Interlocking masonry systems have gained significant attention in modern construction due to their ease of assembly, reduced need for skilled labor, and improved structural performance under various loading conditions. Unlike conventional masonry, interlocking units rely on geometric interlock rather than mortar bonds, providing benefits such as rapid construction, enhanced alignment, and increased energy dissipation capacity. As sustainable construction practices become increasingly important, researchers have explored the incorporation of waste materials—including recycled tire rubber—into concrete masonry units to improve both environmental and mechanical performance.

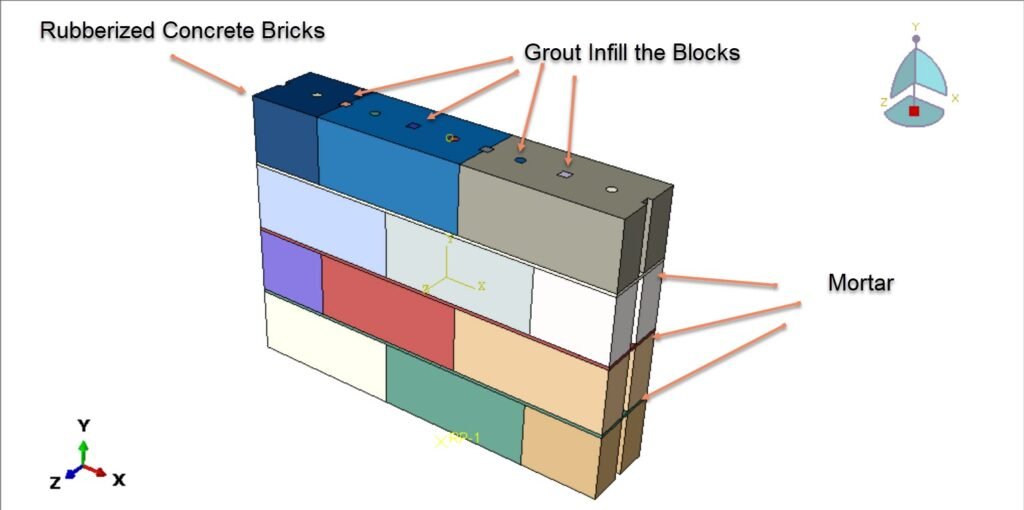

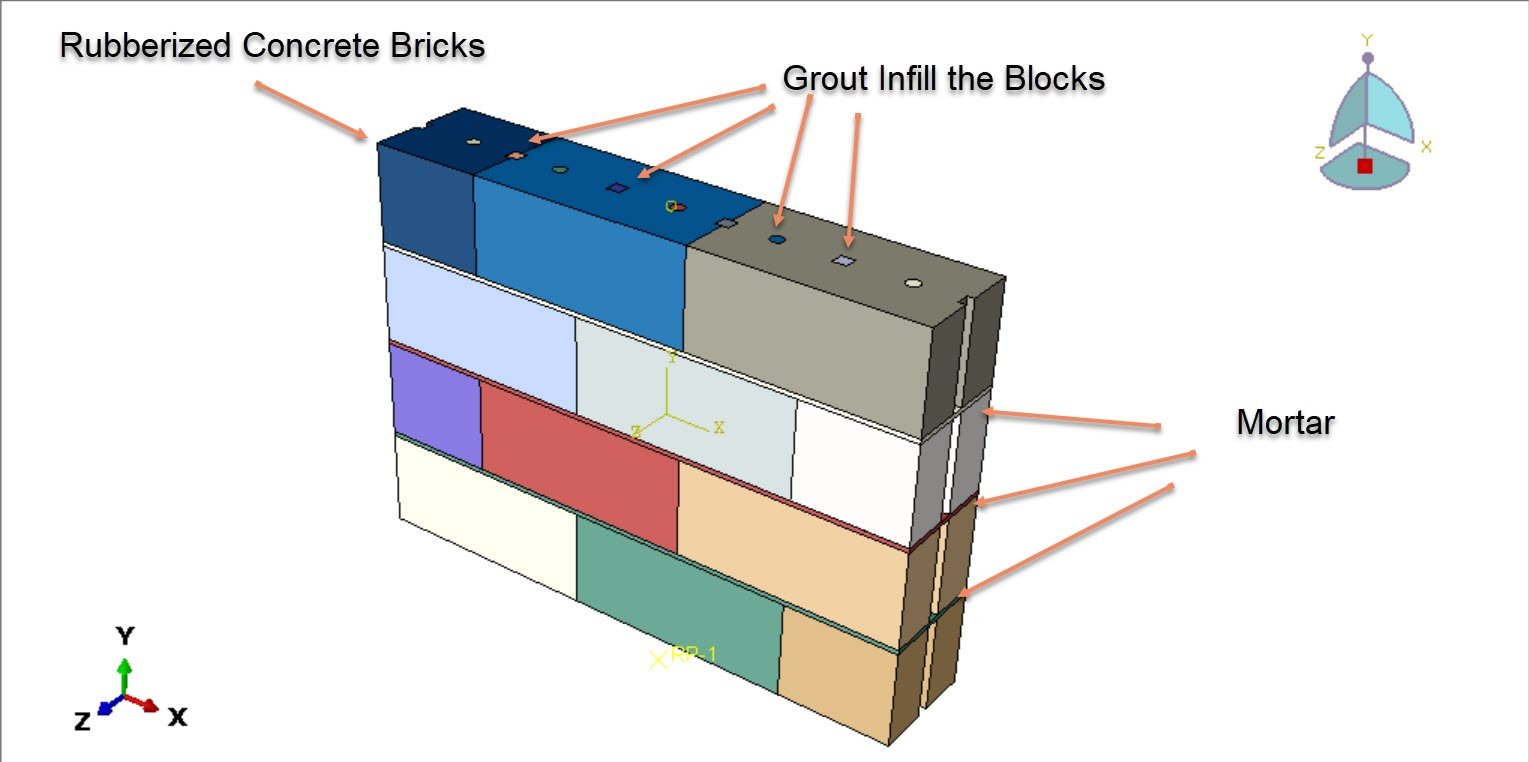

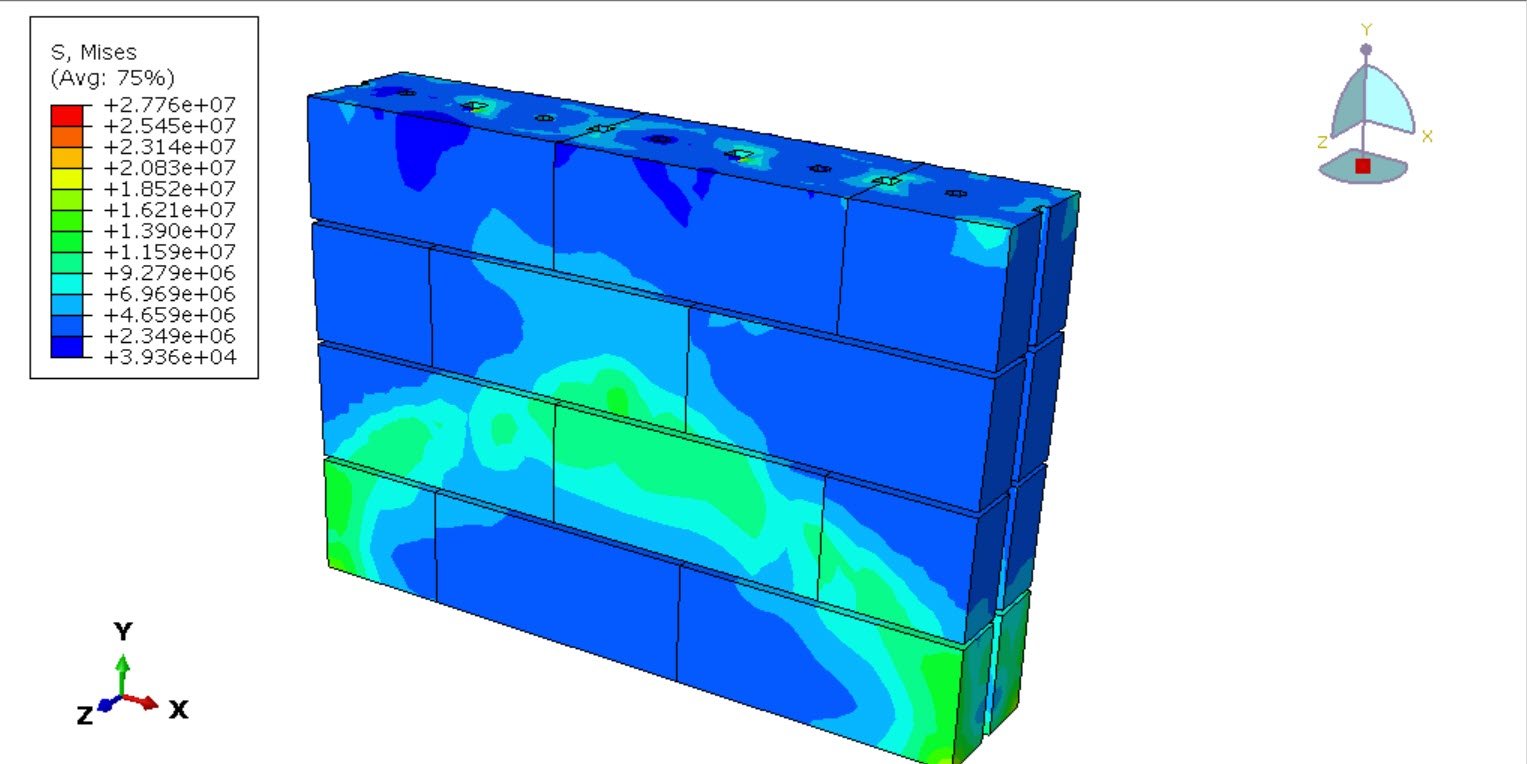

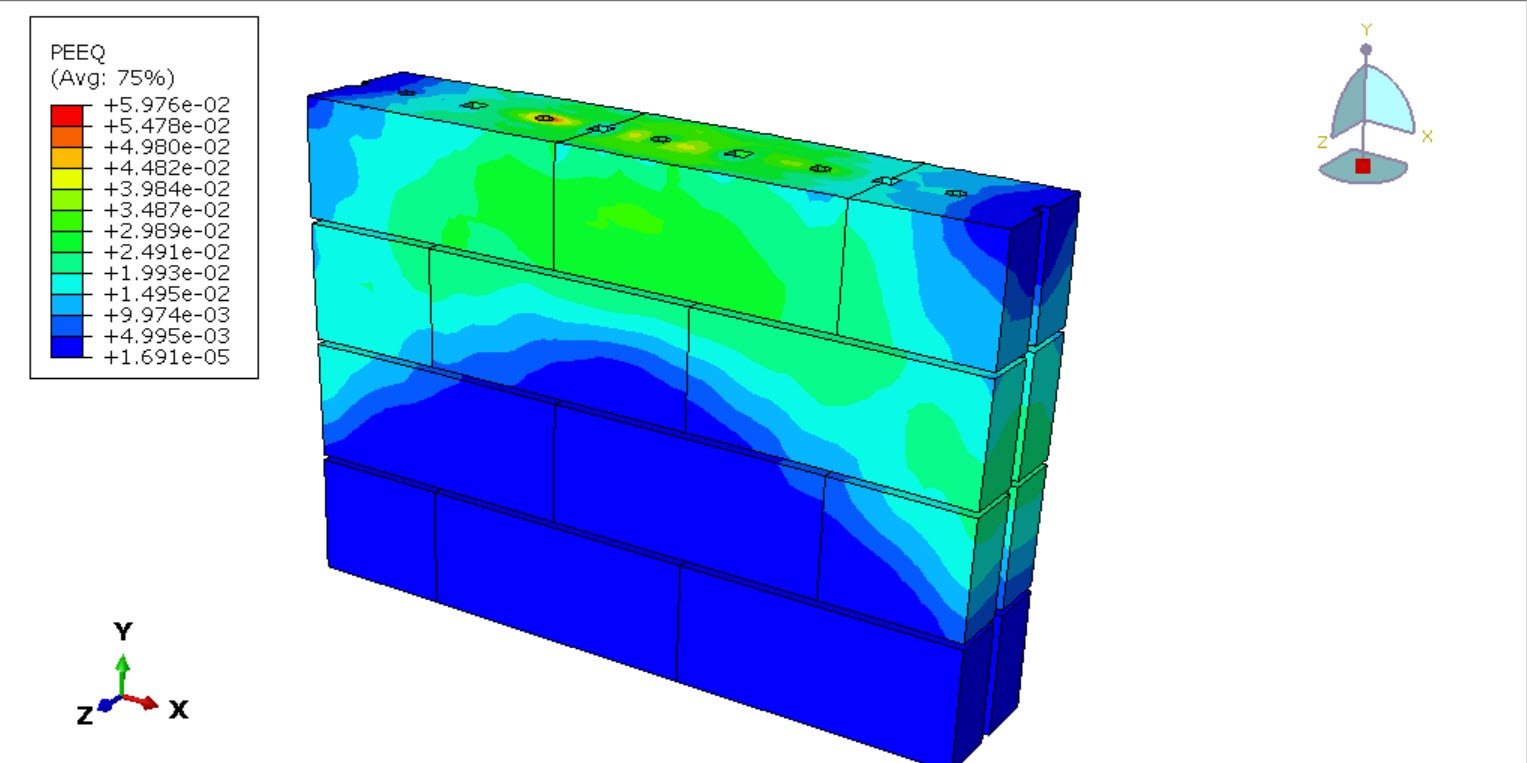

In this example, the rubberized concrete blocks, grouts, and mortar are modeled as 3D parts. For all members in the model, the Concrete Damaged Plasticity is selected. Both dynamic and static approaches can be used to obtain the results of the masonry under vertical, horizontal, or cyclic loading.

Rubberized concrete, produced by partially replacing mineral aggregates with processed waste rubber particles, offers unique characteristics that influence the behavior of masonry under load. The inclusion of rubber tends to reduce density and compressive strength while significantly enhancing ductility, deformability, and impact resistance. These properties make rubberized concrete masonry a promising material for structures requiring good energy absorption, such as seismic-resistant or resilient infrastructure. However, the altered mechanical properties introduce challenges in predicting structural performance, particularly when subjected to vertical (compressive) loads that govern the stability of walls and blocks.

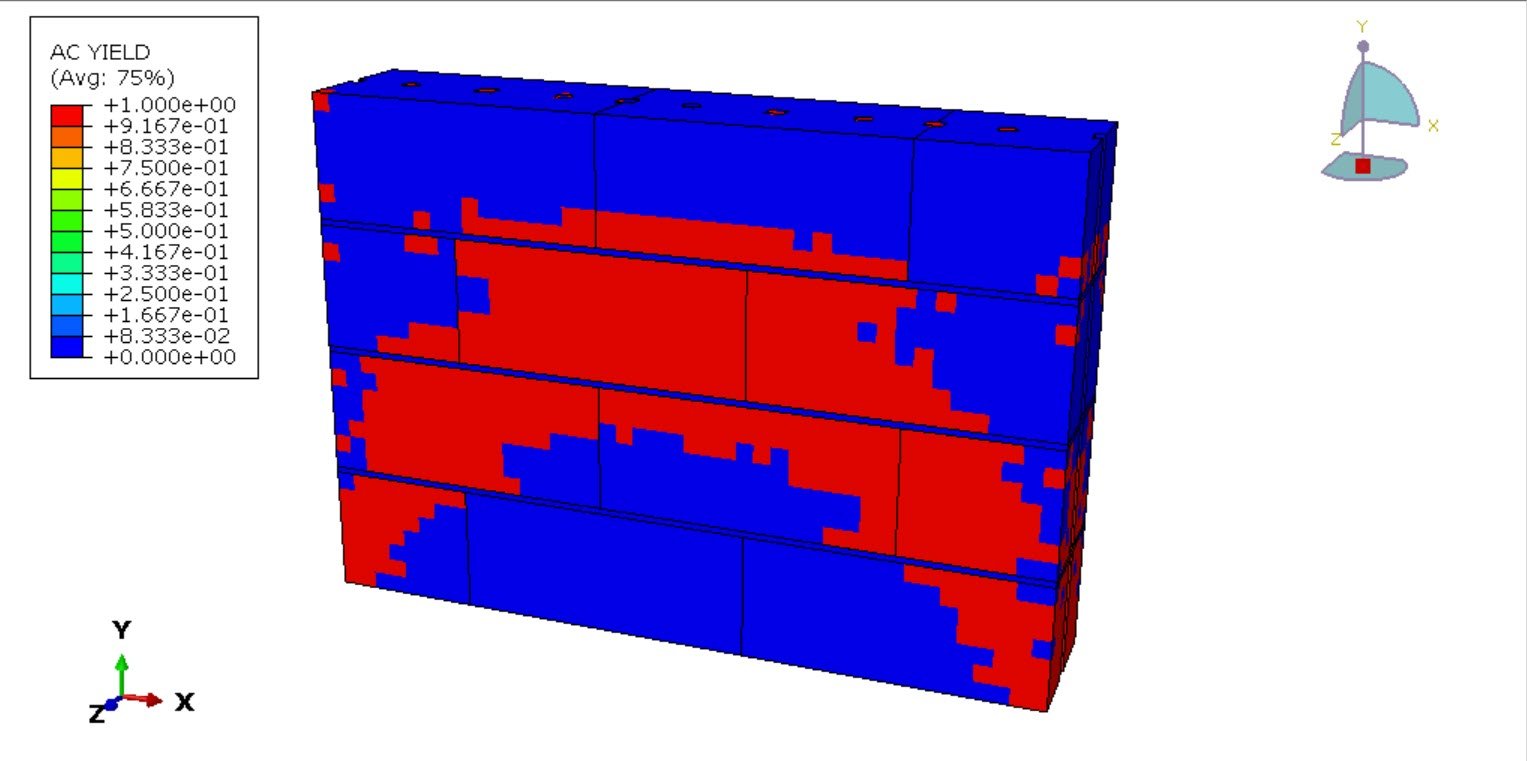

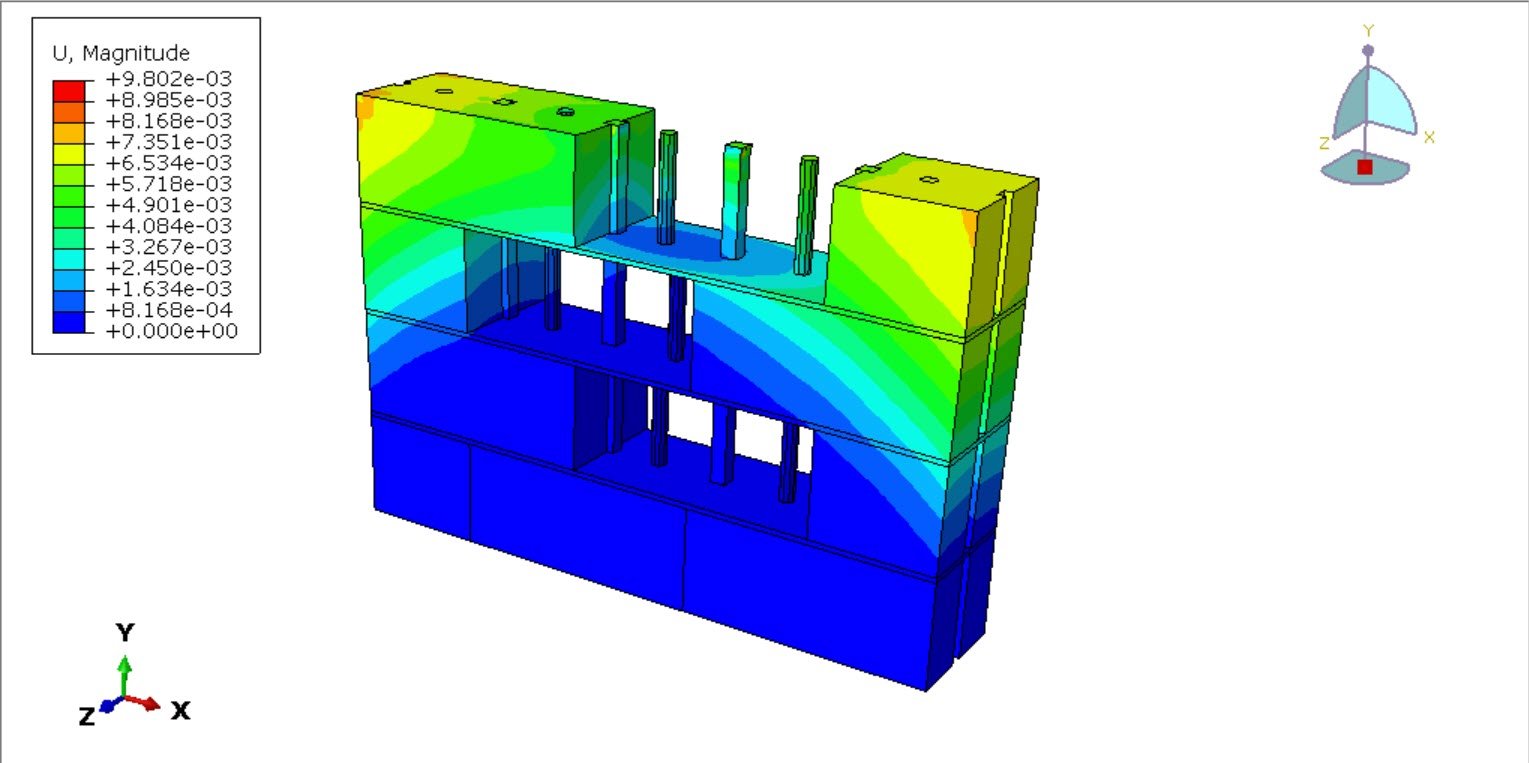

Finite Element Method (FEM) analysis has emerged as a powerful tool for understanding the complex behavior of rubberized concrete interlocking masonry. Because the system involves nonlinear material responses, contact interactions, and potential failure mechanisms—such as crushing, cracking, and block sliding—traditional analytical methods are insufficient. FEM enables detailed modeling of material nonlinearity, block interaction, and load distribution across interlocking geometries. Through numerical simulation, researchers can evaluate stress patterns, deformation profiles, load transfer mechanisms, and failure modes with greater precision.

This study of FEM analysis under vertical loading provides critical insights into the structural capacity and deformation characteristics of rubberized concrete interlocking masonry systems. By examining how rubber content affects stiffness, compressive strength, and energy dissipation, FEM models help optimize block design and material composition. Such analyses support the development of sustainable, cost-effective, and resilient masonry systems, contributing to the advancement of innovative construction materials and environmentally friendly engineering practices.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?