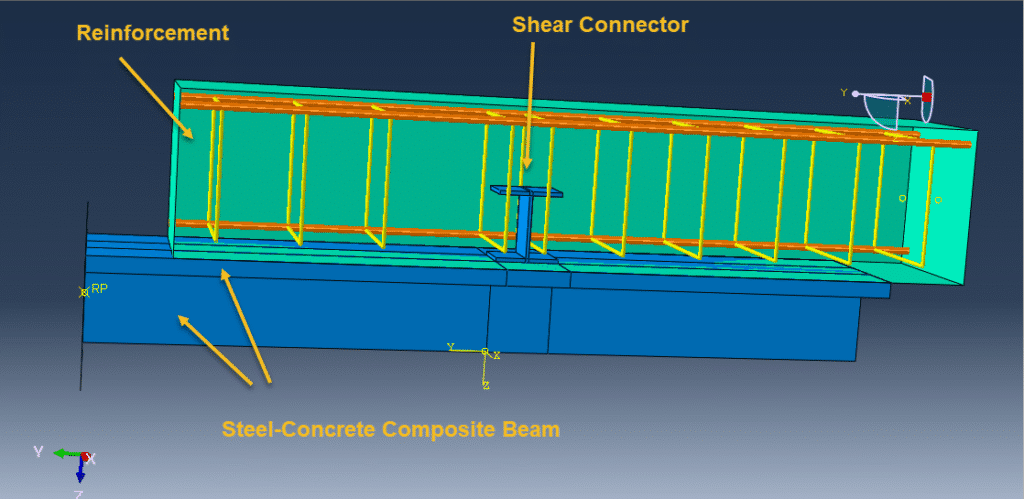

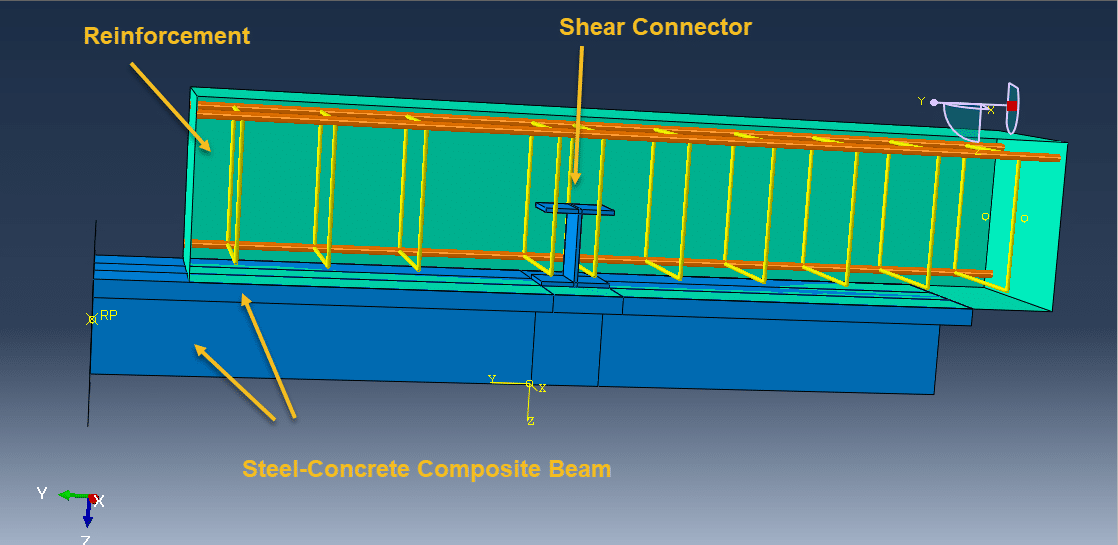

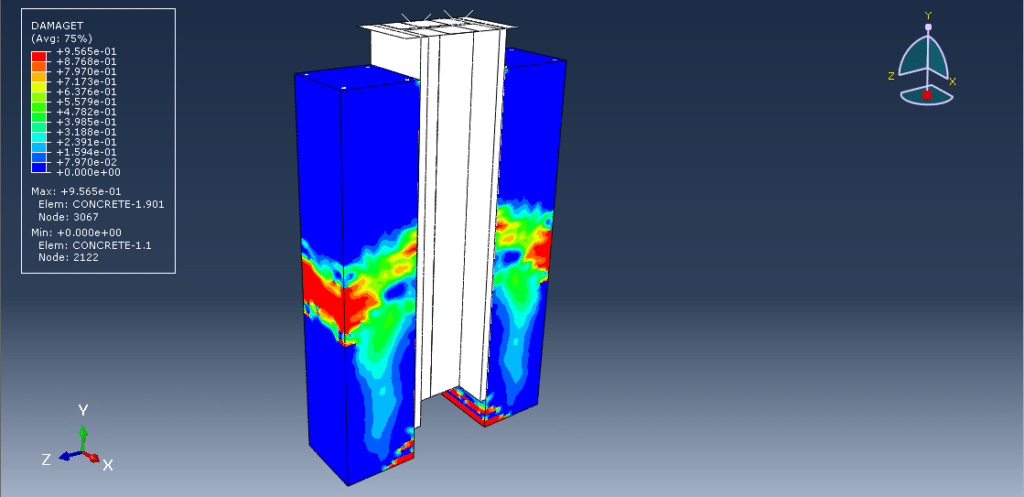

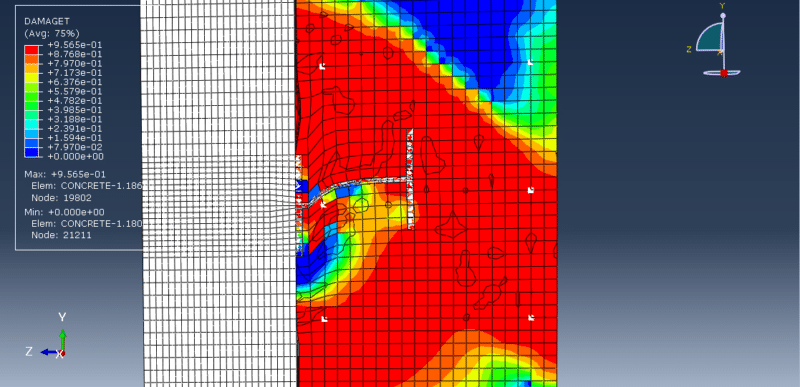

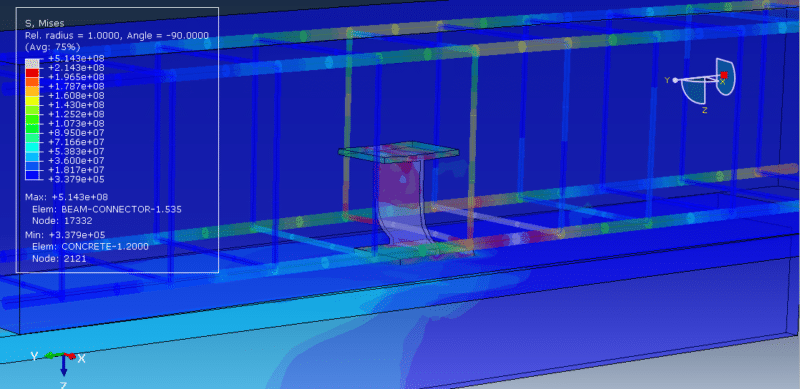

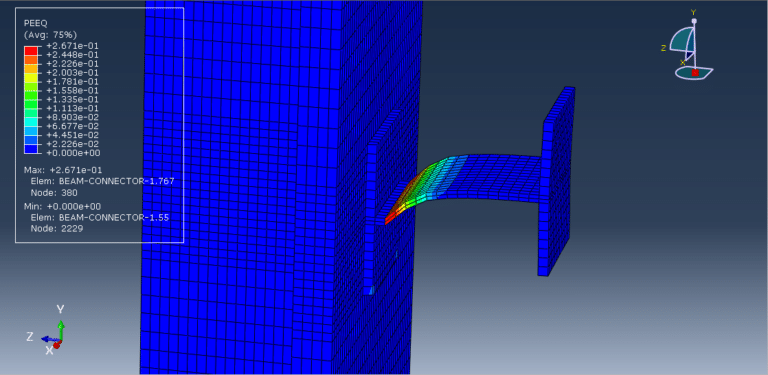

In this tutorial, the simulation of a push out test on a new I-shape shear connector has been carried out in Abaqus. The concrete slab is modeled as a three-dimensional solid part, the steel reinforcements are represented as wire parts, and the steel beam and shear connector are modeled as three-dimensional solid parts. Shear connectors are widely used to ensure composite action in steel concrete composite beams, where their primary function is to resist longitudinal shear forces at the steel concrete interface and prevent vertical separation between the concrete slab and supporting steel beam. While welded stud connectors are the most common in practice due to their simplicity and head shape that helps shear transfer and prevents uplift, they are limited by low load-carrying capacity and fatigue issues under live loads in composite bridges. To overcome these limitations, alternative designs such as angle connectors with anti-uplift features have been proposed and applied in regions like Algeria and other countries. In this simulation, the Concrete Damaged Plasticity (CDP) model is applied to the concrete to capture tensile cracking, compressive crushing, and damage evolution, with tension and compression data provided. The steel members and shear connectors are defined using an elastic-plastic material model. Both dynamic and static analyses can be applied, but the dynamic method is more suitable for this model due to complex part interactions. Surface-to-surface contact with friction is defined between the steel beam and the concrete; reinforcements are embedded in the concrete, and the shear connector is constrained within the slab. Proper boundary conditions and a refined mesh are assigned to all parts to ensure accuracy. After the simulation, results such as stress, strain, tension damage, compression damage, and connector failure are obtained for evaluation.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?