Fire Analysis and Simulation

Fire analysis and simulation is the study and computational modeling of how fire behaves, spreads, and impacts its surroundings. It combines principles from physics, chemistry, material science, and engineering to predict fire dynamics under different conditions.

Engineers, safety experts, and researchers use these tools to:

- Understand fire growth, smoke movement, and heat transfer.

- Assess fire risks in buildings, vehicles, tunnels, forests, and industrial facilities.

- Design fire protection systems (sprinklers, ventilation, suppression systems).

- Support forensic investigations after real fire incidents.

This package includes 12 tutorials that cover all about fire analysis in Abaqus.

Key Elements of Fire Analysis

- Ignition & Combustion

- Examines how materials ignite and sustain burning.

- Considers fuel type, ignition sources, and chemical reactions.

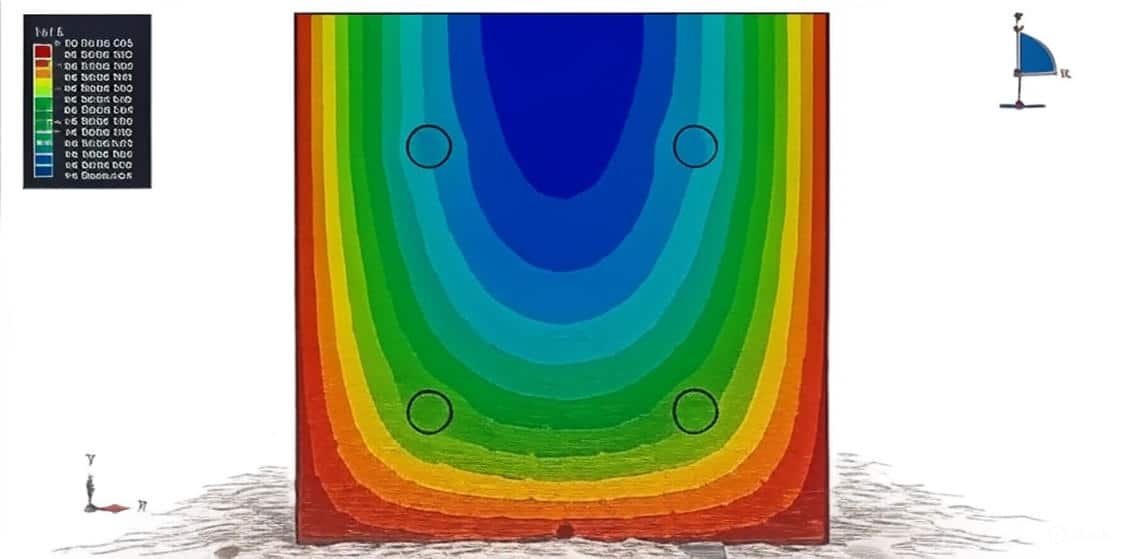

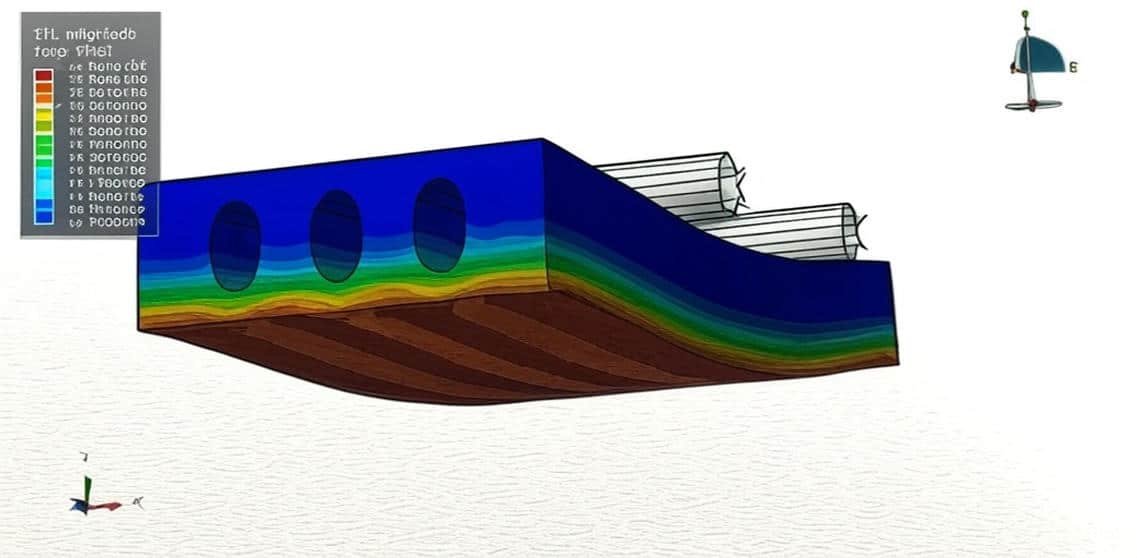

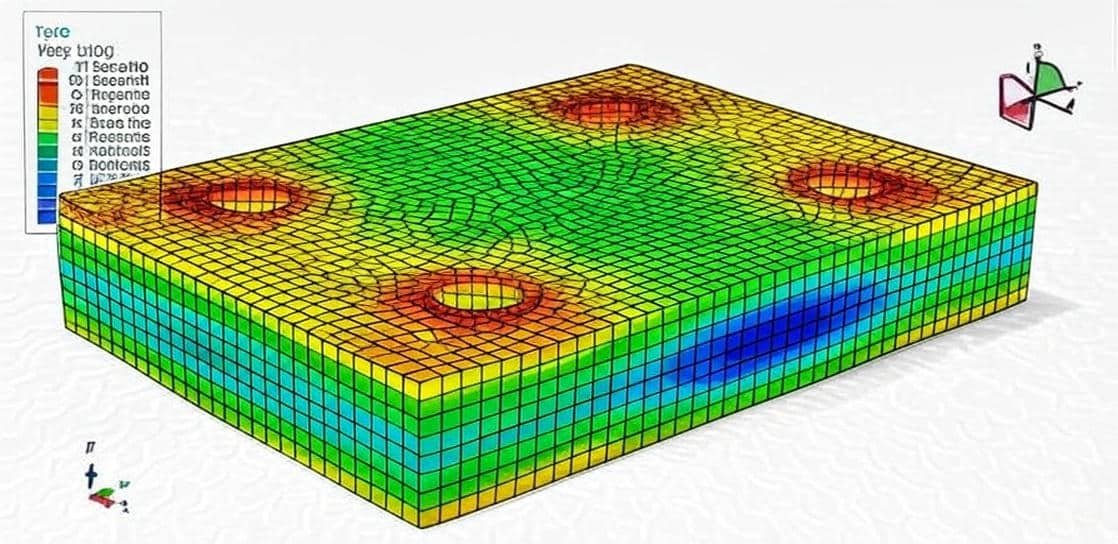

- Heat Transfer

- Fire spreads through conduction, convection, and radiation.

- Heat flux determines whether nearby materials ignite.

- Smoke & Toxic Gas Production

- Simulation tracks the movement and concentrations of smoke and CO, CO₂, and other hazardous gases.

- Fire Growth & Spread

- Modeled with equations for flame spread, pyrolysis, and heat release rate (HRR).

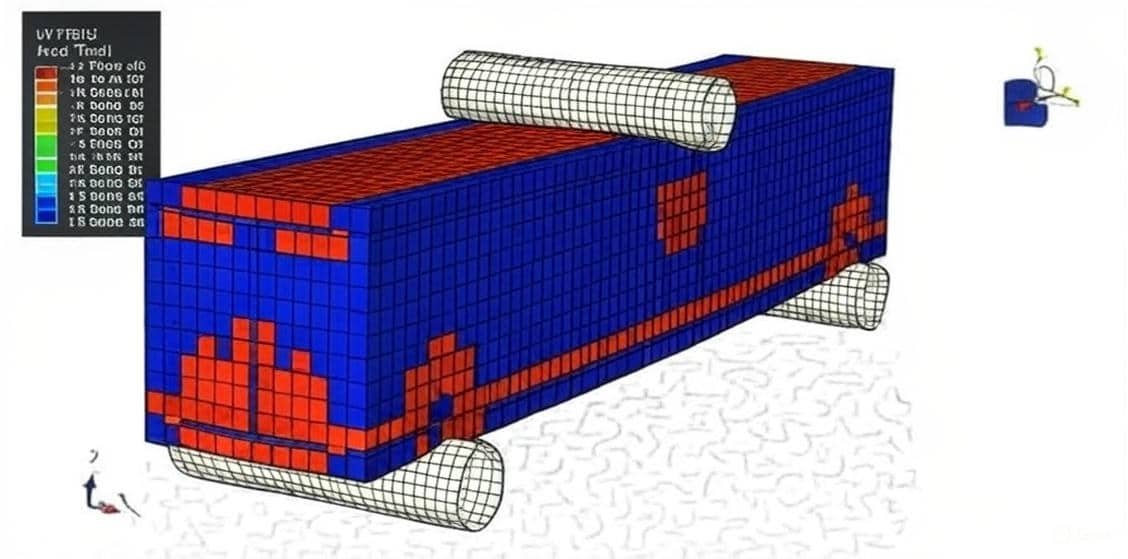

- Human & Structural Response

- Evacuation modeling takes into account human behavior and the available escape time.

- Structural analysis looks at material degradation (e.g., steel losing strength at high temperatures).

Fire Simulation Tools

Fire dynamics are highly nonlinear and complex, so computer model like Abaqus is widely used:

- Zone Models – Simplify the fire environment into zones.

- Field Models

Applications of Fire Simulation

- Building Safety Design – optimizing sprinklers, alarms, and smoke control.

- Tunnel and Transportation Fire Safety – analyzing smoke extraction and evacuation.

- Wildfire Behavior Prediction – forecasting spread and impact under wind/topography conditions.

- Forensic Fire Investigation – reconstructing how and why a fire started and spread.

- Regulatory Compliance – supporting performance-based fire safety designs that go beyond prescriptive codes.

Benefits and Limitations

Benefits

- Safer, cost-effective design (reduces need for full-scale fire tests).

- Flexible—can test many scenarios virtually.

- Helps predict outcomes not easily measurable in experiments.

Limitations

- Requires accurate input data (material properties, ventilation, HRR).

- Computationally intensive (especially CFD models).

- Models are simplifications; real fire behavior can be unpredictable.

In short:

Fire analysis and simulation is a powerful field bridging theory, experimentation, and advanced computational modeling to improve fire safety, investigate incidents, and reduce risks to people, property, and the environment.