Coupled Eulerian Lagrangian (CEL) and Eulerian Analysis

In computational mechanics, two common descriptions are used to model how materials move and deform:

- Lagrangian description: The mesh moves with the material. Each element tracks the same set of particles over time. This is well-suited for solids and structures where deformations are relatively small to moderate. However, when materials undergo very large deformations (e.g., impact, penetration, or fragmentation), Lagrangian meshes can become highly distorted and unstable.

- Eulerian description: The mesh is fixed in space, and material flows through it. This is ideal for modeling fluids or materials with extreme flow or mixing (e.g., explosions, fluid-structure interaction, soil or sand flow). However, it is less efficient for pure solid mechanics since the mesh does not follow the material.

This package includes 24 tutorials that cover all about Euelrian and CEL analysis on Abaqus software. The examples like welding, water sloshing, explosion, impact, forming, spray, soil, water wave, TNT detonation, UNDEX, and many other models.

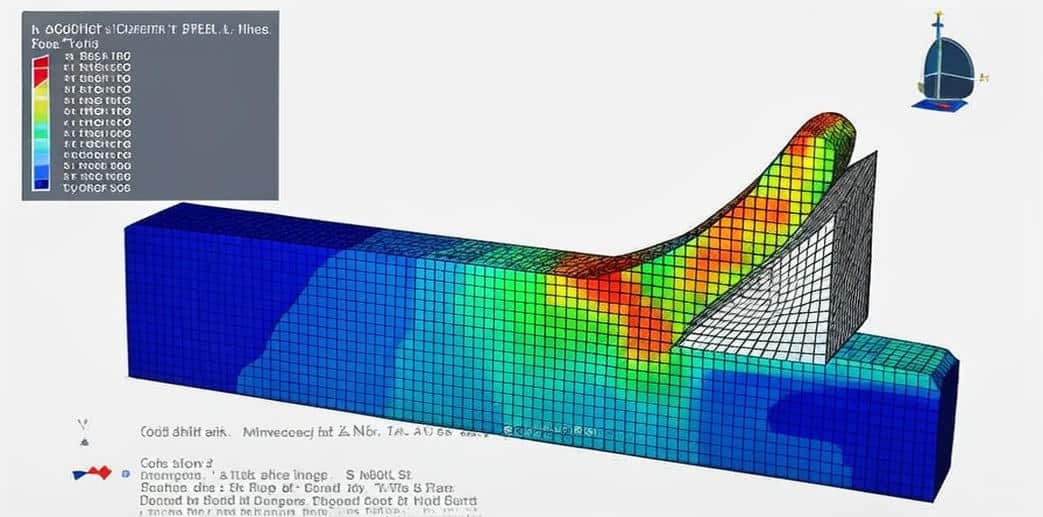

Coupled Eulerian Lagrangian (CEL) Method

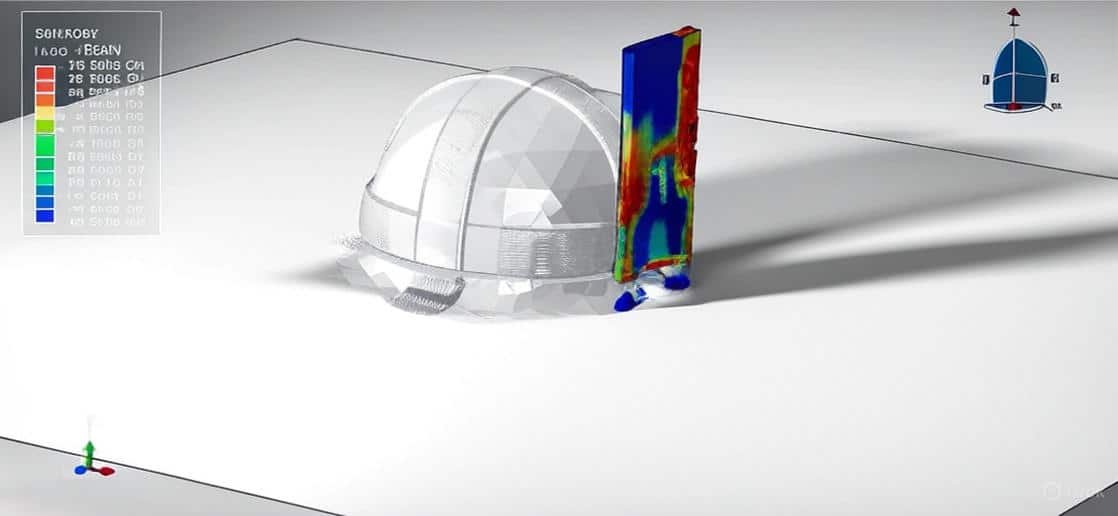

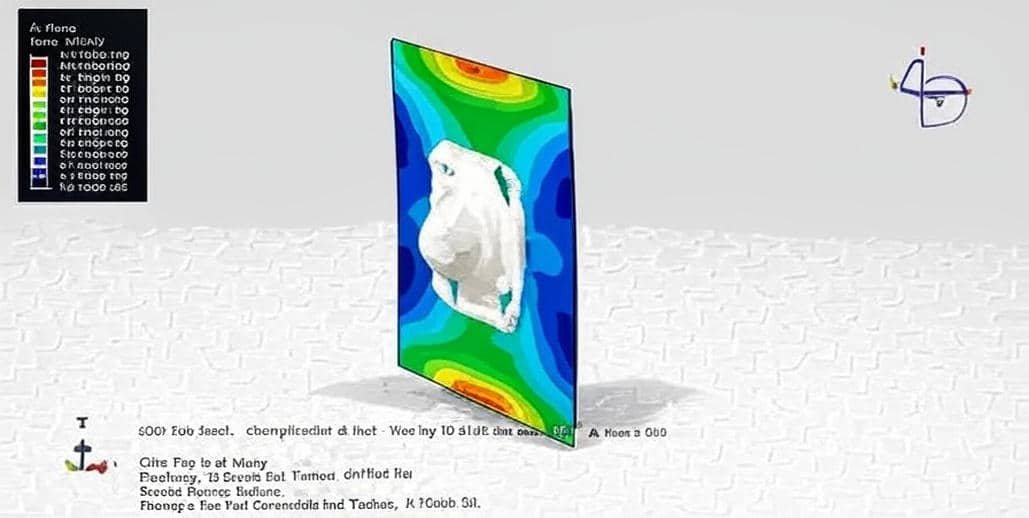

The CEL approach combines the strengths of both frameworks by allowing Eulerian materials (fluid-like or highly deformable materials) to interact with Lagrangian structures (solids) in the same simulation.

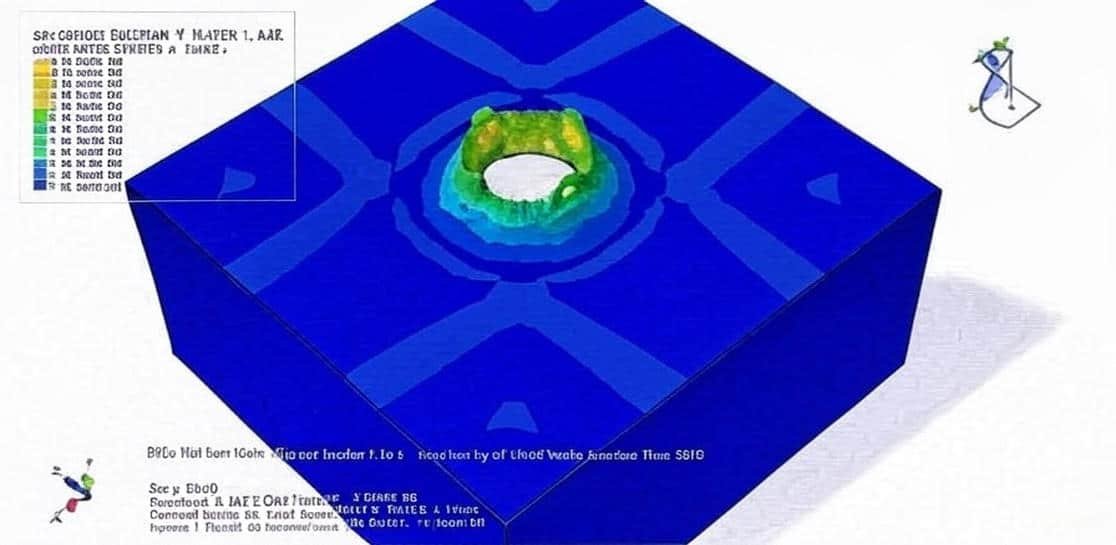

- Eulerian domain: Represents fluids, gases, or deformable materials (e.g., water, soil, explosive gases).

- Lagrangian domain: Represents solid structures or rigid bodies (e.g., projectiles, barriers, armor).

- Coupling: Contact algorithms allow interaction between the two domains, enabling accurate modeling of fluid-structure interaction and extreme events.

Applications of CEL Analysis in Abaqus

CEL simulations are widely used in engineering problems where fluids and solids interact dynamically under extreme conditions. Common applications include:

- Impact and penetration problems (e.g., bullets into armor, spacecraft shielding).

- Explosion and blast simulations (air blast waves impacting structures).

- Soil and granular flow (penetration of foundations, landslides).

- Hydrodynamic phenomena (slamming of ships, water entry problems).

- Manufacturing processes (metal forming, high-speed machining).

Eulerian Analysis Alone

Pure Eulerian simulations (without coupling) are generally used when:

- Only fluid/gas/material flow is of interest.

- No major solid structural response needs to be tracked.

- Examples include fluid mixing, shockwave propagation in air, or detonation modeling.

In summary: