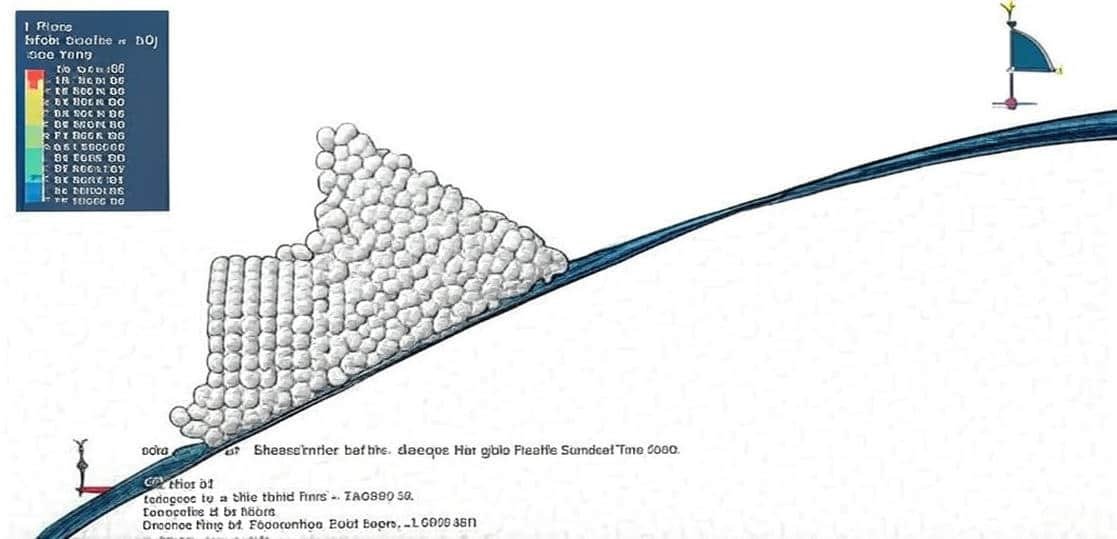

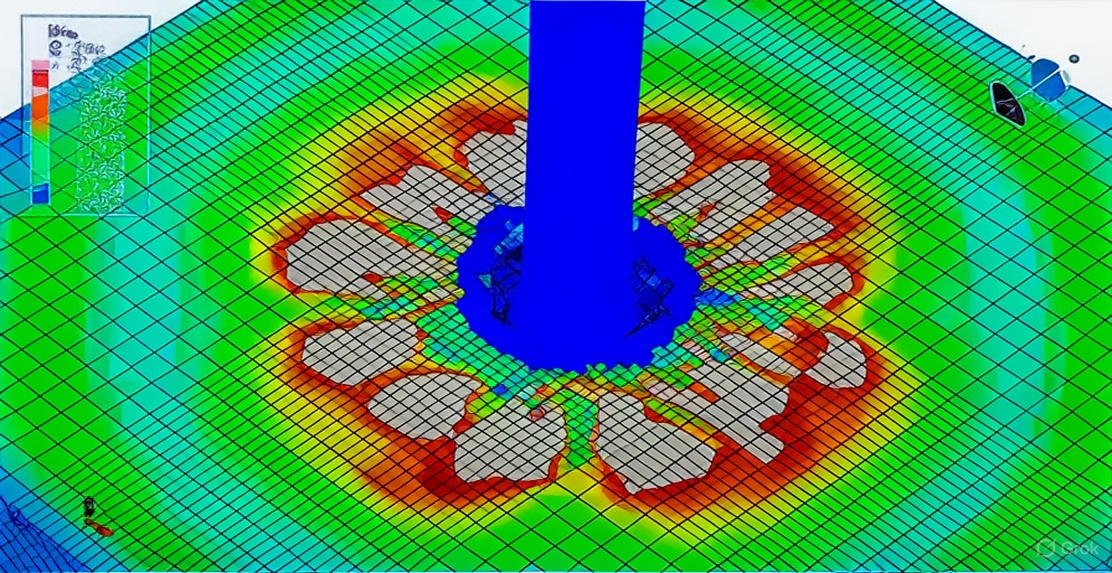

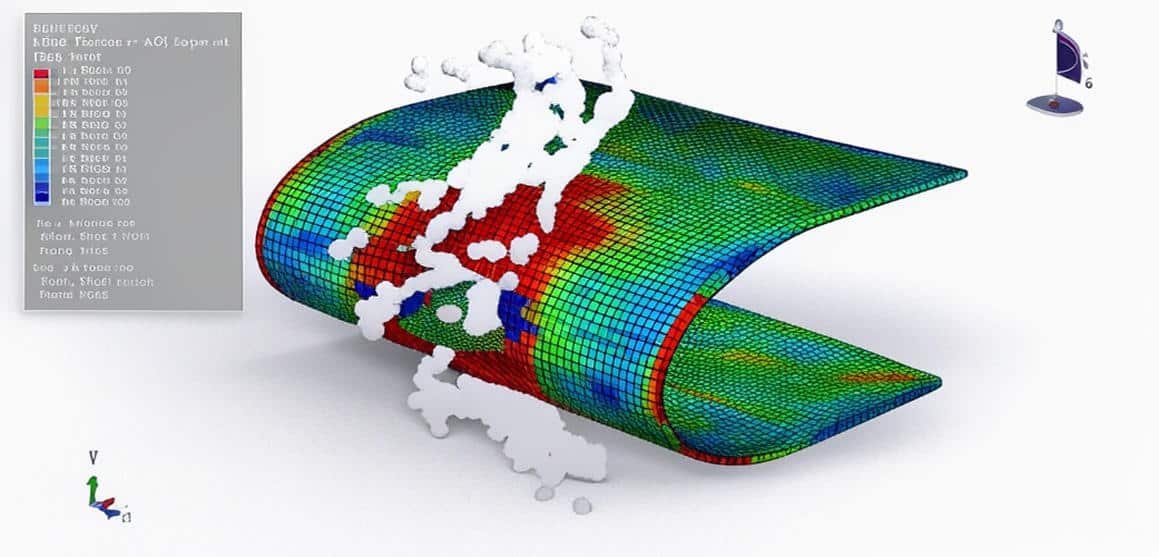

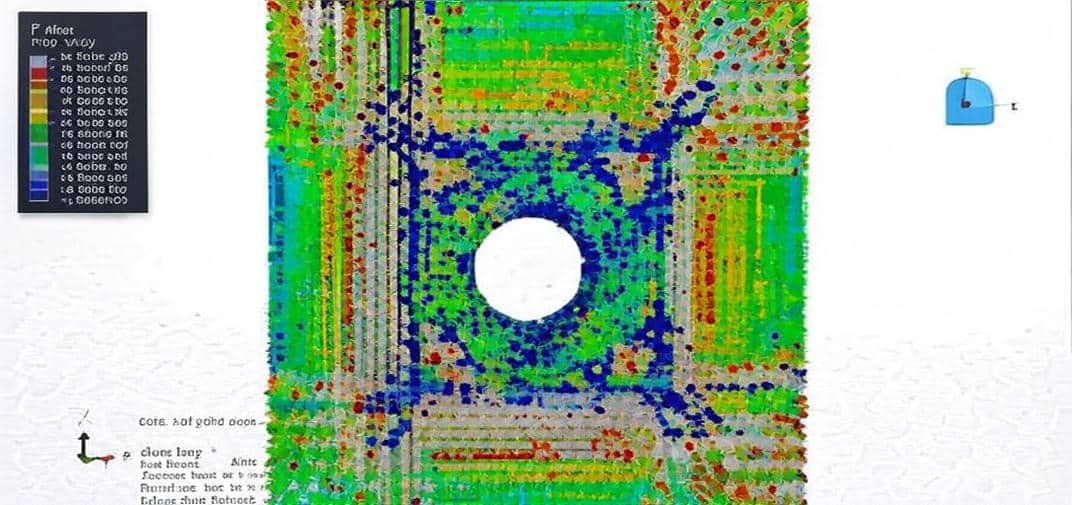

The Discrete Element Method (DEM) and Smoothed Particle Hydrodynamics (SPH) are powerful numerical methods used to simulate and analyze systems involving discrete particles, fluid flows, and their interactions with solid structures. These methods have become essential tools in engineering, geomechanics, materials science, and Multiphysics research.

This package includes 20 tutorials that cover the DEM and SPH analysis in Abaqus. The examples include impact, explosion, non-Newtonian flow, waterjet, hydroforming, cold spray, bird strike, and FSW simulation.

In summary, DEM and SPH simulation and analysis provide robust tools for studying complex particle and fluid systems that are difficult or impossible to capture with traditional continuum or grid-based methods. Their integration in software such as Abaqus makes them highly accessible for practical engineering and scientific applications.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?