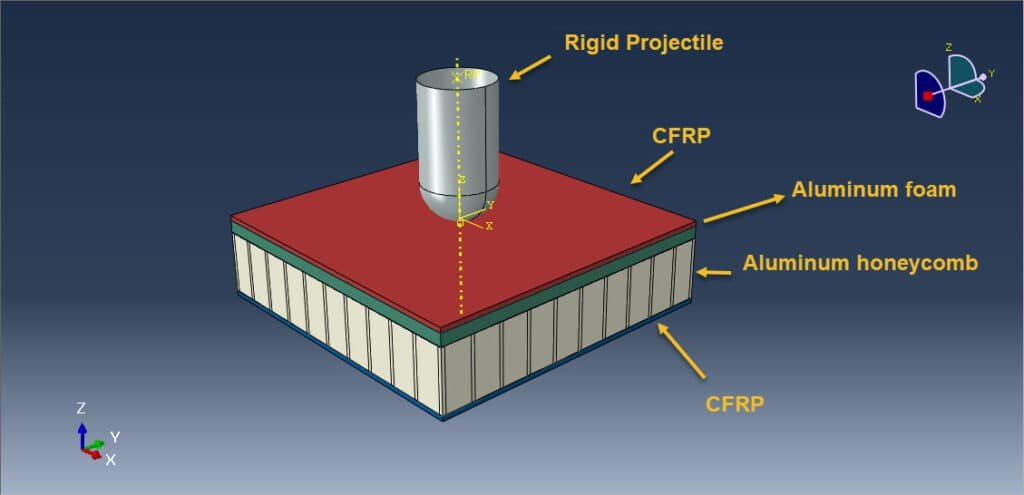

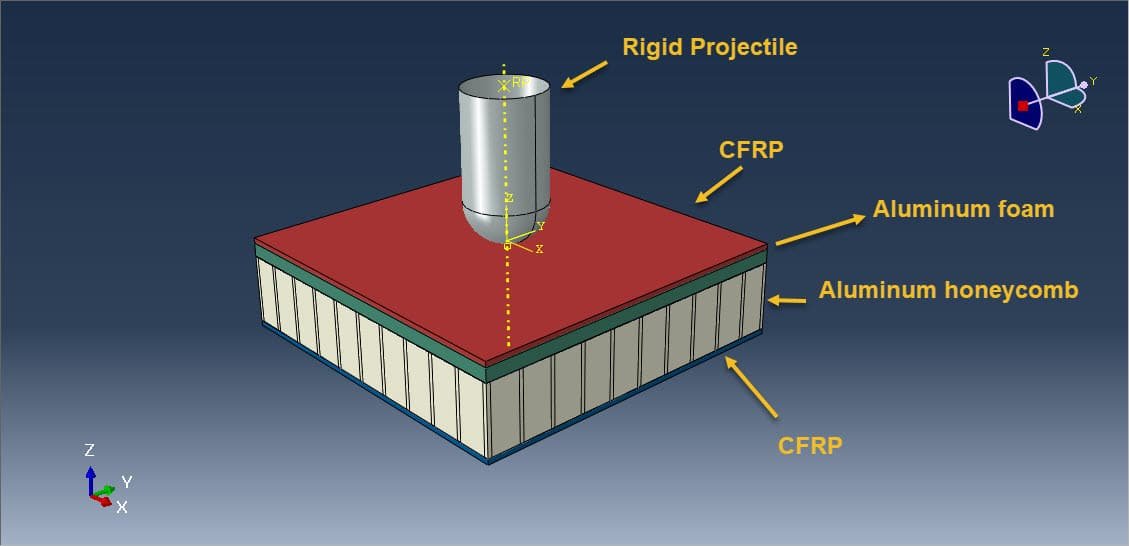

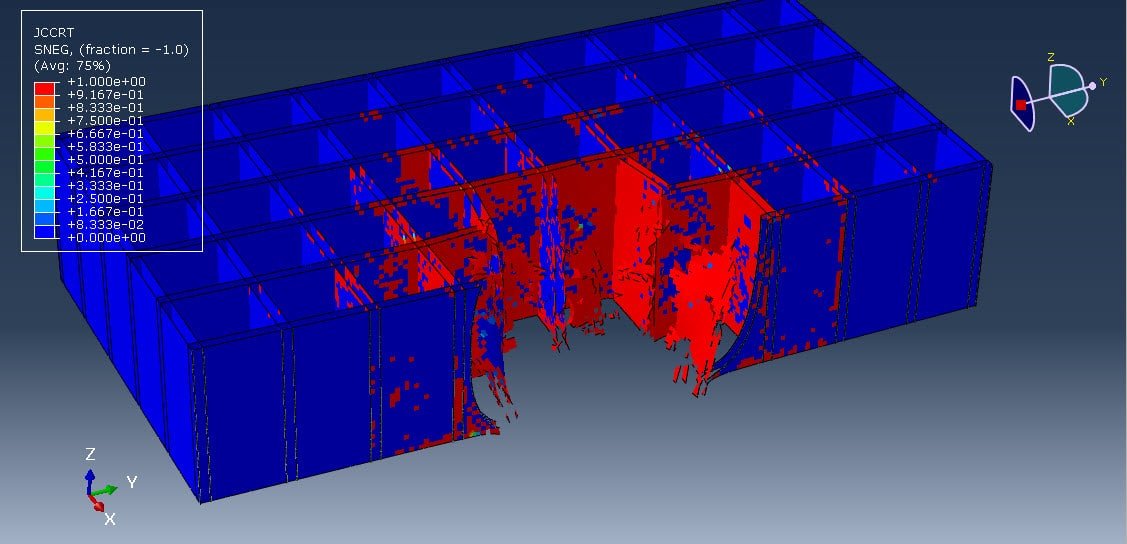

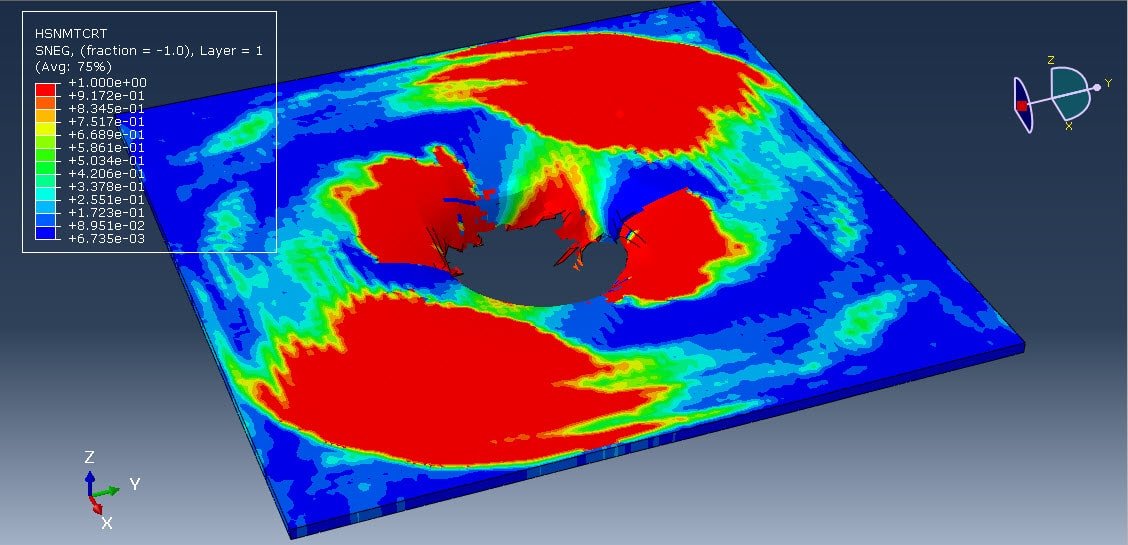

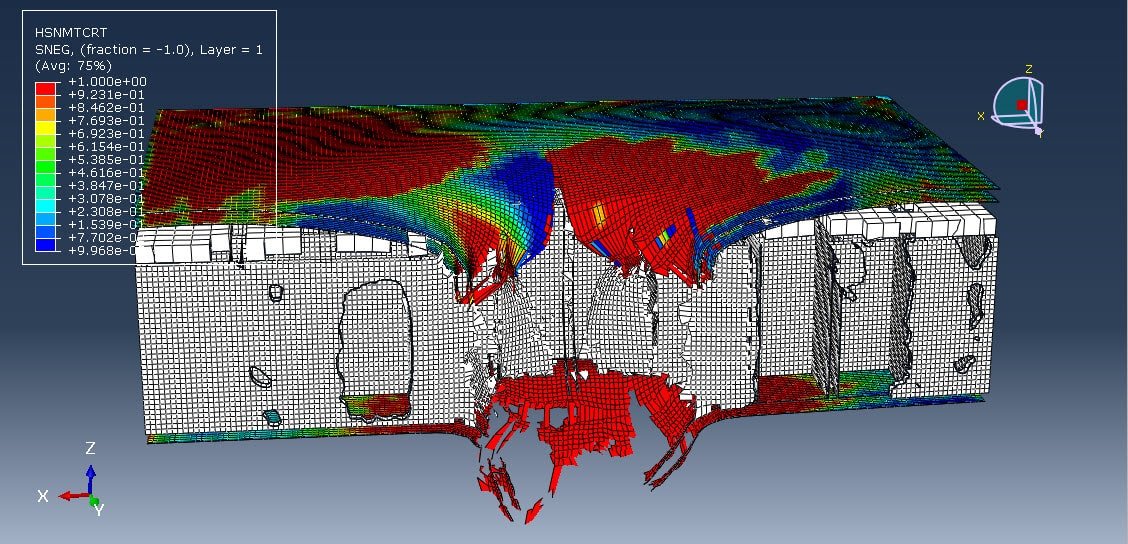

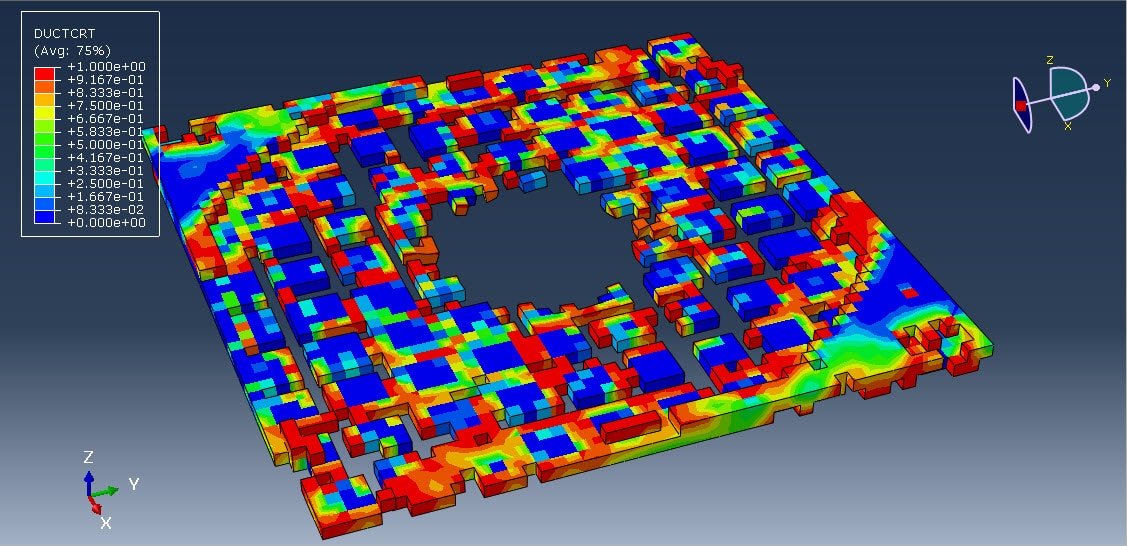

This study presents a comprehensive finite element simulation of a high-velocity impact on a hybrid composite sandwich panel consisting of Carbon Fiber Reinforced Polymer (CFRP) face sheets, an aluminum foam core, and an aluminum honeycomb mid-layer. The structural configuration aims to maximize energy absorption and minimize damage propagation under extreme dynamic loads. A spherical projectile is modeled to strike the panel at high speeds, and the response is analyzed using an explicit dynamic solver. The simulation investigates stress wave propagation, failure modes, and core crushing. Results demonstrate the enhanced impact resistance of the hybrid structure, highlighting the role of each constituent layer in dissipating kinetic energy. These findings contribute to the optimization of lightweight protective structures for aerospace and defense applications.

High-velocity impacts are critical scenarios in aerospace, automotive, defense, and space applications where structural panels are exposed to extreme dynamic loads, such as bird strikes, debris impact, or ballistic threats. Understanding how materials and structural configurations respond to such impacts is essential for ensuring safety and integrity.

Composite sandwich structures offer a promising solution due to their high strength-to-weight ratio, energy absorption capability, and tailored mechanical properties. This study focuses on a multi-layered hybrid composite panel composed of:

Carbon Fiber Reinforced Polymer (CFRP) (outer skins)

Aluminum Foam Core

Aluminum Honeycomb Layer (middle core)

This configuration combines the high stiffness and tensile strength of CFRP, the energy absorption of aluminum foam, and the crush resistance and lightweight properties of honeycomb structures.

CFRP (Carbon Fiber Reinforced Polymer):

Positioned as the front and back face sheets, CFRP offers high in-plane strength and stiffness. Its role is to distribute impact loads across the structure and resist perforation.

Aluminum Foam Core:

Acts as an energy absorber. Upon impact, it undergoes plastic deformation, absorbing kinetic energy and reducing stress transmission to subsequent layers.

Aluminum Honeycomb:

Provides structural stability and maintains the spacing between face sheets. It also contributes to energy absorption through progressive crushing and enhances the panel’s resistance to buckling and delamination.

High-velocity impact involves complex, transient phenomena, including:

Localized deformation

Wave propagation through materials

Delamination and fracture

Plastic collapse and crushing in metallic cores

Perforation or rebound, depending on impact energy

Due to the short timescales and nonlinear behavior, finite element analysis (FEA) and explicit dynamic simulation (ABAQUS/Explicit) are employed to predict structural response.

Evaluate damage progression through each layer

Analyze energy absorption and distribution across the composite

Identify failure modes: fiber breakage, matrix cracking, core crushing, or perforation

The layered CFRP-Aluminum foam-Aluminum honeycomb-CFRP composite panel offers a synergistic combination of strength, stiffness, and energy absorption. Through advanced numerical simulation of high-velocity impacts, it is possible to predict and enhance the panel’s performance, guiding the design of safer and more efficient protective structures. The results of such analyses are crucial for applications where impact tolerance is a key design criterion.

Abaqus

€81,00 €39,00

Abaqus

€299,00 €249,00

Uncategorized

€95,00 €80,00

Abaqus

€79,00 €38,00

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

See more

Want to receive push notifications for all major on-site activities?