🔬 Project Title: Analysis and Validation of a Composite Pressure Vessel for Liquefied Ammonia Storage

🚀 Ready to dive into a real-world engineering project that blends simulation, design, and validation? This package delivers a complete, hands-on experience for anyone interested in composite pressure vessel analysis.

📦 Included Files:

💡 This research demonstrates the mechanical and weight advantages of using composite materials (CFRP/GFRP) for storing liquid ammonia under pressure. The findings are applicable to fuel tank design in transportation, petrochemical systems, and energy storage solutions.

Whether you’re a student, researcher, or professional engineer, this tutorial-style package offers a practical and well-documented path to mastering composite vessel analysis.

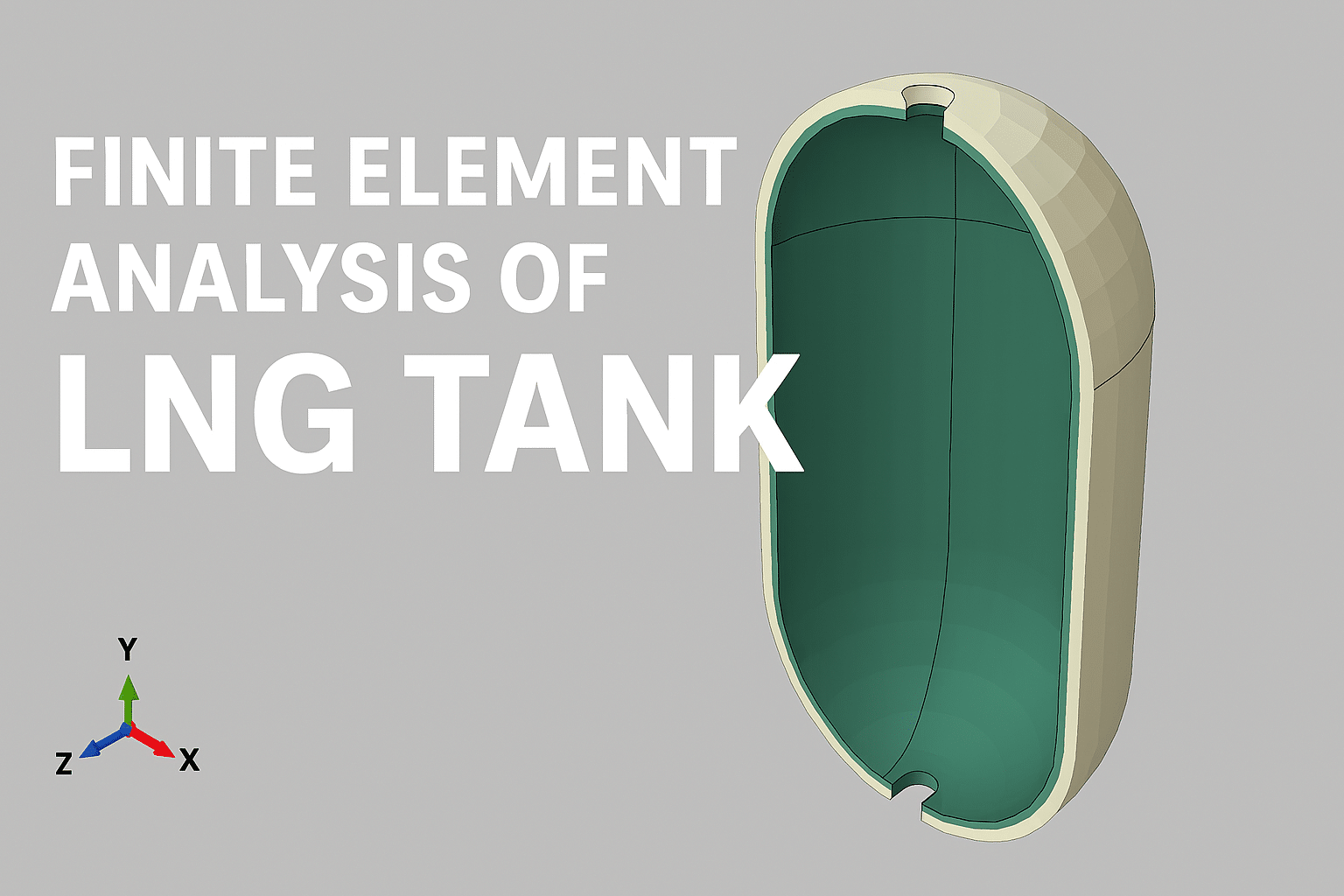

Article: Finite Element Analysis of Liquefied Ammonia Tank for Mobility Vehicles Employing Polymers and Composites

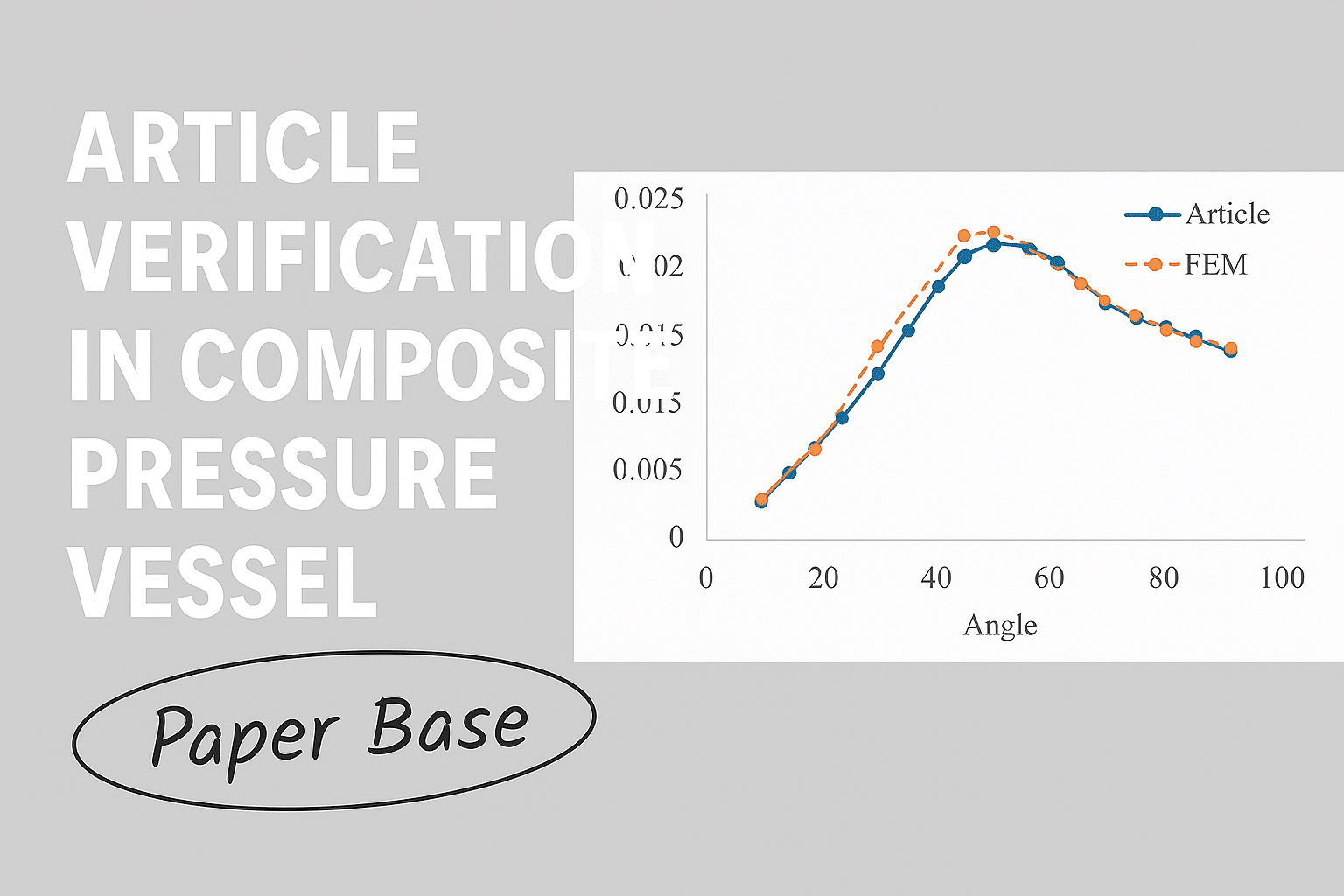

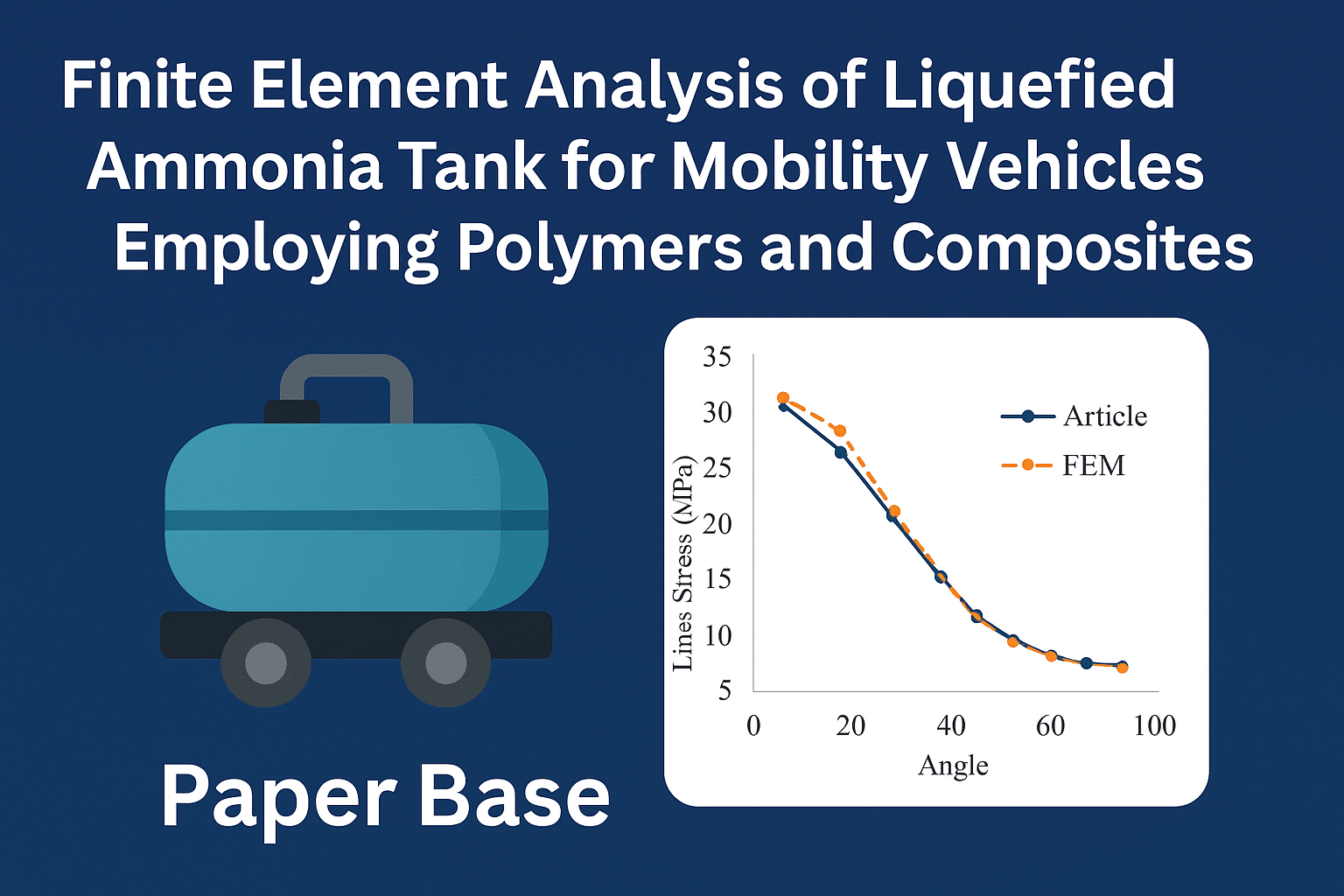

Article Abstract: Hydrogen has attracted global attention as a clean secondary energy source and has numerous possible applications, including fuel for vehicles. To store the hydrogen e ectively, ammonia is considered promising due to high hydrogen density, stability, and total energy e ciency. Adopting ammonia as a fuel in vehicles requires a proper fuel tank design to fulfill the required volumetric content and safety standards, without neglecting the economic objectives. In general, a type-IV pressure vessel is utilized as a fuel tank because it is the lightest one, compared to other types of pressure vessel. This paper focuses on the e ort to develop a lightweight type-IV ammonia pressure vessel designed for mobility vehicles. The material combination (liner and composite) and composite stacking sequence are analyzed for both burst and impact tests by using a finite element method. Two polymer materials of polyethylene terephthalate (PET) and polypropylene (PP) are evaluated as the liner considering their ultimate tensile strength, density, cost, and compatibility with ammonia, while carbon-fiber-reinforced polymer (CFRP) and glass-fiber-reinforced polymer (GFRP) are adopted as composite skins. In addition, five composite stacking sequences are analyzed in this study. Von Mises stress and Hashin’s damage initiation criteria are used to evaluate the performance of liner and composite, respectively. As the results, PP-based pressure vessels generate lower stress in the liner compared to PET-based vessels. In addition, CFRP-based pressure vessels have a higher safety margin and are able to generate lower stress in the liner and lower damage initiation criteria in the composite skin. The material combination of PP-CFRP with a stacking sequence of [90/ 30/90]3s gives the lowest maximum stress in the liner during the burst test, while, for the impact test, the stacking sequence of [90/ /90]3s is considered the most appropriate option to realize a lower stress at the liner, although this tendency is relatively small for vessels with PP liner.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?