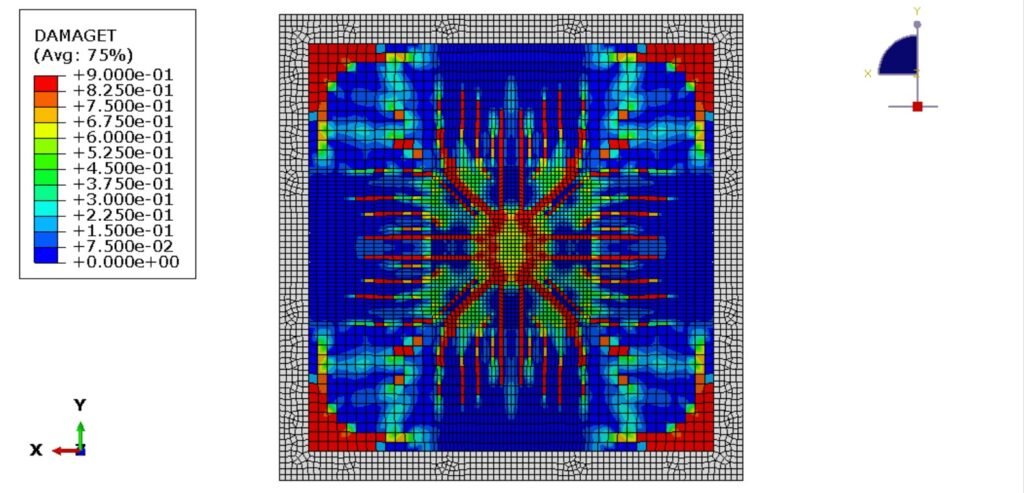

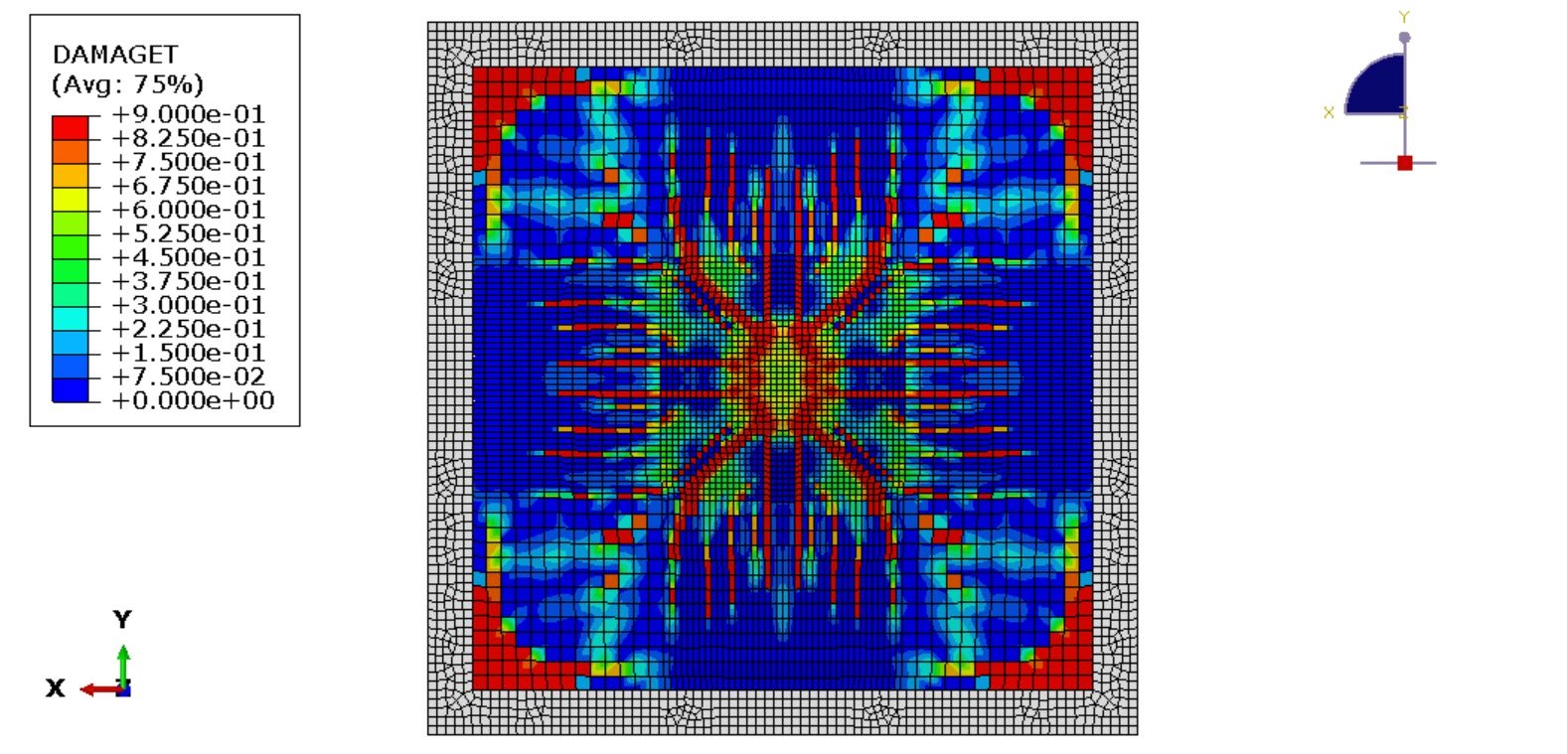

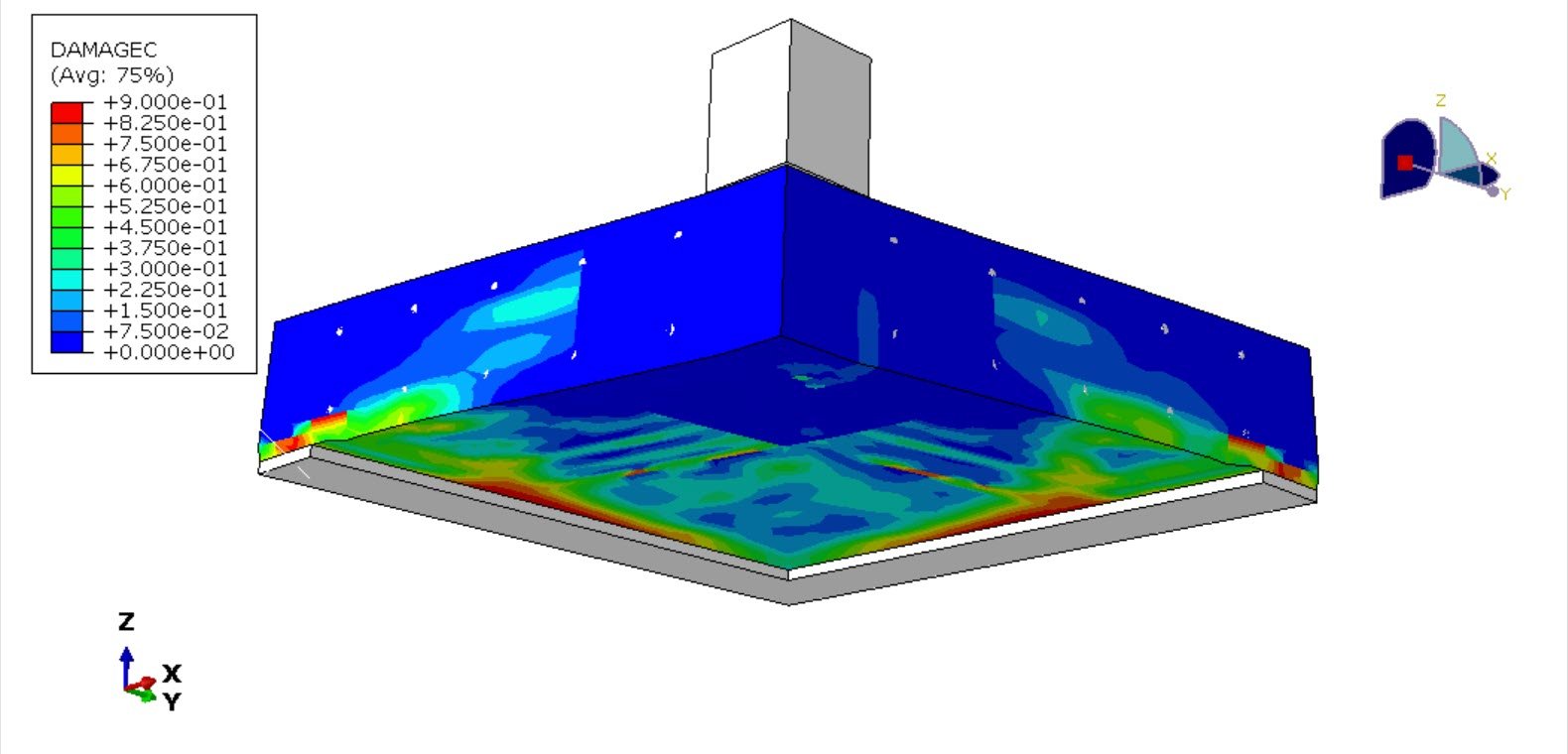

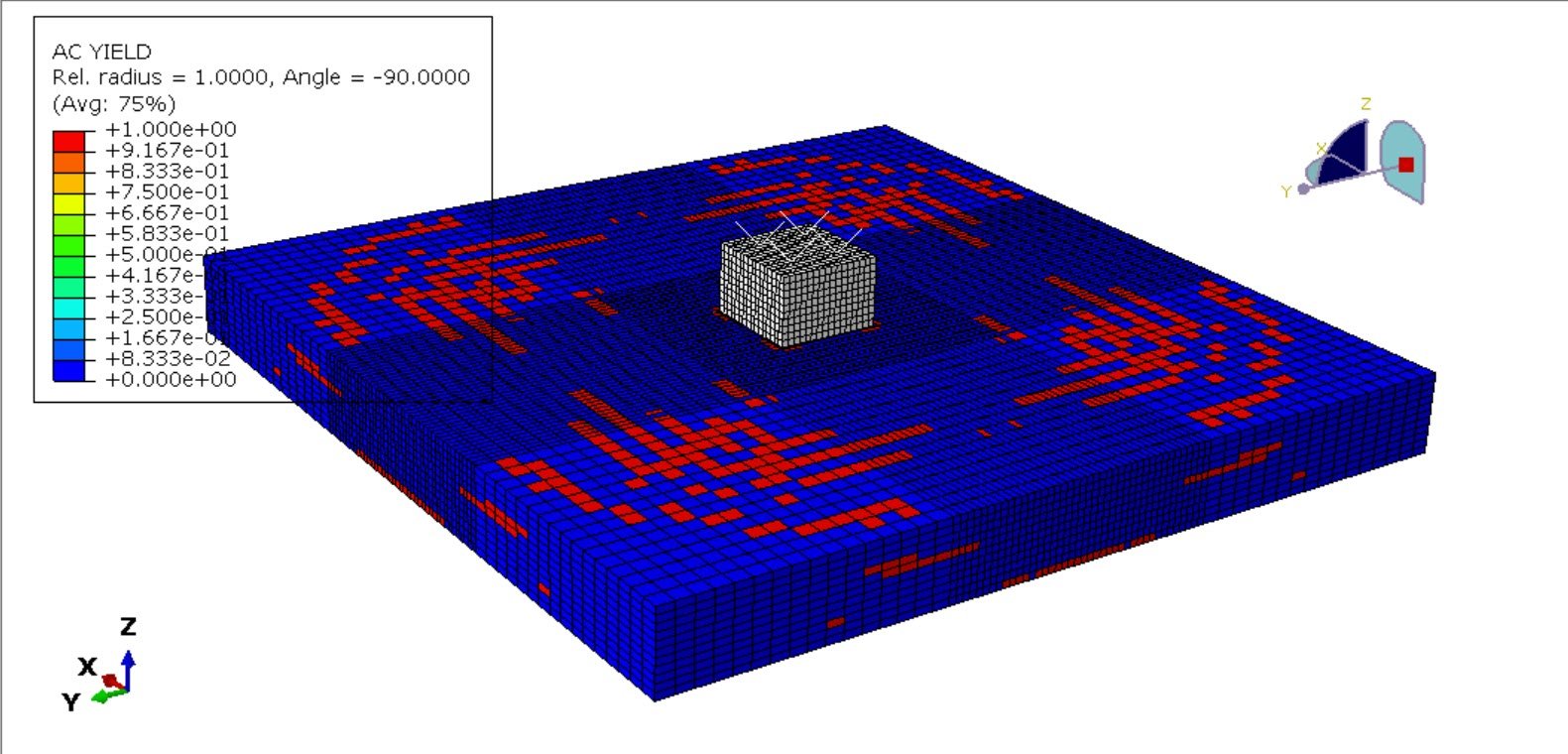

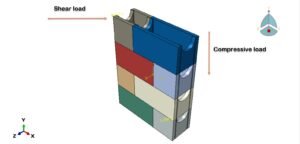

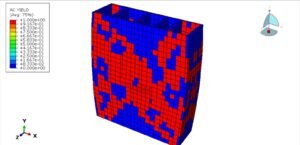

Both Normal Concrete (NC) and UHPFRC were simulated using the Concrete Damaged Plasticity (CDP) model, which is well-suited for nonlinear analysis of quasi-brittle materials. The CDP model enables:

Representation of tensile cracking and compressive crushing

Stiffness degradation through damage variables

Distinction between tensile and compressive damage evolution

Capture of confinement and dilation effects

For NC, standard stress–strain relationships reflecting limited tensile capacity and brittle softening were adopted. For UHPFRC, enhanced tensile strength, strain hardening (if modeled), and higher fracture energy were incorporated to reflect fiber bridging and crack control mechanisms.

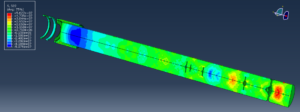

Steel reinforcement was modeled as embedded elements within the slab concrete matrix. The reinforcement layout was designed to reflect realistic slab detailing around the column region.

A Static General solver in Abaqus was employed to simulate monotonic loading up to failure.

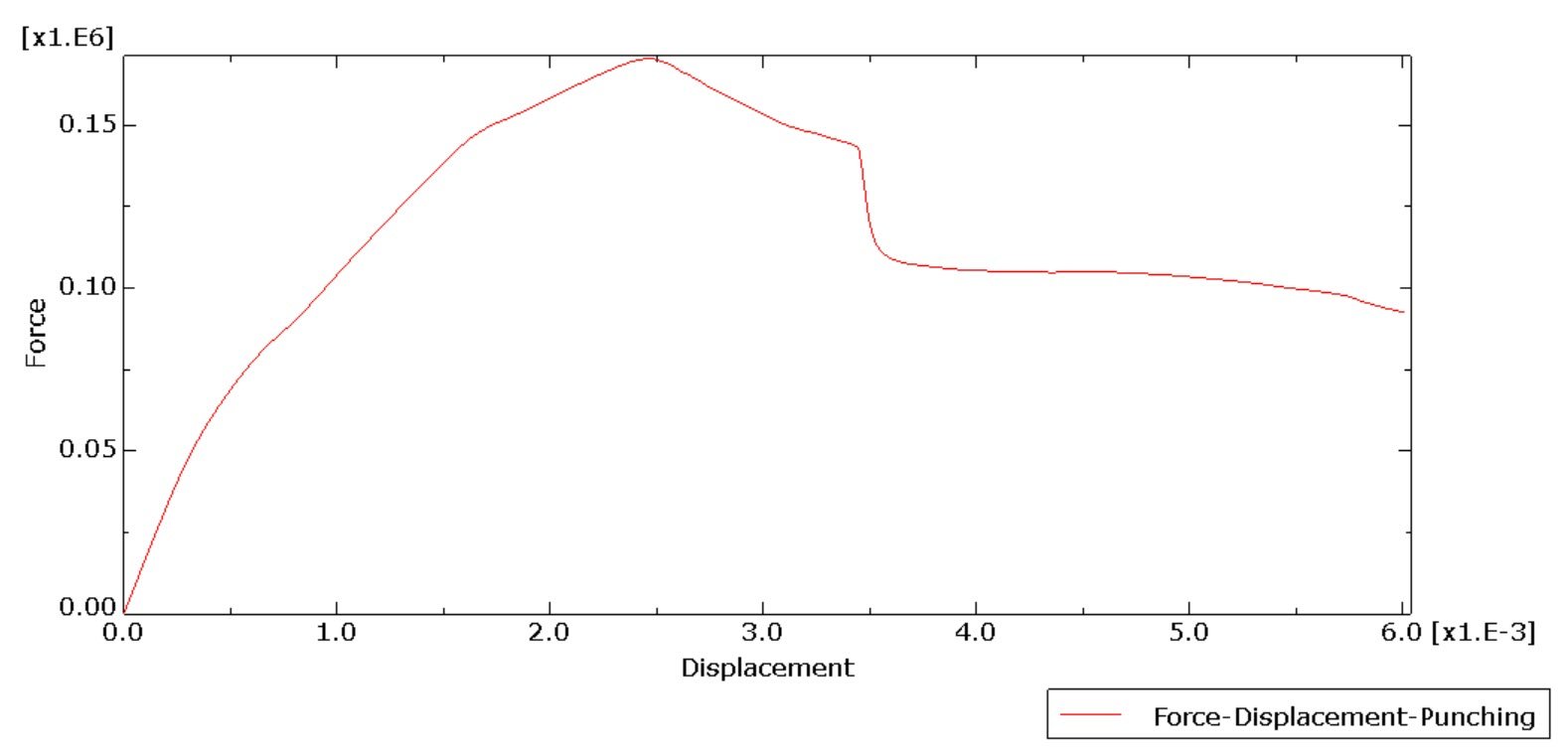

Load–deflection response

Crack initiation and propagation

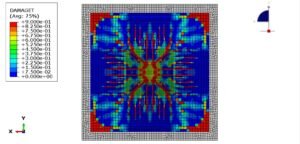

Damage evolution in NC and UHPFRC

Stress redistribution after cracking

Ultimate punching failure mechanism

Abaqus

€78,00 €39,00

Abaqus

€84,00 €41,00

Abaqus

€86,00 €43,00

Abaqus

€88,00 €49,00

Abaqus

€86,00 €42,00

Abaqus

€86,00 €42,00

Abaqus

€78,00 €41,00

Abaqus

€100,00 €80,00

See more

Want to receive push notifications for all major on-site activities?