Revolutionizing Corrosion Simulation in Pipes and Vessels: Leveraging AI and FEM Software for Accurate Predictive Maintenance

Corrosion is one of the most challenging issues in engineering, especially when considering its long-term impact on the integrity of critical infrastructure, such as pipes, pressure vessels, and marine structures. The need for advanced methods to simulate corrosion and predict material degradation over time has never been more critical. In this blog, we explore how Finite Element Analysis (FEA) tools like Abaqus and ANSYS, combined with AI/ML technologies, are revolutionizing the field of corrosion simulation, enhancing predictive maintenance, and supporting real-time decision-making.

Why Corrosion Simulation Matters?

In industries like oil and gas, chemical processing, power generation, and aerospace, corrosion leads to significant maintenance costs, structural failures, and even catastrophic accidents. Simulation offers a more accurate understanding of the effects of corrosion, enabling engineers to plan maintenance, replacement, and repair strategies based on precise predictions.

Advanced Corrosion Simulation Using FEM Software

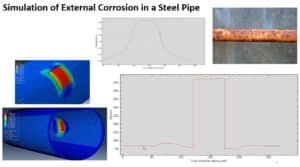

Finite Element Analysis (FEA) has emerged as the go-to method for simulating complex corrosion effects on structures. FEM tools such as Abaqus, ANSYS, and others have proven to be invaluable in predicting how materials will degrade over time, helping engineers design more resilient components and plan for the future.

Abaqus for Corrosion Modeling

Abaqus, a powerful FEA tool, allows engineers to simulate the effects of corrosion on pipes and vessels with high spatial accuracy. Corrosion mapping is one of the most widely used techniques within Abaqus. By integrating real-world corrosion data into the simulation, engineers can predict material degradation under various operating conditions. This process is particularly valuable in industries such as oil and gas, petrochemical, and marine engineering, where the risk of corrosion is high.

Key Features:

- Material Degradation Modeling: Simulate material degradation using customized damage models.

- Localized Corrosion Simulation: Predict pitting and uniform corrosion, ensuring more accurate results for high-risk areas.

- API 579-2/ASME PTB-14 Compliance: Abaqus supports Level 3 assessments for corrosion mapping, aligning with industry standards for corrosion inspection and fitness-for-service (FFS) evaluation.

ANSYS and Other FEM Tools

ANSYS is another robust tool for corrosion simulation, offering both structural analysis and fluid-structure interaction capabilities. For more detailed analysis, ANSYS incorporates coupled thermal-mechanical simulations to model the effects of temperature-induced corrosion, especially relevant in power generation and aerospace sectors. Check Estimating metal pipelines corrosion using Ansys Video.

Other FEM tools, such as COMSOL Multiphysics and OpenFOAM, provide additional capabilities for modeling the electrochemical processes behind corrosion, enabling more detailed simulations for applications like hydrogen-induced stress cracking and seawater corrosion.

AI and ML: The Future of Corrosion Simulation

Artificial intelligence and machine learning are dramatically enhancing the accuracy and efficiency of corrosion simulations. By incorporating AI, engineers can now predict corrosion behavior under dynamic conditions, identify early warning signs of failure, and even optimize material selection based on historical corrosion data.

- AI for Predictive Maintenance: Machine learning algorithms can analyze vast amounts of data to predict when and where corrosion will occur, helping engineers make timely interventions before catastrophic failures happen.

- Real-Time Monitoring: AI can be combined with real-time data from sensors and IoT devices to track the condition of pipes and vessels, allowing for predictive analytics to foresee potential issues before they escalate.

- Automated Damage Detection: AI-driven image recognition techniques can automatically detect corrosion patterns on equipment surfaces, reducing the need for manual inspections and improving accuracy.

Application in the Industry

The application of these advanced corrosion simulation techniques can transform industries. Here’s a quick look at how different sectors benefit:

- Oil & Gas: Corrosion is a significant risk factor in pipelines and offshore structures. Predicting when and where corrosion will occur can significantly reduce downtime and maintenance costs.

- Petrochemical and Chemical Plants: Corrosion impacts the integrity of pressure vessels and pipelines. Simulation tools ensure these structures maintain their safety and reliability over their operational lifetimes.

- Power Generation: In high-temperature environments, corrosion can compromise the performance and lifespan of critical equipment. FEA helps mitigate these risks by simulating high-stress and high-temperature scenarios.

- Aerospace: Corrosion of aircraft components, particularly under harsh environmental conditions, can lead to significant safety concerns. FEM-based corrosion modeling can predict damage before it compromises structural integrity.

Best Practices for Corrosion Simulation

To get the most out of corrosion simulations, it’s essential to follow a few best practices:

- Use Real-World Data: Always integrate actual corrosion data from inspections into your simulations to ensure accurate results. Explore our detailed Case Study for a practical example.

- Combine Multiple Software Tools: While Abaqus and ANSYS are powerful, using a combination of FEA tools (including COMSOL and OpenFOAM) can offer a more comprehensive view of corrosion effects.

- Adopt AI and ML Early: As AI and machine learning evolve, adopting these technologies can provide a competitive edge in predicting and preventing corrosion-related failures.

- Stay Updated with Industry Standards: Always align your simulations with the latest API 579 and ASME guidelines for corrosion mapping and fitness-for-service assessments.

Conclusion: The Future of Corrosion Simulation

The integration of AI/ML with FEM software like Abaqus and ANSYS is pushing the boundaries of what’s possible in corrosion simulation. By accurately predicting the long-term effects of corrosion, these tools are helping engineers make smarter decisions, reduce operational downtime, and significantly improve asset life cycles.