Introduction:

In modern engineering, multi-layer composite panels are widely used in defense, aerospace, and infrastructure due to their high strength-to-weight ratio, damage tolerance, and energy absorption capabilities. With increasing threats from blast and impact loading, it’s crucial to assess the performance of these panels under extreme dynamic conditions, such as an air blast explosion.

This study focuses on the numerical simulation of an air blast explosion over a composite panel composed of:

- CFRP (Carbon Fiber Reinforced Polymer): A high-strength, lightweight material providing structural integrity and stiffness.

- Ceramic Core: A brittle, hard layer designed to dissipate energy and provide thermal protection.

- Glass Fiber Polypropylene (GFPP): A more ductile, energy-absorbing backing layer that helps in preventing fragmentation and spall.

Simulation Objective:

The simulation aims to:

- Predict the structural response of the composite panel subjected to an air blast.

- Understand the failure mechanisms across each layer.

- Assess energy absorption and damage propagation within the layered structure.

Simulation Overview:

1. Modeling Approach:

- Software Tools: Finite Element Analysis (FEA) platform ABAQUS/Explicit is commonly used.

- Geometry: A layered sandwich structure with CFRP as the front face, ceramic core as the middle, and GFPP as the rear.

- Blast Source: The CONWEP method is an easy way to model the blast load.

2. Material Behavior:

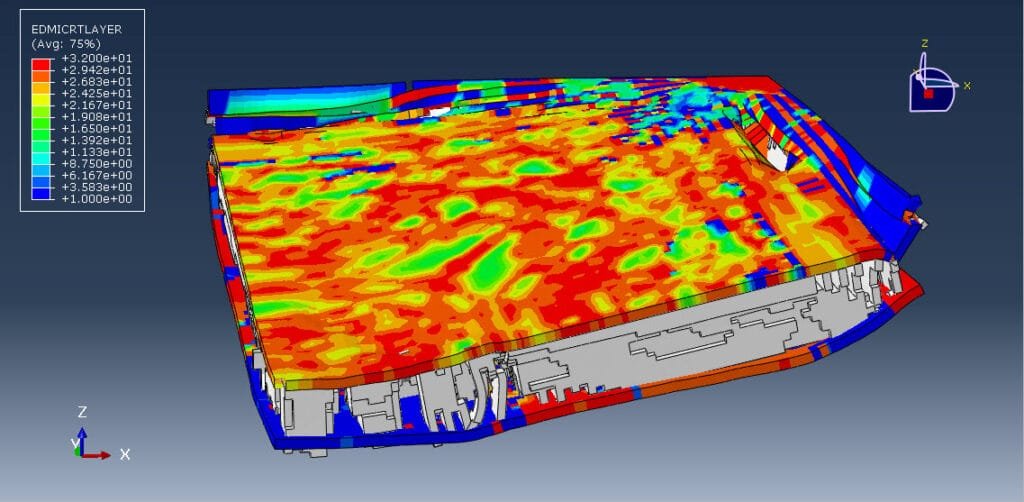

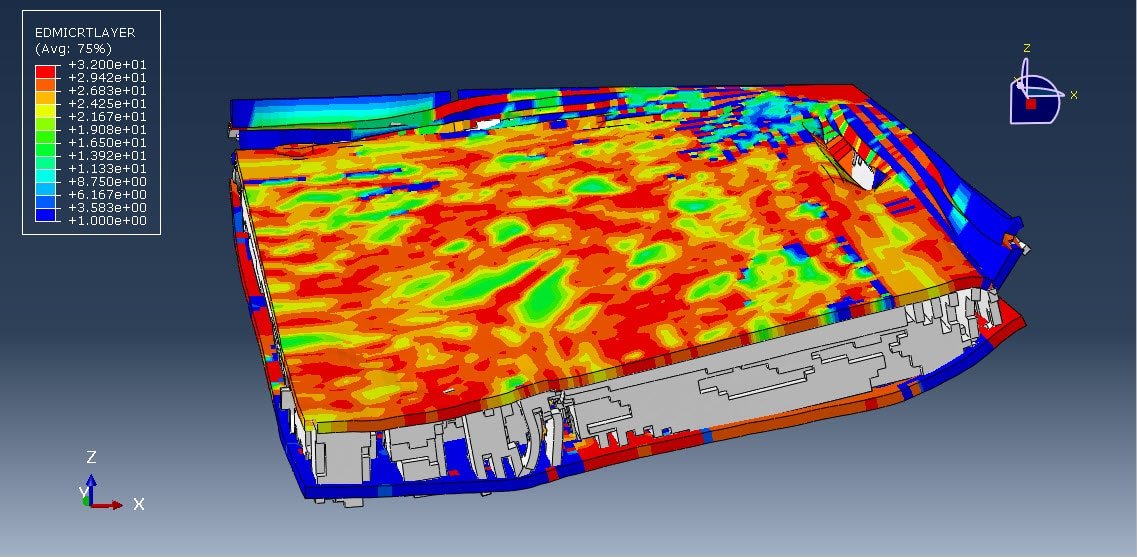

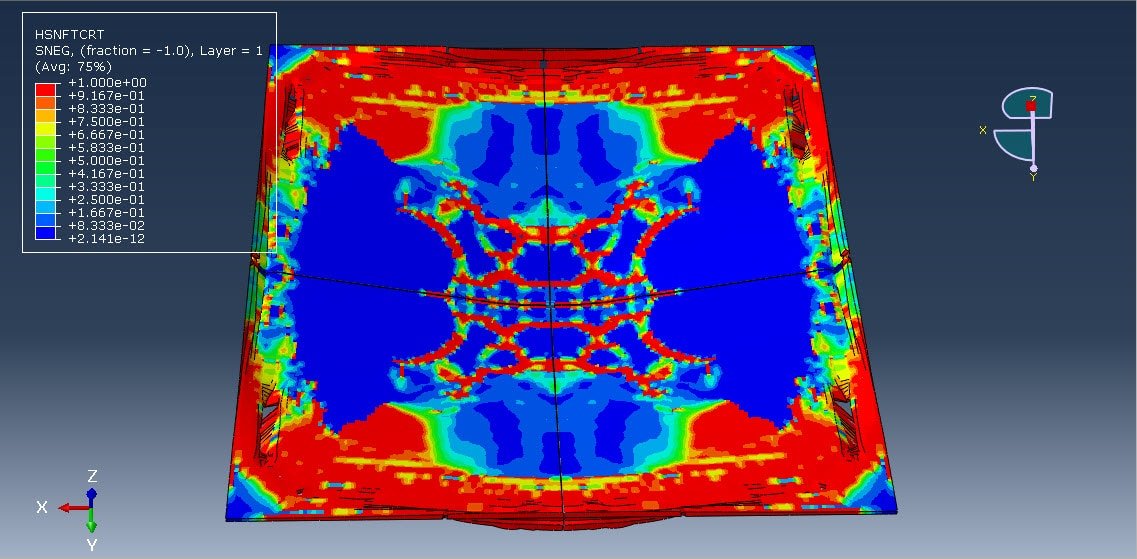

- CFRP: Modeled with an orthotropic damage model capturing delamination and fiber failure. Hashin’s damage criterion is appropriate for the CFRP fiber.

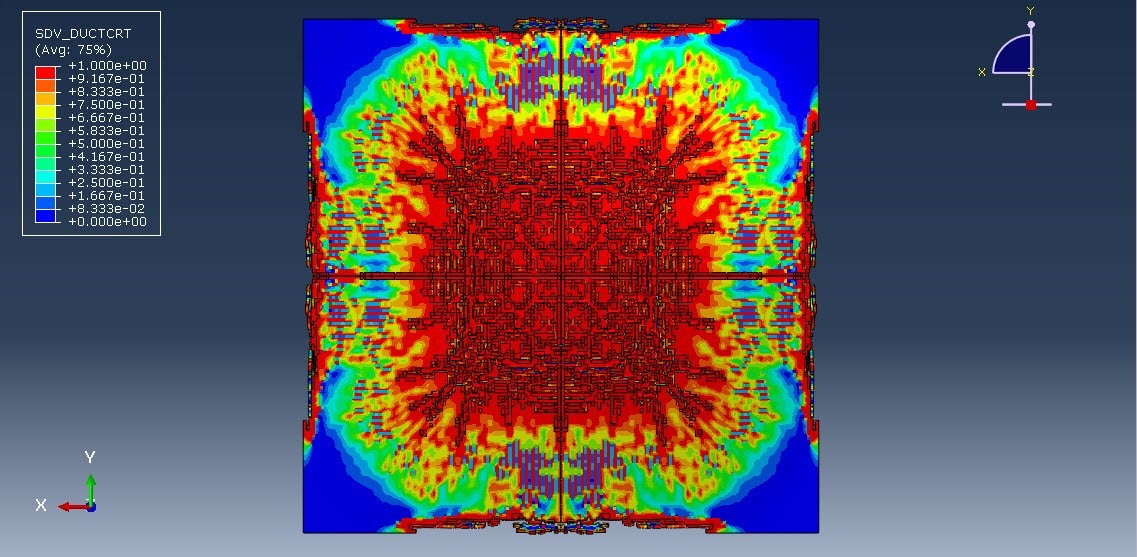

- Ceramic Core: Brittle fracture models, such as Johnson-Holmquist II, account for crack initiation and propagation. In this case, the JHB model is selected.

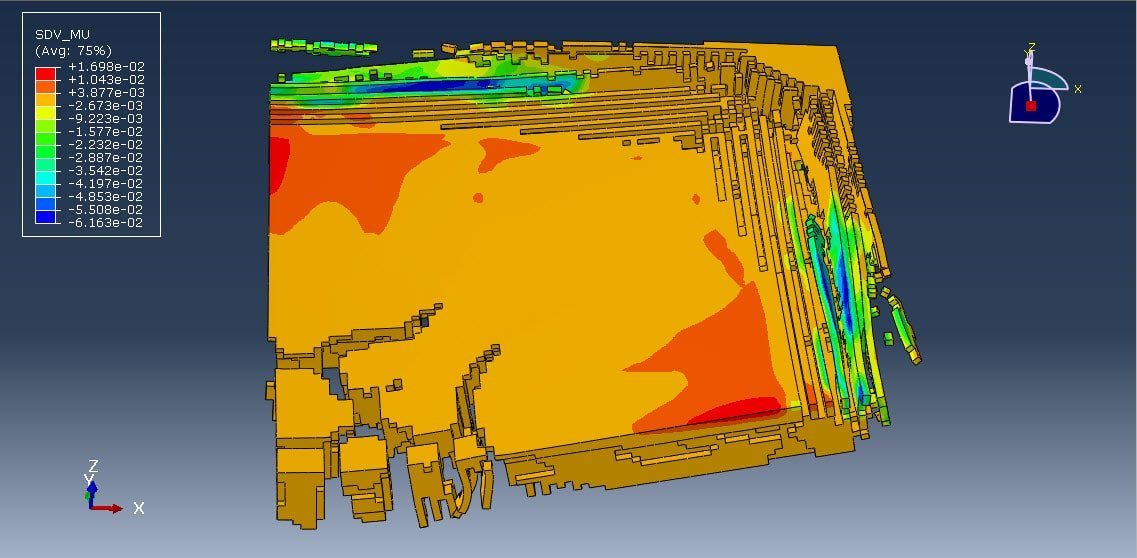

- GFPP: Nonlinear viscoplastic behavior simulating ductile deformation and energy absorption. In this case, Hashin’s damage criterion is considered.

Expected Results and Analysis:

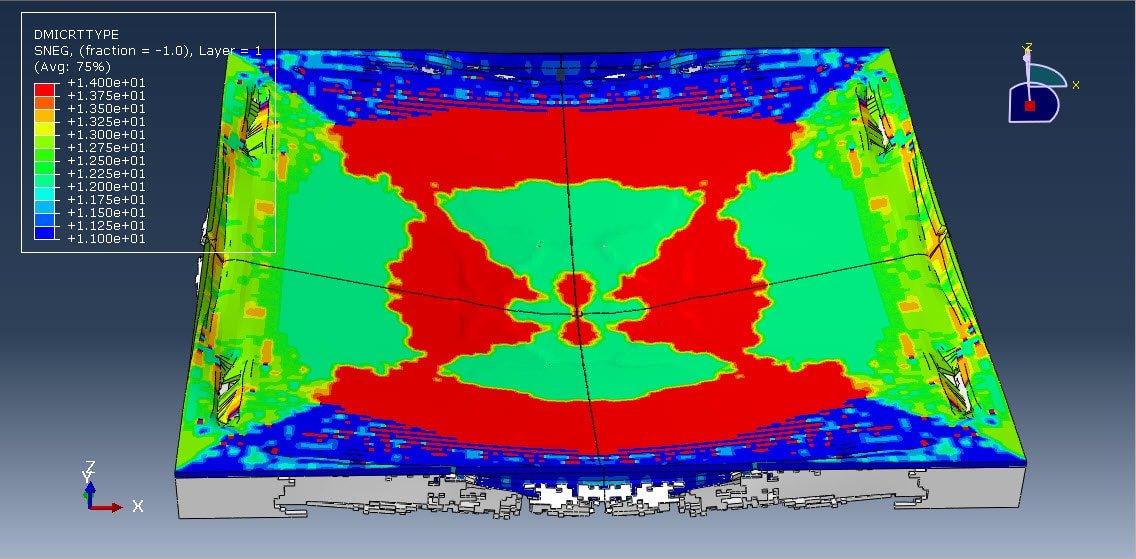

- Deformation Profile: Out-of-plane displacement and local damage zones.

- Stress Distribution: Through-thickness stress and interlayer delamination.

- Failure Modes:

- CFRP: Fiber breakage, matrix cracking.

- Ceramic: Brittle fragmentation.

- GFPP: Ductile tearing, bulging.

- Energy Dissipation: Contribution of each layer to absorbing and mitigating the blast energy.

- Residual Strength: Ability of the panel to sustain load post-blast.

Applications and Significance:

- Military armor systems for personnel or vehicles.

- Protective cladding for critical infrastructure.

- Lightweight shielding in aerospace environments.

This simulation offers valuable insights into how different materials behave under high-strain-rate loading, enabling the design of advanced protective structures with tailored performance characteristics.