Introduction: Bridging Physical and Virtual Worlds in Engineering

Imagine if every physical machine or product you design had a living virtual copy that evolves alongside it, predicting issues before they occur and optimizing performance in real-time. This is the promise of the Digital Twin. In the world of engineering simulation, digital twins are revolutionizing how we design, test, and maintain systems. They create a continuous connection between virtual models and real physical assets, blurring the line between simulation and reality. The result is a new paradigm for Computer-Aided Engineering (CAE) and Finite Element Analysis (FEA) that’s proactive, data-driven, and incredibly powerful.

In this comprehensive guide, we’ll explore what digital twins are, how they work in our field (including tools like Abaqus, Ansys, Altair, COMSOL, etc.), and why they’re game-changing for engineering simulation. We’ll also highlight real-world applications – from predictive maintenance to design optimization – and discuss how our consulting team can help you harness this technology. Let’s dive in with a friendly, no-jargon approach to understand the digital twin revolution in CAE and FEA.

What Is a Digital Twin?

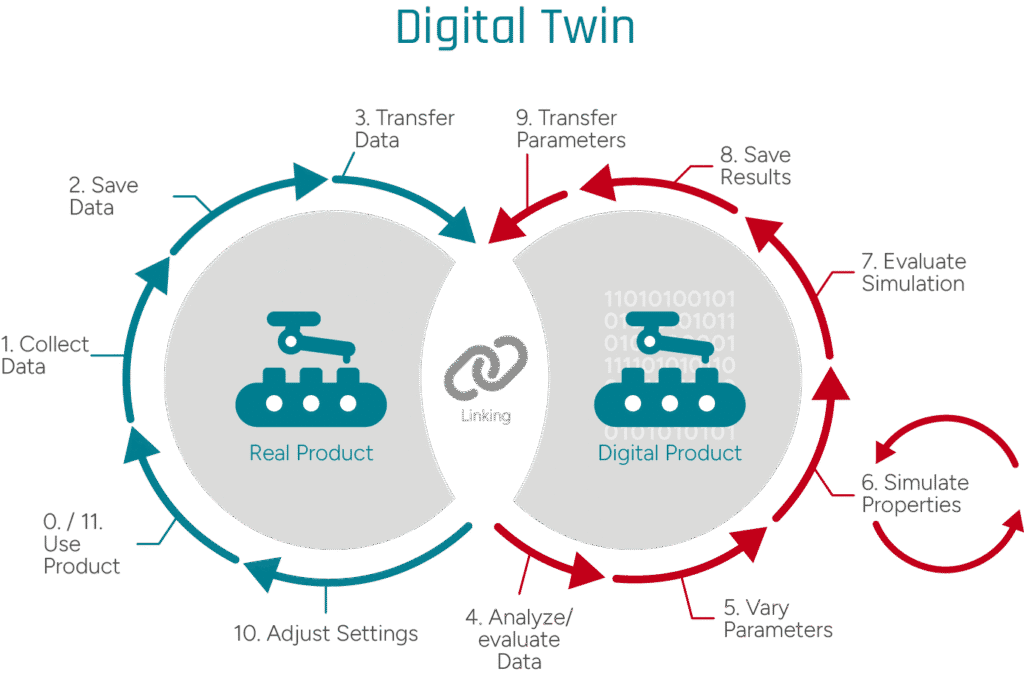

Digital twin is essentially a virtual replica of a physical object or system, kept in sync with the real thing via data. It’s more than just a static 3D CAD model; it’s a living simulation that receives continuous updates from sensors on the physical asset (through IoT, the Internet of Things) and in turn can simulate and predict the asset’s behavior in real time. Think of it as the “other half” of a physical product – one that exists in software, but mirrors the real-world status and performance of that product at any given moment.

Key characteristics of a digital twin include:

- Real-Time Data Flow: The digital twin is linked to the physical twin by streams of data from sensors, providing an up-to-the-moment reflection of operating conditions. This two-way data flow (often called the digital thread) allows the virtual model to update as the physical asset changes, and vice versa.

- Simulation-Driven Insights: Because the twin is essentially an advanced simulation model (often high-fidelity, physics-based), engineers can use it to test “what-if” scenarios and predict outcomes without interrupting the real asset. It’s like a safe sandbox to experiment in, backed by real-world data.

- Lifecycle Perspective: Unlike a one-off simulation run, a digital twin persists throughout the asset’s lifecycle. From design and manufacturing through operation and maintenance, the twin evolves as the product goes through changes and wear. This lifecycle-long engagement is what empowers things like long-term performance optimization and predictive maintenance strategies.

- Integration of Technologies: Digital twins bring together several tech domains – CAE simulation models, IoT sensor networks, data analytics, cloud computing, and often AI/machine learning. By integrating these, a twin can not only mirror reality but also learn and improve its predictions over time.

In short, a digital twin is “a set of adaptive models that emulate the behavior of a physical system in a virtual system, getting real time data to update itself along its life cycle”. It’s the synergy of simulation + data that makes the digital twin so powerful in engineering.

Digital Twin vs. Traditional Simulation: What’s the Difference?

You might be wondering: How is this different from the simulations we engineers have been running for decades? There are indeed important differences between a conventional CAE simulation and a digital twin:

- Static vs. Dynamic: A traditional FEA or CFD simulation is typically static or offline – you set up a model with certain assumptions and run it to analyze performance under those assumptions. A digital twin, however, is dynamic and online. It continuously updates with real-world sensor inputs, so it reflects the current state of the asset at all times. The twin can run simulations on the fly as conditions change.

- One-Time vs. Continuous Improvement: Simulations are often used in design phase or troubleshooting as one-off analyses. A digital twin is continuous, operating in parallel with the product. It doesn’t stop at design; it keeps working through deployment, operation, and maintenance. This means the twin can capture how performance drifts over months and years and help adjust strategies accordingly.

- Hypothetical vs. Real Data-Driven: In regular simulation, any changes in inputs are manually imagined by an engineer (e.g., “what if the load increases 10%?”). In a digital twin, changes come from actual usage data. The twin is grounded in reality, not just hypothetical scenarios. This leads to more accurate and relevant insights.

- Scope of Impact: Traditional CAE focuses on product design validation – a critical but narrow scope. Digital twins have a broader scope of use, impacting operations, maintenance, and even business strategy. For example, a simulation might tell you if a design will fail; a digital twin can tell you when a specific in-service machine will likely fail and how to prevent it, thereby influencing maintenance scheduling, inventory, and training.

Crucially, simulation is usually open-loop (no automatic feedback once the product is built), whereas a digital twin is closed-loop. The continuous feedback between physical and digital allows the twin to inform decisions in a way standalone simulations cannot. As one source puts it, “while simulations and digital twins both use digital models to replicate products or processes, a digital twin creates a virtual environment able to study several simulations, backed up with real-time data and two-way data flow”. In practice, this means digital twins can drive proactive decisions (e.g., adjusting operations for efficiency, planning service interventions) based on what’s actually happening in the field, not just on theoretical models.

That said, it’s not simulation versus digital twin as much as it is simulation enabled by digital twin workflows. Traditional CAE tools remain essential – a digital twin starts as a simulation model, after all – but with IoT connectivity and data, it becomes a living model.

How Digital Twins Work in Engineering Simulation

So, how do you actually build and use a digital twin in the context of CAE and FEA? Here’s a simplified step-by-step breakdown:

- Create a High-Fidelity Virtual Model: Begin with developing a detailed simulation model of the physical asset or process. This could be a finite element model (for structural behavior), a computational fluid dynamics model (for thermal/fluid behavior), or often a coupled multiphysics model if needed. Tools like Ansys, Abaqus, COMSOL, Altair, etc., are used here to ensure the model is as realistic as possible in representing the physics of the real system. This model is the initial digital prototype of your twin.

- Instrument the Physical Asset (IoT Sensors): Equip the real-world asset with sensors and data acquisition systems. These sensors will collect information on key parameters – for example, loads, pressures, temperatures, vibrations, etc., depending on the application. In the IoT era, modern machinery often comes with many built-in sensors. The goal is to have a stream of data that characterizes the asset’s operating state in real time.

- Establish Data Connectivity (Digital Thread): Set up a communication pipeline to feed the sensor data into the digital model continuously. This might involve IoT platforms or middleware that aggregate data and send it to the simulation environment. The digital twin ingests this data, which keeps the virtual model synchronized with the physical twin’s latest conditions. For instance, if the physical machine’s motor is running at 2000 RPM and the temperature is 75°C, the digital twin model receives those inputs and reflects the same scenario virtually.

- Calibrate and Validate the Model: Early on, you’ll compare the twin’s outputs with real measurements to ensure it’s accurate. For example, do the stress or temperature predictions from the simulation match sensor readings? If not, refine the model (adjust material properties, boundary conditions, etc.) until the digital twin reliably reproduces the physical behavior. This validation builds trust that the twin can be used for predictive purposes.

- Real-Time Simulation & Prediction: Now the digital twin is live. At this stage, the twin can run simulations in parallel with real operations. Because it’s getting live data, it can do things like: predict performance metrics that are hard to measure directly (the twin can calculate internal states or stresses where you might not have a sensor); test what-if scenarios (e.g., “if we push the machine 10% harder, will it overheat?”) without risking the real asset; and estimate remaining useful life of components by running accelerated simulations based on current conditions. Advanced twins incorporate AI to speed up these predictions – for instance, using a reduced-order model or neural network trained from detailed simulations so that the twin can respond in real-time. This hybrid of AI + physics allows fast computations with high fidelity.

- Feedback & Action: The insights from the digital twin are fed back to engineers, operators, or even directly to the control systems. This could trigger maintenance work orders when the twin predicts a failure, adjust control settings to optimize performance, or update design assumptions for the next product iteration. The twin essentially becomes a decision-support system, bridging the gap between engineering simulation and operational decision-making.

It’s worth noting that building a digital twin isn’t trivial. It requires good up-front modeling (your FEA/CFD skills come into play heavily) and a robust data infrastructure. In many cases, engineers use cloud platforms or edge computing to host twins, because the data volumes can be large and sometimes you need to run many simulations quickly. Scalability is key – for example, Ansys notes that their twin technology supports cloud and edge deployment so you can manage many instances and keep them updated across distributed operations.

Also, not every twin uses a full 3D simulation all the time – often, we create a simplified model or surrogate for the twin. One approach is to generate a high-fidelity model (say, a detailed FEA) and then create a reduced-order model (ROM) or a machine learning model from it. The Ansys Twin Builder tool, for instance, lets engineers build ROMs and integrate data so that the twin can run fast while still grounded in physics. Similarly, a COMSOL-based workflow demonstrated training a deep neural network inside the COMSOL Multiphysics environment to act as a faster proxy for the full physics, enabling real-time predictions that closely match the high-fidelity results. The twin thus updates almost instantly as new data comes in, providing actionable results without heavy computation delay.

By following these steps, you end up with a digital twin that serves as a digital mirror of your asset. This mirror not only reflects the current state but can look into the future (through simulation) and advise you on how to improve outcomes.

Key Applications and Benefits of Digital Twins in Simulation

Digital twin technology is transforming how we approach various engineering challenges. Below are some key applications and benefits of integrating digital twins with CAE/FEA simulations:

- Predictive Maintenance: Perhaps the most celebrated application, digital twins enable predictive maintenance in industrial machinery and infrastructure. By continuously analyzing real-time data, the twin can predict when components will wear out or fail before it happens. This allows companies to schedule maintenance only when needed (avoiding unnecessary downtime) and prevent catastrophic failures. For example, an aerospace digital twin of a jet engine can monitor strain, temperature, and vibration data; the twin’s simulation might predict a turbine blade fatigue crack weeks in advance, so the blade can be replaced proactively. This reduces unscheduled downtime and extends equipment life, yielding huge cost savings.

- Performance Optimization: Digital twins help optimize performance by allowing engineers to tweak inputs and see the outcome instantly on the virtual model. If you have a twin of, say, a wind turbine or a manufacturing line, you can simulate adjustments (blade angles, equipment settings, etc.) under current conditions to see what yields the best performance or efficiency. Over time, the twin learns the system’s behavior, so it can even recommend optimal operating parameters. One example: Altair’s digital twin platform blends physics and data to let companies maximize product performance and energy efficiency throughout the product’s lifecycle. In a customer story, an Italian coffee machine manufacturer (Gruppo Cimbali) used digital twins via Altair’s tools to design better products, shorten development times, and increase energy efficiency in their machines. That’s performance optimization both in R&D and in operation.

- Real-Time Monitoring & Control: With a live digital twin, engineers and operators get a window into the system in real time. You can monitor conditions that are difficult to measure directly using the twin’s simulation outputs. For instance, if an internal part doesn’t have a sensor, the twin can infer its state (like internal stresses or temperatures) from external sensor inputs. This comprehensive view improves situational awareness. In some cases, the twin can feed directly into control systems – e.g. an advanced HVAC system might use a building’s digital twin to adjust airflow dynamically for comfort and energy savings, based on both sensor data and simulation of air circulation.

- Design Improvement and Validation: The insights gathered from a digital twin in operation loop back to design improvements for the next product iteration. By comparing the twin’s predictions vs. actual outcomes, engineers can validate and refine their simulation models. This helps close the gap between expected and actual performance. It’s effectively a continuous validation loop. Notably, Boeing integrated digital twins into their design and production processes to simulate how materials would perform throughout an aircraft’s lifecycle – they reportedly improved the quality of certain parts by 40% as a result. The twin highlighted where designs could be optimized beyond what initial simulations considered, leading to a better product.

- Troubleshooting and Diagnostics: When something goes wrong, a digital twin can be a lifesaver. Instead of guessing the cause of an issue, engineers can use the twin to replay events or test various fault scenarios virtually. Because the twin mirrors the exact state of the asset before and during the issue, it helps pinpoint root causes much faster. This is similar to how NASA used simulations (early form of twins) during Apollo 13 to diagnose problems remotely. Today, if a factory machine is behaving oddly, its twin might help simulate different failure modes to see which matches the symptoms – essentially providing a diagnosis.

- Training and Virtual Commissioning: Digital twins can serve as ultra-realistic simulators for training personnel. For instance, operators can practice emergency shutdowns or new procedures on the digital twin without risking the real equipment. Likewise, in commissioning new systems, you can test the entire operation in the twin (sometimes called virtual commissioning) to ensure everything will work as intended before actual startup. This reduces the risk of surprises when the system goes live. Augmented reality (AR) can be layered with digital twins as well – for example, an engineer wearing AR glasses might see real-time data and simulation predictions from the twin overlaid on the physical machine for an interactive training or diagnostic experience.

- Enterprise-Level Integration & Efficiency: Looking at the bigger picture, digital twins are increasingly used to drive business strategy and efficiency improvements. For example, by having a twin of an entire production line or facility (sometimes called a system or process twin), companies can simulate how changes in one area affect the whole operation. This supports decisions in inventory management, scheduling, and process optimization as part of Industry 4.0 digital transformation. Twins can also contribute to sustainability – by analyzing data, a twin might find ways to reduce energy consumption or waste. In fact, digital twin technology has been cited as a tool for reducing carbon emissions and making operations more energy efficient, contributing to corporate sustainability goals.

Each of these applications demonstrates the tangible benefits of digital twins in the engineering domain: higher reliability, lower costs, improved performance, and informed decision-making. Companies like Tesla rely on digital twins extensively – Tesla creates a twin for each car they produce, which collects data from the vehicle’s sensors. This allows them to optimize designs (via over-the-air updates), enhance autonomous driving algorithms, and anticipate maintenance needs based on real-world usage of each car. The two-way flow of data (from cars to the twin and back to design improvements) is a prime example of digital twin benefits in action.

It’s important to note that implementing digital twins does require investment and effort – they are typically employed where the value is high. For critical assets or large-scale operations, the ROI of a twin is clear. But for simpler cases, a basic simulation might suffice. In practice, digital twins are usually justified for high-value, complex, or critical systems, especially where downtime is very costly (like power plants, aircraft, heavy machinery). In those domains, the advantages far outweigh the costs of sensors and integration.

Digital Twin in Major CAE Tools (Abaqus, Ansys, Altair, COMSOL & More)

Leading CAE software providers have embraced digital twin technology, integrating it into their tool offerings. If you’re using tools like Abaqus, Ansys, Altair HyperWorks, or COMSOL, here’s how each is contributing to the digital twin landscape:

- Ansys (Twin Builder and Twin AI): Ansys has a dedicated platform for building simulation-based digital twins called Ansys Twin Builder. It allows engineers to create dynamic system models and Reduced-Order Models (ROMs) from 3D physics simulations, and then integrate real-time data for twin development. Essentially, you can take detailed FEA/CFD results and package them into a faster running model suitable for real-time use. Ansys also provides Twin AI capabilities, which combine the accuracy of physics with machine learning for predictive analytics. With these, Ansys enables what they call Hybrid Digital Twins – blending data-driven and physics-driven approaches for maximum accuracy. A highlight of Ansys’ approach is its focus on predictive insights: they emphasize scheduling maintenance based on twin simulations and using twins to boost efficiency and reduce downtime in operations. There are even case studies like using Ansys Twin Builder to create a twin of the Golden Gate Bridge (for structural health monitoring) and of GE wind turbines (for performance optimization). The Ansys ecosystem supports deployment of twins on cloud or edge, making it scalable for industrial use. In short, if you’re an Ansys user, the company provides a clear path to build and deploy digital twins leveraging your simulation models.

- Altair (One Total Twin & Altair Activate): Altair has positioned itself as offering a comprehensive, end-to-end digital twin solution under the banner “One Total Twin”. Altair’s strength is historically in simulation (with HyperWorks suite, FEA, CFD, etc.), optimization, and also data analytics. They combine these with IoT connectivity in an open, software-agnostic platform. Altair emphasizes that their digital twin approach is flexible and scalable to any industry or system, rather than a proprietary closed solution. A key product in Altair’s lineup is Altair Activate, a system modeling tool (0D/1D simulations) used for dynamic simulation and often for control systems – it was mentioned in a case where Gruppo Cimbali used Activate to implement their product’s digital twin, resulting in faster innovation (as noted earlier). Altair also provides powerful data intelligence tools which can complement physics models – for example, using data from many assets to find patterns or using machine learning for anomaly detection. They’ve been advocating digital twins since before it was a buzzword (they claim “we’ve been doing digital twin since the 80s”), and now have a Digital Twin Global Survey Report highlighting trends. If you use Altair’s simulation software (like HyperMesh, MotionSolve, Flux, etc.), you can integrate those models into a bigger digital twin strategy using their platform.

- Dassault Systèmes (Abaqus/3DEXPERIENCE Virtual Twin): Dassault (the maker of Abaqus, CATIA, etc.) uses the term “Virtual Twin” for its approach. Through the 3DEXPERIENCE platform, Dassault enables linking of CAD, PLM, and simulation models (like Abaqus FEA or Dymola systems models) with real-world data from products in the field. The idea is to provide a Virtual Twin Experience – not just the product’s physics, but also its manufacturing and operational context are modeled. This can be applied from aerospace (e.g., virtual twins of aircraft to manage their entire lifecycle) to life sciences (they even talk about virtual human twins for healthcare). For an engineer using Abaqus, this means your high-fidelity FEA model can become part of a digital twin when connected via the 3DEXPERIENCE environment to IoT data. One example is using Abaqus to simulate stress in a component, and continuously updating the simulation with loads measured by strain gauges on the actual component in service – thus the Abaqus model becomes a twin that predicts if and when stress limits will be exceeded. Dassault has demonstrated such capabilities in aircraft maintenance and in optimizing production lines by comparing the “as-designed” vs “as-produced” data. They highlight that a digital twin strategy accelerates continuous improvement by tightening the loop between engineering design and actual performance. So if you’re in the SIMULIA ecosystem, the path to twins is through the broader 3DEXPERIENCE platform that connects all the dots (design, simulation, manufacturing, operation).

- COMSOL Multiphysics: COMSOL’s simulation software is known for multiphysics FEA/CFD and for its ability to create custom simulation apps. COMSOL users have leveraged this to build digital twin applications especially for scenarios requiring real-time multiphysics simulation. A recent approach involved training a deep neural network within COMSOL to act as a fast surrogate to the multiphysics model, and coupling it with continuously updated sensor data via COMSOL’s live link capabilities. In one case study, an COMSOL-based digital twin was created for an industrial thermal process: sensors measured temperatures in an experimental setup, the data was fed into a COMSOL model that had a DNN to quickly compute the full temperature field (the “thermal map”) of the system in real time. The twin could instantly show hot spots and effects of changing fan speed or heater power, which normally would require a time-consuming CFD simulation, but by integrating AI and simulation, it delivered fast results without losing accuracy. Moreover, COMSOL’s Application Builder allows deploying such a model as a user-friendly app with a custom interface, making it easier for operators or non-CAE experts to use the digital twin. In summary, COMSOL provides a flexible environment to build bespoke digital twin solutions, particularly when you need high-fidelity multiphysics and are willing to incorporate techniques like surrogate modeling to meet real-time requirements.

- Siemens (Simcenter & Mindsphere): [Bonus: not in the original list, but noteworthy] Siemens offers the Simcenter portfolio (which includes tools formerly known as NX CAE, LMS, etc.) for simulation and testing, and they integrate this with IoT via Mindsphere (Siemens’ cloud platform). Siemens promotes digital twins at multiple levels: product, production, and performance twins. For example, Simcenter Amesim (one-dimensional systems simulation) can be used to create real-time capable models that run as twins for control systems. Siemens also has specific industry solutions, like digital twins of factories for production optimization. If you’re using Siemens NX or Femap for FEA, they envision those detailed models being used in the design phase and then simplified for runtime use in a twin. They also often highlight MBSE (Model-Based Systems Engineering) where the digital twin concept ties into designing and verifying complex systems from the get-go. The integration of test data with simulation (through Simcenter testing hardware/software) is another way Siemens helps calibrate twins.

Each CAE vendor has its flavor of digital twin enablement, but a common theme is emerging: hybrid models (combining physics simulations with data analytics/AI) and support for the full lifecycle of the product. Whether you prefer Ansys, Altair, Abaqus, COMSOL, or another tool, you can be sure the company has a strategy for digital twins. As engineers, it’s a great time to leverage our simulation expertise in this new, connected context.

Challenges in Implementing Digital Twins

Before we wrap up, it’s worth acknowledging some challenges you might face when bringing digital twins into your engineering projects:

- Data Management & Quality: Digital twins thrive on data, but setting up the pipelines for high-quality, real-time data can be difficult. Sensors must be correctly specified, placed, and maintained. You’ll also need to handle big data streaming from potentially thousands of data points. Ensuring that data is accurate, synchronized, and securely transmitted to the simulation is a non-trivial task. Poor data quality can lead to a “garbage in, garbage out” situation for the twin’s predictions.

- Modeling Complexity vs. Speed: There’s always a trade-off between simulation detail and computational speed. High-fidelity models (think millions of finite elements, or very fine fluid meshes) are too slow to run in real-time. So you may need to invest time in model reduction techniques or surrogate modeling (as we discussed with ROMs or neural networks) to make the twin responsive. Achieving the right balance of detail vs. speed is a key engineering decision in any twin project.

- Integration of Technologies: A digital twin project is inherently interdisciplinary. It may involve mechanical engineers, software developers, data scientists, and IT specialists to set up. Integrating the hardware (sensors/IoT devices) with software (simulation & analytics) and ensuring compatibility between different tools (maybe using APIs or custom code to link a sensor feed to an FEA model) can be challenging. It requires a systems engineering approach.

- Cost and Scalability: Implementing a full-blown digital twin can be expensive. The cost of sensors, data infrastructure, simulation software licenses, and expert labor adds up. This is why, as mentioned, digital twins are usually applied where the business case justifies it – typically high-value assets or operations. For smaller scale projects, one might start with a pilot or a partial twin to prove value before scaling up. Additionally, if you aim to deploy thousands of twins (e.g., one for every individual product sold), you need a scalable architecture (cloud computing, etc.) which introduces ongoing costs.

- Maintenance of the Twin: The digital twin itself needs maintenance. As the physical asset ages or is modified, the twin’s model may need updating. If a sensor fails and gives no data or wrong data, the twin could drift from reality. Engineers must periodically recalibrate and update the digital model to ensure it remains an accurate reflection of the physical twin.

- Security and Privacy: In some cases, twins could pose security concerns. Streaming detailed operational data could be sensitive (think proprietary process data or personal data in healthcare). Protecting that data from cyber threats is important. Moreover, one must consider data privacy regulations if applicable (for instance, a digital twin of a human would have to protect personal health data under laws like HIPAA or GDPR).

Despite these challenges, the trajectory is clear: each year it’s becoming easier to implement digital twins thanks to advancements in IoT devices, cloud computing, and AI integration. The major engineering software companies are also actively smoothing the path by providing more out-of-the-box twin solutions (like pre-built connectors for sensors, dashboards for monitoring, etc.).

Our team has extensive experience in overcoming these challenges – from choosing the right sensors and integrating them with simulation, to simplifying models for real-time use and setting up robust data flows. We’ve learned that a pragmatic approach (start small, demonstrate value, then expand) works best to get digital twin initiatives off the ground.

The Future of Digital Twin Technology in CAE

The future looks bright for digital twins in engineering. Adoption is skyrocketing across industries, as companies see the competitive edge it gives them. Here are a few trends and predictions for the coming years:

- Ubiquitous Twins: We may reach a point where almost every complex product has a digital twin from the moment it’s designed through the end of its life. Engineers will expect to create a twin as a standard deliverable, just like they create CAD drawings or FEA reports today. This is aided by new tools that automate aspects of twin creation (for example, CAD programs that auto-generate simulation models, or IoT platforms that auto-map sensor data to simulation inputs).

- AI-Enhanced Twins: Artificial intelligence and machine learning will play a bigger role. We will see more self-learning twins that improve their models as more data becomes available. AI can also help interpret the twin’s output, giving higher-level recommendations (e.g., not just “bearing temperature is high” but “bearing will fail in 10 days unless load is reduced or it’s serviced”). The concept of Hybrid Analytics – combining AI with physics – will mature, making twins more accurate and faster.

- Edge Computing for Twins: Instead of sending every bit of data to the cloud, certain twins (especially for fast control loops) will run on the edge – meaning on local devices or on the machines themselves. This reduces latency for real-time control. We already see this in IIoT (Industrial IoT) where a twin for a motor might run on a nearby industrial PC and adjust controls instantaneously.

- Digital Twin Ecosystems: Expect better interoperability and standards. Organizations like the Industrial Internet Consortium (IIC) and others are working on reference architectures and standards for digital twins so that different components can work together. This might mean your CAD, PLM, simulation, and IoT systems talk more seamlessly when setting up a twin.

- Broader Scope Twins: Beyond single products, we’ll have twins of systems of systems – like whole factories, power grids, cities (smart city twins), and even the human body (“digital twin of a patient” for personalized medicine). These broad twins will integrate multiple models. For engineers in CAE, this means opportunities to connect our models (e.g. an FEA of a bridge) into larger digital ecosystems (e.g. a smart city twin for infrastructure management).

- Democratization and Accessibility: Just as simulation tools have become more user-friendly over time (with better UIs and templates), digital twin tools will become easier to use, so that non-experts can interact with twins. Web-based interfaces, AR/VR visualizations of twins, and template solutions for common equipment will bring this technology to a wider audience.

At the end of the day, digital twins are about making better decisions with the help of simulations and data. They won’t replace engineers – rather, they’ll supercharge engineers’ abilities to understand and influence the behavior of their designs in the real world. It’s an exciting evolution of CAE from a back-office design tool to a front-and-center operational tool.

Our Consulting Team: Helping You Leverage Digital Twins

Implementing a digital twin might sound complex – and truth be told, it can be. But you don’t have to navigate this journey alone. Our consulting team at EngineeringDownloads is here to help you every step of the way, from concept to deployment.

We are a team of experienced CAE engineers, simulation experts, and IoT/data specialists who have a passion for merging virtual simulations with real-world data. What sets us apart is our holistic understanding of both the physics and the digital infrastructure. We’ve worked with the major tools – Ansys, Abaqus, Altair, COMSOL, and more – and have hands-on experience building digital twin solutions in various industries.

Here’s how we can assist you:

- Digital Twin Strategy: Not sure where to start? We can evaluate your project or operation to identify high-impact opportunities for a digital twin. We’ll help you understand the ROI and outline a phased implementation plan (perhaps starting with a pilot on one critical asset).

- Model Development & Integration: Our experts can develop or refine the simulation models (FEA, CFD, system models) required for your twin with high accuracy. We also handle the integration of sensor data channels into these models – essentially setting up that digital thread. Whether it’s configuring an Ansys Twin Builder workflow or writing a custom interface for Abaqus to ingest field data, we’ve got you covered.

- Data Analytics & AI: We have data scientists in our team who can develop the AI/ML components for your twin, such as training predictive algorithms on historical data or creating reduced-order models. This ensures your twin runs efficiently and provides intelligent insights (not just raw data).

- Deployment & Scaling: Whether you need the twin deployed on a local server, on cloud infrastructure, or at the edge, we’ll deploy a robust solution. We also create user-friendly dashboards or apps so that your engineers or operators can easily interact with the digital twin – viewing live status, running simulations, and getting alerts.

- Training & Support: We believe in empowering your team. We’ll train your engineers on how to use and maintain the digital twin system. And of course, we offer ongoing support and updates as your needs evolve. Digital twins are a journey, and we’ll be your partner in the long run to ensure it continuously delivers value.

By leveraging our consulting services, you significantly reduce the risk and learning curve associated with implementing digital twins. We’ll help you avoid common pitfalls and deliver a solution that’s tailored to your specific needs and industry standards. We take pride in writing blogs like this to educate and share knowledge, but we get even more excited working hands-on to implement these ideas and see the improvements firsthand.

Conclusion & Call to Action

Digital twin technology is transforming the landscape of engineering simulation. It extends the power of CAE beyond the virtual realm and into real-world operation, creating a feedback loop that drives better products and more efficient processes. In this blog, we’ve covered how digital twins work, their benefits, applications across various domains, and how major CAE tools are facilitating their adoption. We’ve also candidly discussed challenges and how to address them, emphasizing that with the right expertise, those challenges can be overcome.

The bottom line is that digital twins represent a shift from being reactive to being proactive and predictive in engineering. Instead of responding to failures or guessing performance margins, we can now have ongoing insight and foresight into our systems. Whether you are designing the next sustainable high-rise building, managing a fleet of machines in a factory, or optimizing a wind farm, digital twins can be a game-changer.

Ready to explore digital twins for your projects? We’re here to help! Our consulting team at EngineeringDownloads is enthusiastic about partnering with you to implement cutting-edge digital twin solutions tailored to your needs. We invite you to reach out to us for a discussion. No matter if you’re just curious about the concept or you have a specific project in mind, feel free to contact us for an initial consultation.

Let’s work together to bring your simulations to life and take your engineering capabilities to the next level. The era of the digital twin is here – make sure you’re ahead of the curve. Get in touch with us today, and let’s twin your success!