The increasing threat of accidental and intentional explosions in industrial facilities, military infrastructures, and critical civil structures has highlighted the necessity for construction materials with superior resistance to extreme dynamic loads. Conventional reinforced concrete, although widely used due to its strength and durability, exhibits brittle behavior and limited energy absorption capacity when subjected to high-intensity air blast loads. This vulnerability often leads to severe cracking, spalling, and catastrophic failure. As a result, the development of advanced cementitious composites with enhanced blast resistance has become a significant area of research in structural and materials engineering.

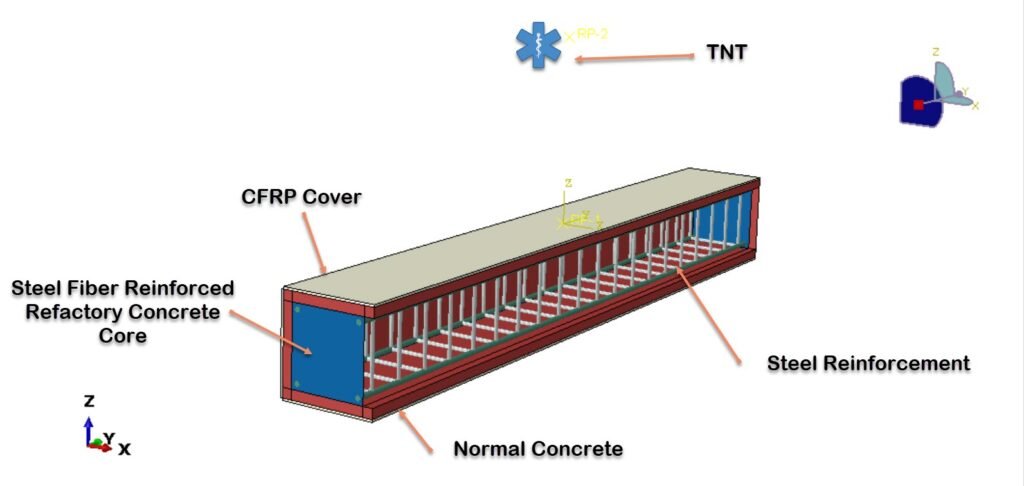

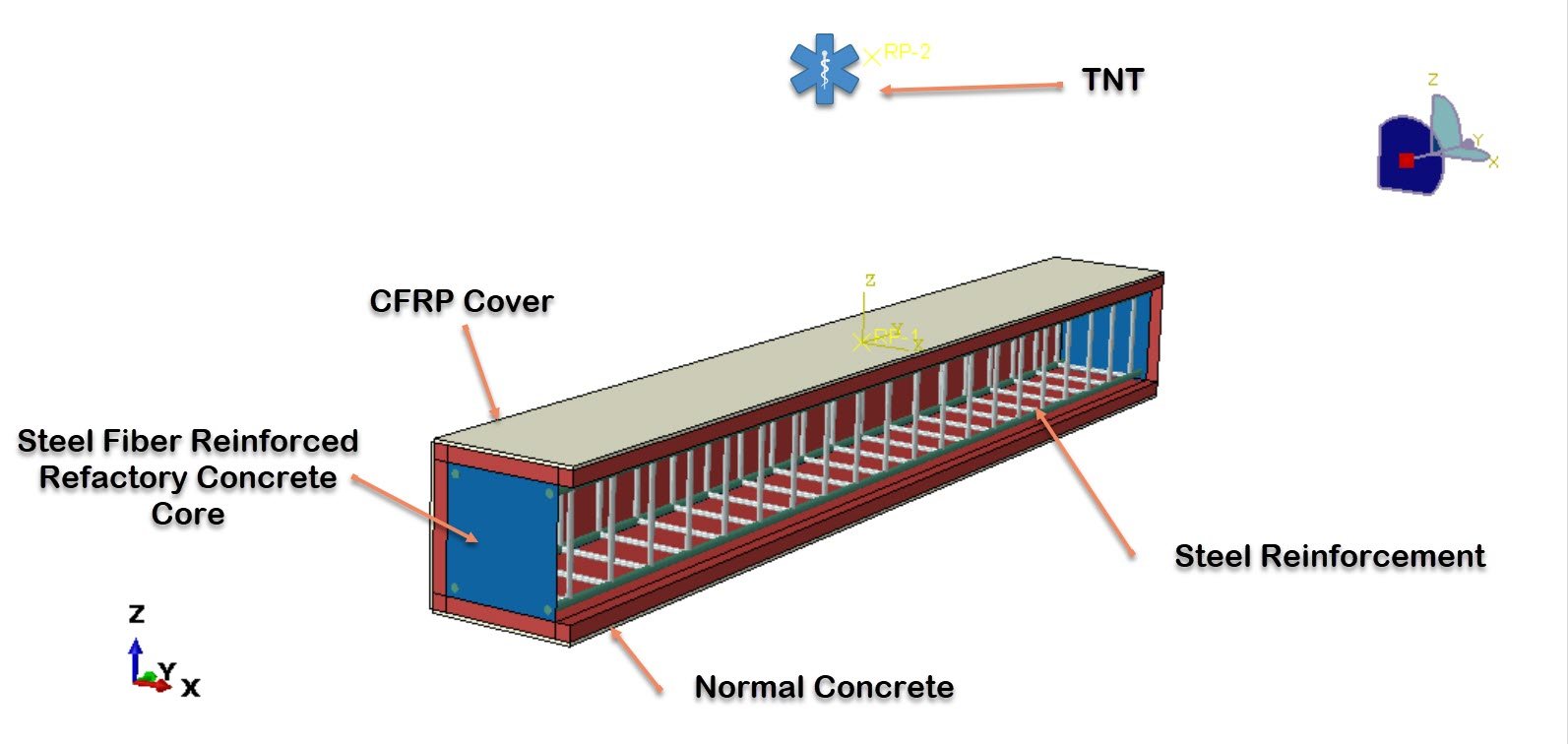

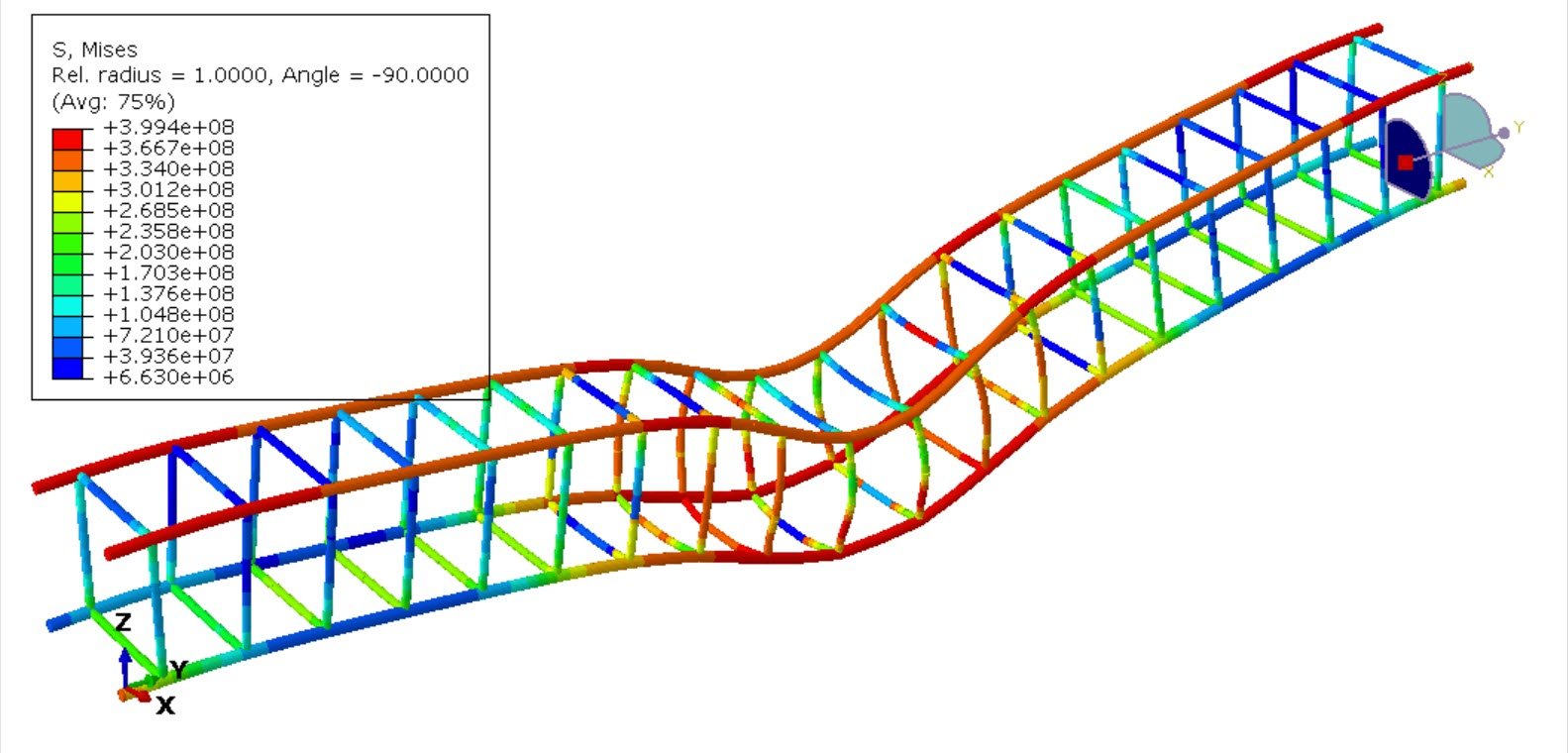

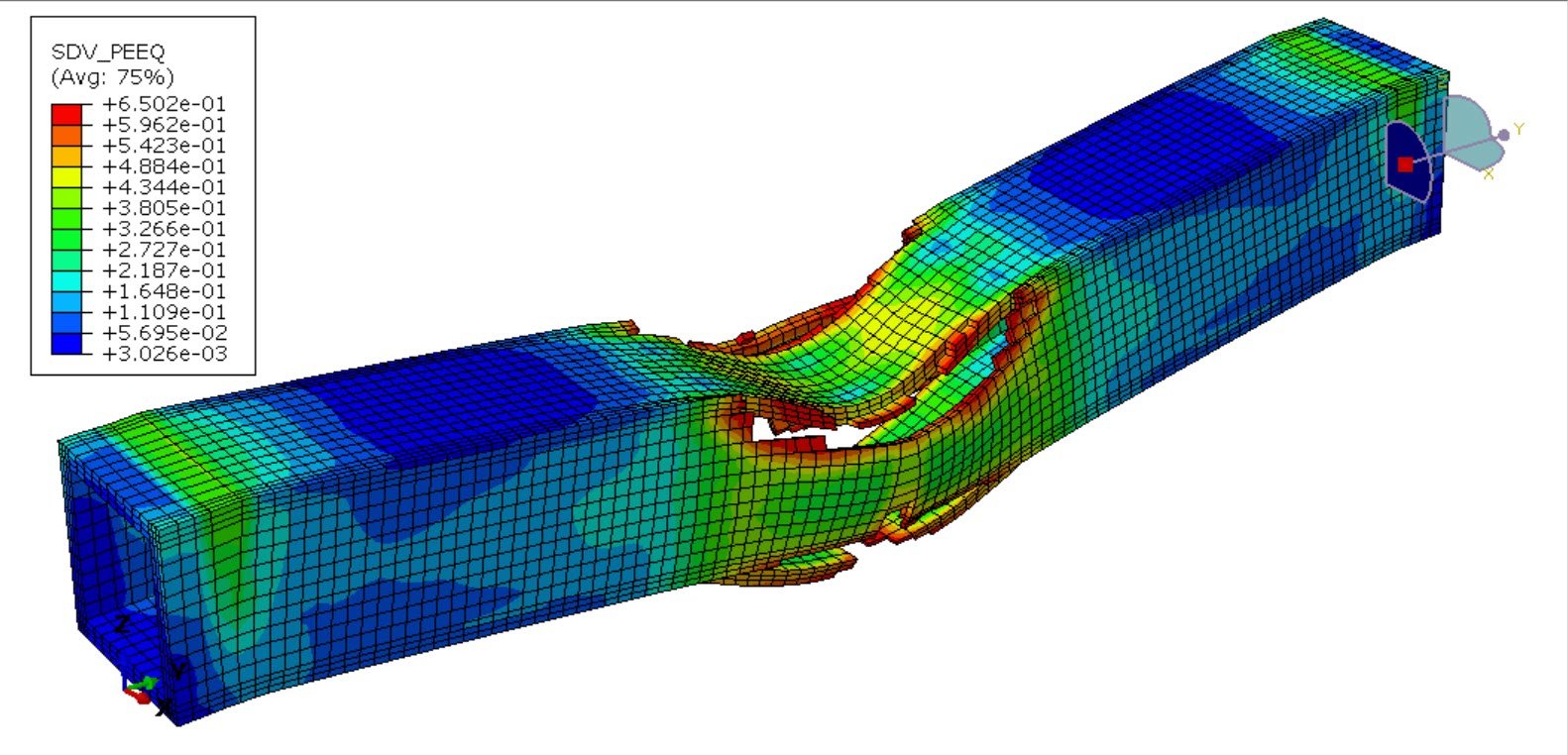

In this example, an SSFRRC beam with a normal concrete outer layer, CFRP composite material, and steel bars as reinforcement is considered. To model the SSFRRC beam, the Concrete Damaged Plasticity model is used for the refractory concrete; the Johnson–Holmquist model is applied to the normal concrete; the Johnson–Cook hardening and damage model is adopted for the steel reinforcement; and finally, the Hashin damage model is employed for the CFRP composite material. A dynamic explicit analysis step, the CONWEP air blast model, and material definitions implemented through the input file are selected.

Stainless steel fiber reinforced refractory concrete (SSFRRC) represents a promising class of high-performance composite materials designed to withstand extreme thermal and mechanical environments. Refractory concrete is traditionally used in high-temperature applications due to its excellent fire resistance, thermal stability, and low thermal conductivity. The incorporation of stainless steel fibers further enhances its mechanical performance by improving tensile strength, crack-bridging capability, ductility, and energy dissipation capacity. Stainless steel fibers are particularly advantageous under blast loading conditions because of their high strength, corrosion resistance, and ability to maintain mechanical integrity at elevated temperatures.

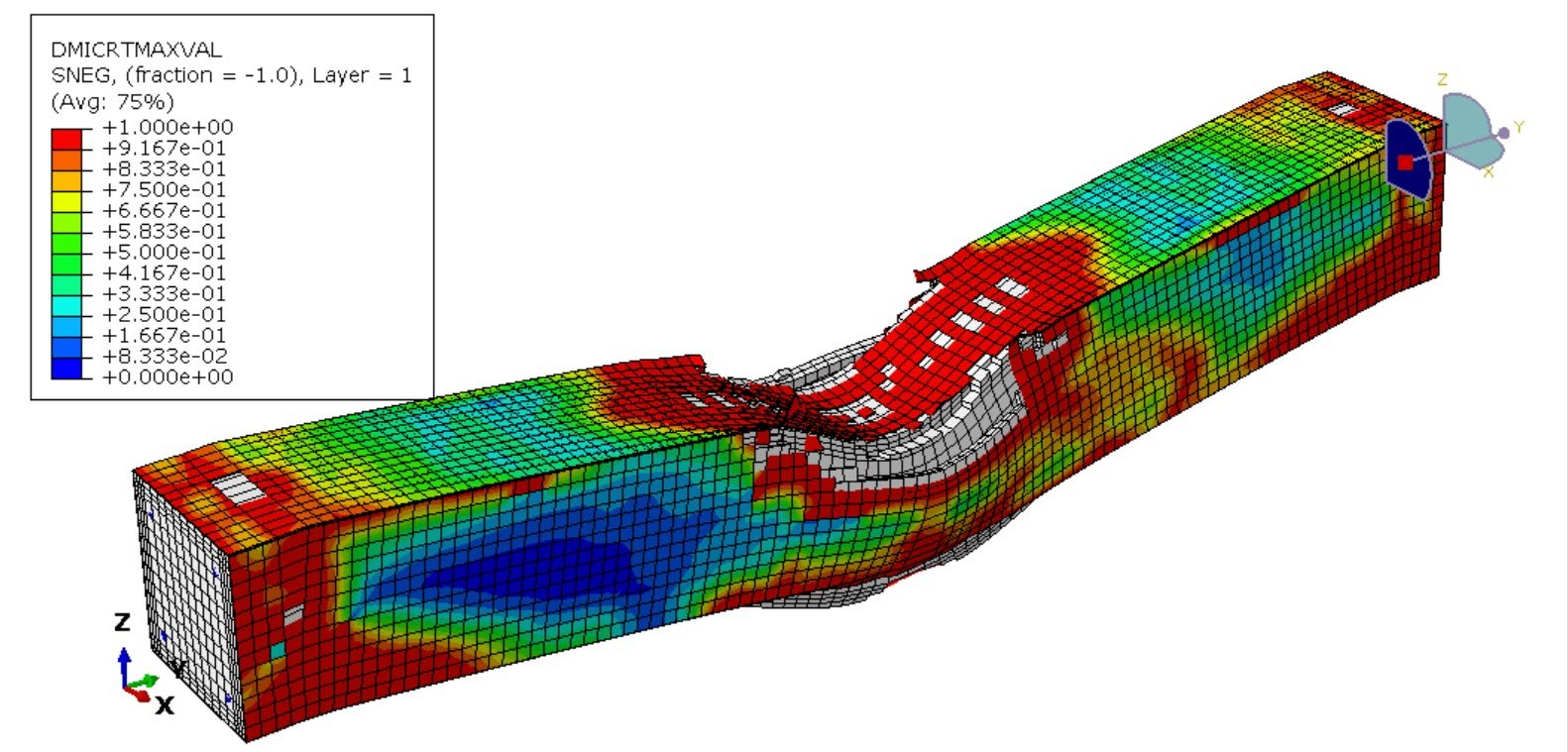

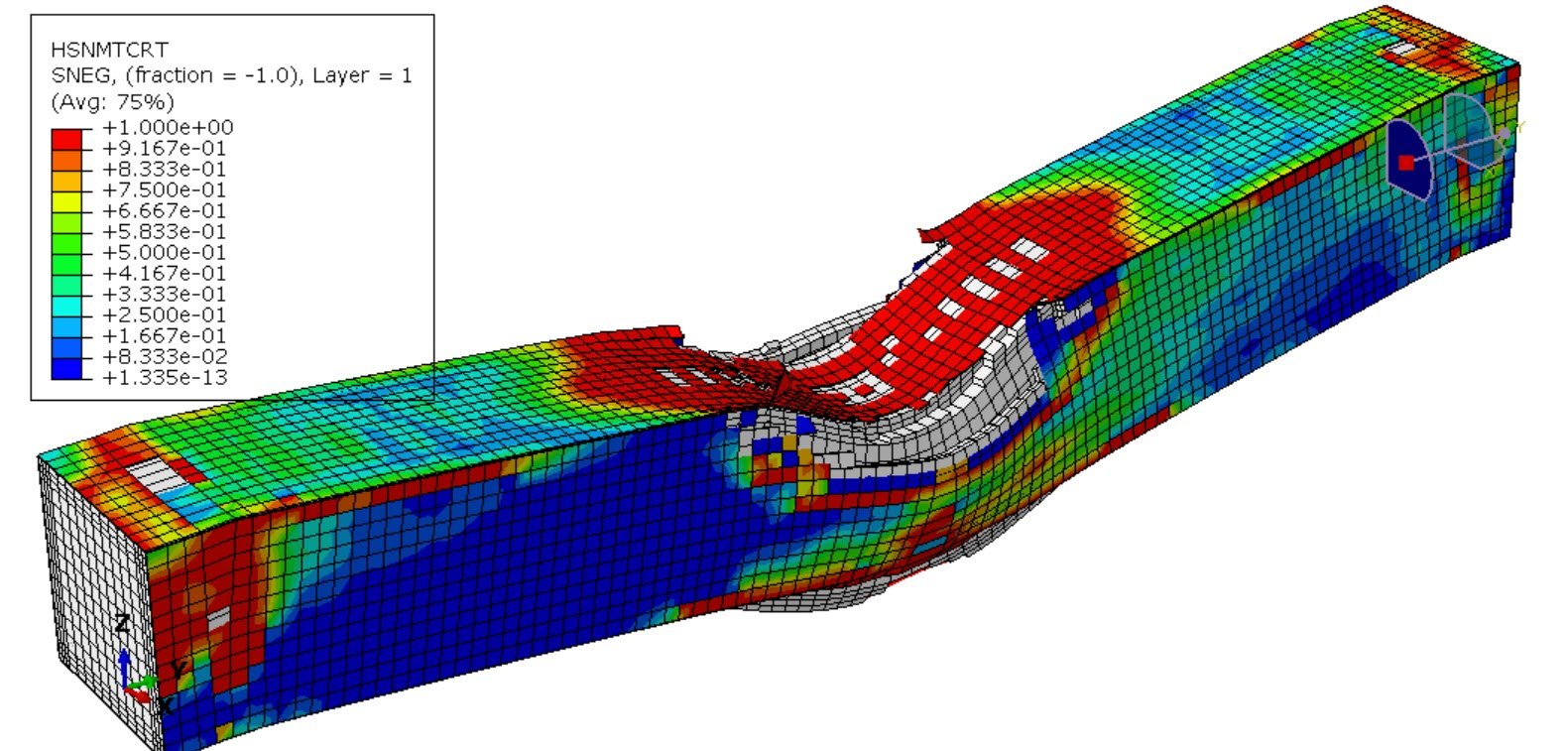

When SSFRRC is used in beam elements, the synergistic interaction between the refractory concrete matrix and the randomly distributed stainless steel fibers significantly alters the structural response under dynamic loading. Under air blast loads, SSFRRC composite beams exhibit delayed crack initiation, reduced crack propagation, enhanced flexural capacity, and improved post-cracking behavior compared to plain or conventionally reinforced refractory concrete beams. The fibers act as micro-reinforcement, controlling crack widths and redistributing stresses, thereby mitigating localized damage and reducing spall formation on the tension and compression faces of the beam.

The analysis of SSFRRC composite beams subjected to air blast loading involves complex multi-physics and multi-scale considerations. Air blast loads are characterized by extremely short durations, high strain rates, and nonlinear pressure–time histories, which demand advanced analytical, numerical, and experimental approaches. Material nonlinearity, strain-rate sensitivity, fiber–matrix interaction, and dynamic boundary conditions play crucial roles in accurately predicting the structural response. Understanding these behaviors is essential for optimizing fiber content, beam geometry, and reinforcement strategies to achieve superior blast resistance.

This study focuses on the analysis of stainless steel fiber reinforced refractory concrete composite beams under air blast loading, aiming to evaluate their dynamic response, damage mechanisms, and failure modes. By investigating parameters such as fiber volume fraction, blast intensity, and support conditions, valuable insights can be obtained into the effectiveness of SSFRRC as a protective structural material. The outcomes of such analyses contribute to the development of safer, more resilient structural systems for applications in defense, petrochemical, and critical infrastructure sectors.

Ansys

€129,00

Abaqus

€79,00 €38,00

Abaqus

€78,00 €37,00

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

See more

Want to receive push notifications for all major on-site activities?