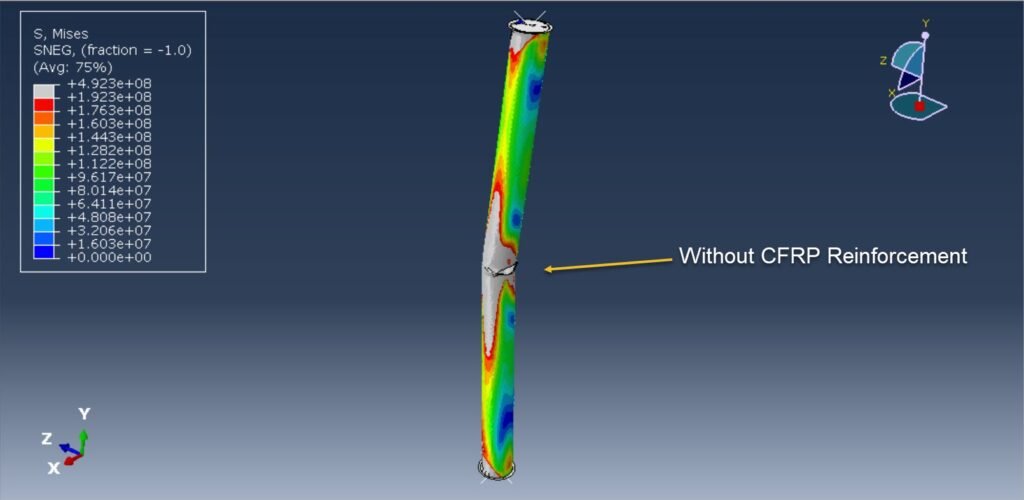

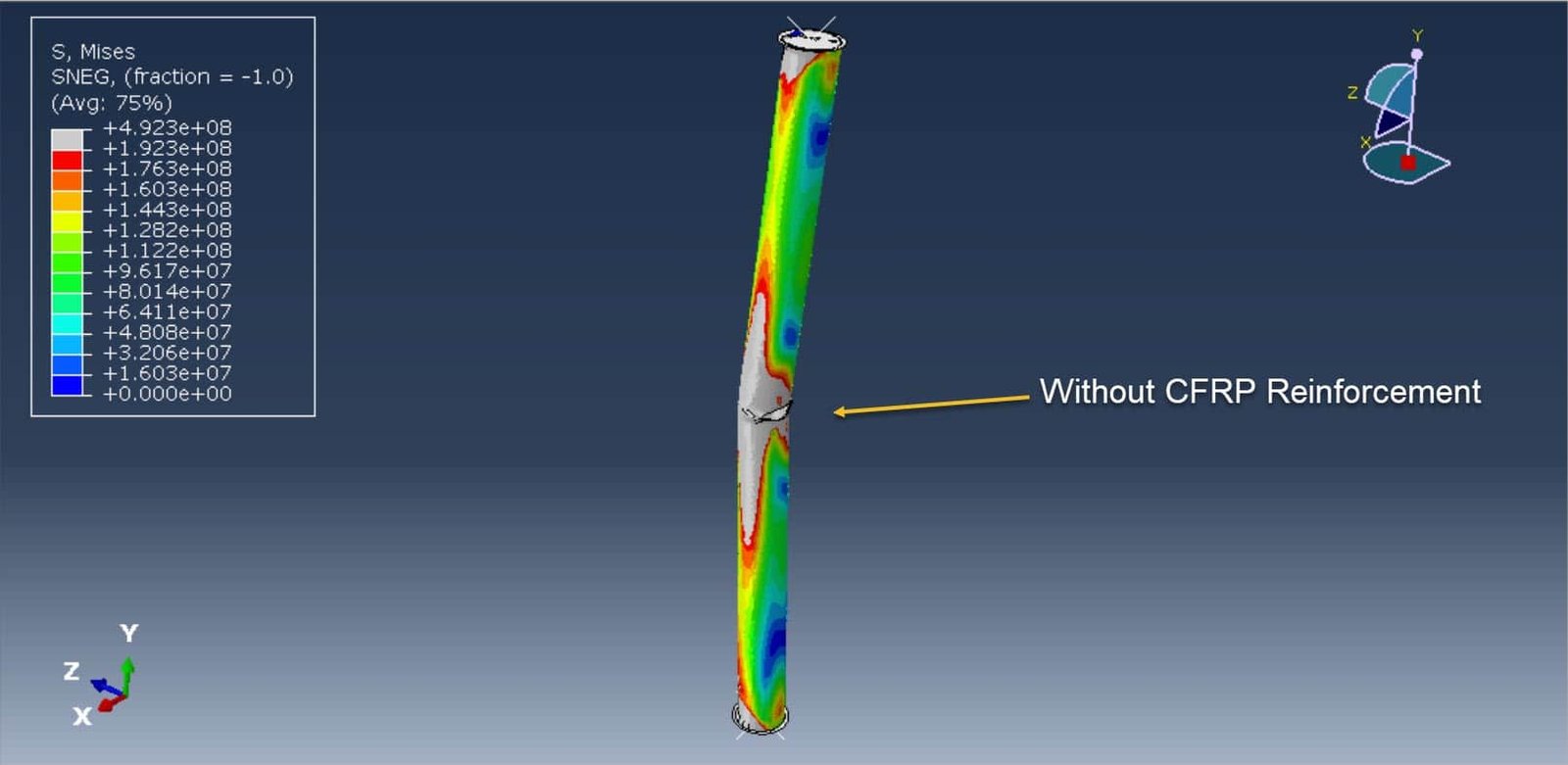

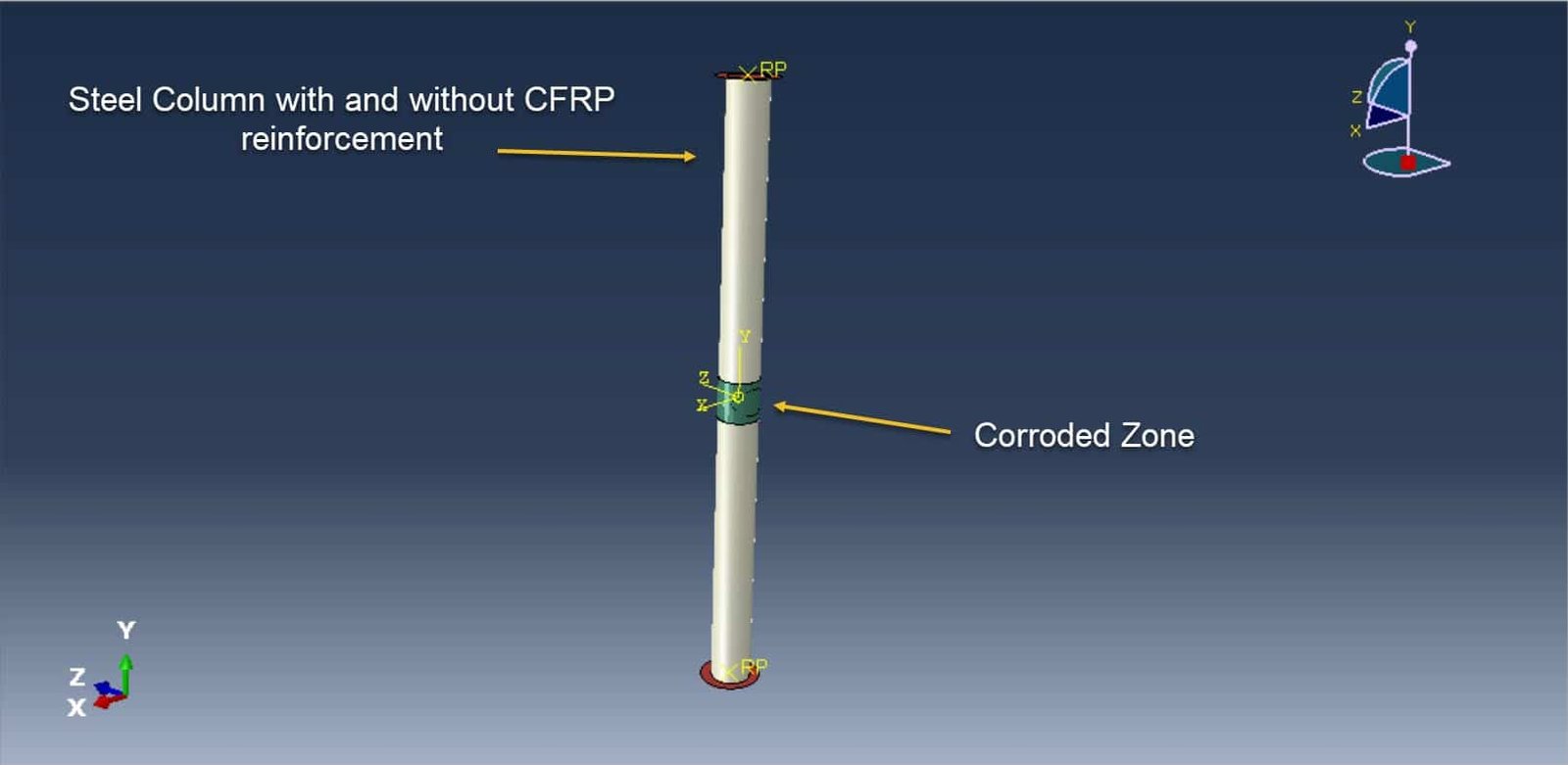

Steel Circular Hollow Section (CHS) columns are widely used in engineering structures due to their high strength-to-weight ratio, aesthetic appeal, and excellent performance under axial and bending loads. However, over time, these structural elements are vulnerable to corrosion, especially in harsh or marine environments. Corrosion reduces the cross-sectional area of the steel, compromises structural integrity, and significantly decreases the load-carrying capacity and service life of the column.

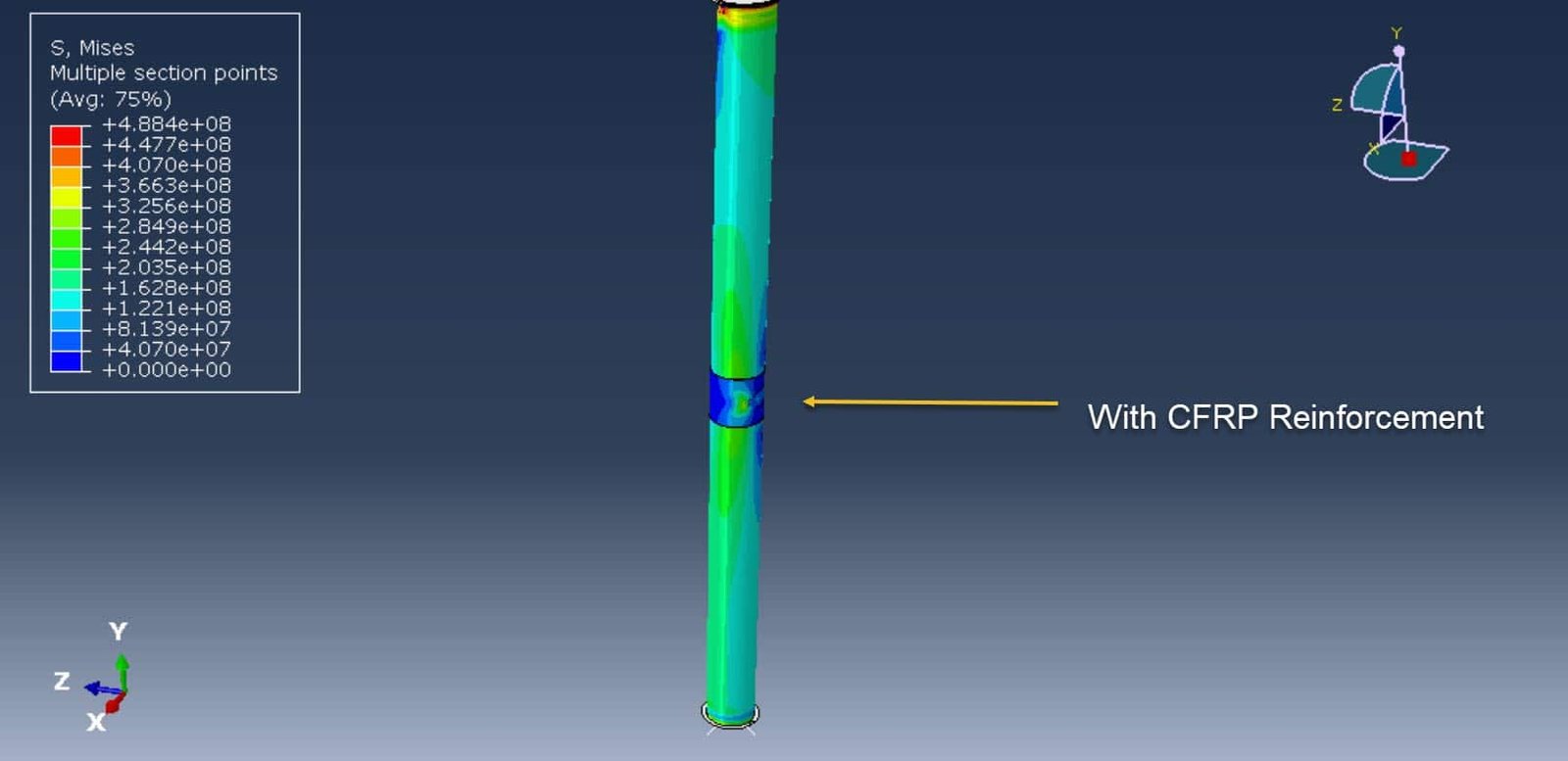

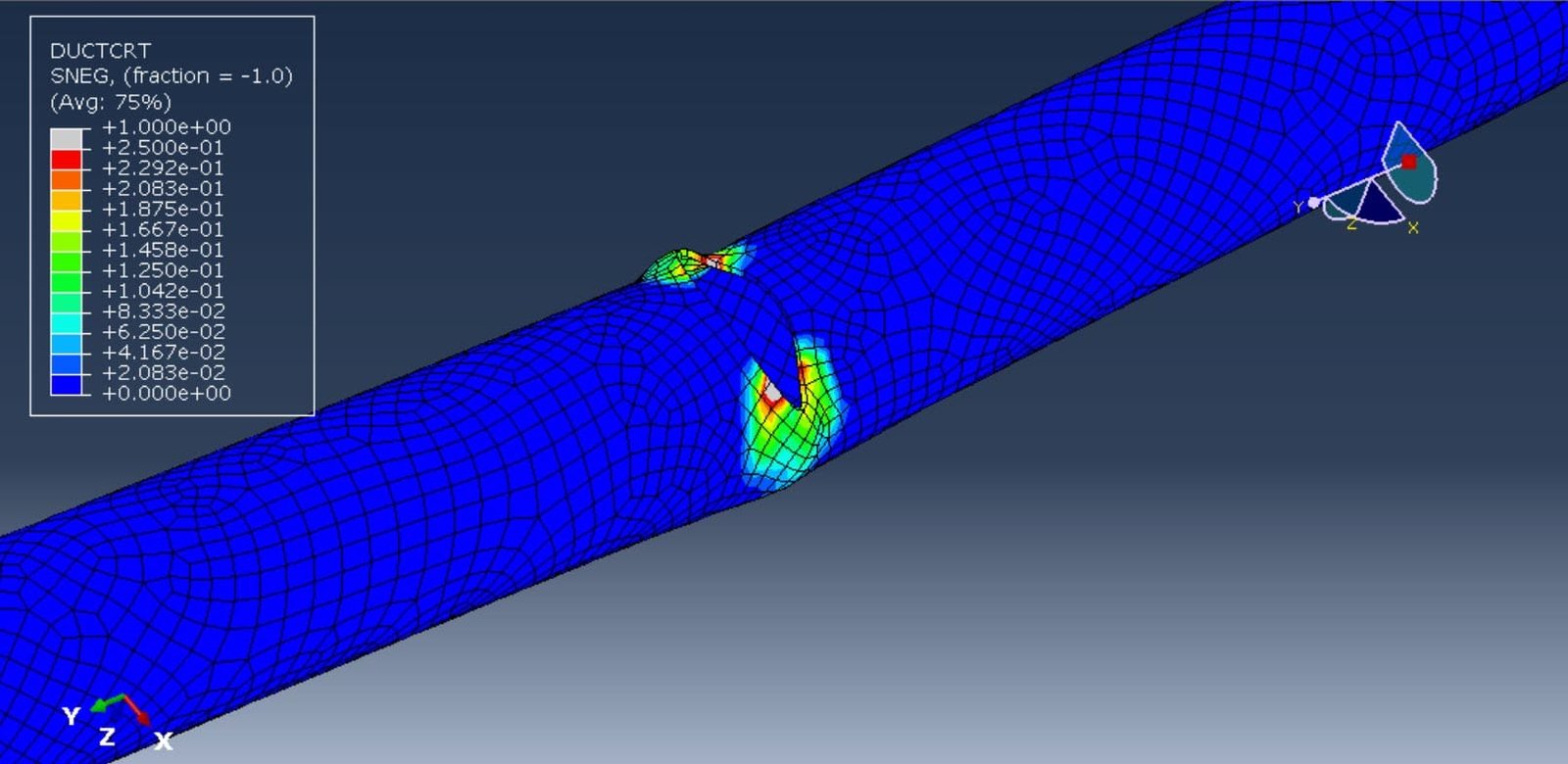

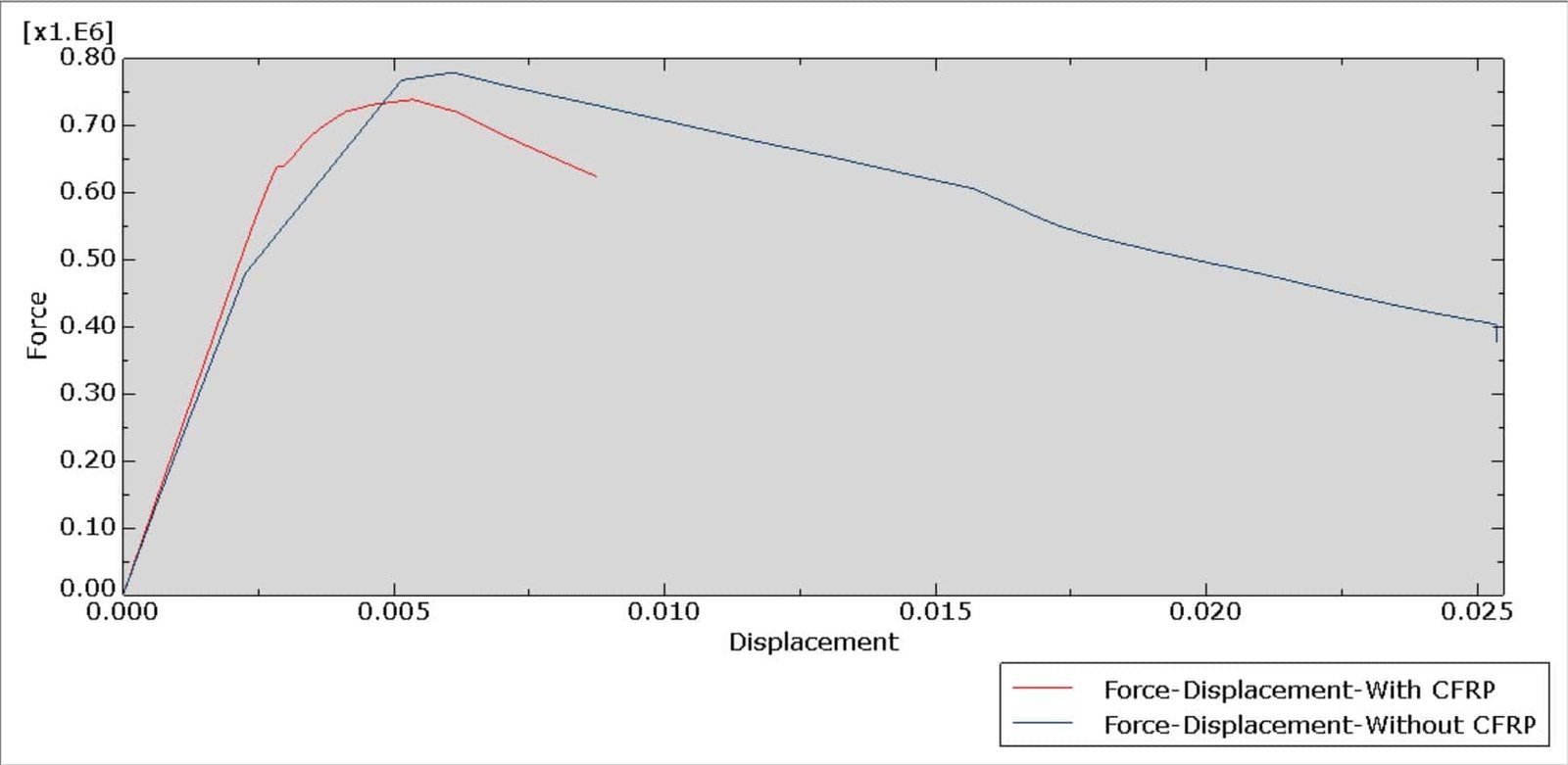

To restore or enhance the capacity of corroded CHS columns, various strengthening techniques have been explored. Among these, the use of Carbon Fiber Reinforced Polymer (CFRP) composites has gained increasing attention due to their high strength-to-weight ratio, corrosion resistance, ease of application, and minimal addition to the weight or dimensions of the existing structure. CFRP wraps can be externally bonded to the steel surface, providing confinement, delaying local buckling, and enhancing both the stiffness and ultimate strength of the columns under axial compressive loads.

This study (or review) focuses on the effectiveness of CFRP in strengthening corroded steel CHS columns subjected to axial compression. It examines key parameters influencing performance, such as corrosion severity, number of CFRP layers, bond quality, and wrapping configuration. The goal is to evaluate CFRP as a viable retrofitting solution to extend the service life of aging steel infrastructure, ensure structural safety, and reduce the need for costly replacements.

This example is so close to this research paper: Strengthening of corroded steel CHS columns under axial compressive loads using CFRP

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?