Beam column joints are critical regions in framed structures where beams and columns intersect, transferring loads and moments between the vertical and horizontal members. The structural performance of these joints significantly influences the overall stability, ductility, and energy dissipation capacity of a building, especially under lateral loads such as wind or earthquakes. Consequently, accurate simulation and analysis of beam-column joints are essential for understanding their behavior and ensuring structural safety.

This package includes 23 detailed tutorials that comprehensively cover the modeling and analysis of steel and concrete beam-column joints in Abaqus. It describes various types of joints, including steel-to-steel, concrete-to-concrete, and steel-to-concrete connections, as well as open-leg columns and wide beam-column configurations. The tutorials address a wide range of loading conditions, such as seismic and cyclic loading, axial load, and compression. In addition, different joint types and strengthening components are discussed, including bolted connections, welded steel angles, gusset plates, stiffeners, FRP, ECC, and more.

In both steel and reinforced concrete (RC) structures, the joint region experiences complex stress states due to the interaction of axial, shear, and bending forces. Failure or excessive deformation of these joints can lead to progressive collapse of the entire frame system. Therefore, their design and analysis require detailed consideration of material behavior, load transfer mechanisms, and connection detailing.

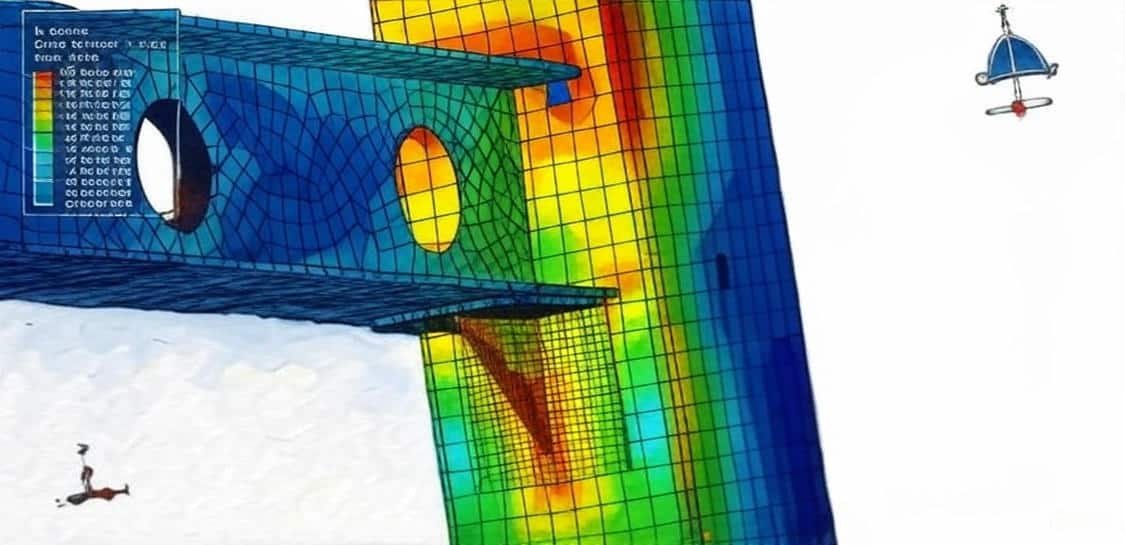

In steel structures, beam-column joints are typically formed using bolted or welded connections. These joints are designed to provide sufficient stiffness and strength while accommodating deformation.

Key factors influencing the performance of steel joints include:

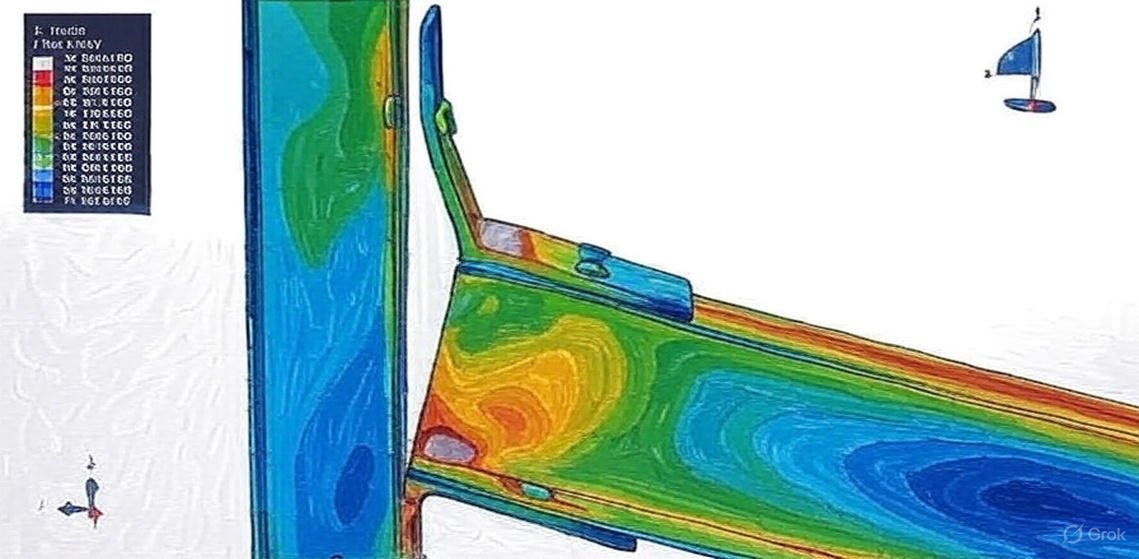

Finite Element Analysis (FEA) tools such as Abaqus are widely used to model these connections, capturing non-linear material behavior, contact interactions, and potential failure modes like bolt shear or plate yielding.

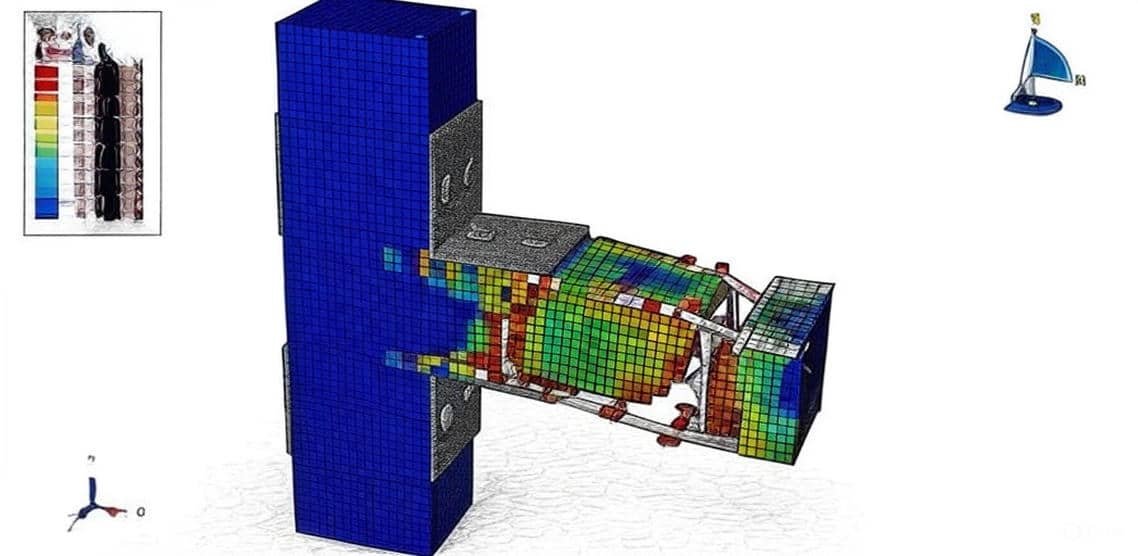

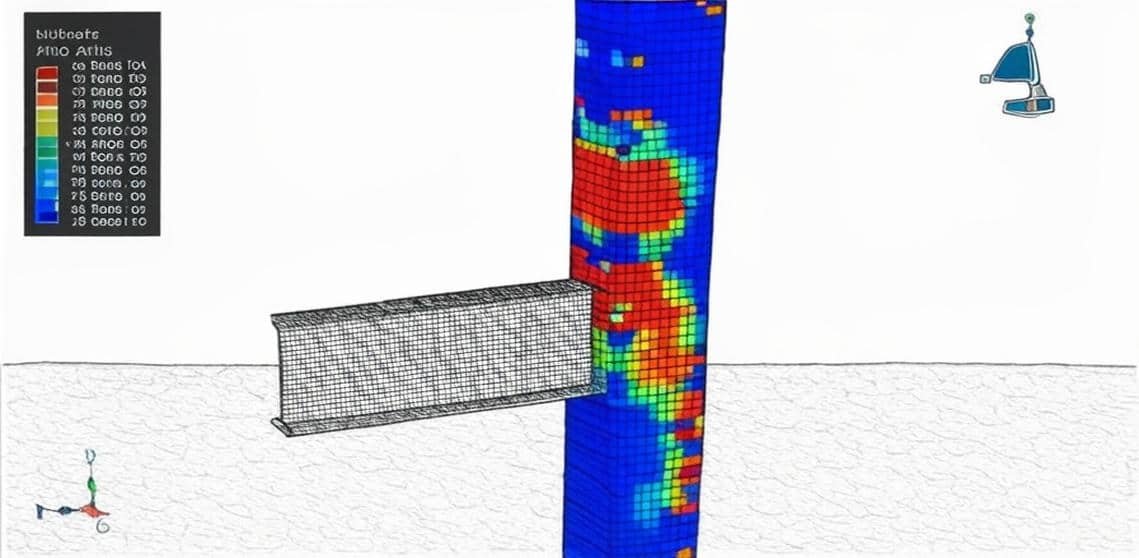

In reinforced concrete frames, joints are monolithic regions where reinforcement from beams and columns intersect. Under seismic or cyclic loading, these joints are often the most vulnerable zones due to stress concentration and bond deterioration between concrete and steel.

Important aspects include:

Nonlinear analysis in Abaqus can simulate these effects using material models such as the Concrete Damaged Plasticity (CDP) model, rebar embedded constraints, and contact definitions between steel and concrete.

Abaqus provides an advanced environment for modeling both steel and concrete beam-column joints through:

Parametric studies can be conducted to evaluate the effects of geometry, reinforcement ratio, connection detailing, and loading conditions on joint behavior. Results typically include stress distribution, load-displacement response, and potential failure mechanisms.

Code validation and performance-based design research

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?