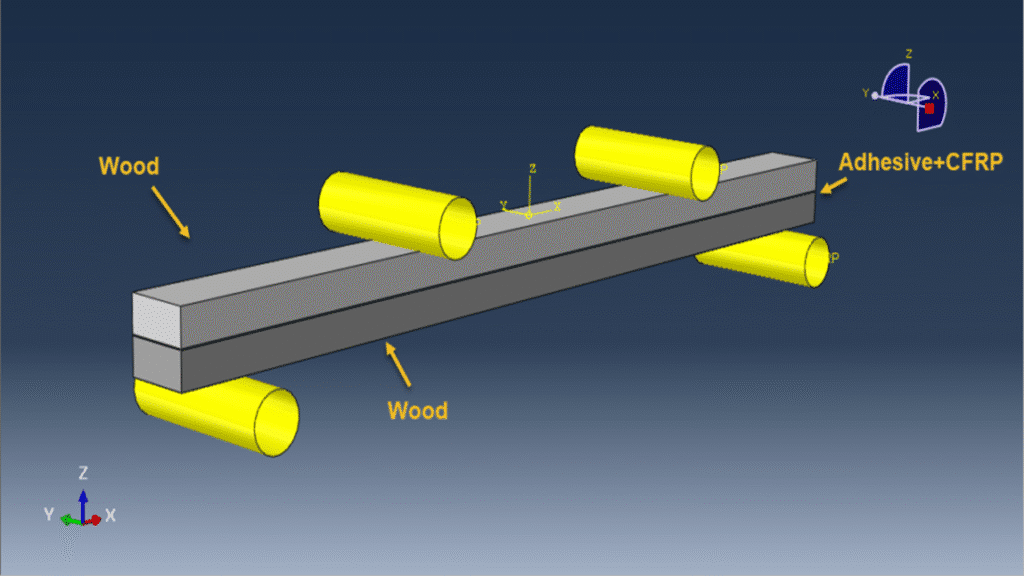

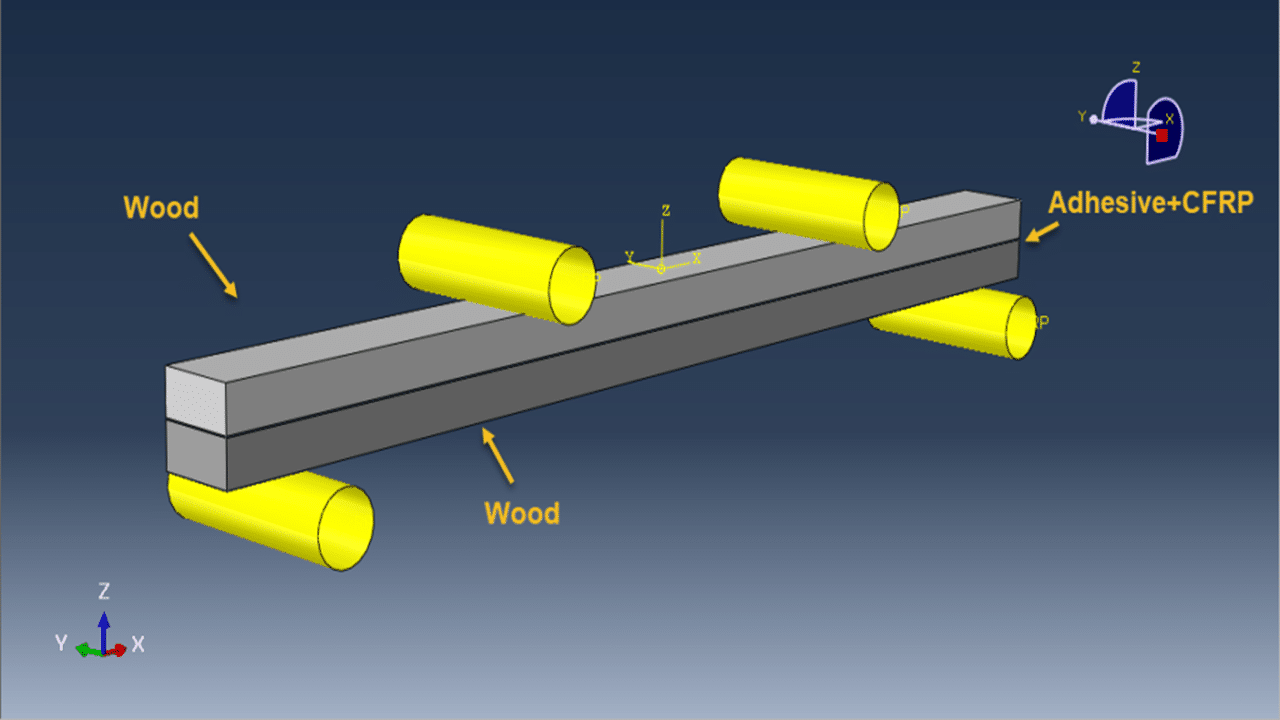

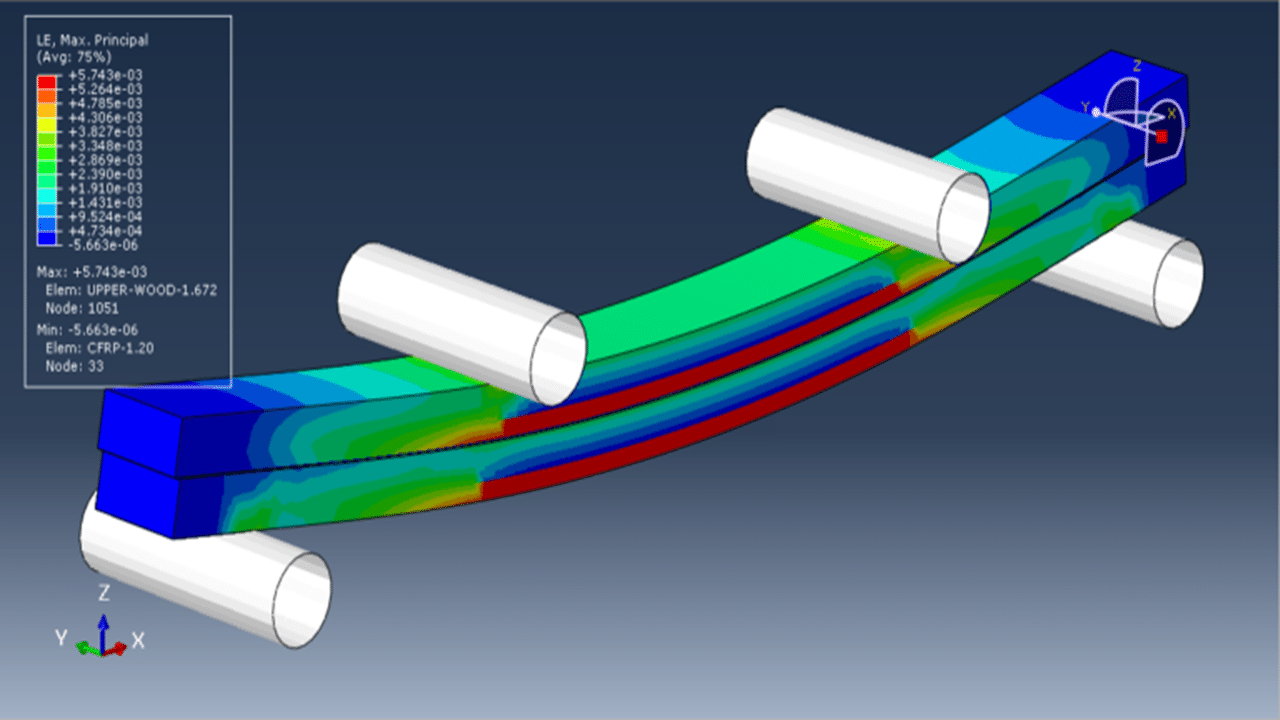

In this tutorial, the dynamic four-point bending simulation of a Wood–Glue–CFRP composite beam in Abaqus is investigated. The wood beam, adhesive layers, and CFRP strips are modeled as three-dimensional solid parts, while the loading and support rollers are defined as rigid shell bodies.

Composite structural systems combining timber with fiber-reinforced polymers (FRP) have become a focus of modern structural research. Reinforcing timber elements with CFRP strips can be done in various ways, such as bonding reinforcement to the tension face of a beam, partially reinforcing the width, folding the composite along vertical faces, or embedding CFRP into slotted sections. These methods aim to enhance the structural performance of wood beams under bending and shear loads.

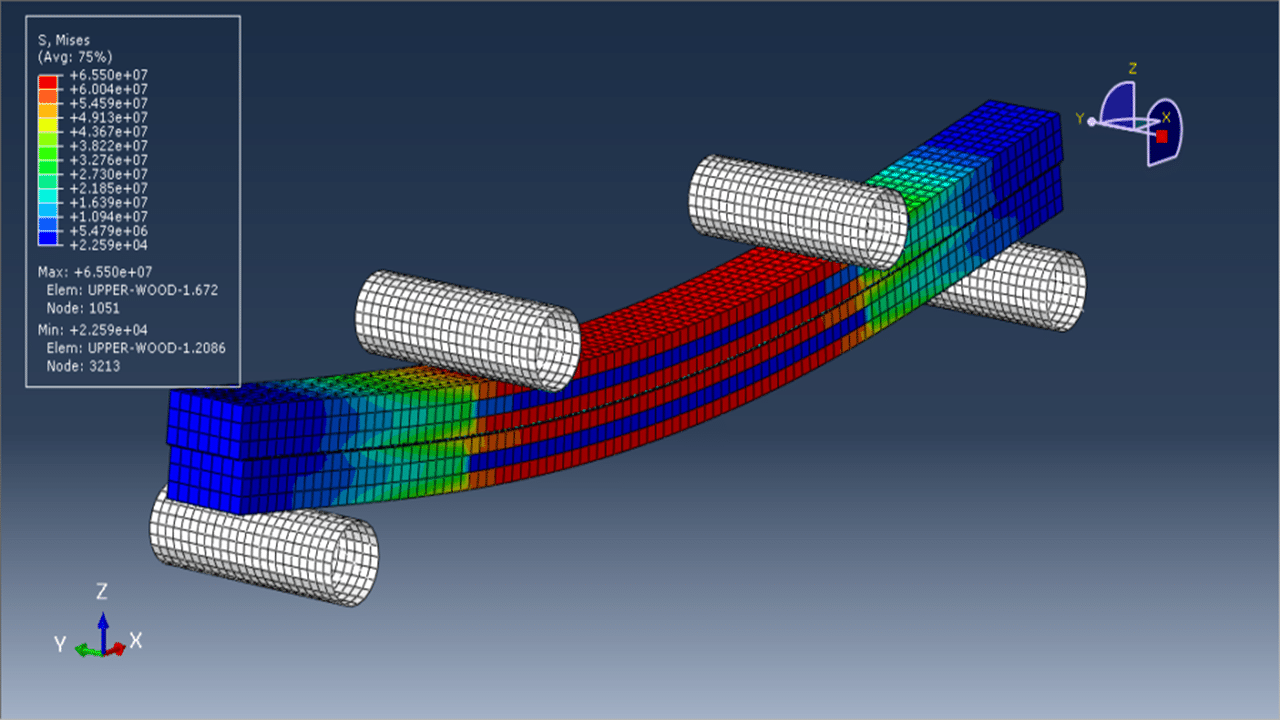

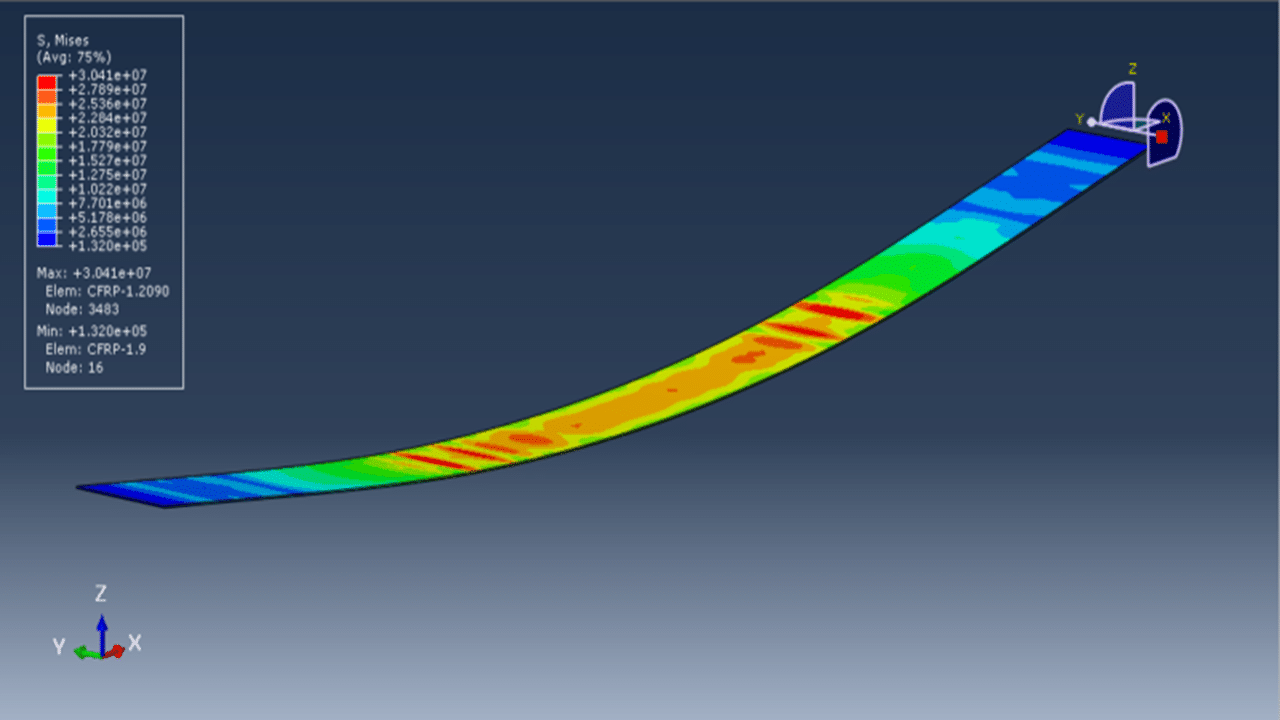

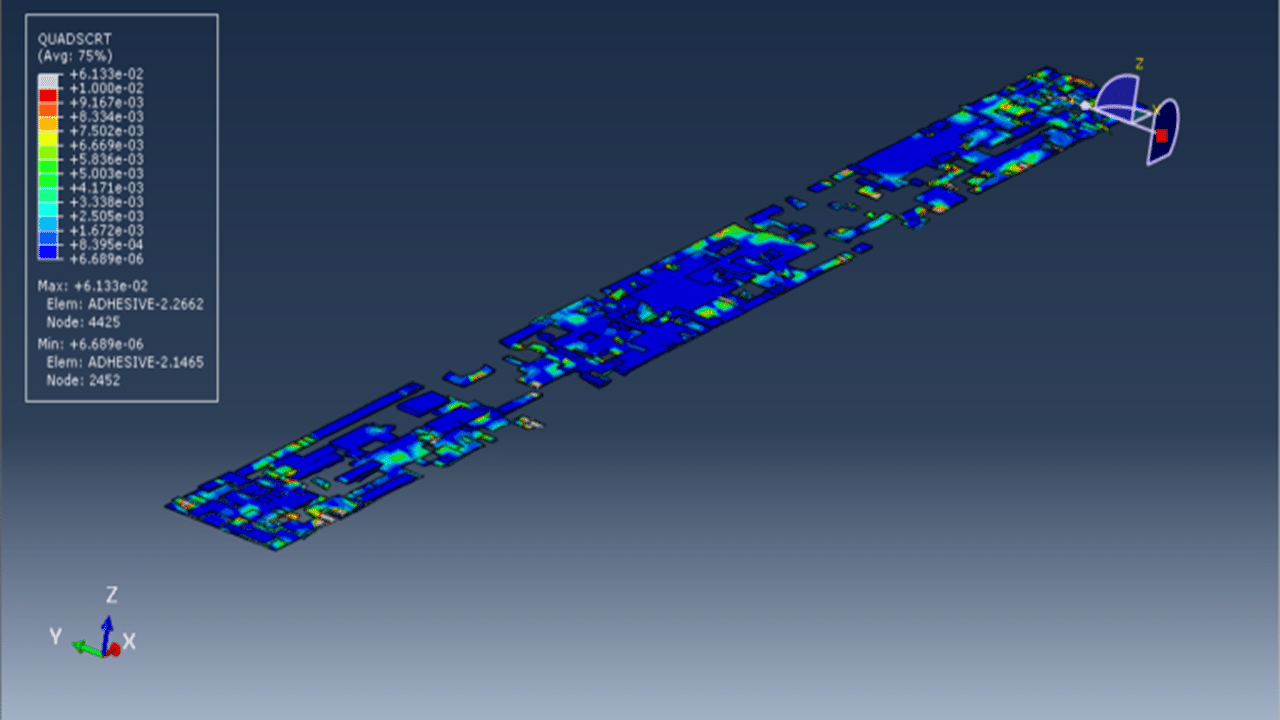

For this analysis, wood and CFRP materials are defined using Elastic Engineering Constants with Plastic Isotropic behavior and Hill’s yield criterion via the Potential option to represent directional strength characteristics. The adhesive layers are modeled using Elastic Traction behavior with Quads Damage for progressive failure simulation, suitable for representing polyurethane (PUR) glue behavior.

Although both Static General and Dynamic Explicit steps can be used, the Dynamic Explicit step with mass scaling is chosen to reduce computation time while maintaining accuracy. Idealized tie constraints are applied between wood–adhesive and CFRP–adhesive interfaces. Surface-to-surface contact with defined interaction properties is used between the rigid rollers and the beam. Proper boundary conditions and load applications are assigned to the rigid parts to simulate the four-point bending test. A sufficiently fine mesh is applied to ensure accurate stress and damage predictions.

Upon completion of the simulation, results such as stress distribution, strain, adhesive damage, CFRP behavior, and force–displacement responses are available for evaluation.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?