In the development of high-rise and super high-rise buildings, structural systems with improved performance are required to enhance the load-bearing capacity of buildings. Concrete-filled steel tube (CFST) composite structures have emerged as a relatively new structural form in the construction industry and have been widely applied worldwide. With the development of CFST columns, special-shaped CFST columns have attracted increasing attention from researchers and designers because of their advantages in avoiding column protrusions from walls and increasing usable interior space. However, in special-shaped CFST columns, the steel tube provides relatively weak confinement to the core concrete, and negative angles exist in the cross-section. Under loading, the negative-angle regions may experience large deformations and damage, which can lead to a reduction in the bearing capacity of special-shaped CFST columns. In particular, for T-shaped columns, the separation between the steel tube and the concrete at the inner corner may prevent the two materials from fully interacting, and the large width-to-thickness ratio of the steel plates may lead to premature local buckling.

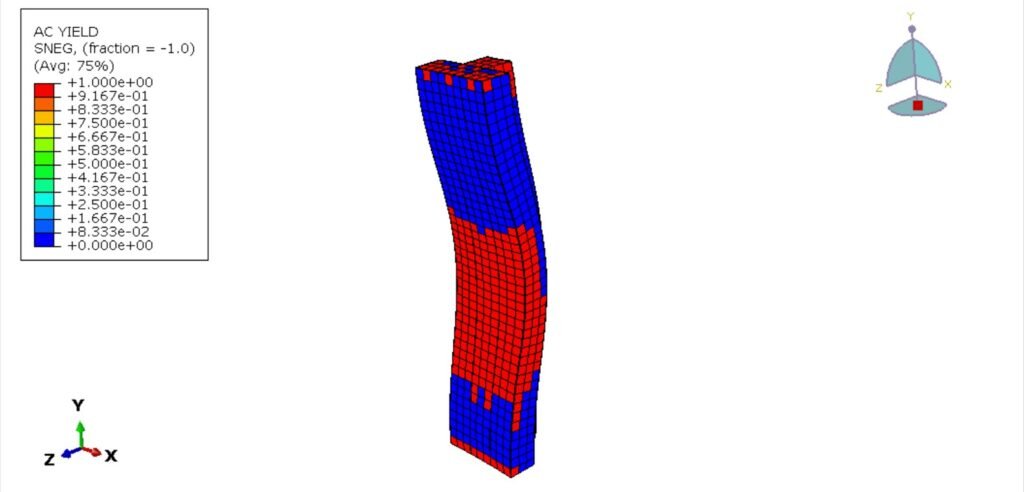

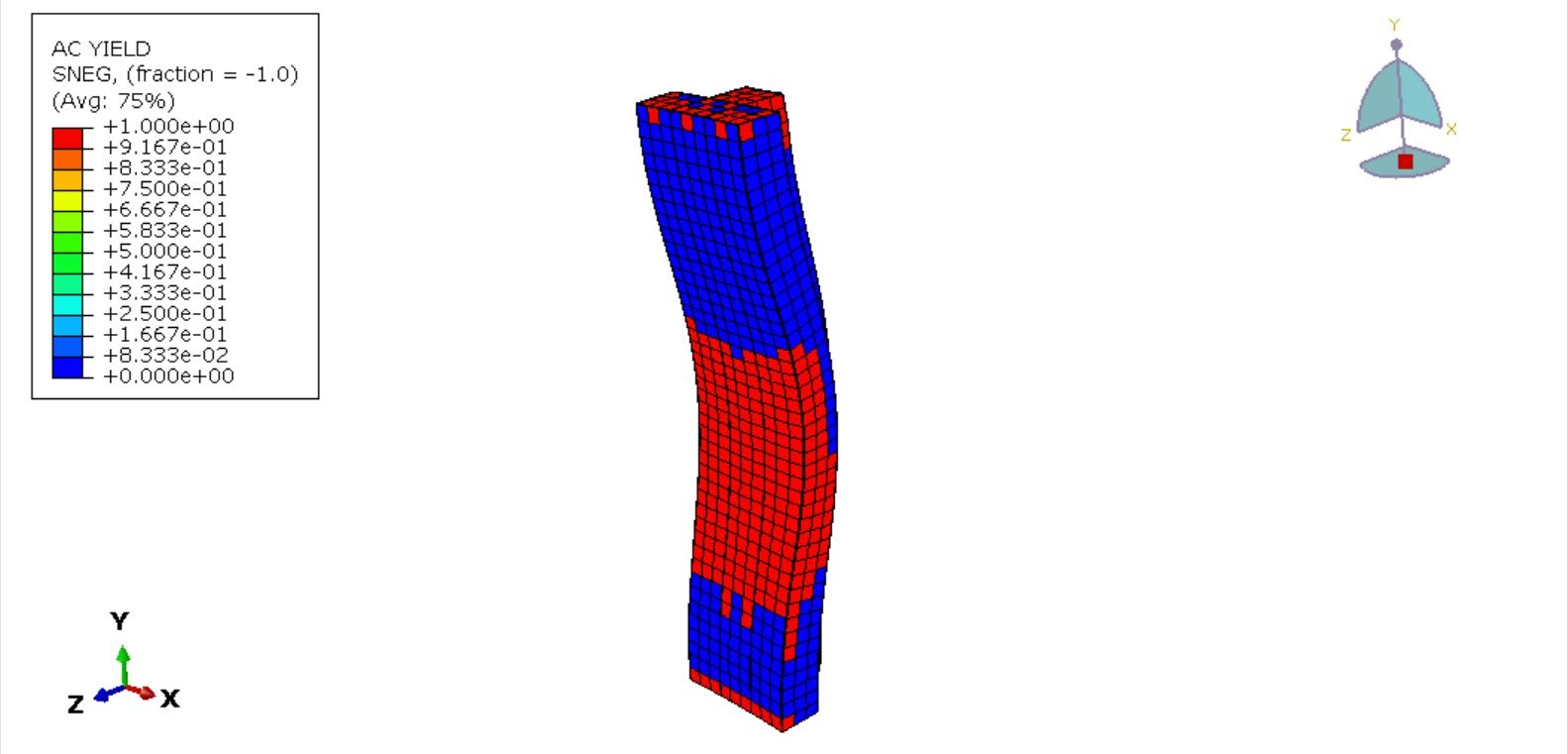

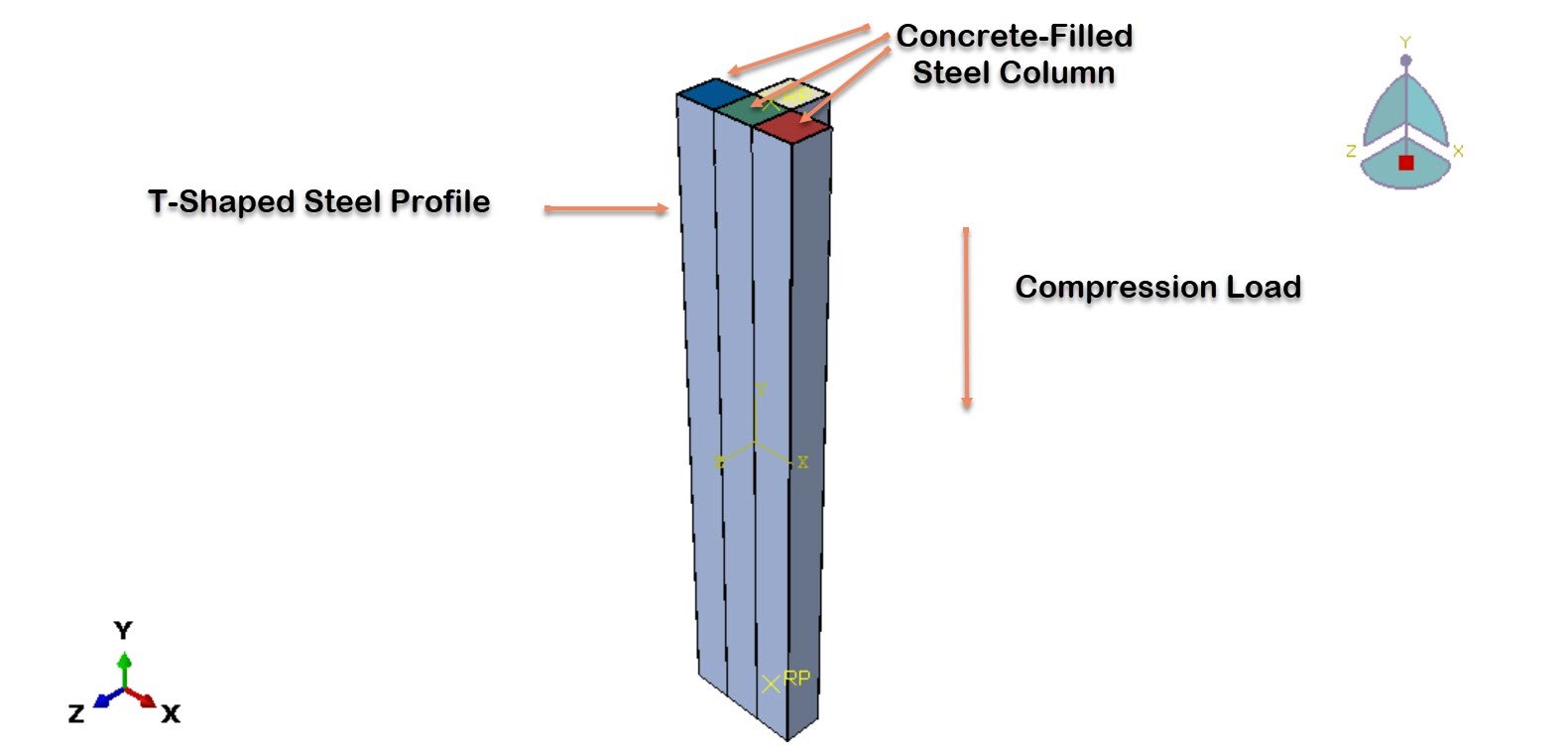

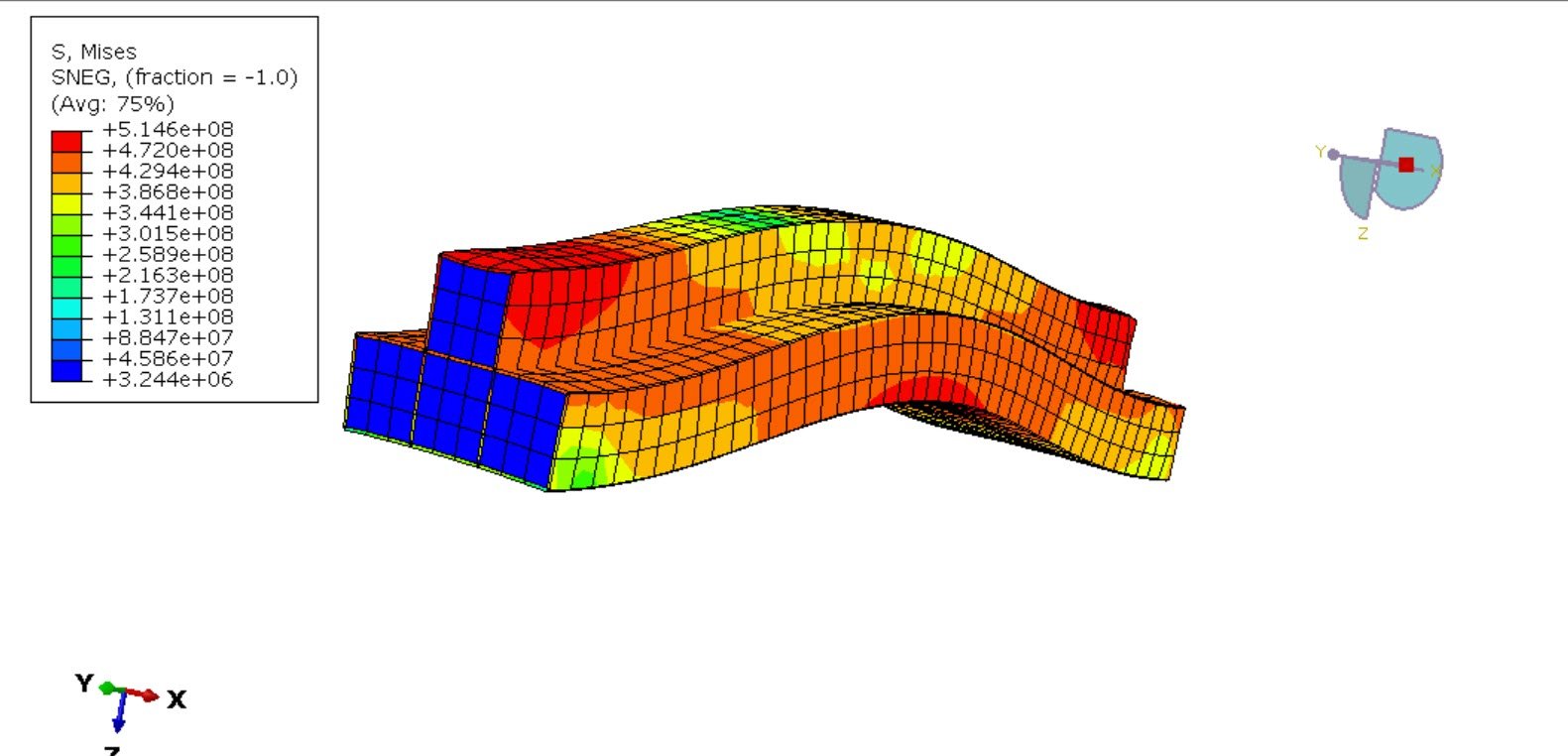

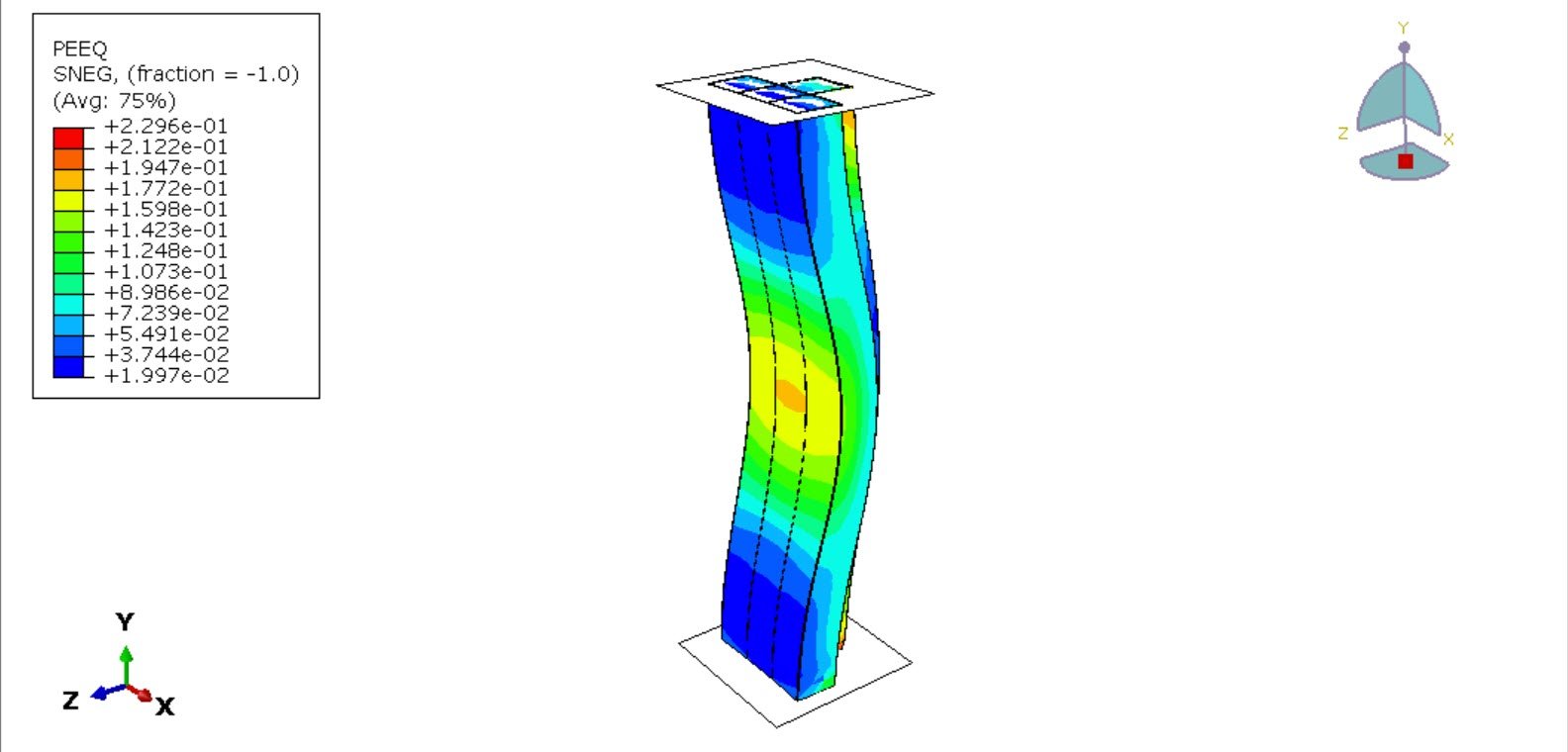

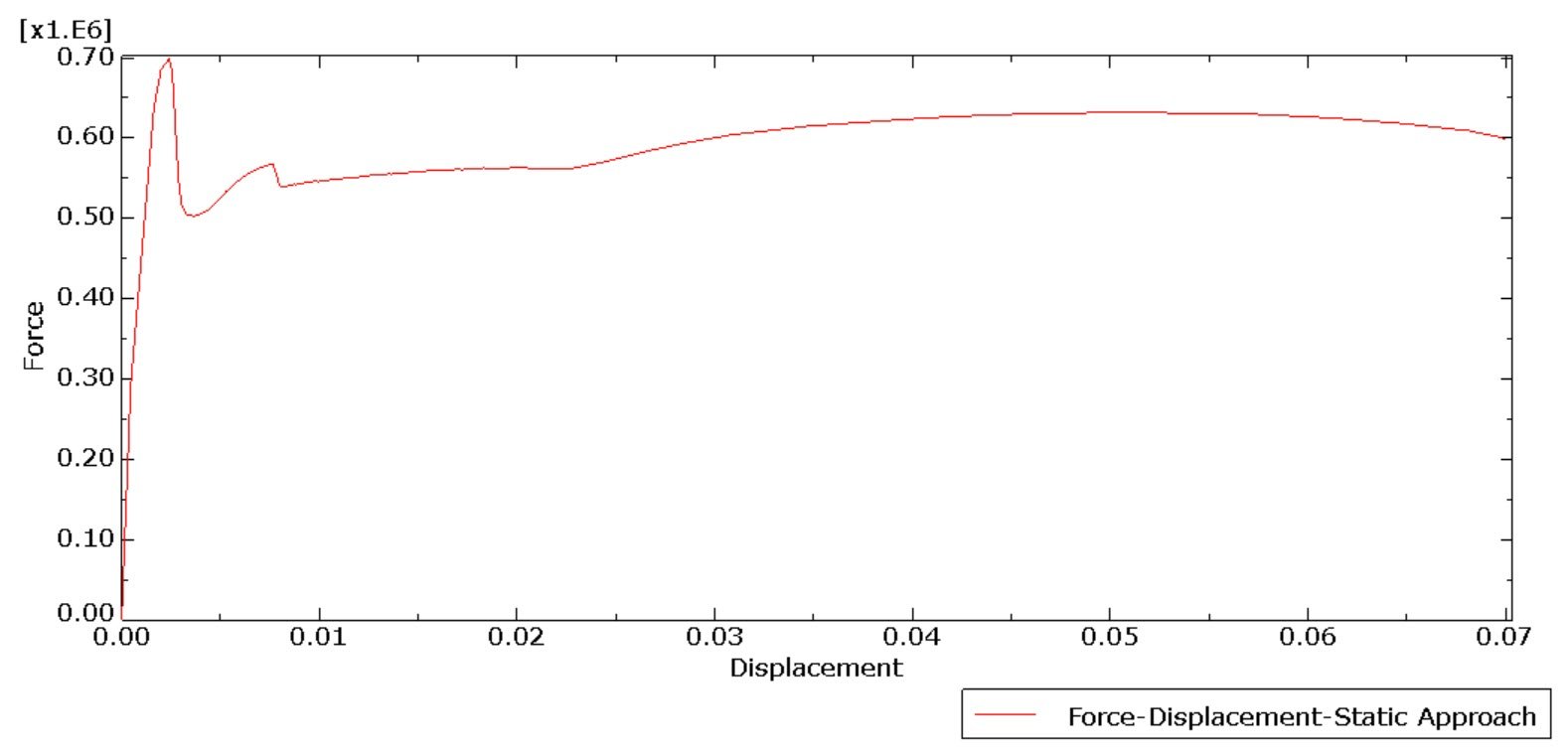

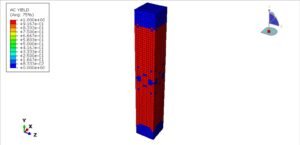

To investigate the axial compression performance of T-shaped multi-cavity concrete-filled steel tube shear walls, the specimen was designed and tested under axial compression. Additionally, a three-dimensional finite element analysis was conducted using ABAQUS to assess the axial bearing capacity of the shear walls. The multi-cavity CFSTSW adopts a three-dimensional model, in which the steel tube is adopted. The S4R shell element and the concrete adopt the C3D8R solid element.

Ansys

€129,00

Abaqus

€79,00 €38,00

Abaqus

€78,00 €37,00

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

See more

Want to receive push notifications for all major on-site activities?