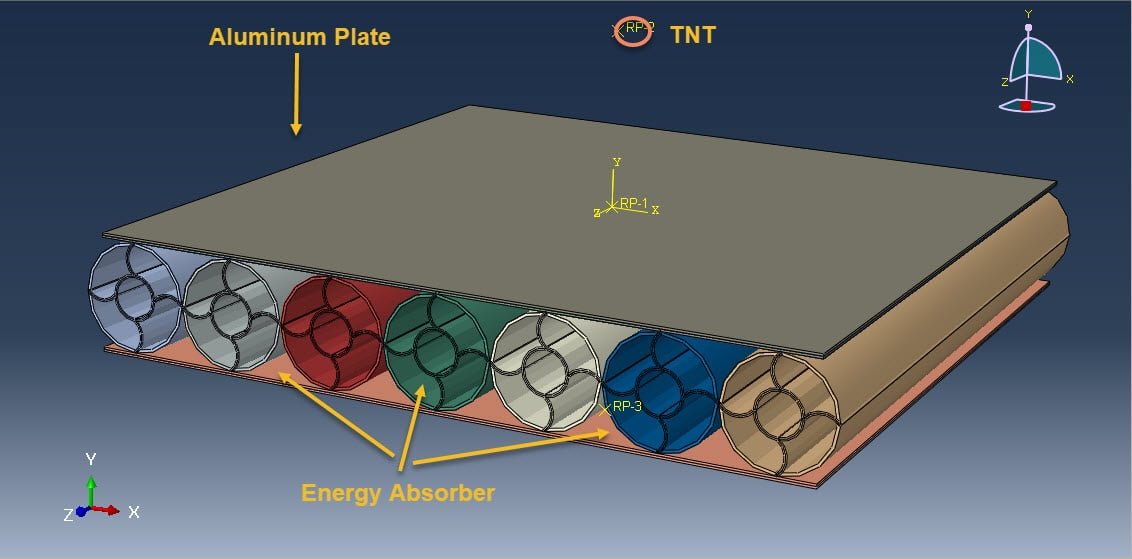

Aluminum sandwich structures are widely used in modern engineering due to their lightweight, high stiffness, and energy absorption capabilities. These structures typically consist of two strong outer face sheets and a lightweight core (e.g., honeycomb, foam, or lattice). When subjected to air blast loads, such as those from explosions, these structures can help absorb and dissipate energy, protecting critical components or personnel.

To further enhance the blast resistance, internal energy absorbers such as foam inserts, corrugated layers, or metallic tubes can be integrated into the core. These absorbers are designed to undergo controlled deformation, thus mitigating transmitted forces.

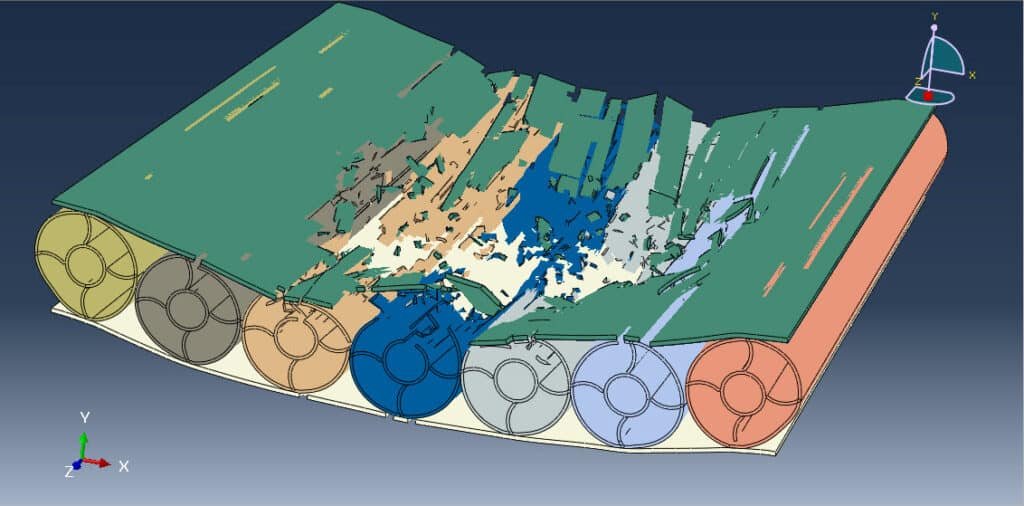

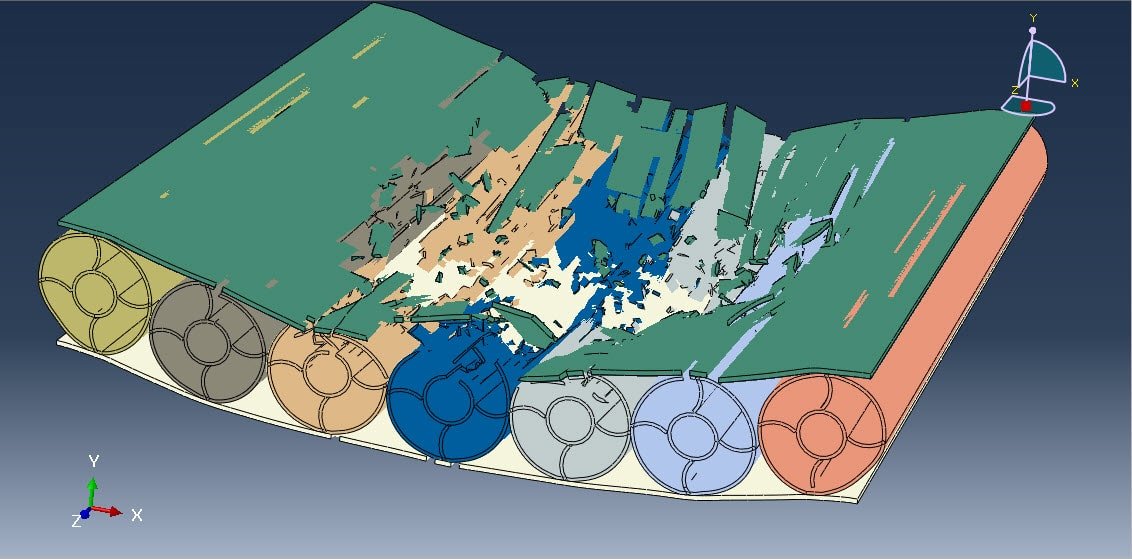

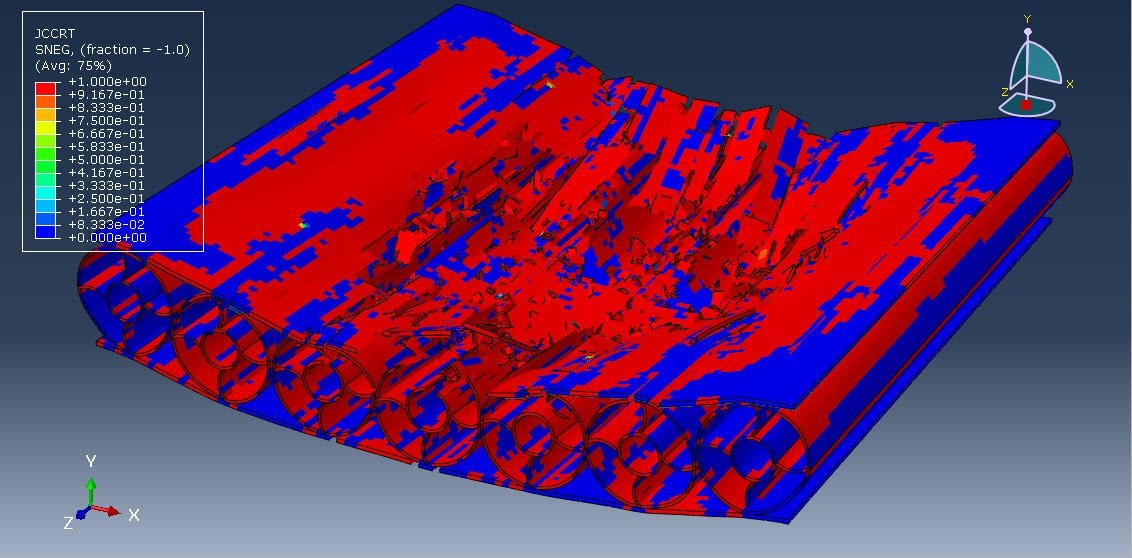

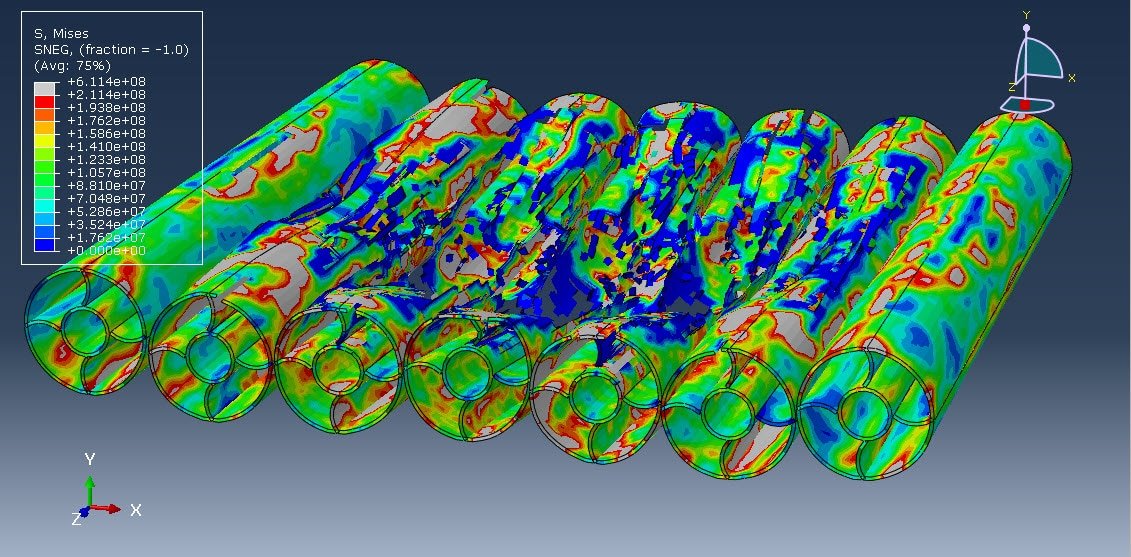

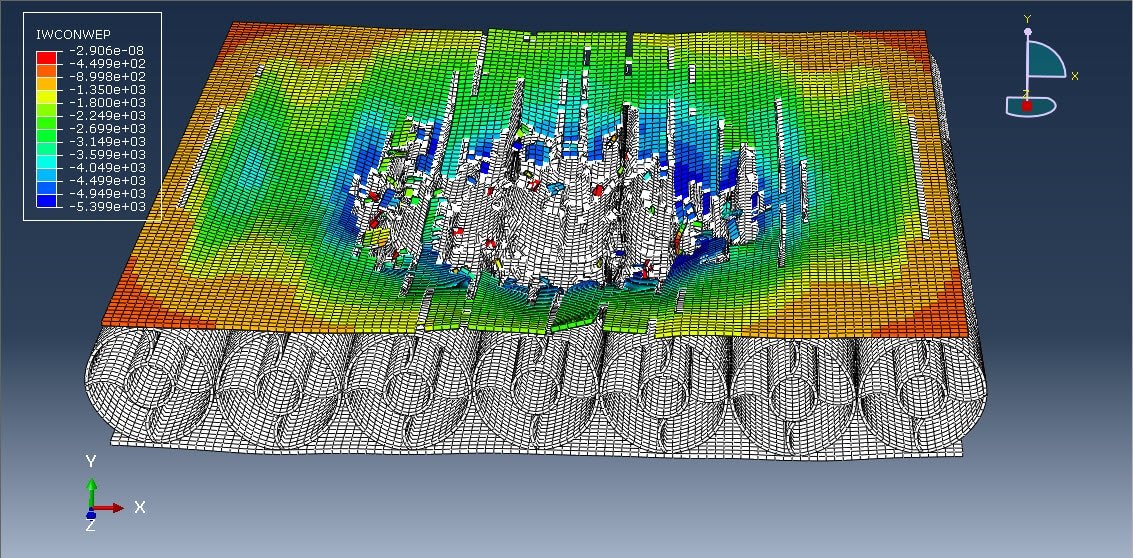

Simulating air blast loads on these advanced structures allows researchers to predict failure modes, optimize material configuration, and assess the effectiveness of the absorbers under dynamic conditions.

Aluminum sandwich structures with integrated energy absorbers have gained significant attention in protective engineering due to their high strength-to-weight ratio, excellent energy absorption capabilities, and tunable response under dynamic loading. One critical scenario for which these structures are designed is air blast loading, commonly caused by explosions in air. This type of loading results in a rapid pressure rise followed by a decay, imparting significant impulsive forces to any exposed structure.

When such a blast wave interacts with a sandwich panel typically comprising two thin aluminum face sheets and a lightweight core (e.g., foam, honeycomb, or lattice) the response is governed by the material properties, core geometry, and the presence of inner energy absorbers. These absorbers are added to improve structural survivability by enhancing energy dissipation and delaying or mitigating failure mechanisms.

An air blast wave from an explosion propagates through the air and can be idealized (for structural analysis) using the Friedlander equation for the pressure-time profile:

P(t)=Ps(1−tdt) e−bt/td

Where:

P(t): overpressure at time t

Ps: peak overpressure

tdt: positive phase duration

b: decay coefficient

The impulse delivered to the structure is the area under this pressure-time curve and is a key factor in determining structural damage.

Face Sheets: Typically thin aluminum alloy (e.g., 2024-T3, 6061-T6) providing bending stiffness.

Core: Lightweight material like aluminum foam, honeycomb, or lattice, offering shear strength and initial energy dissipation.

Under blast loading, these panels can fail through:

Face sheet yielding or fracture

Core shear failure or crushing

Delamination between the face and the core

Global bending or deflection exceeding limits

Energy absorbers (e.g., metallic foam inserts, crushable tubes, origami structures) are placed inside or behind the core to:

Absorb blast energy via plastic deformation

Reduce transmitted force to critical components (e.g., payload or personnel)

Delay face sheet rupture and panel debonding

Metallic foams (aluminum, steel)

Tubular systems (crush tubes)

Origami-based structures

Layered or gradient cores with varying densities or materials

Placement: Between core layers or behind the rear face sheet

Crush characteristics: Plateau stress, densification strain

Mass efficiency: Trade-off between added weight and energy absorption

To evaluate performance under blast loading:

Numerical simulation using finite element analysis (FEA) with Abaqus software

Constitutive models for foam and face sheets (e.g., Johnson-Cook, damage,…)

Aluminum sandwich structures with integrated energy absorbers offer a promising solution for blast mitigation. Their design must balance lightweight requirements with sufficient strength and energy dissipation. Advances in materials and multi-functional absorber designs continue to push the boundaries of blast protection.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?