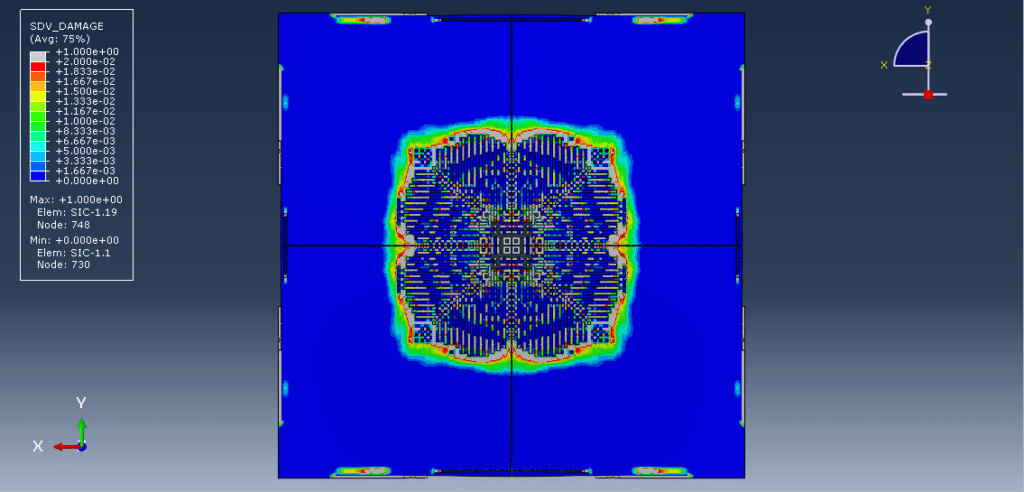

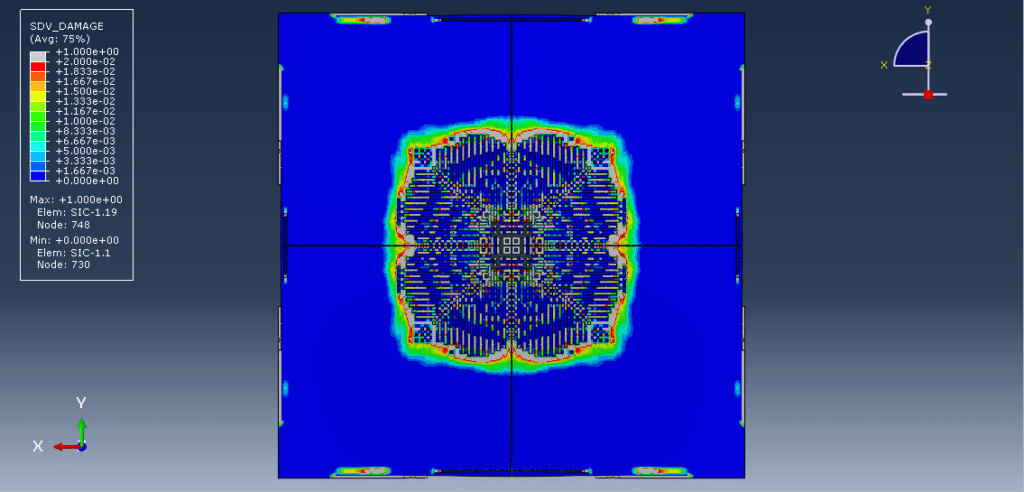

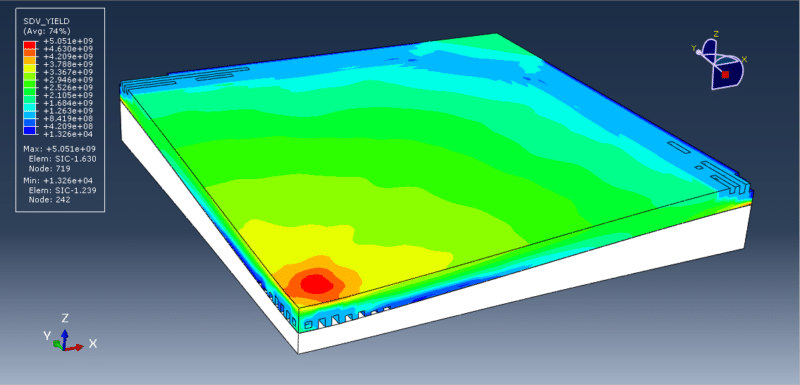

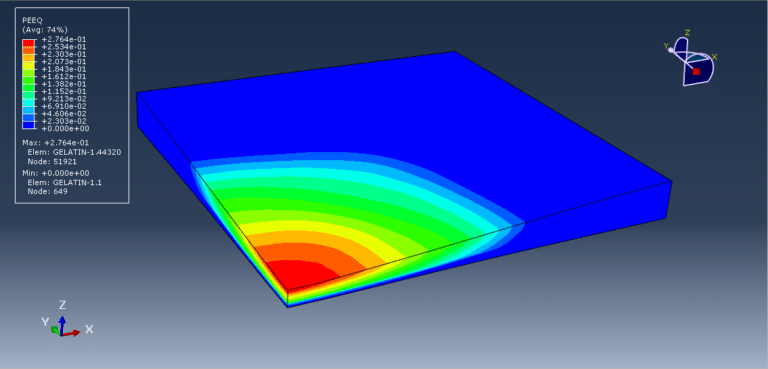

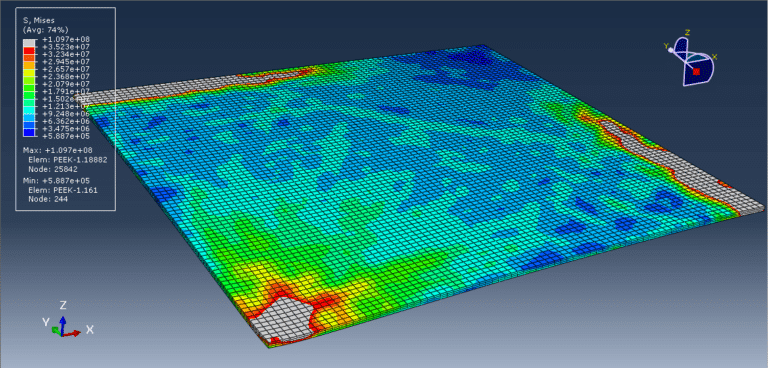

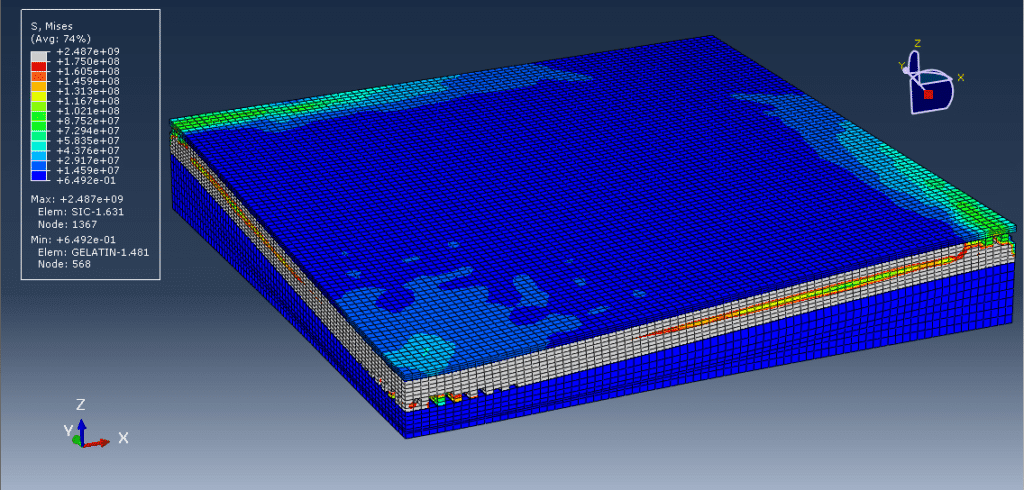

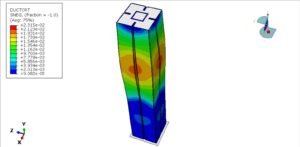

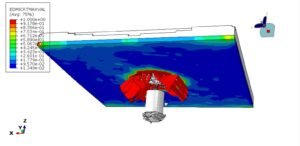

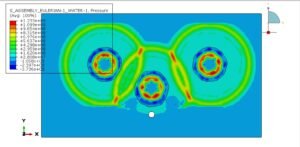

In this tutorial, the air blast simulation of a PEEK/ceramic/gelatin composite is investigated in Abaqus to evaluate behind armor trauma (BAT). The composite structure consists of three layers: a thin polyether-ether-ketone (PEEK) solid layer at the front to protect the underlying layers, a silicon carbide (SiC) ceramic layer modeled as a three-dimensional solid in the middle, and a gelatin layer representing human tissue as a three-dimensional solid back plate. Ceramic-based armor systems are designed to arrest projectile penetration and dissipate a significant amount of impact energy, and in this study the total linear momentum transferred to the wearer is considered as the measure of behind-armor blunt trauma (BABT). To analyze the effect of detonation on human tissue, the influence of adding a thin PEEK layer to the face of the SiC ceramic under blast loading is examined. The ceramic is represented using the Johnson-Holmquist (JH-2) model, which accounts for its high hardness, strong performance under compression, and low tensile resistance. SiC is widely used in applications such as bulletproof vests and automotive brakes due to its endurance, and its strength is pressure-dependent, with material damage playing a major role in its performance under high-speed impact. When SiC fails completely, it cannot sustain any load, and the JH-2 model assumes progressive damage accumulation with plastic deformation. The PEEK material is defined using the Johnson-Cook hardening and damage model, while gelatin is modeled as an elastic-plastic material. All materials are assumed to be homogeneous and isotropic, and the PEEK layer is bonded to the ceramic to quantify the momentum transferred to the wearer. The analysis is performed using a dynamic explicit step, which is appropriate for blast simulations. Perfect contact is assumed between the layers, although cohesive contact can also be used. Blast loading is applied using the CONWEP procedure to demonstrate the blast pressure acting on the panel surface. Symmetric boundary conditions are assigned to the symmetry surfaces on the panel sides, and a fine mesh is applied to ensure accuracy of the results. After running the simulation, outputs such as stress, strain, damage, failure, fracture, and force–displacement curves are obtained for evaluation.

Abaqus

€68,00 €34,00

Abaqus

€77,00 €39,00

Abaqus

€79,00 €39,00

Abaqus

€75,00 €37,00

Abaqus

€76,00 €38,00

Abaqus

€79,00 €38,00

See more

Want to receive push notifications for all major on-site activities?