Hydrogen embrittlement (HE) is a phenomenon where metals become unexpectedly brittle and crack due to the absorption and diffusion of hydrogen atoms into the material. Essentially, hydrogen infiltrating the metal reduces its ductility and fracture toughness, so that even below the normal yield strength the material can fracture in a brittle manner. This insidious form of corrosion (often called hydrogen-assisted cracking) is of great concern for pipelines, pressure vessels, high-strength fasteners, and other critical components. In this comprehensive guide, we’ll explore what causes hydrogen embrittlement, how it affects industries (especially pipelines and pressure vessels), how we can simulate it using finite element analysis (FEA) tools like Abaqus and Ansys, and how to prevent or mitigate its damaging effects. We’ll also touch on the emerging role of AI/Machine Learning in predicting and managing hydrogen embrittlement. Let’s dive in with a friendly, understandable approach to this complex topic, mixing both industrial insights and academic perspectives for a full picture!

What is Hydrogen Embrittlement?

Hydrogen embrittlement occurs when metals become brittle due to the uptake of hydrogen into their microstructure. The hydrogen is usually in atomic form (individual H atoms or ions) that diffuse into the metal and reside at sensitive sites. High-strength metals (often identified by high hardness) are particularly susceptible – their microstructures provide traps like dislocations or precipitates where hydrogen accumulates, leading to weakness. In practical terms, the metal loses ductility and load-bearing capacity, and cracks can initiate and grow much more easily than in hydrogen-free material. This means a component might fail suddenly under stress levels that would normally be safe.

Three key ingredients must coincide for hydrogen embrittlement to happen: (1) the presence of hydrogen (in atomic form), (2) a susceptible material structure (typically high-strength or hardened metal), and (3) tensile stress on the part (either external load or residual stress). Hydrogen by itself won’t crack a metal – but under stress, the absorbed hydrogen facilitates crack initiation and propagation by lowering the stress needed to fracture the metal. Notably, temperature plays a role: most metals become immune to hydrogen embrittlement above about 150 °C, whereas at room temperature and below, hydrogen embrittlement is typically most severe. Hydrogen also has the greatest impact at lower strain rates (slow loading), which give it time to diffuse to where cracks form.

How does hydrogen get into the metal? Hydrogen atoms are tiny and can permeate through the crystal lattice of many metals. However, molecular hydrogen gas (H₂) does not readily dissociate into atoms at ambient temperature, so pure hydrogen gas at room temperature doesn’t directly attack steel. The danger is when processes generate atomic hydrogen on the metal surface – those atoms can then dissolve into the metal. This happens in several ways:

- Corrosion reactions: Ordinary aqueous corrosion (especially in acids or in the presence of H₂S) produces hydrogen atoms on the metal surface as a by-product. For example, steel exposed to acidic water or hydrogen sulfide (sour environments) undergoes reactions that release atomic hydrogen, which can enter the steel and cause hydrogen-induced cracking (HIC) and sulfide stress cracking (SSC).

- Electrochemical processes: Operations like acid pickling, electroplating (galvanizing, zinc plating), and even cathodic protection can generate hydrogen on the surface. During acid cleaning or electroplating, hydrogen evolves at the metal surface and may be absorbed, especially if not properly mitigated. High-strength plated fasteners are notorious for failures due to trapped hydrogen (a classic case of internal embrittlement from manufacturing).

- Welding and casting: Molten metal can dissolve hydrogen readily. During welding, moisture or hydrocarbon contamination can dissociate and introduce hydrogen into the weld metal. If the hydrogen isn’t baked out or allowed to diffuse away before the weld cools, it can lead to cold cracking or delayed cracking in the heat-affected zone. This is why procedures call for low-hydrogen electrodes and post-weld heating for certain steels.

- High-pressure gaseous hydrogen: At elevated temperatures or if assisted by catalysts, even H₂ gas can dissociate and enter the metal. In high-pressure hydrogen gas service (like hydrogen storage tanks or pipelines), some hydrogen will slowly diffuse into the metal over time, particularly at welds or defects. Aerospace and industrial standards consider this Hydrogen Environment Embrittlement (HEE) for components exposed to pressurized hydrogen gas.

Once inside, hydrogen atoms tend to migrate to areas of high stress or microstructural trap sites. For instance, at the tip of a crack (a region of very high triaxial stress), hydrogen will concentrate and make the metal more prone to further cracking. Hydrogen can also collect at grain boundaries, inclusions, or carbide interfaces. There are several scientific theories for how hydrogen actually causes embrittlement: one idea is that hydrogen reduces the cohesive strength of the metal (making it easier for cracks to form between atoms – the HEDE or hydrogen-enhanced decohesion mechanism), another is that hydrogen enhances localized plasticity (making dislocations move freely and concentrate damage – the HELP mechanism), and some metals even form brittle hydride compounds. In truth, multiple mechanisms may operate together, and the dominant one depends on the material and conditions. The bottom line is that hydrogen is extremely effective at finding the microscopic weak points in a metal and making them weaker.

Types and Causes of Hydrogen Embrittlement

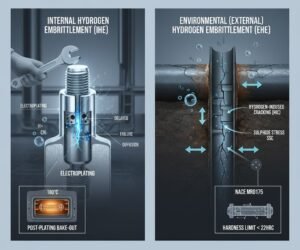

It’s useful to distinguish between two broad types of hydrogen embrittlement, based on when and how the metal picks up hydrogen:

- Internal Hydrogen Embrittlement (IHE): This refers to hydrogen introduced during manufacturing or fabrication of a component. For example, high-strength steel bolts can absorb hydrogen during acid pickling or electroplating at the factory. The hydrogen invades the metal lattice and may become trapped in microvoids or inclusions. If a critical amount of hydrogen is trapped and the part is under stress, it can crack. A classic scenario is a plated high-tensile screw that snaps under load due to hydrogen introduced in plating. Welding can also cause IHE if hydrogen is trapped in the weld. IHE often leads to delayed failures – the part may look fine initially, but cracks appear hours or days later as the hydrogen diffuses to stress points (hence the term “delayed cracking” after welding). To mitigate IHE, manufacturers use techniques like post-plating bake-outs (heating the part at ~150–200 °C to drive out hydrogen) and careful control of plating bath chemistry (adding inhibitors to reduce hydrogen release).

- Environmental (External) Hydrogen Embrittlement (EHE): This occurs when the metal absorbs hydrogen during its service life from the environment. Common sources are corrosion processes – for example, a buried pipeline in wet, acidic soil will corrode and generate hydrogen that enters the steel. Similarly, components in H₂S-rich (sour) environments absorb hydrogen from the sulfide corrosion reaction, leading to the notorious hydrogen-induced cracking in pipelines and pressure vessel steels. Even humidity can contribute: a galvanized steel in a wet atmosphere might slowly pick up hydrogen over years due to micro-corrosion. Cathodic protection systems on steel structures (used to prevent general corrosion) ironically can introduce hydrogen as well, if driven to very negative potentials. External HE typically manifests as sub-surface cracks (sometimes forming blisters or internal cracks if hydrogen collects and forms gas pockets) or as embrittlement that makes the metal vulnerable to normal stresses. A well-known industry term is Hydrogen-Induced Cracking (HIC) for the cracking seen in pipeline steels from hydrogen in service. Another is Sulphide Stress Cracking (SSC) for cracking caused by hydrogen in the presence of hydrogen sulfide, especially in high-strength steels.

Despite the different origins, internal and external hydrogen embrittlement have the same effect: hydrogen invades the metal and, under stress, causes cracking. Often the failures are brittle in appearance – the fracture surface may show intergranular or cleavage features typical of low-toughness failure, even though the material was a tough steel.

To visualize the conditions: imagine a hardened steel component in a corrosive environment under load. The corrosion generates hydrogen atoms on the steel surface. Those atoms diffuse into the steel, especially driven by the tensile stresses (they actually tend to move towards regions of high tensile stress due to stress gradients). If the steel’s strength (hardness) is above a certain threshold, it cannot tolerate much hydrogen without cracking. Over time (and often accelerated by cyclic loads or temperature changes), cracks nucleate at stress concentrators (like notches, grain boundaries, or existing micro-cracks) and then grow, often leading to sudden failure. This is why a high-hardness steel, a sour environment, and stress together are a dangerous combination. In fact, industry standards (like NACE MR0175 / ISO 15156 for oil & gas sour service) impose strict hardness limits on steels used in H₂S environments to avoid hydrogen cracking – essentially using slightly lower-strength (softer) steels to improve safety.

It’s worth noting that not all metals are equally vulnerable. As mentioned, high-strength ferrous alloys (steels) are the prime victims. Austenitic stainless steels and aluminum alloys are generally much more resistant to hydrogen embrittlement – austenitic stainless, for example, doesn’t experience the same trapping and hydrogen diffusion rates as ferritic steel, and it doesn’t form brittle hydrides. Indeed, austenitic stainless steels (like 304 or 316) have been successfully used in high-pressure hydrogen gas service and are considered among the best materials for hydrogen resistance. Nickel-based alloys and copper alloys also tend to perform better (copper is quite immune to hydrogen). On the other hand, hardened carbon steels, alloy steels, and titanium alloys are more at risk – titanium can absorb hydrogen to form titanium hydride, which is very brittle. In practice, however, even supposedly “resistant” metals can show some embrittlement if hydrogen content is high enough or the conditions severe. So engineering for hydrogen environments is always done with caution.

Impact on Pipelines, Pressure Vessels, and Industry Standards

Hydrogen embrittlement is a major concern in industries such as oil and gas, chemical processing, and emerging hydrogen energy applications. Let’s talk about pipelines and pressure vessels – these are structural systems that often face hydrogen exposure:

- Pipelines (Natural Gas & Hydrogen Blends): Modern efforts to use hydrogen as a clean energy carrier include blending hydrogen into natural gas pipelines or building dedicated hydrogen pipelines. Pipeline steels (typically API 5L grade carbon-manganese steels like X52, X70, X80, etc.) are high strength and usually operate at high pressures. Unfortunately, higher-strength pipeline steels tend to be more susceptible to HE than lower grade ones. Using thinner-wall high-strength pipes might be cost-efficient, but it comes with the trade-off of increased embrittlement risk. Research has shown, for example, that an X70 or X80 pipeline steel exposed to pressurized hydrogen can suffer reduced fracture toughness and faster fatigue crack growth. Engineers are actively studying this: in one study, hydrogen gas at just 6.9 MPa (≈1000 psi) caused a significant drop in fracture toughness of pipeline steel until a saturation point at higher pressures. This indicates even relatively low hydrogen pressures can be damaging. Industry codes like ASME B31.12 (the Hydrogen Piping and Pipeline Code) specifically address these concerns. B31.12 provides guidance on material selection, design, and operating limits to mitigate hydrogen embrittlement in pipelines – for instance, it omits certain alloys entirely if they are unsuitable for hydrogen service, and adds safety factors for known embrittlement effects. The code also defines the “hydrogen embrittlement temperature range” for materials (generally up to 150 °C for steels, aligning with that threshold where embrittlement ceases). In essence, special care is taken so that pipeline steels used with hydrogen have adequate toughness, often by choosing slightly lower-strength grades or adding safety margins. There are also ongoing R&D efforts (some by NIST, DOE, etc.) to evaluate hydrogen resistance of pipeline welds and seams since welds can be a weak link.

- Pressure Vessels and Tanks: Any vessel storing high-pressure gas (like hydrogen storage tanks, refinery hydrotreaters, ammonia reactors, etc.) may face hydrogen embrittlement issues. In the petroleum industry, a classic problem is High-Pressure Hydrogen Attack (HPHA or HTHA), which is actually a different mechanism occurring at high temperatures (~>200 °C) where hydrogen reacts with carbon in steel to form methane, decarburizing and weakening the steel. However, at lower temperatures, vessels can suffer ordinary HE as well – especially if they cycle pressure or have residual stresses. To manage this, vessel codes (ASME Section VIII, for example) and API recommended practices provide guidance. API 941 is a well-known standard for avoiding high-temperature hydrogen attack by using certain alloys, but for embrittlement at ambient temperatures the strategies include using stainless steel cladding or choosing materials with proven hydrogen resistance. For ammonia and fertilizer plants, thick-walled reactors often use 2.25Cr-1Mo steels with austenitic stainless liners to protect against hydrogen. API 579 (Fitness-for-Service) and similar documents include assessment techniques for HIC and hydrogen-induced stepwise cracking in vessels. Furthermore, in sour oil & gas service, NACE MR0175 / ISO 15156 is essentially law – it mandates using materials below certain hardness (typically <22 HRC for most steels) and with strict controls on strength and microstructure to avoid sulfide cracking. If higher strength is needed, the material must be proven with extensive lab testing in hydrogen sulfide environments.

- High-Strength Bolts and Components: Although our focus is on pipes and vessels, it’s worth noting that high-strength fasteners (like Grade 8 bolts, alloy steel shafts, etc.) have to be carefully managed to prevent hydrogen embrittlement. Many catastrophic failures (bridge collapses, crane failures) have been traced to hydrogen cracking in a critical bolt that was electroplated or exposed to the weather. Standards such as ASTM F1941 (for zinc electroplating) require a baking step for high-strength bolts to remove hydrogen. Aerospace components made of ultra-high-strength steel (landing gear, for example) are similarly prone – which is why cadmium plating (less hydrogen charging) was often used instead of zinc, and why any acid processing is done with care.

In summary, industry standards and best practices have evolved to combat hydrogen embrittlement. They often prescribe material choices (favoring more HE-resistant alloys or lower hardness), protective measures (coatings, inhibitors), and design margins. Companies and research institutions are continuously working on this because the move toward a “hydrogen economy” raises new challenges – for instance, how do we safely transport hydrogen in pipelines that weren’t originally designed for it? Ongoing research includes developing new alloys or microstructures that trap hydrogen in harmless ways (for example, adding titanium or vanadium carbides in steel can act as hydrogen traps to reduce its mobility) and finding operational strategies like blending in a bit of oxygen to the gas, which has been found to inhibit hydrogen embrittlement in some cases by scavenging atomic hydrogen. On the regulatory side, design codes (ASME, API, ISO) are being updated with specific guidance for hydrogen service as our understanding improves.

Finite Element Simulation of Hydrogen Embrittlement (FEA Modeling)

Understanding hydrogen embrittlement is one thing – predicting it in a specific component is another challenge entirely. This is where finite element analysis (FEA) and multiscale modeling come into play. By simulating how hydrogen moves and how cracks develop in a metal under stress, engineers can anticipate problems and design against them. However, hydrogen embrittlement is notoriously difficult to model because it involves coupled phenomena: hydrogen diffusion (a chemical process) and mechanical stress/strain (material deformation and fracture) influence each other simultaneously.

Coupled diffusion-stress modeling: In an embrittlement simulation, we typically need to solve for hydrogen concentration within the metal over time, while also solving for the stress and strain in the metal. High stress can drive hydrogen to diffuse towards that region (this is called stress-assisted diffusion or the chemical potential gradient effect). Conversely, hydrogen concentration can reduce the material’s local strength or ductility, affecting how stress is distributed. Finite element software like Abaqus, Ansys, and COMSOL Multiphysics can handle such coupled problems by either built-in physics or user-defined subroutines. For example, one research implementation used an Abaqus user subroutine (UMATHT) to solve the hydrogen diffusion equation concurrently with mechanical equations. In fact, many researchers leverage Abaqus’s ability to accept user-defined material behavior: hydrogen effects can be coded as an influence on the yield strength, fracture energy, or cohesive strength of the material elements. A 2019 study presented a weakly coupled simulation of hydrogen embrittlement in Abaqus, demonstrating a custom cohesive zone model that degrades material toughness based on local hydrogen concentration. In essence, as hydrogen concentration at a crack tip increases, the cohesive elements in the model (which represent the cracking resistance) weaken, allowing the crack to grow more easily – thus replicating embrittlement in the virtual specimen.

Another approach uses damage mechanics models informed by microphysics. A notable example is the so-called hydrogen-informed Gurson model for ductile fracture. The Gurson model is a porous metal plasticity model used for void growth and fracture; researchers have modified its parameters to depend on hydrogen content, capturing the Hydrogen-Enhanced Localized Plasticity (HELP) mechanism in a continuum sense. Yu et al. (2019) developed such a model and touted it as the first practical HE simulation tool based on the HELP mechanism (essentially making void nucleation/growth easier in the presence of hydrogen). This kind of model can simulate things like a notched tensile test of a hydrogen-charged steel: without hydrogen, the material might neck and tear at a high elongation, but with hydrogen, the simulation shows an earlier, more brittle fracture – matching experimental observations.

Multiscale modeling: One of the grand challenges is that hydrogen embrittlement is inherently a multiscale problem – atomic interactions cause macroscopic failures. A single hydrogen atom in a lattice might sit at a trap site (like a dislocation core or a carbide interface) and change the local properties. To truly predict embrittlement, we may need input from atomistic simulations (like Density Functional Theory or molecular dynamics) to know how strongly hydrogen binds to various traps, or how it affects the cohesion of grain boundaries. These atomistic results can then be upscaled. For instance, the EU project “MultiHy” (Multiscale Modelling of Hydrogen Embrittlement) created a framework linking atomistic calculations to continuum FE models. In their approach, they used atomistic simulations to quantify things like hydrogen diffusion rates along grain boundaries and hydrogen trapping energies at carbide particles. Then, using kinetic Monte Carlo (kMC) simulations, they bridged the gap between the fast, small-scale atomic events and the slower, larger-scale behavior. Finally, those results fed into FE models at the component scale, which could simulate, say, a crack propagating in a steel with a certain distribution of traps. This multiscale strategy allowed them to study real industrial case studies: they looked at hydrogen-assisted cracking in nickel rocket engine components, automotive high-strength steels, and wind turbine bearing failures. By validating the simulations with lab experiments on custom samples, they improved confidence that the models can predict embrittlement in practical scenarios. The key takeaway is that no single-scale model is enough – you often need to incorporate microstructural knowledge (trapping sites, diffusion paths) into the macro-model to get realistic results.

FEA software tools: Several commercial and research codes are used for hydrogen embrittlement modeling:

- Abaqus: Popular in academia for its advanced material modeling capabilities. Users implement hydrogen diffusion and damage coupling via subroutines (e.g., UMAT/UMATHT). Cohesive element approaches and extended finite element method (XFEM) for hydrogen-assisted cracking have been demonstrated in Abaqus. Abaqus was used in many cited studies because of this flexibility.

- Ansys: Also capable of coupled field simulations. Ansys can solve diffusion equations together with mechanical stress, and one can write APDL scripts or use usermat in Ansys as well. For example, one aerospace study predicting high-cycle fatigue life in hydrogen environment performed its FEA using Ansys, with custom post-processing to evaluate life reduction due to hydrogen. Ansys has also been highlighted in webinars focusing on hydrogen embrittlement failure analysis (even Ansys’ own R&D team has presented on using Ansys for HE prediction).

- COMSOL Multiphysics: This software is well-suited for such problems because it allows straightforward coupling of physics. One can set up diffusion equations with concentration-dependent material properties and solve alongside mechanical equations. COMSOL is often used for prototyping HE models or studying hydrogen diffusion in complex geometries (like weld residual stress fields).

- Other tools: There are specialized research codes and frameworks (like DAMASK for multi-physics at micro-scale, or phase-field modeling codes for hydrogen cracking). The finite element community has also developed open-source codes and plugins (e.g., a GitHub project “PoliHydra” provides tools for simulating HE in Abaqus with cohesive elements). Additionally, emerging techniques like phase-field modeling are being applied to hydrogen embrittlement, treating the crack as a diffused phase-field variable and coupling it with hydrogen concentration. These advanced methods can capture complex crack path evolution under the influence of hydrogen without having to predefine crack locations.

The goal of all these simulations is to help answer questions like: Where in my component is hydrogen likely to concentrate? Will a crack initiate, and if so, when and where? How much will hydrogen reduce the fracture toughness or fatigue life? By calibrating models against experiments (for example, using laboratory data of hydrogen-charged specimens), engineers can make quantitative predictions. This is extremely useful for critical applications – instead of waiting for a failure, one can simulate a worst-case scenario (e.g., a pipeline containing 10% hydrogen gas over 20 years) and design safeguards accordingly.

It’s important to mention that modeling hydrogen embrittlement still has uncertainties. We might not know exact trap densities or diffusion coefficients in a complex alloy, or the true material behavior under very high hydrogen content. Therefore, simulation is used in conjunction with conservative design and testing. Nevertheless, FEA gives us a powerful “magnifying glass” to see how hydrogen might be harming our structure before it actually does.

Emerging Role of AI and Machine Learning in Hydrogen Embrittlement

As in many fields of engineering, AI and machine learning (ML) are beginning to make an impact on corrosion and embrittlement analysis. These data-driven approaches complement physics-based modeling by finding patterns in experimental data or by speeding up predictions where simulations are too slow. In the context of hydrogen embrittlement, researchers have started training ML models on databases of material properties, test results, and environmental conditions to predict embrittlement outcomes.

For example, a recent study used machine lea

rning to predict the fracture toughness of various steels in hydrogen environments. They compiled data from many experiments (on pipeline steels like X70, X80, on different strength levels and hydrogen pressures) and fed them into several ML algorithms. The ML models – including techniques like k-nearest neighbors and random forests – learned how variables such as hydrogen pressure, steel strength, and alloy composition affect the fracture toughness reduction due to hydrogen. One interesting finding was that hydrogen gas pressure and the metal’s yield strength were the most influential factors in determining the embrittlement severity, with hydrogen pressure alone explaining about one-third of the variation in toughness. The model showed a clear trend: fracture toughness drops sharply as you introduce even a little hydrogen pressure (up to ~7 MPa in their data), then tends to plateau at higher pressures– suggesting a saturation effect where the steel is “as embrittled as it can get.” Such insights are valuable for setting safe operating limits. The ML approach could then be used to do “parametric studies” much faster than running new experiments or complex simulations – for instance, exploring how a small increase in strength or a different tempering process might change the susceptibility to HE.

Another application of AI is in material design: by analyzing large datasets on alloy chemistry and performance, machine learning can suggest what alloying additions or heat treatments might yield a steel that resists hydrogen better. There is ongoing work to use genetic algorithms and neural networks to design new high-strength steels that still have good resistance (perhaps by optimizing the type and amount of hydrogen traps in the microstructure). Moreover, AI can help develop better interatomic potentials for atomistic simulations of hydrogen in metals, which in turn improves the multiscale modeling accuracy.

In practical terms, we might soon see ML-based software tools in corrosion engineering where you input your material, strength, environment (H₂ pressure, H₂S level, etc.) and the tool predicts the likelihood of hydrogen embrittlement or the expected life of the component. These would be akin to advanced expert systems, trained on both experimental data and simulation results. The advantage is speed – running a complex 3D hydrogen diffusion FEA might take days of setup and computation, whereas a trained ML model could give a quick estimate in seconds. Of course, the ML models need to be used carefully within their trained scope, and they work best in synergy with classical modeling: AI might screen possibilities and flag high-risk scenarios, which you then examine in detail with FEA or targeted experiments.

To summarize, AI/ML is an emerging tool that can greatly assist in predicting hydrogen embrittlement, optimizing materials for resistance, and even real-time monitoring (imagine sensors feeding data to an AI that predicts if a pipeline is at risk of hydrogen cracking). While not a replacement for deep physical understanding, it’s a promising ally in the quest to manage corrosion and embrittlement in the era of big data.

Prevention and Mitigation Strategies

Given the potentially catastrophic consequences of hydrogen embrittlement (imagine a pipeline rupturing or a pressure vessel cracking), prevention is paramount. Both materials engineering and operational controls are used to mitigate HE:

- Material Selection: The simplest way to avoid HE is to use a material that is not prone to it. Where possible, choose more hydrogen-resistant alloys – for example, austenitic stainless steels or nickel-based alloys for components that will see high-pressure hydrogen. In oilfield equipment exposed to sour environments, materials are limited to certain low-hardness steels or CRA (corrosion-resistant alloys) by ISO 15156. If using high-strength steels (sometimes unavoidable for strength reasons), one can introduce alloying elements that form hydrogen traps. As mentioned, micro-alloying with Ti, V, or Nb to form carbides/nitrides can provide trap sites that sequester hydrogen and prevent it from freely diffusing to critical areas. These traps don’t stop embrittlement altogether but raise the threshold by keeping some hydrogen out of harm’s way. Research in high-strength pipeline steels has shown that a fine dispersion of carbide particles can indeed improve resistance by acting like “hydrogen sponges.”

- Control of Environment: Minimizing the exposure of the metal to sources of hydrogen is a fundamental strategy. In practice this means:

- Prevent aqueous corrosion as much as possible (use coatings, paints, inhibitors, or dry gas blankets) so that hydrogen isn’t generated on the surface.

- If using cathodic protection (CP) on pipelines or structures, ensure the CP potential is not overly negative – overprotection can evolve hydrogen on the metal. Standards (like NACE SP0169) give safe CP limits to avoid hydrogen generation on high-strength steels.

- For processes like acid pickling or electroplating, use inhibitors that reduce hydrogen evolution, and remove the part promptly once clean to avoid excess exposure. Modern plating shops have strict QA to prevent embrittlement (including testing plated parts per standards like ASTM F519 which uses notched bars to detect embrittlement).

- Limit exposure to hydrogen sulfide by material choice or environmental control – e.g., use scavengers to remove H₂S from process fluids, or clad the steel with a corrosion-resistant layer.

- In high-temperature processes where hydrogen is present (furnace atmospheres, chemical reactors), allow the equipment to outgas hydrogen before it cools down. This is often done in heat-treatment furnaces: if hydrogen-bearing gases are used, the last cycle can be a hydrogen-free purge at high temperature so hydrogen doesn’t remain in the metal as it comes to room temp.

- Processing and Design: Certain manufacturing steps are adjusted to mitigate HE:

- After electroplating or pickling of high-strength parts, perform a baking heat treatment (typically at 190–220 °C for 4+ hours, depending on standard) to drive out hydrogen while the metal is warm and diffusion is faster. This “bake-out” is a routine operation for critical plated components.

- In welding high-strength steels, apply preheat and post-weld heat treatments when applicable. Preheating drives off moisture and slows cooling (preventing hard microstructures that trap hydrogen), while post-weld bake-outs at ~200 °C can help any absorbed hydrogen diffuse out before the weld cools to ambient. Welding procedures are often qualified with diffusible hydrogen limits (e.g., using low-hydrogen electrodes and fluxes).

- Avoid high residual stresses in design – for example, after fabrication processes like forming or quenching, a stress-relief heat treatment can lower residual tensile stresses so that if hydrogen is present, the driving force for cracking is less. Likewise, designing to minimize stress concentrators (sharp notches, etc.) will reduce the local stress that could attract hydrogen or start a crack.

- Use coatings intelligently: a good impermeable coating (paint, epoxy, polymer liners) on steel can act as a barrier to hydrogen entry in service (and also prevent corrosion). However, beware of coatings that involve processes causing hydrogen entry during their application (e.g., electroplated coatings as we discussed). Sometimes a duplex system is used: a sacrificial plating plus a sealer on top.

- Hydrogen detectors: In some critical systems, sensors measure hydrogen in the metal or coming off the metal. For example, tanks may have monitors for hydrogen permeation, so if you see hydrogen coming through, you know the steel is saturated and possibly cracking internally. This is more of a monitoring strategy than prevention, but it can prompt early maintenance.

- Standards and Testing: Adherence to standards like NACE MR0175/ISO15156 (for oil & gas) or ASME B31.12 (for hydrogen pipelines) is itself a preventive measure – these standards encapsulate a lot of experience on what works and what doesn’t. Additionally, performing qualification tests can prevent surprises. For instance, performing a Hydrogen Induced Cracking test per NACE TM0284 on a steel plate intended for a sour service vessel will reveal if the material is prone to blistering or HIC. If it is, one can select a different steel (many steel suppliers offer “HIC-resistant” steel that’s been cleaned of certain impurities and treated for better performance). For fasteners, standards like ISO 15330 mandate accelerated embrittlement testing on each batch of hardened plated fasteners, catching any embrittled batch before it goes into service. These tests act as quality gates to ensure preventive measures were effective.

To sum up prevention: keep hydrogen out, or keep it harmless. That means using resistant materials or suitable coatings to bar hydrogen entry, controlling processes so hydrogen isn’t produced at the metal surface, using heat treatments or traps to nullify any hydrogen that does enter, and designing components to be tough enough (and unstressed enough) to tolerate the hydrogen they might see. It’s a multifaceted approach – no single fix can eliminate hydrogen embrittlement, but a combination can reduce the risk to a manageable level.

In the end, hydrogen embrittlement may be a 150-year-old problem (noted since the 19th century), but it’s one that modern engineering can deal with through smart science and engineering vigilance. As industries push towards hydrogen fuel and other aggressive environments, staying on top of HE through simulation, data, and sound materials practice will be key.

At EngineeringDownloads.com we pride ourselves on staying at the forefront of these topics – from conducting advanced FEA simulations of corrosion and embrittlement to advising on materials and mitigation strategies per the latest ASME/API standards. By combining academic insight with industry know-how, we aim to ensure your pipelines, vessels, and critical components stay safe from hydrogen embrittlement and related failures. Feel free to reach out for consulting or simulation services if you’re facing a hydrogen embrittlement challenge – our team is here to help translate this deep research into practical solutions.