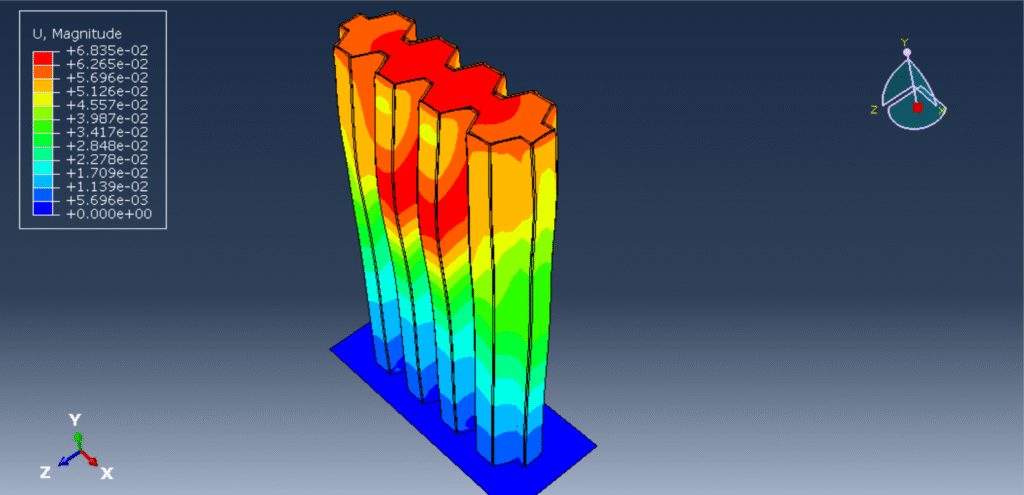

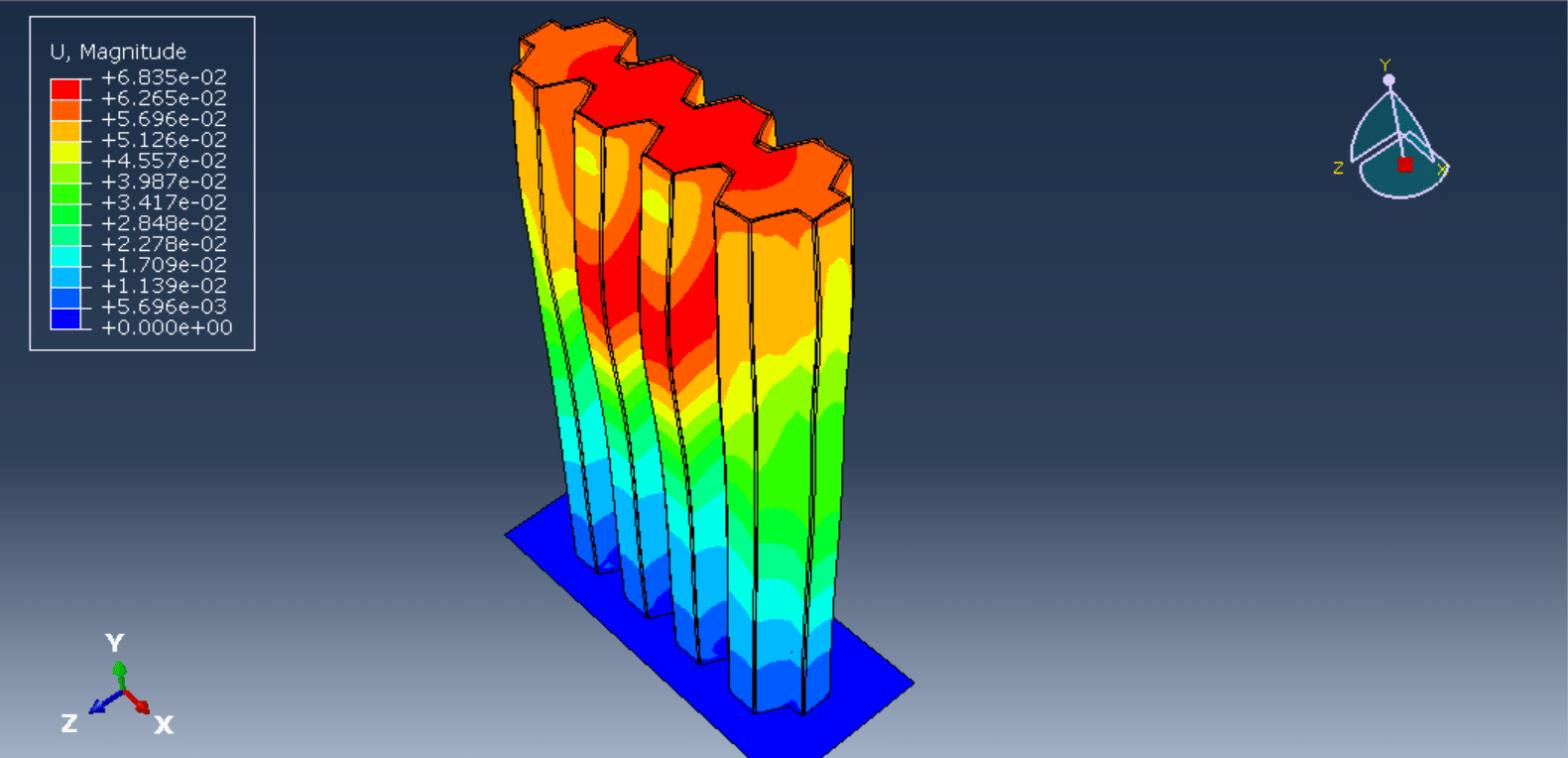

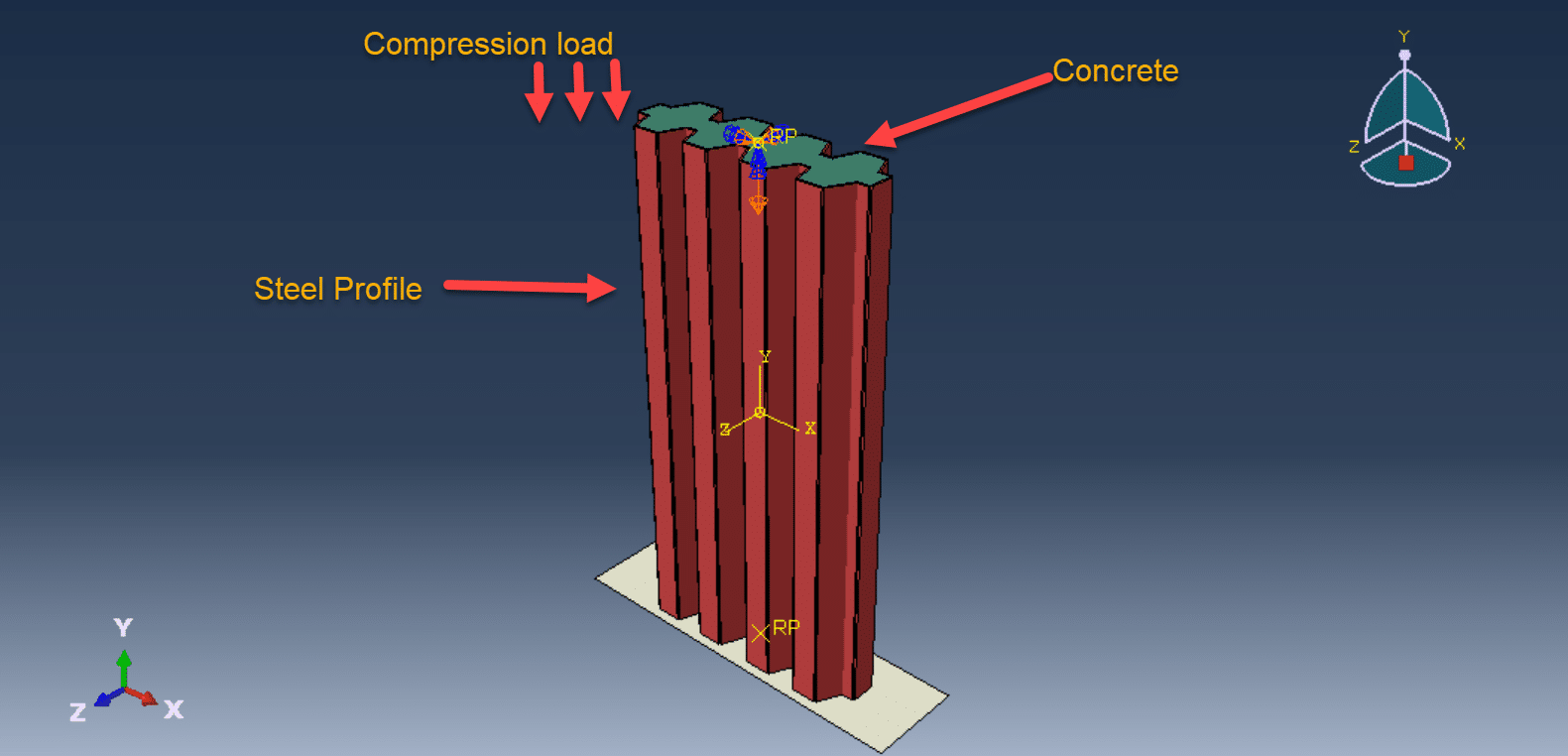

Composite panels comprising profiled steel skins and a concrete core have gained increasing attention in modern structural engineering due to their high strength-to-weight ratio, rapid assembly, and favorable mechanical properties. These sandwich-type panels, often referred to as steel-concrete composite panels (SCCPs), are commonly used in applications such as modular construction, prefabricated buildings, and protective structures.

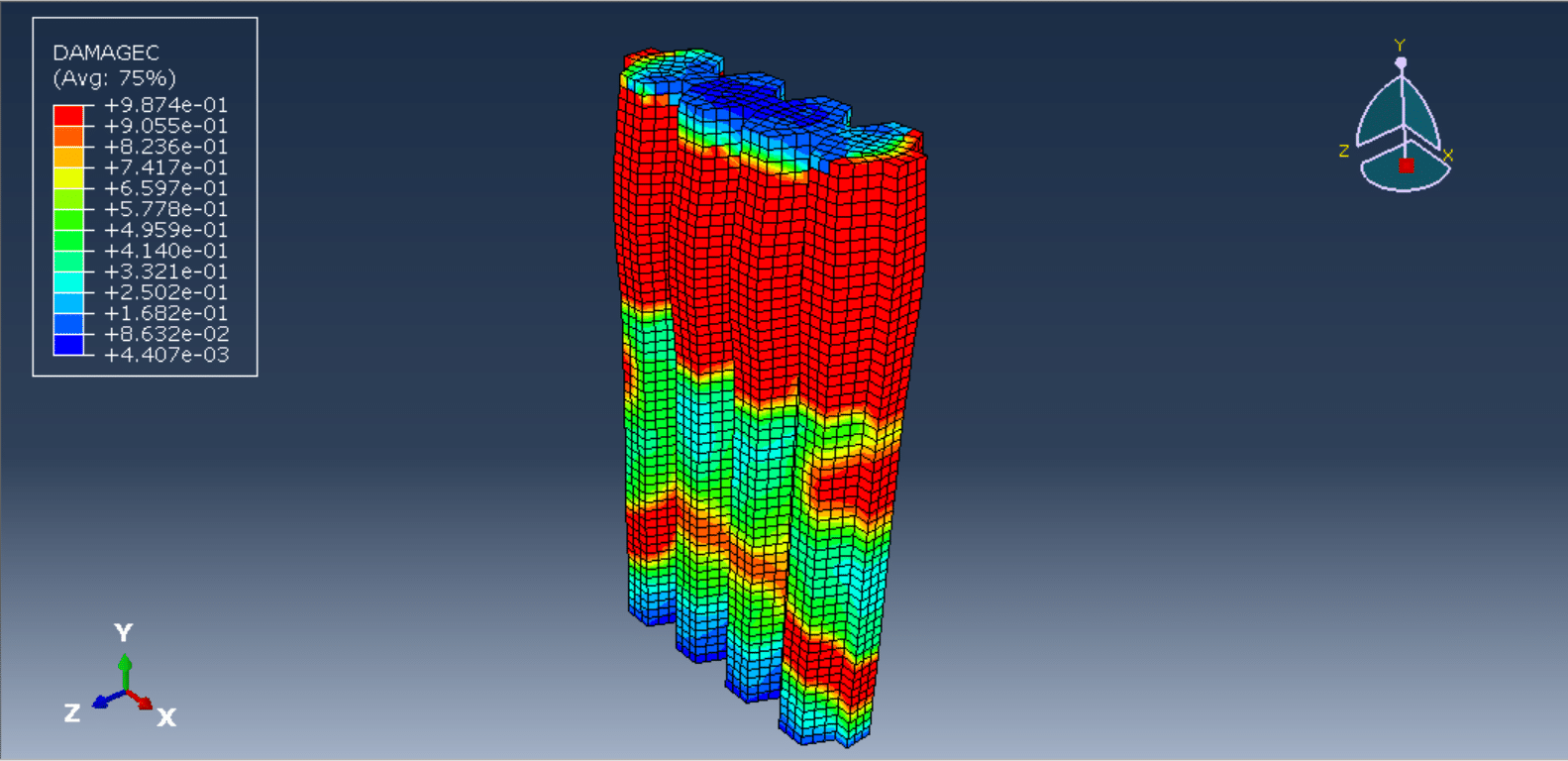

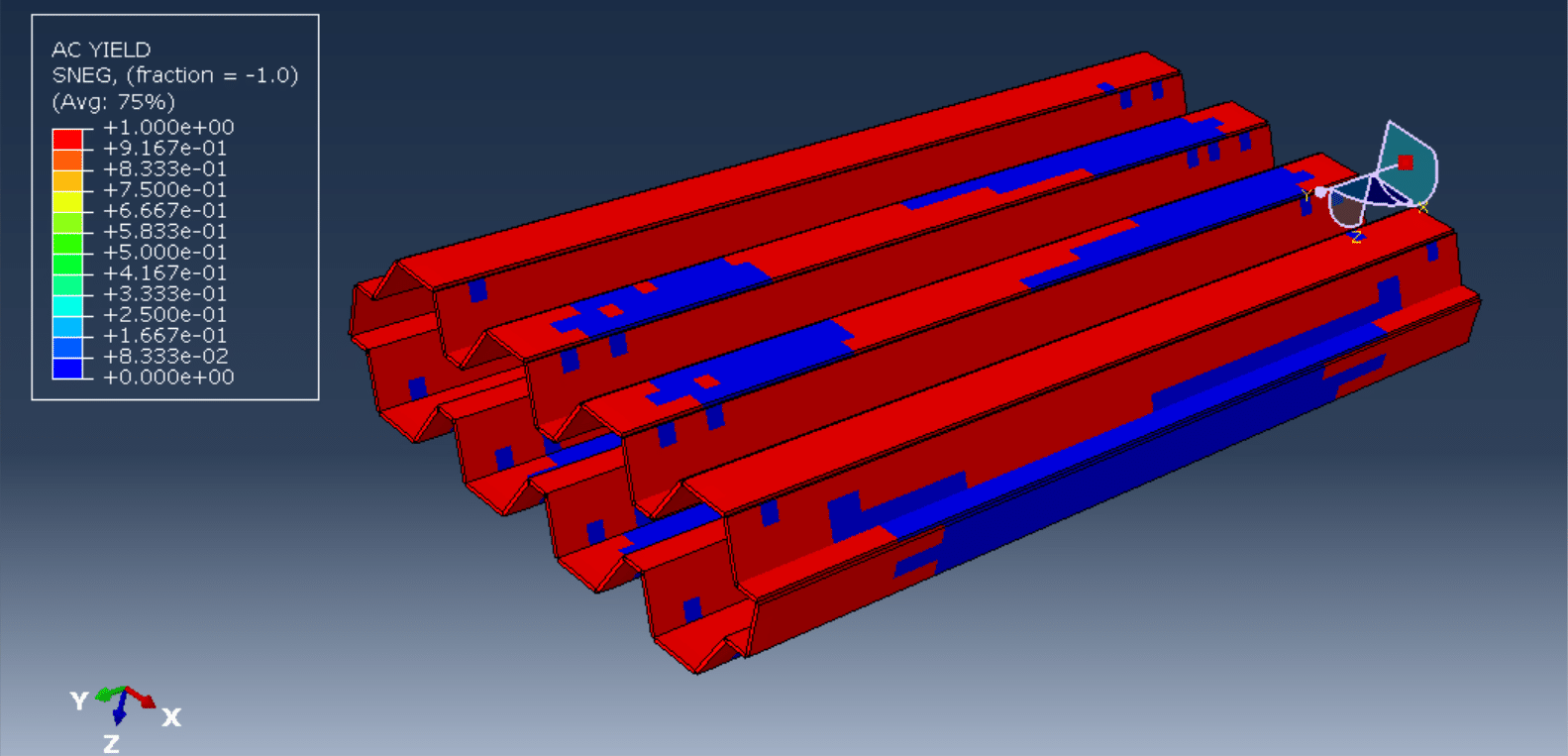

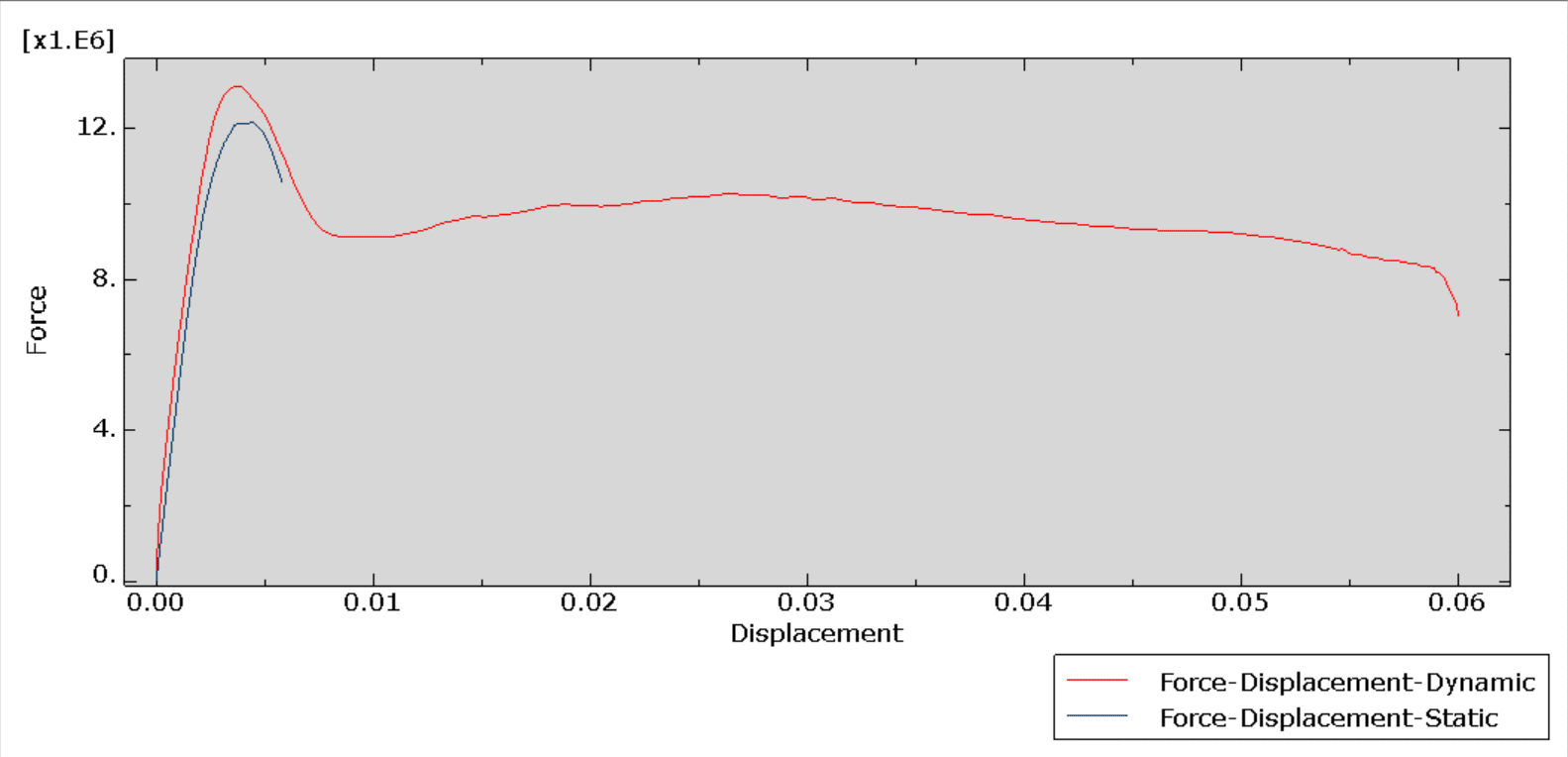

Under axial compressive loads, the interaction between the steel skins and the concrete core is critical in dictating the overall structural performance. The profiled geometry of the steel faceplates enhances mechanical interlock with the core, improves local buckling resistance, and facilitates composite action. The concrete core, often made with lightweight or high-performance concrete, provides rigidity, load distribution capacity, and contributes to the energy absorption characteristics of the panel.

Key parameters influencing the axial behavior include:

Skin profile geometry (depth, pitch, and corrugation pattern),

Core thickness and material properties,

Boundary conditions and loading eccentricities.

Experimental and analytical studies have demonstrated that the failure modes under axial compression can include local buckling of the steel skins, crushing or cracking of the concrete core, depending on the configuration and loading. Understanding these behaviors is crucial for optimizing the design of such panels to ensure safety, serviceability, and cost-effectiveness.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?