Introduction to Bolt Analysis and Simulation

Bolts are among the most common fastening elements in engineering, used to join parts in machinery, structures, and vehicles. Although they may seem simple, bolts are often critical for safety and reliability, failure of a single bolt can cause entire systems to fail.

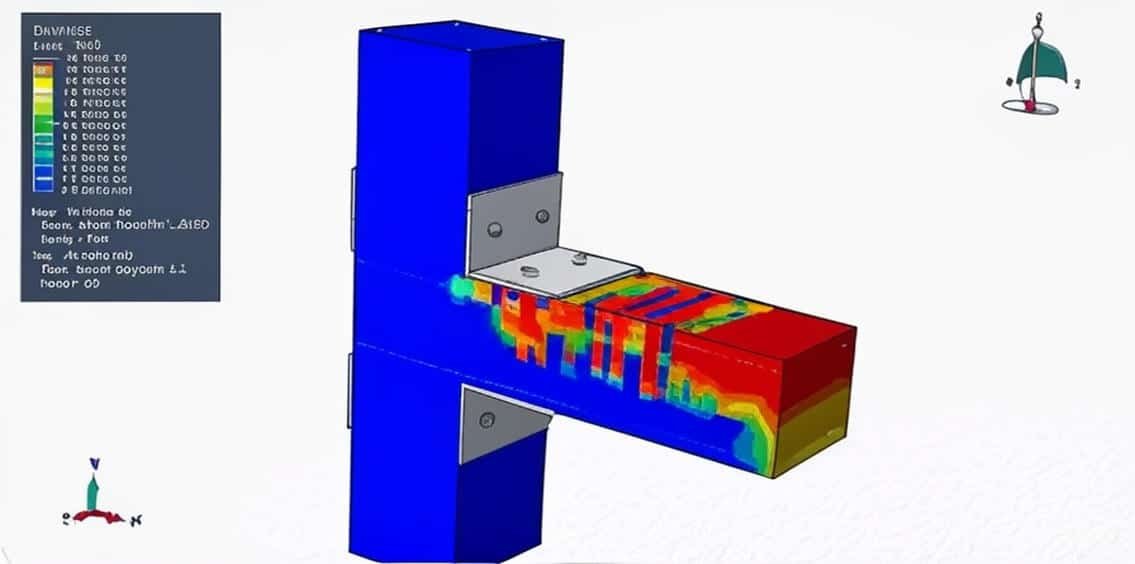

To ensure performance, engineers use bolt analysis and simulation techniques to predict how bolts behave under different conditions.

This package includes 17 tutorials that cover everything about bolt simulation in Abaqus.

1. What is Bolt Analysis?

Bolt analysis is the process of evaluating the strength, stiffness, and load distribution of bolted joints. The goal is to ensure the bolt (and the joint) can withstand:

- Preload (tightening force): The clamping force applied when tightening.

- External loads: Forces, moments, and vibrations acting on the joint during service.

- Stress concentrations: Localized stresses around threads and contact surfaces.

- Fatigue: Cyclic loading that may cause failure over time.

Key parameters considered:

- Bolt preload (torque–tension relationship).

- Tensile and shear stresses.

- Thread and bearing stresses.

- Joint stiffness vs. bolt stiffness.

- Safety factors (static and fatigue).

2. Why Simulate Bolted Joints?

Analytical formulas can estimate stresses, but simulation (often via Finite Element Analysis, FEA) gives a more accurate picture, especially for complex assemblies.

Simulation helps to:

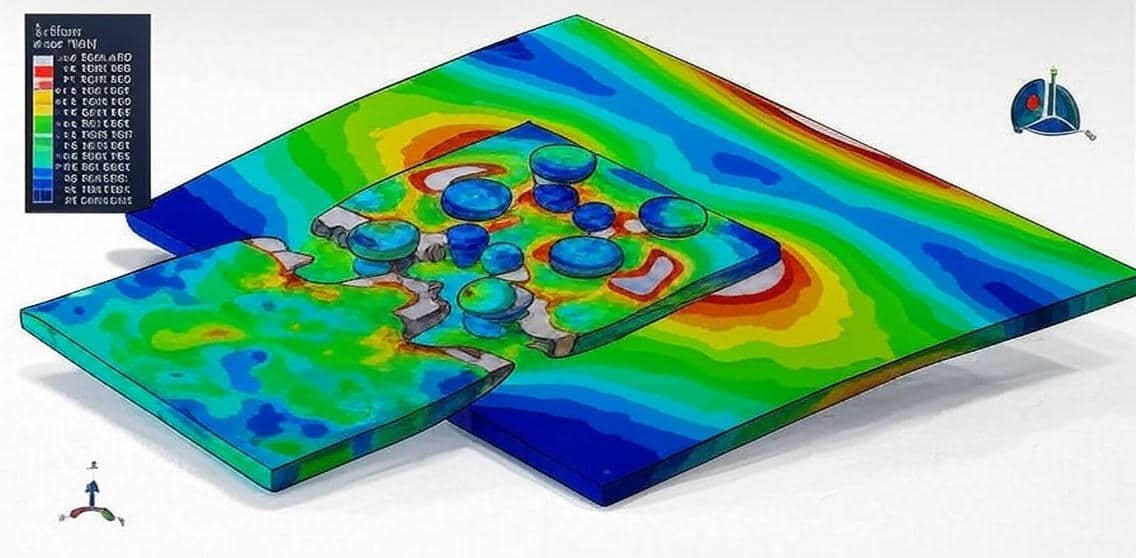

- Model load distribution across multiple bolts.

- Study gasket or flange behavior (sealing performance).

- Capture nonlinear effects like friction, contact, and plastic deformation.

- Evaluate loosening under vibration.

- Predict fatigue life.

3. Steps in Bolt Simulation (using FEA tools like ANSYS, Abaqus, Nastran, etc.)

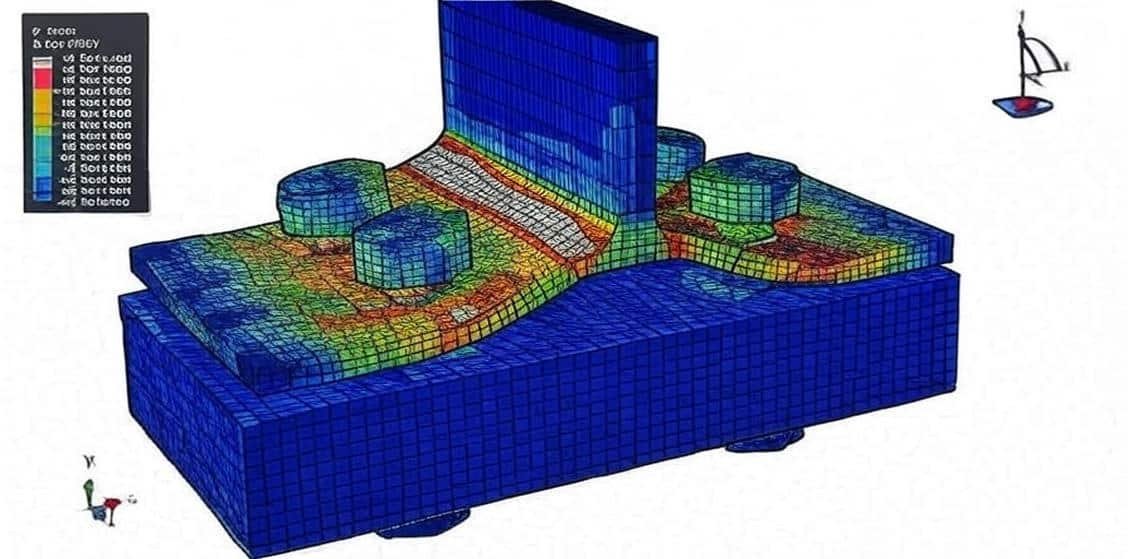

- Geometry & Meshing

- Represent bolts explicitly (3D solid model) or with simplified bolt connector elements.

- Define contact surfaces (threaded regions, bolt head/nut bearing areas).

- Preload Application

- Apply bolt tightening using pretension elements, temperature methods, or displacement constraints.

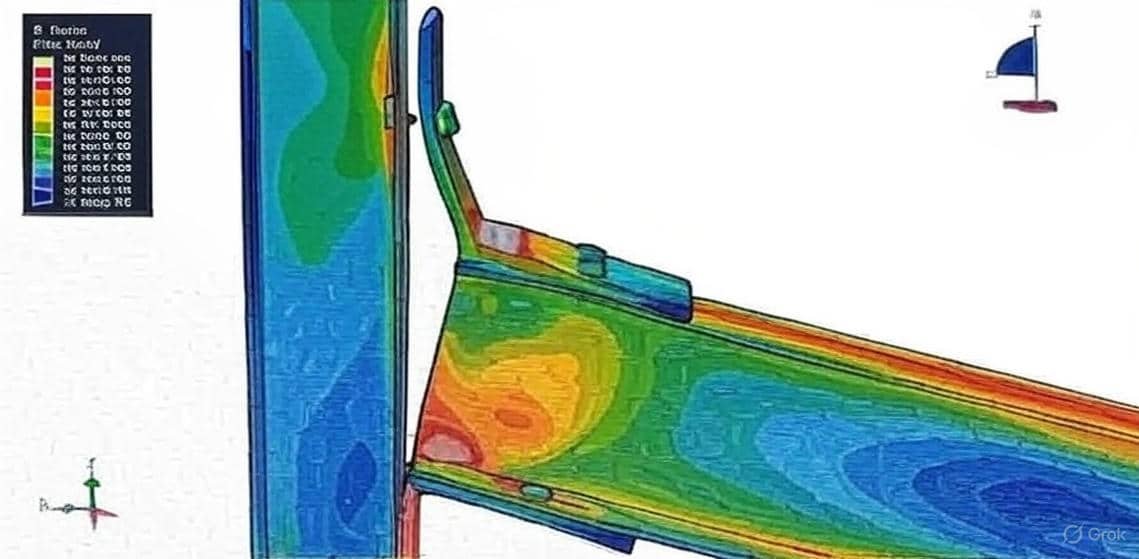

- External Loading

- Apply service loads: tensile, shear, bending, or dynamic loads.

- Analysis Types

- Linear static: Basic stress distribution.

- Nonlinear static: Includes friction, contact, and plasticity.

- Fatigue/dynamic analysis: To study vibration and loosening.

- Post-Processing

- Check bolt stress vs. allowable stress.

- Evaluate joint separation, slip, or overstress.

- Assess fatigue safety factor.

4. Common Considerations in Bolt Analysis

- Torque vs. preload scatter (due to friction uncertainty).

- Load distribution (not all bolts share the load equally).

- Joint relaxation (creep, embedment, or gasket compression).

- Failure modes: Tensile breakage, shear failure, thread stripping, fatigue, and self-loosening.

5. Applications

- Automotive (engine assembly, chassis joints).

- Aerospace (critical fasteners in wings, fuselage).

- Pressure vessels and pipelines (flange/gasket analysis).

- Heavy machinery and civil structures (steel connections, cranes, wind turbines).

In summary:

Bolt analysis ensures joints remain safe and reliable under preload and service conditions, while simulation (FEA) provides deeper insight into stress, deformation, and fatigue behavior. Together, they form a powerful approach to designing robust bolted connections.